Patents

Literature

52 results about "ARSENATE ION" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

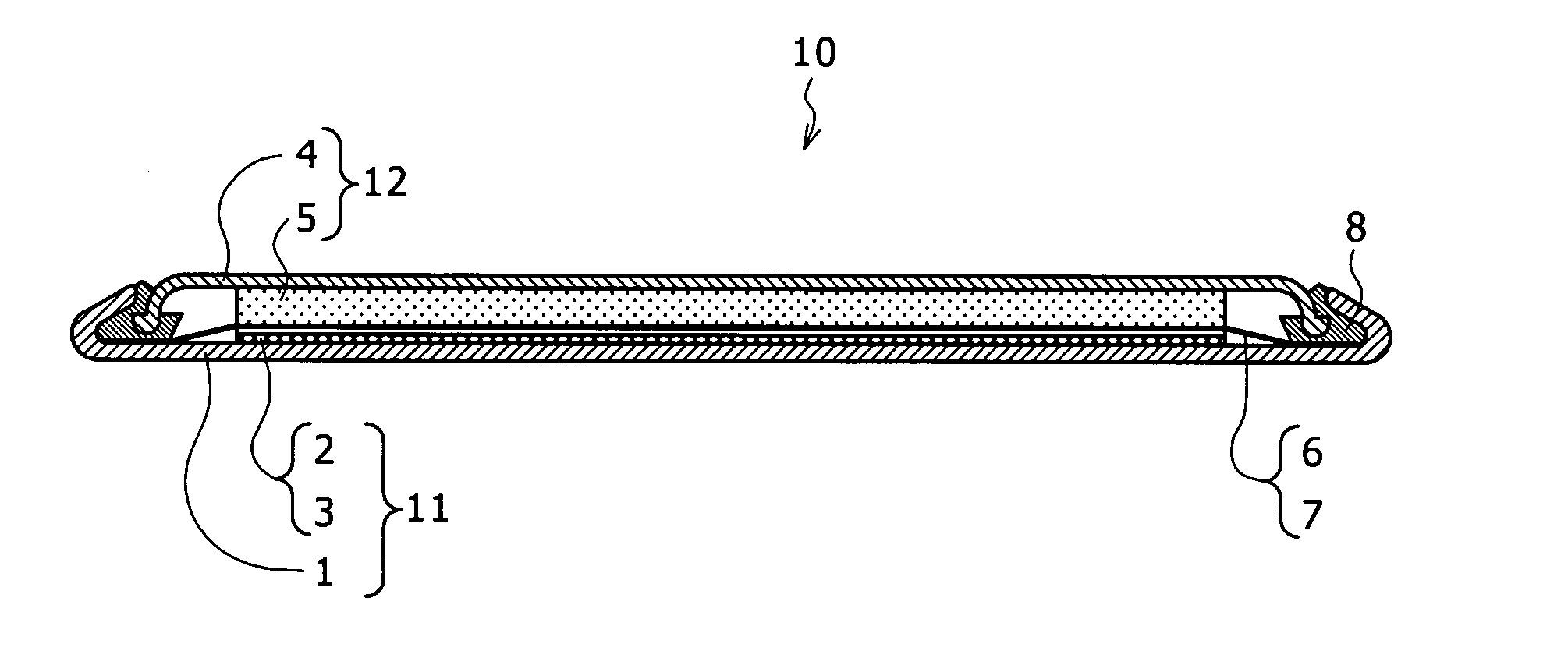

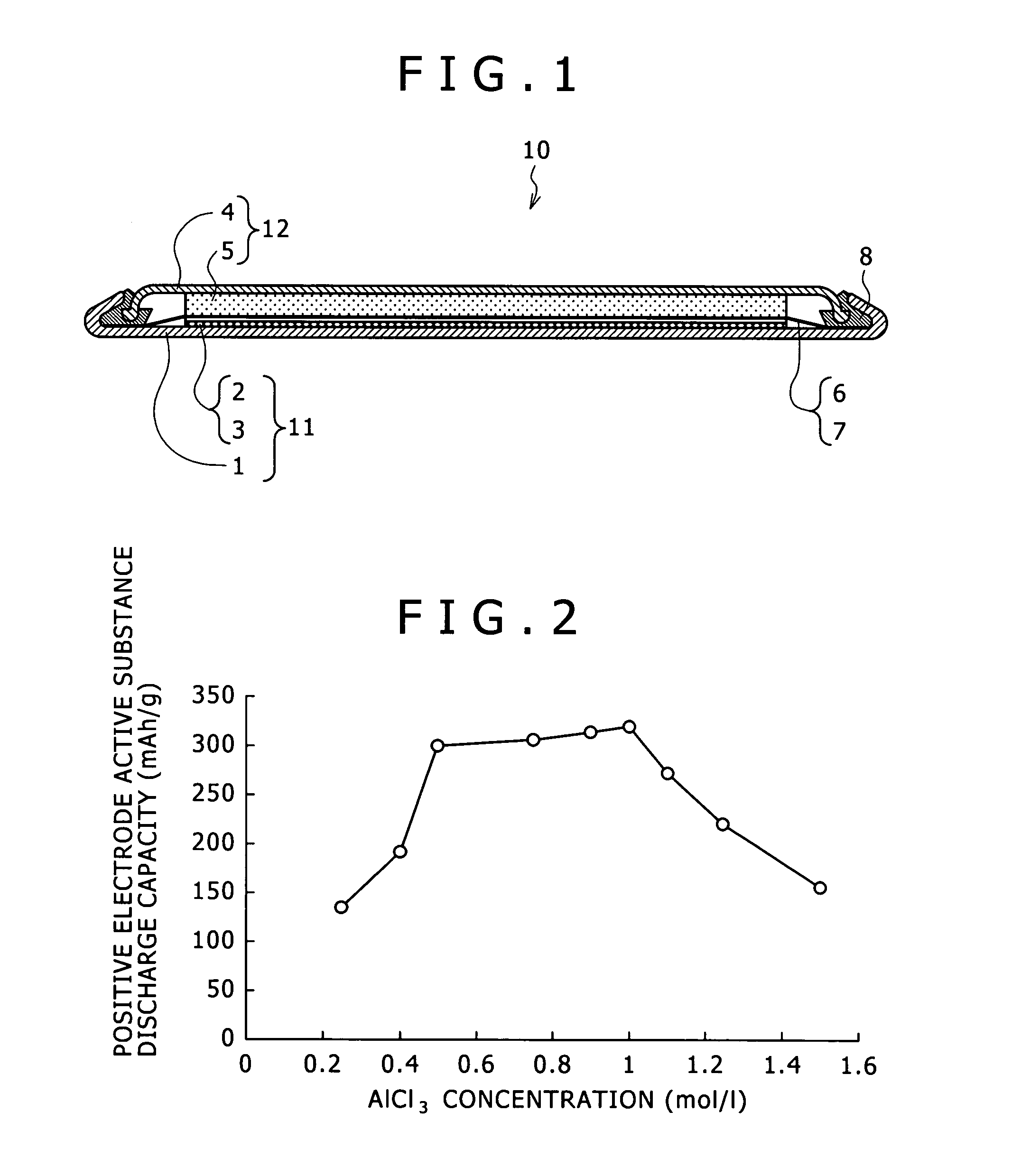

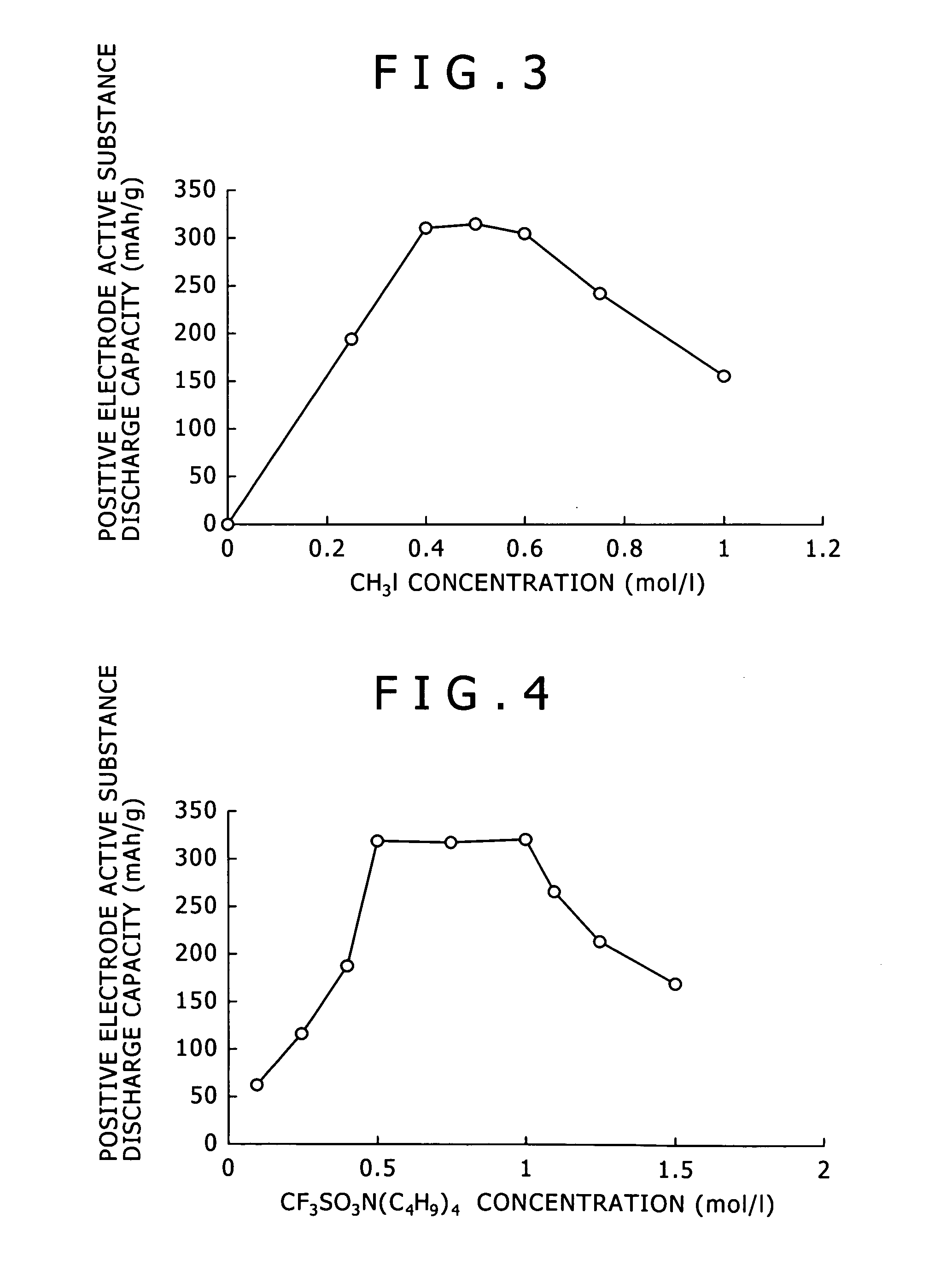

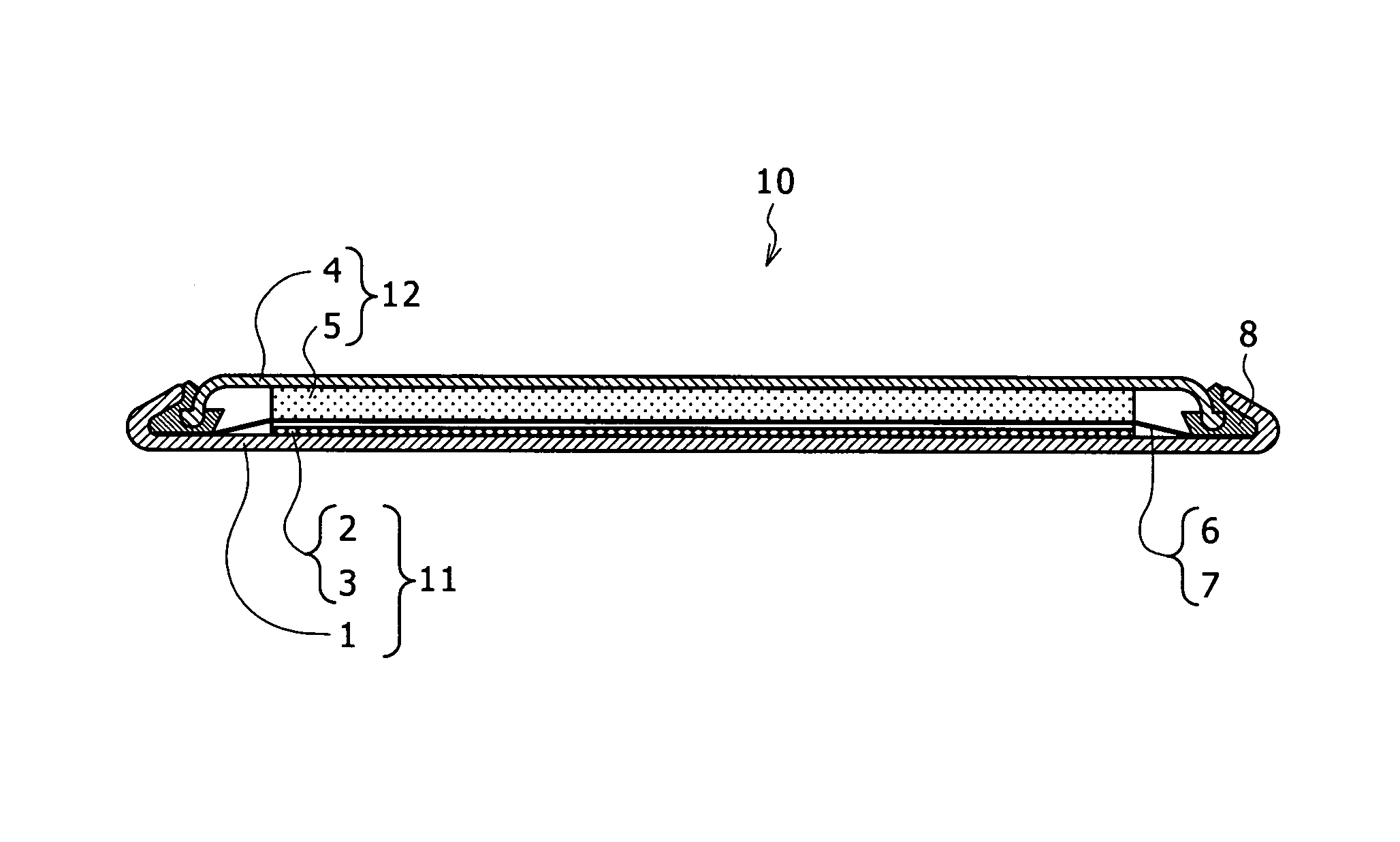

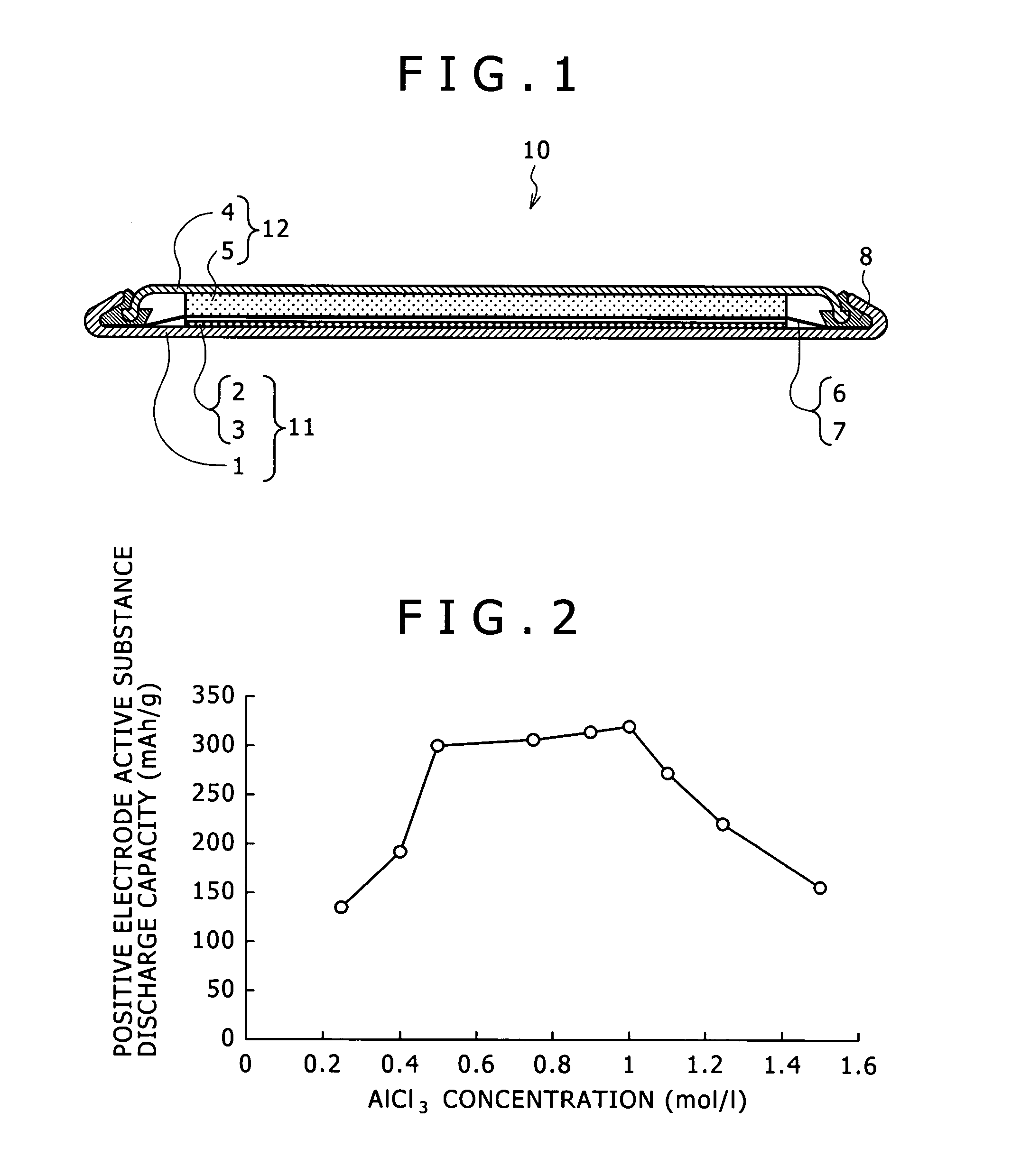

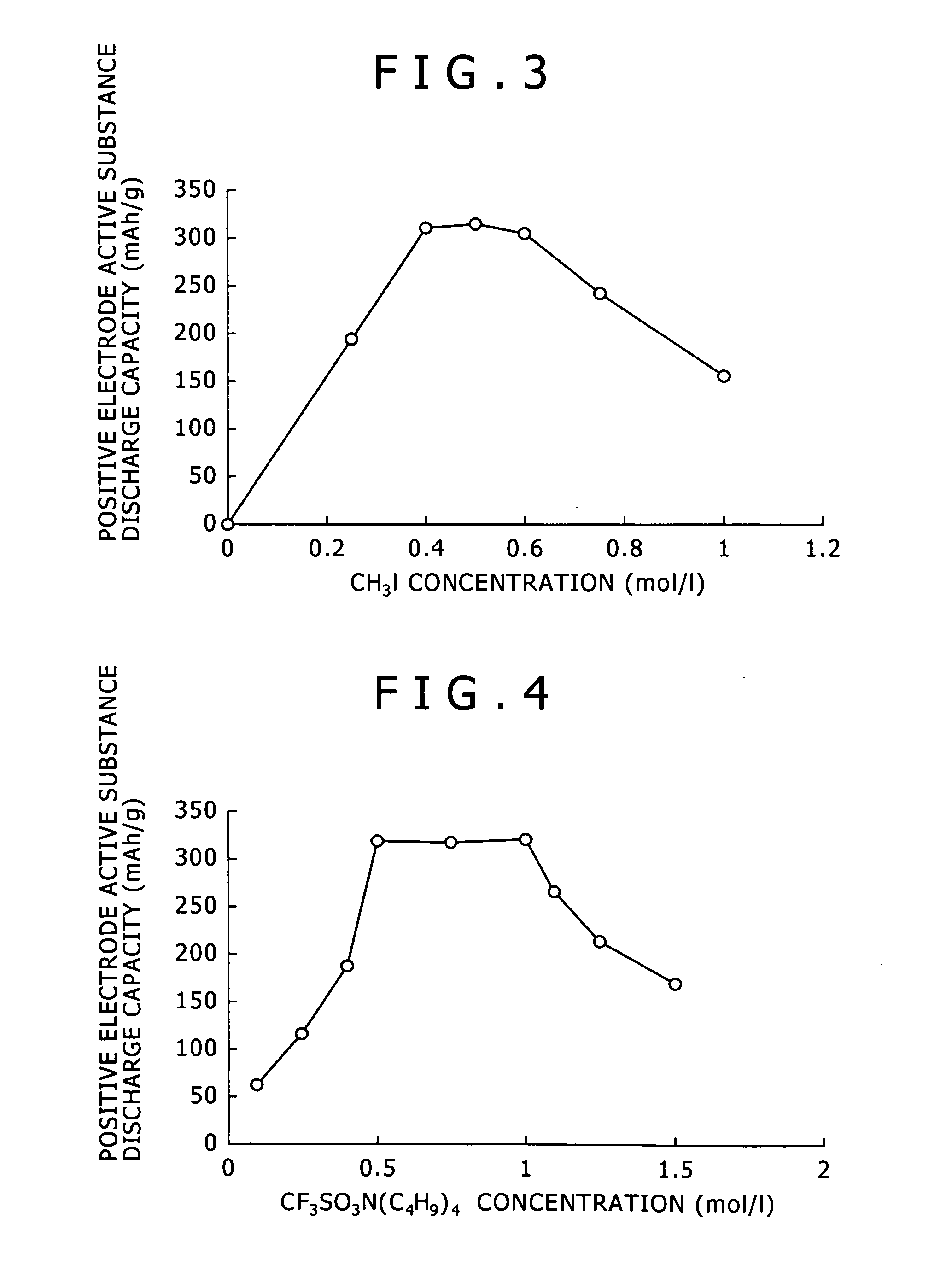

Magnesium ion-containing non-aqueous electrolyte and a production process thereof, as well as electrochemical device

ActiveUS20090068568A1Effective resourcesEfficient use ofCell electrodesOrganic electrolyte cellsAluminum IonPhosphate ion

A magnesium ion containing non-aqueous electrolyte in which magnesium ions and aluminum ions are dissolved in an organic etheric solvent, and which is formed by: adding metal magnesium, a halogenated hydrocarbon RX, an aluminum halide AlY3, and a quaternary ammonium salt R1R2R3R4N+Z− to an organic etheric solvent; and applying a heating treatment while stirring them (in the general formula RX representing the halogenated hydrocarbon, R is an alkyl group or an aryl group, X is chlorine, bromine, or iodine, in the general formula AlY3 representing the aluminum halide, Y is chlorine, bromine, or iodine, in the general formula R1R2R3R4N+Z− representing the quaternary ammonium salt, R1, R2, R3, and R4 represent each an alkyl group or an aryl group, and Z− represents chloride ion, bromide ion, iodide ion, acetate ion, perchlorate ion, tetrafluoro borate ion, hexafluoro phosphate ion, hexafluoro arsenate ion, perfluoroalkyl sulfonate ion, or perfluoroalkyl sulfonylimide ion.

Owner:MURATA MFG CO LTD

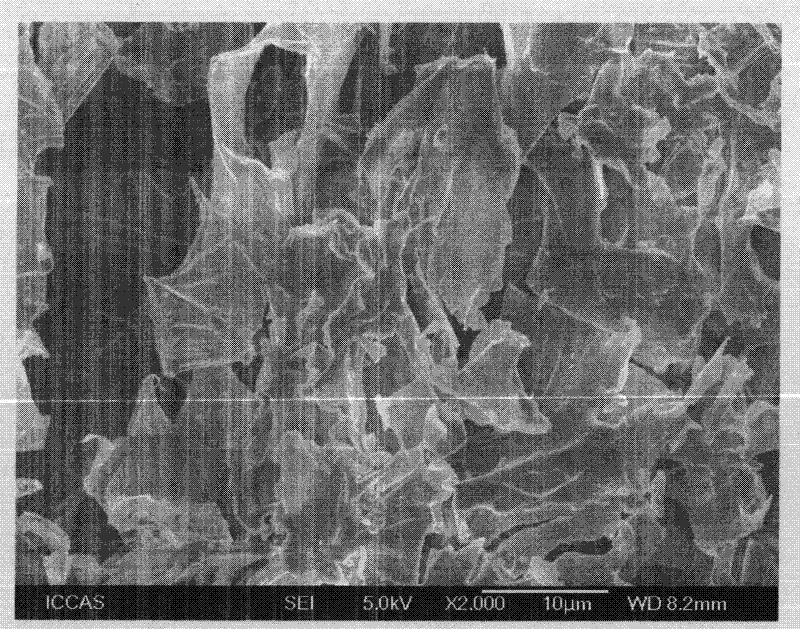

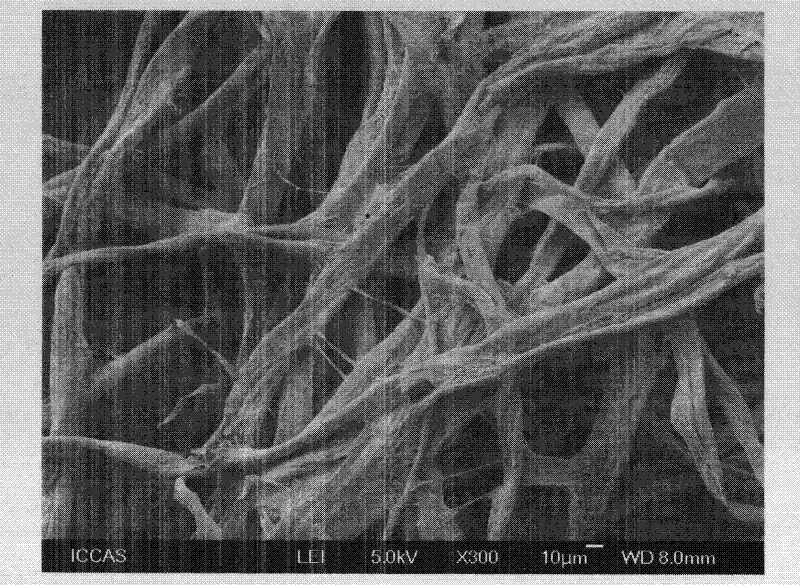

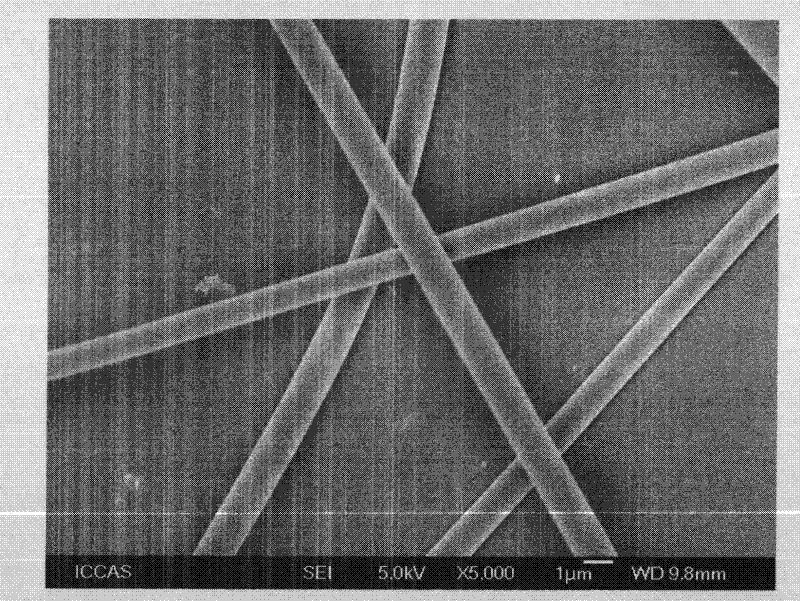

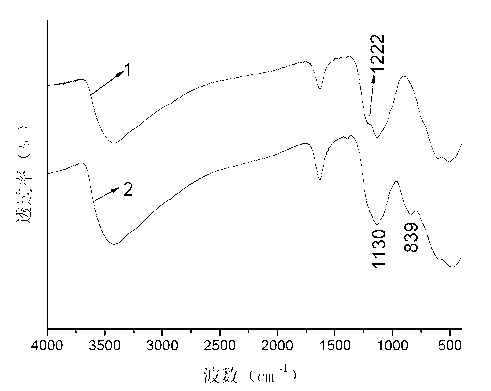

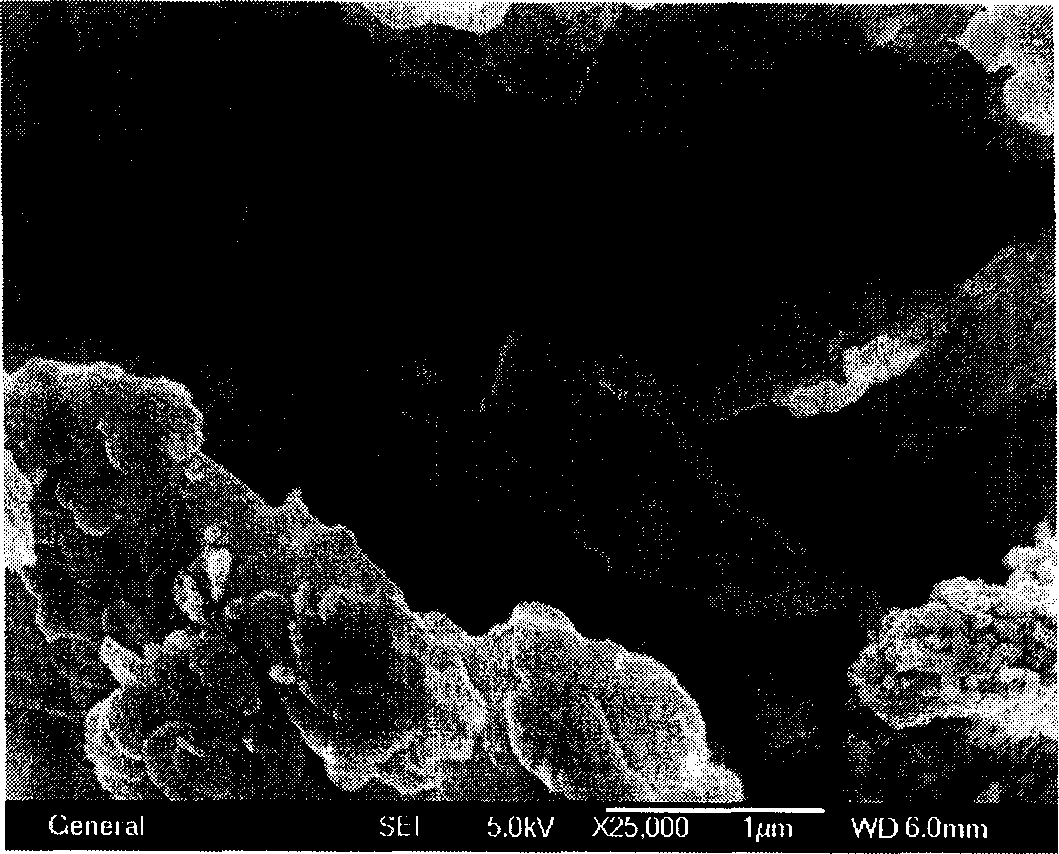

Cellulose base/Fe3O4 composite adsorption material used for removing arsenic in water and preparation method thereof

ActiveCN102476043AImprove adsorption capacityWide working pH rangeOther chemical processesWater/sewage treatment by sorptionAlkaline waterNational standard

The invention relates to a cellulose base / Fe3O4 composite adsorption material used for removing arsenic in water and a preparation method thereof. According to the invention, with fibers or powder of natural cellulose or fibers of a cellulose derivative as a cellulose matrix material for the composite adsorption material, in an alkaline water system provided by ammoniacal liquor, Fe3O4 particles are loaded on the surface of the cellulose matrix material through in-situ co-precipitation, and the loaded Fe3O4 particles enable the obtained cellulose base / Fe3O4 composite adsorption material to have magnetism and to be easily removed from water, and allow harmful ions like arsenate ions and arsenite ions in water to be absorbed. Compared to arsenic removal materials in the prior art, the invention has the following characteristics: a natural biomass is used as an adsorption carrier, and the natural biomass is cheap and highly efficient, enables the content of arsenic in water to be substantially lower than a national standard and is easy to remove and convenient to use.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

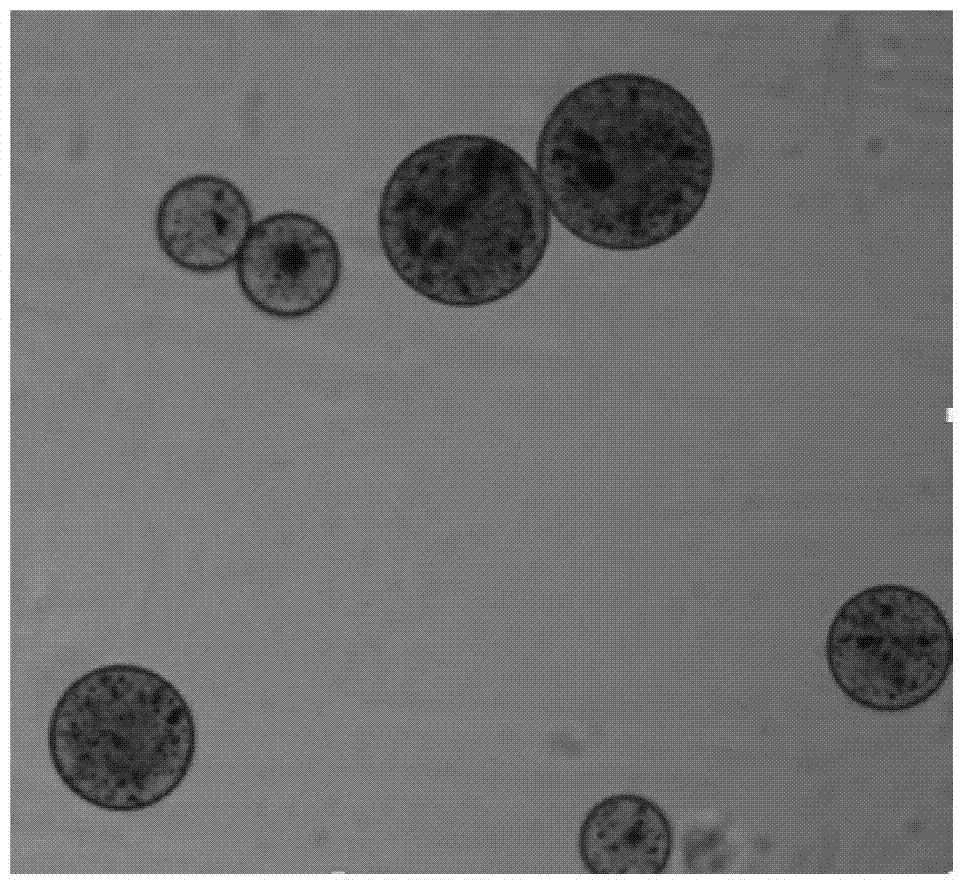

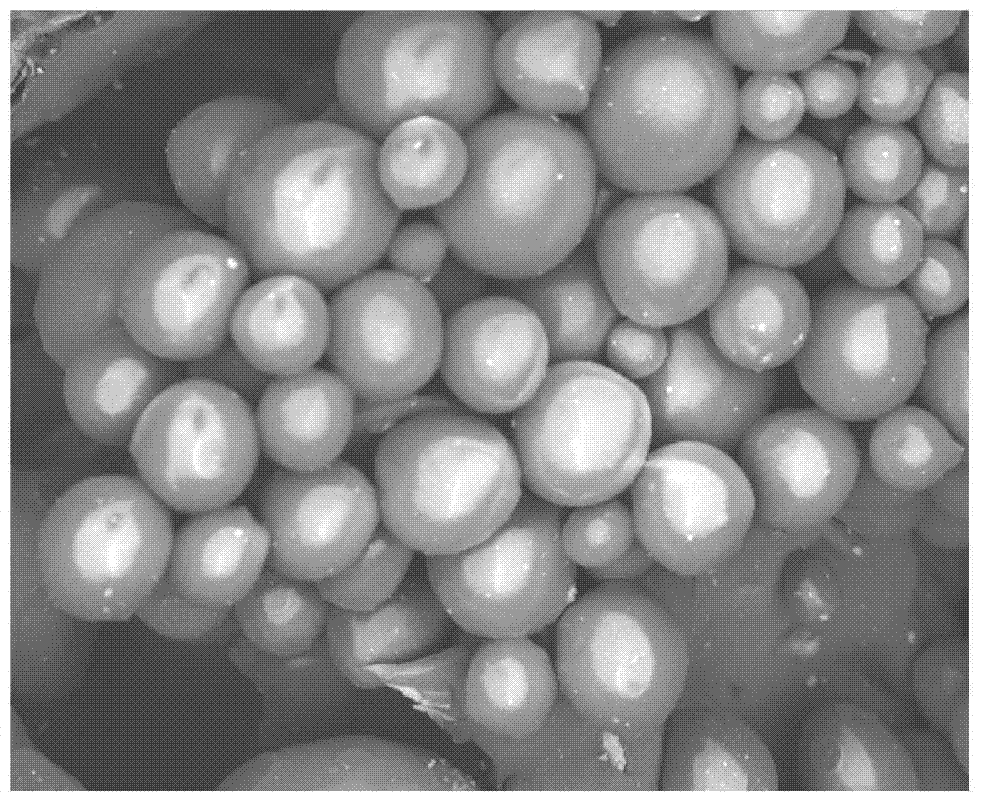

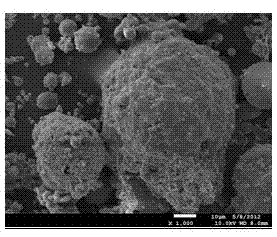

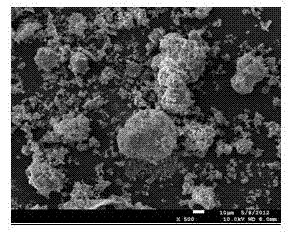

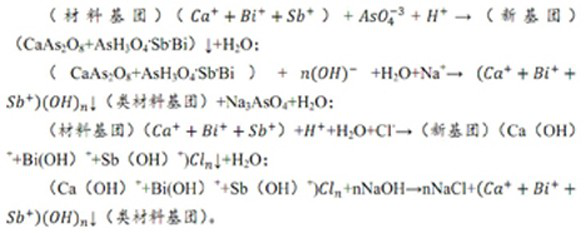

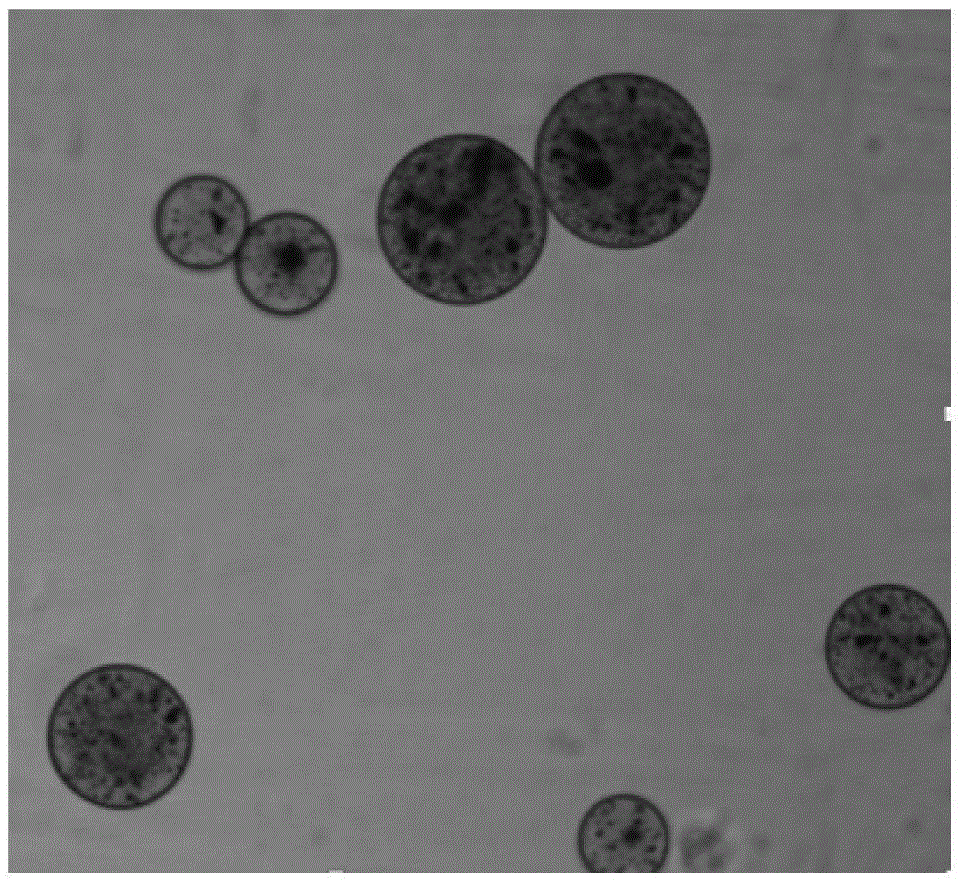

Chitosan and chitosan quaternary ammonium salt composite magnetic microsphere and preparation method thereof

ActiveCN104258822AImprove adsorption capacityStrong pH adaptabilityOther chemical processesAnion exchangersPhosphate ionMicrosphere

The invention discloses a chitosan and chitosan quaternary ammonium salt composite magnetic microsphere and a preparation method thereof. The method comprises the steps of preparing a water phase, stirring and dissolving chitosan, chitosan quaternary ammonium salt and a pore-foaming agent PEG or PVP according to a ratio in an acetic acid aqueous solution, and adding magnetic particles for stirring and ultrasonic treatment; preparing an oil phase, and stirring liquid paraffin and Span80 to obtain the oil phase; gradually adding the water phase into the oil phase drop by drop while stirring is carried out to obtain a liquid mixture; adding a sodium polyphosphate aqueous solution into the liquid mixture drop by drop, carrying out stirring, and adding a glutaraldehyde aqueous solution for reaction; carrying out centrifugation and washing to obtain the chitosan and chitosan quaternary ammonium salt composite magnetic microsphere. The composite magnetic microsphere disclosed by the invention is higher in adsorption to electronegative materials such as humic acid, anionic dyes, arsenate ions, phosphate anions and nitrate ions, is higher in pH adaptability, magnetic separation property and regeneration performance, and is high in exchange capacity, high in adsorption speed and easy to separate.

Owner:TIANJIN POLYTECHNIC UNIV

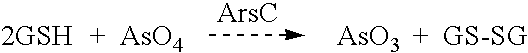

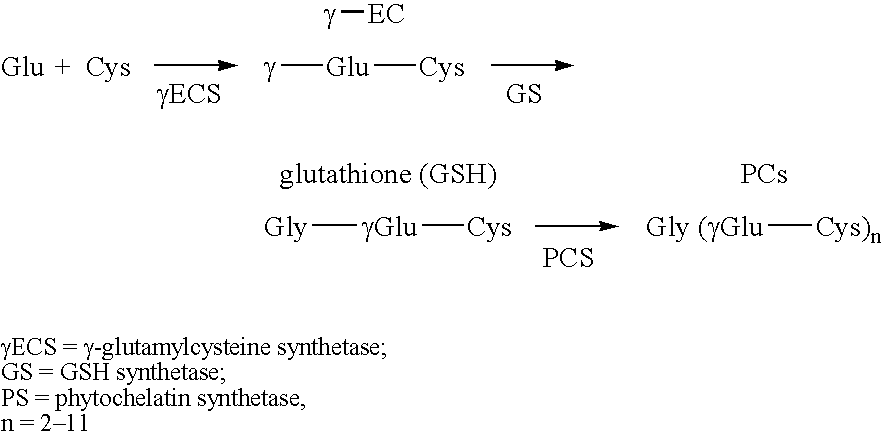

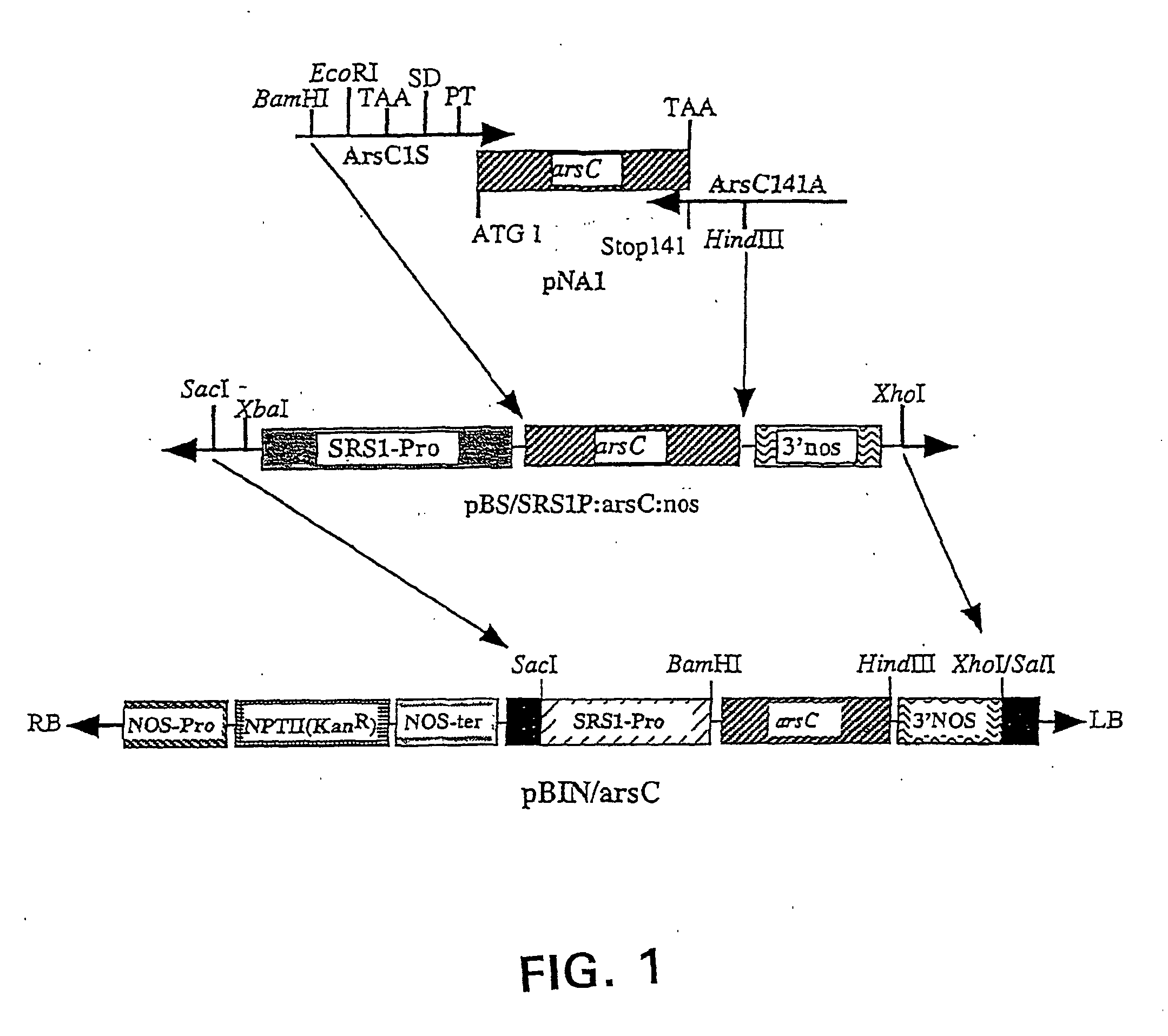

Metal resistant plants and phytoremediation of environmental contamination

The present disclosure provides methods, recombinant DNA molecules, recombinant host cells containing the DNA molecules, and transgenic plant cells, plant tissue and plants which contain and express at least one phytochelatin biosynthetic coding sequence under the regulatory control of the strong ACT2 constitutive promoter or the light-inducible SRS1 promoter and / or a plant-expressible arsenate reductase coding sequence. Optionally the plant expressing the at least one phytochelatin biosynthetic enzyme coding sequence can also express a mercuric ion reductase coding sequence. The transgenic plants are tolerant of heavy metal ions, e.g., cadmium, arsenate and / or mercury, and can accumulate those ions from a contaminated environment, to thus, effect phytoremediation of a contaminated soil or water environment which contains mercury, cadmium and / or arsenate ions.

Owner:UNIV OF GEORGIA RES FOUND INC

Process for regenerating and protonating a weak-base anion exchange resin

ActiveUS7875186B2Low costEasy disposalIon-exchanger regenerationOrganic anion exchangersSelenateIon exchange

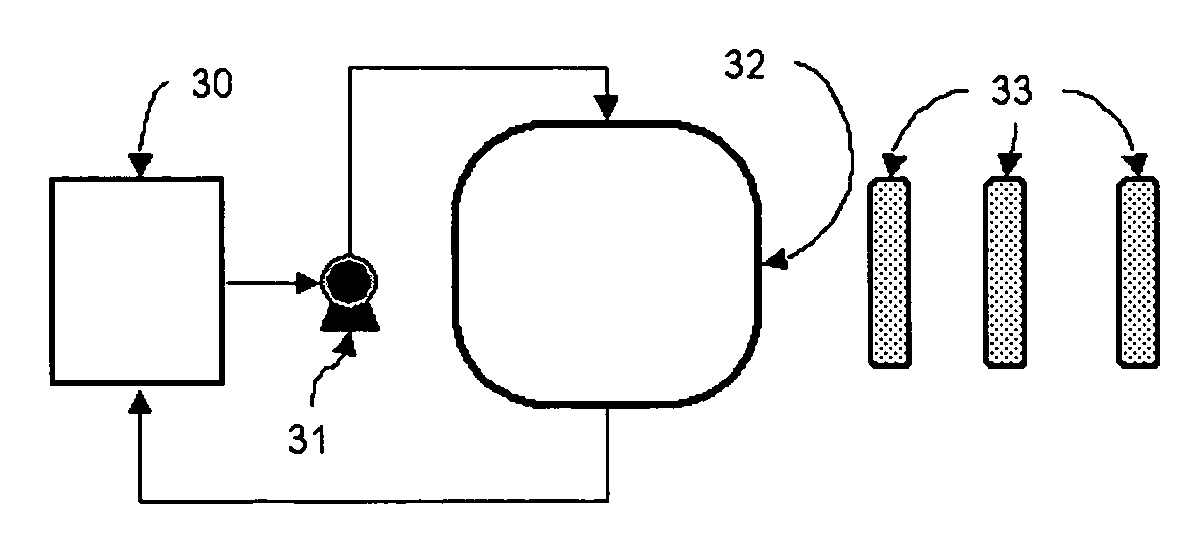

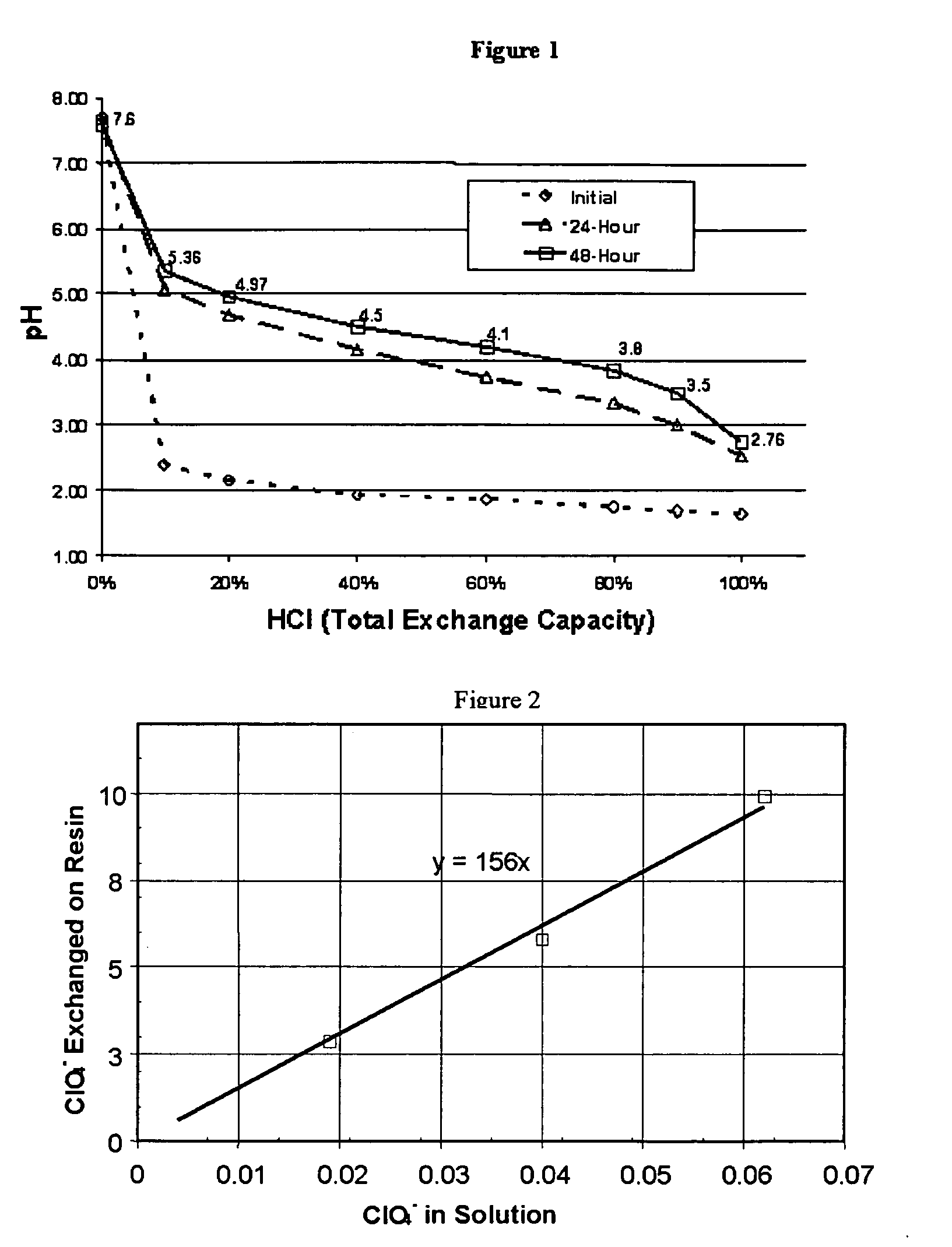

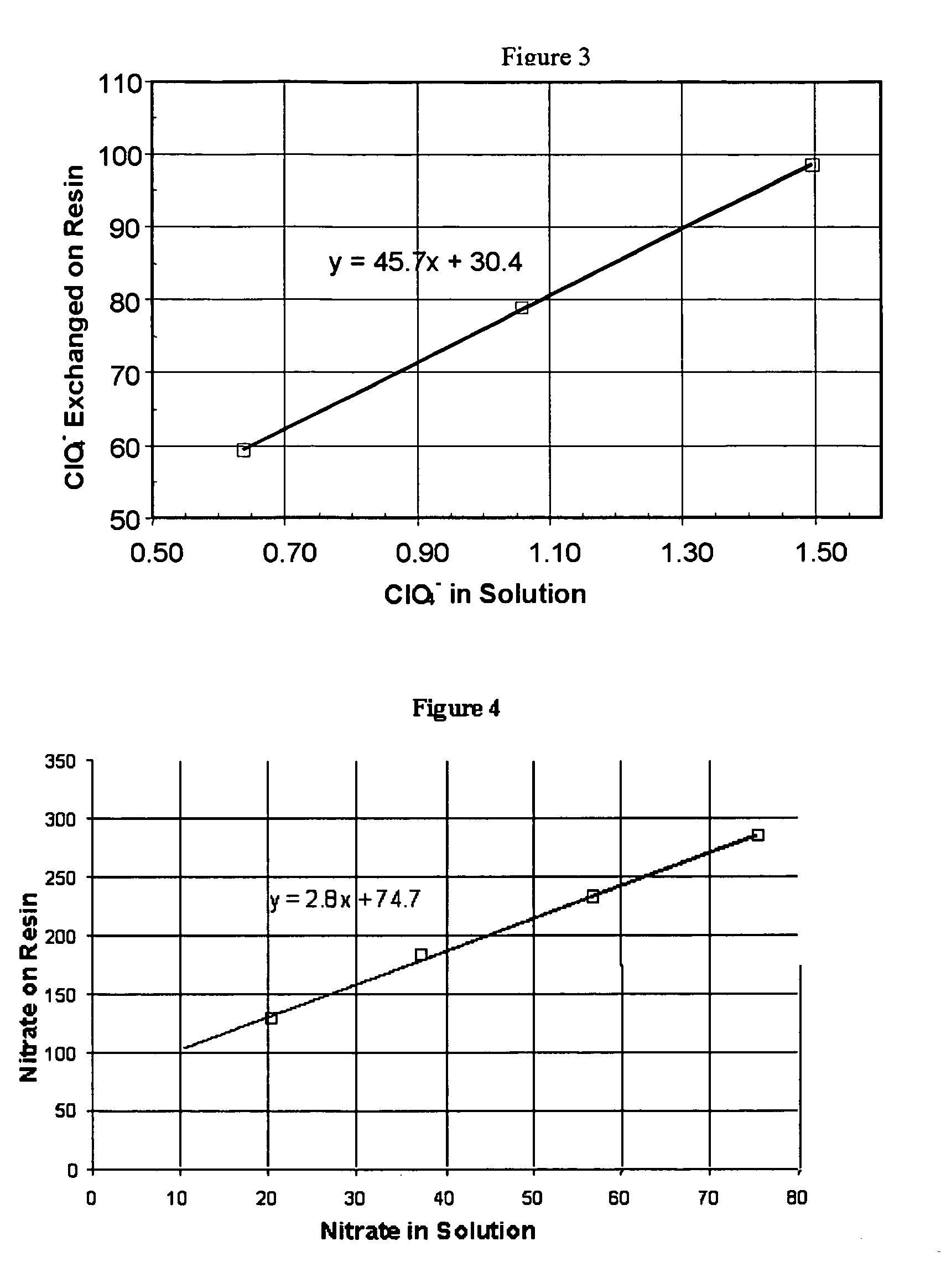

The invention consists of a water treatment process using selective and regenerable weak base anion exchange resins to remove any number of complex anions, especially oxyanions including perchlorate, nitrate, chlorate, arsenate, selenate, and chromate, from aqueous solutions. The treatment process is comprised of three key processes including 1) pretreatment to lower pH, 2) ion exchange, and 3) post treatment to adjust pH and alkalinity. The invention also includes processes for regenerating weak base anion resins and treatment of the residuals generated. This invention employs pressurized treatment, carbon dioxide management, and reuse of regenerating solution to minimize pumping and treatment costs.

Owner:APPLIED RES ASSOCS INC +1

Method for preparing composite assembled object of magnetic ferriferous oxide/ molecular sieve of Nano zeolite

InactiveCN1915849ALow costPromote regenerationWater/sewage treatment by magnetic/electric fieldsWater/sewage treatment by sorptionChemical reactionPhosphate ion

This invention relates to a method for preparing magnetic iron oxide / nanoscale zeolite molecular sieve composite. The method comprises: (1) selecting nanoscale zeolite crystal material; (2) introducing Fe2+ / Fe3+ as active reaction sites through ion exchange under the action of electrostatic attraction; (3) dropping 25% ammonia solution for reaction of the active sites in an alkaline medium, washing with water and drying; (4) removing phosphate ions and arsenate ions from water by using a dynamic adsorption apparatus. The method has such advantages as low cost, simple operation and high adsorption rate, and can be widely used for water purification.

Owner:SHANGHAI JIAO TONG UNIV

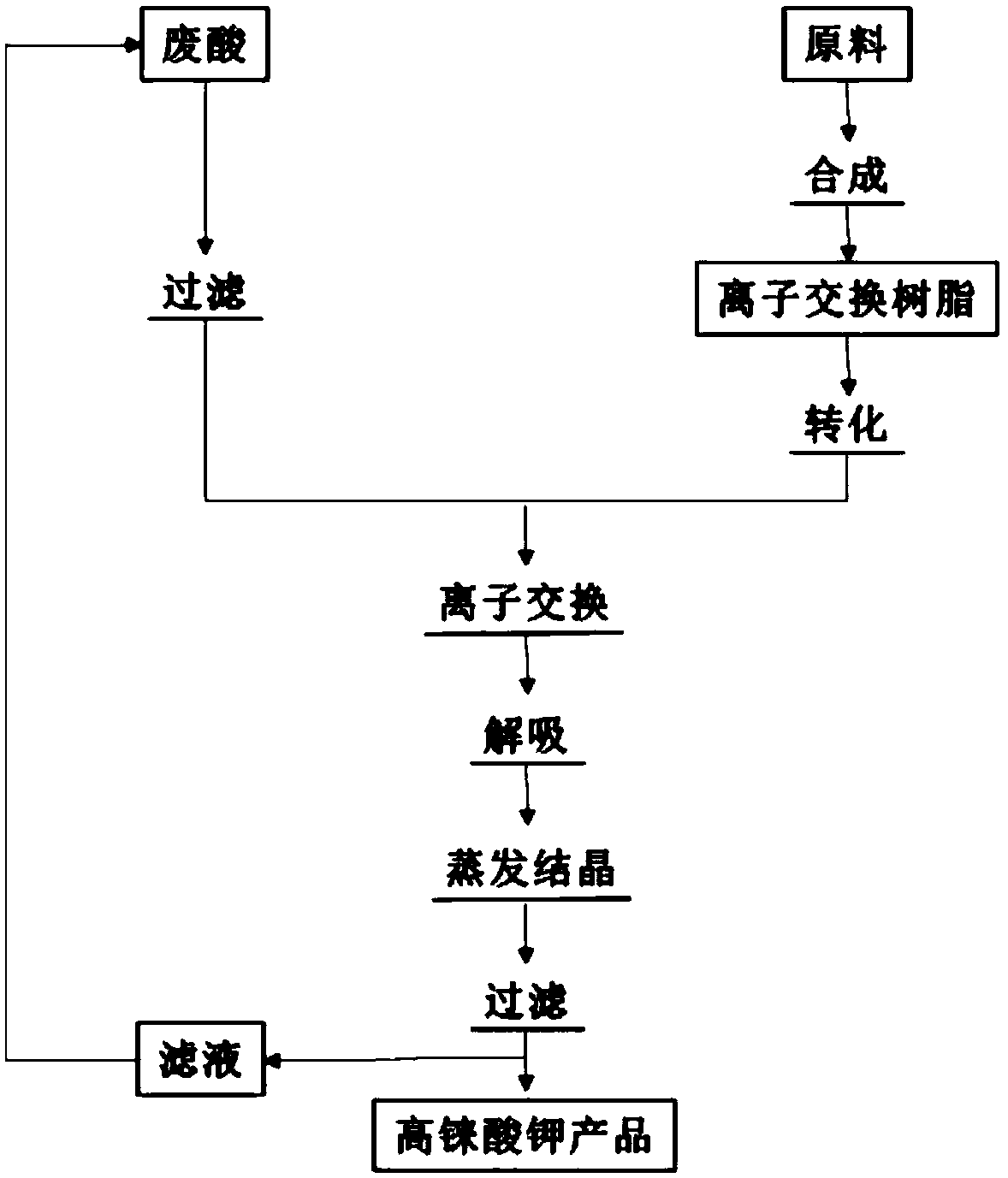

Composite vinylamine-series weakly-basic anion exchange resin and method for recovering rhenium from waste acid produced in copper smelting

The invention relates to a composite vinylamine-series weakly-basic anion exchange resin and a method for recovering rhenium from waste acid produced in copper smelting, belonging to the technical field of recycling of metallic rhenium. The composite vinylamine-series weakly-basic anion exchange resin is prepared by swelling chloromethylated polystyrene microspheres in an organic solvent for 4 to 10 h; then slowly adding a mixture of dicyclohexylamine, pyridine and N-methylcyclohexylamine and carrying out a reaction at room temperature for 1 to 6 h; then carrying out heating to 40 to 90 DEG C and continuing the reaction for 6 to 18 h; and then carrying out vacuum pumping filtration. The composite vinylamine-series weakly-basic anion exchange resin provided by the invention has good adsorptive selectivity on low-concentration rhenium (2 to 10 mg / L) under the conditions of high acidity and existence of high-concentration impurity ions, and almost does not adsorb impurity ions, especially toxic arsenate ions; waste acid directly enters an arsenate after filtering; so process flow is simplified and the recovery rate of rhenium is increased.

Owner:ZHENGZHOU MINERALS COMPOSITIVE UTILIZATION RES INST CHINESE GEOLOGICAL ACAD +1

Adsorbent for removing arsenate ions in waste water

The invention provides a method for removing arsenate ions in waste water according to magnesium-iron binary hydrotalcite, which belongs to the field of water treatment adsorption of environmental protection. The Mg2Fe-LDHs adsorbent is prepared in a co-precipitating manner. Under the room-temperature condition, the adsorbent is added into a waste water solution according to a mass ratio of the adsorbent to the arsenate negative ions in the waste water being (0.16 to 8) to 1 and stirred for one hour, so that the adsorption balance can be achieved. The adsorption capability of the adsorbent forthe arsenate negative ions can reach 415 mg / g. The method has the advantages of low cost, simple process and good treatment effect.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

Adsorbent for removing toxic element arsenic in water and application thereof

InactiveCN102886240AImprove adsorption capacityEasy to manufactureOther chemical processesWater/sewage treatment by sorptionSorbentManganese

The invention relates to an adsorbent for removing a toxic element arsenic in water and application thereof. The adsorbent is formed by carrying out modification on pickled coal powder ash by zirconium manganese composite oxide. The invention also provides a method for removing arsenate ions in polluted water by utilizing the adsorbent. The adsorbent disclosed by the invention overcomes the defects of characteristics of low arsenic adsorption capacity, low selectivity and poor adsorption effect, utilizes solid waste, i.e. the coal powder ash and recycles waste materials so as to fulfill the aim of treating the waste by the waste. Meanwhile, the coal powder ash has low price and a method for preparing the adsorbent is simple, and thus, the adsorbent has good economic and environmental benefits.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

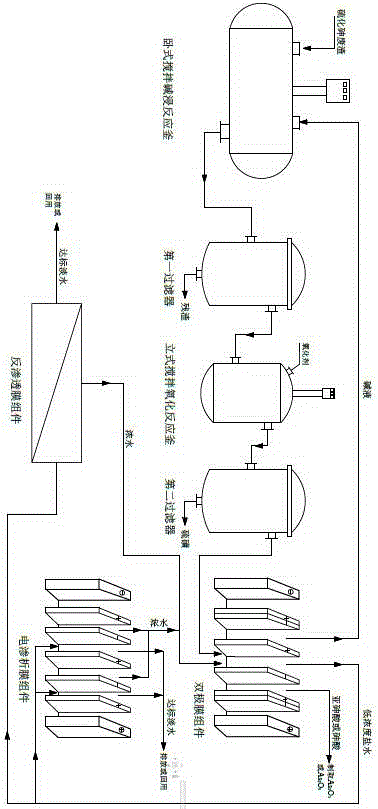

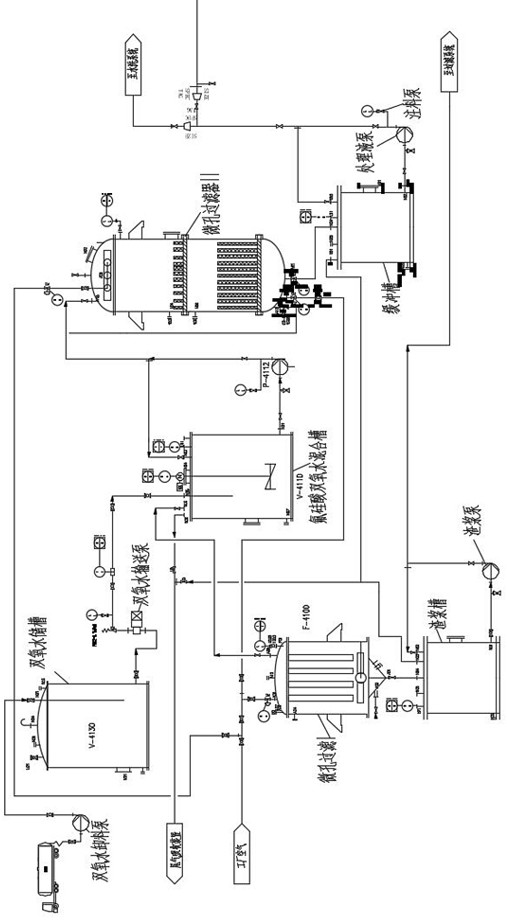

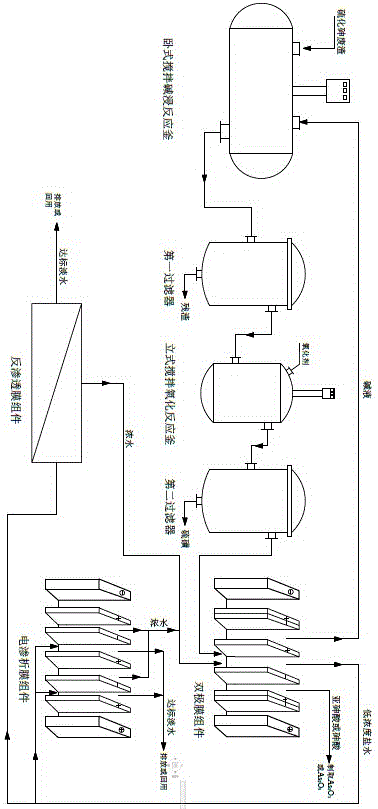

Arsenic sulfide waste residue recycling treatment method and device thereof

ActiveCN104438287AEffluent water quality is stable and up to standardAvoid secondary hazardous wasteSolid waste disposalReverse osmosisSulfidation

The invention discloses an arsenic sulfide waste residue recycling treatment method, which comprises the following steps: performing alkaline leaching to obtain sulfo-arsenite or sulfo-arsenate solution, filtering to remove waste residues through a filter, to obtain alkaline leachate, then performing oxidation desulfurization, so as to oxidize sulfo-arsenite or sulfo-arsenate into sulfo-arsenite or arsenate ions, then filtering and separating elemental sulfur through another filter to obtain arsenite or arsenate solution, recovering acid-base from the arsenite or arsenate solution by utilizing a bipolar membrane device, returning base solution for alkaline leaching and acid solution for crystalization and preparation of As2O3 or As2O5, performing electrodialysis or reverse osmosis concentration on residual liquor in a bipolar membrane salt chamber, returning concentrated liquor as inflowing water of the salt chamber of the bipolar membrane device, and draining or recovering fresh water. According to the arsenic sulfide waste residue recycling treatment method, the problems that for the traditional arsenic sulfide waste residue treatment method, consumption is large, the content of arsenic in effluent water does not reach the standard, the recycling rate is low, the technological process is complicated, secondary pollution exists and the like can be solved, the content of arsenic in effluent water reaches the standard, the recycling rate of As and S is high, the advantages of low consumption, low running cost, simple technological process and the like can be achieved.

Owner:BEIJING CYCLE COLUMBUS ENVIRONMENTAL SCI & TECH

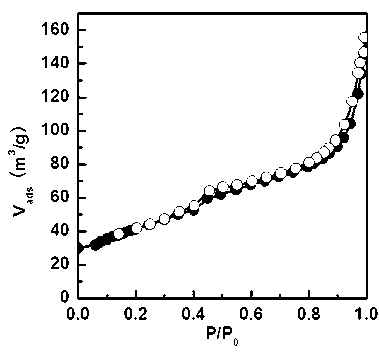

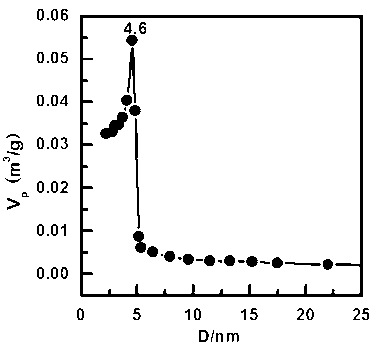

Method for preparing arsenic adsorbent and method for treating waste water

InactiveCN102698703AImprove adsorption capacityThe synthesis method is simpleOther chemical processesWater/sewage treatment by sorptionSorbentWastewater

The invention provides a method for preparing an arsenic adsorbent. The arsenic adsorbent has zirconium oxide of nano-pore structure. The material can effectively treat arsenate and arsenite in the waste water, and can be recycled after waste water treatment. Another objective of the invention is to provide a method for treating waste water containing arsenate or arsenite ions by the arsenic adsorbent prepared by the method. The method contains a 'regeneration' step, so that the arsenic adsorbent can be reused cyclically.

Owner:CHONGQING THREE GORGES UNIV

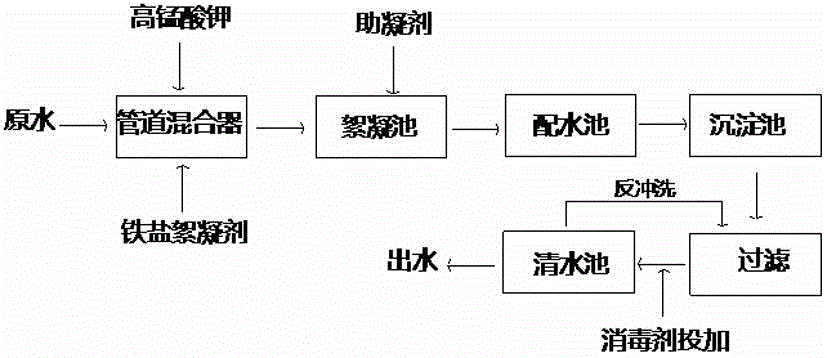

Arsenic removing water purification treatment method

InactiveCN104961275AGood arsenic removal effectWater contaminantsMultistage water/sewage treatmentIron saltsUltrafiltration

The invention discloses an arsenic removing water purification treatment method and belongs to the technical field of water purification treatment. Arsenic in water exists in two main valence states including tervalence (arsenite ions) and pentavalence (arsenate ions), wherein the pentavalent arsenic can be removed by an iron salt flocculating agent, but the tervalent arsenic cannot be removed by the iron salt flocculating agent. According to the process, potassium hypermanganate is used for pre-oxidizing, and the iron salt flocculating agent and an auxiliary flocculating agent are added together; the arsenic in raw water is removed by a coagulant sedimentation method; finally, tiny floc, which is not settled and is adsorbed by the flocculating agents, is further intercepted by quartz sand filtering or an immersing type ultrafiltration membrane, so that the content of the arsenic in the output water reaches 0.1 microgram per liter.

Owner:毛允明

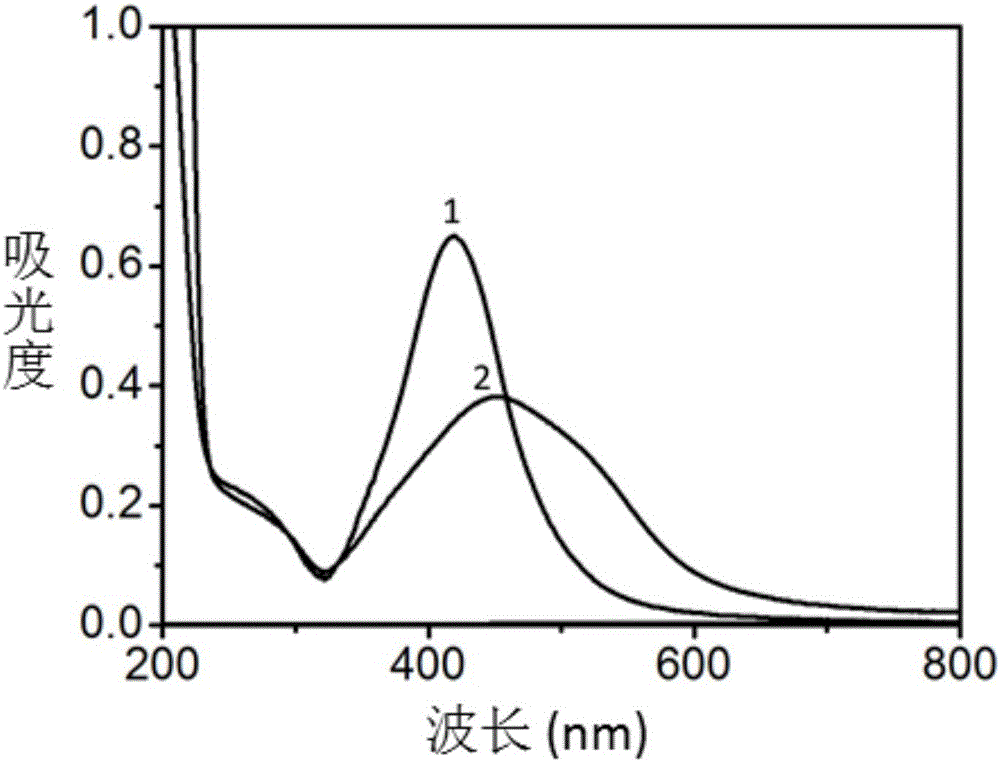

Core-shell SERS (surface enhanced Raman spectroscopy) probe, method for preparing same and application of core-shell SERS probe to trace arsenate ion detection

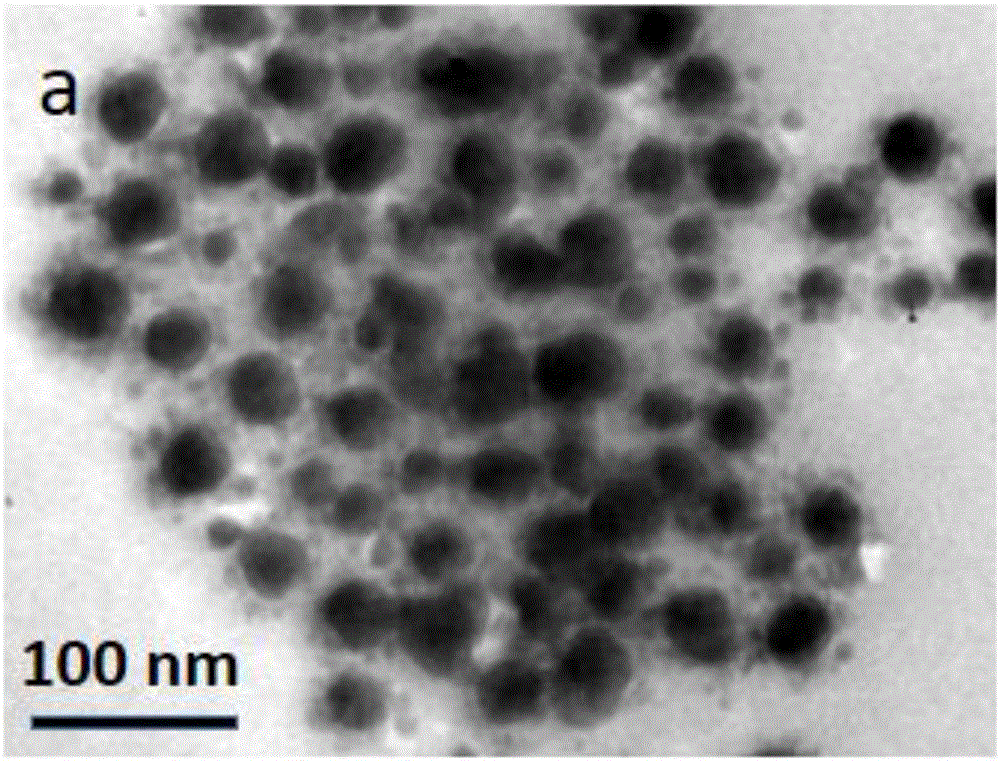

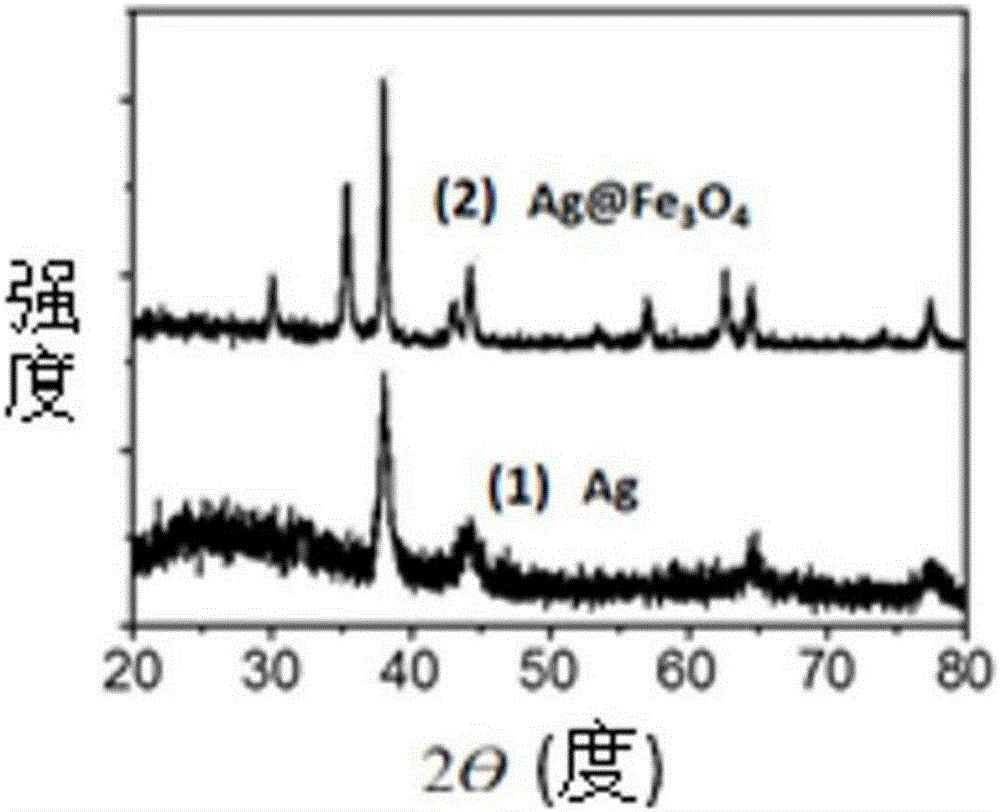

ActiveCN105842229AEasy to detectValid setMaterial nanotechnologyRaman scatteringSodium acetrizoateSodium acetate

The invention discloses a core-shell SERS (surface enhanced Raman spectroscopy) probe, a method for preparing the same and application of the core-shell SERS probe to trace arsenate ion detection, and belongs to the technical field of drinking water safety detection. The method includes the steps: concentrating 5-20 mL of citrate-stable precious metal nano-particle colloidal solution by the aid of centrifugal separation processes until the volume of the citrate-stable precious metal nano-particle colloidal solution is 1.5-3% of the original volume of the citrate-stable precious metal nano-particle colloidal solution so as to obtain concentrated solution; dispersing the obtained concentrated solution into 2-5 mL of organic alcohol solvents, sequentially adding 0.5-2 g of sodium acetate and 0.01-0.05 g of iron salt into the organic alcohol solvents, then strenuously stirring the sodium acetate, the iron salt, the concentrated solution and the organic alcohol solvents and completely dissolving reactants to obtain mixtures; carrying out hydrothermal reaction on the mixtures under the condition of the temperature of 180-250 DEG C for 8-18 h to obtain precious metal @Fe3O4 core-shell nano-particles. The core-shell SERS probe, the method and the application have the advantages that physical and chemical characteristics of precious metal cores and Fe3O4 shell layers can be effectively integrated on the core-shell SERS probe, and arsenate ions can be adsorbed by the Fe3O4 shell layers and accordingly can be effectively enriched on the surface of precious metal; the limit of detection of the arsenate ions of the core-shell SERS probe can be obviously lowered, and the core-shell SERS probe and the method can have important application prospects in the field of drinking water safety detection owing to magnetic separation and desorption recycling.

Owner:JILIN UNIV

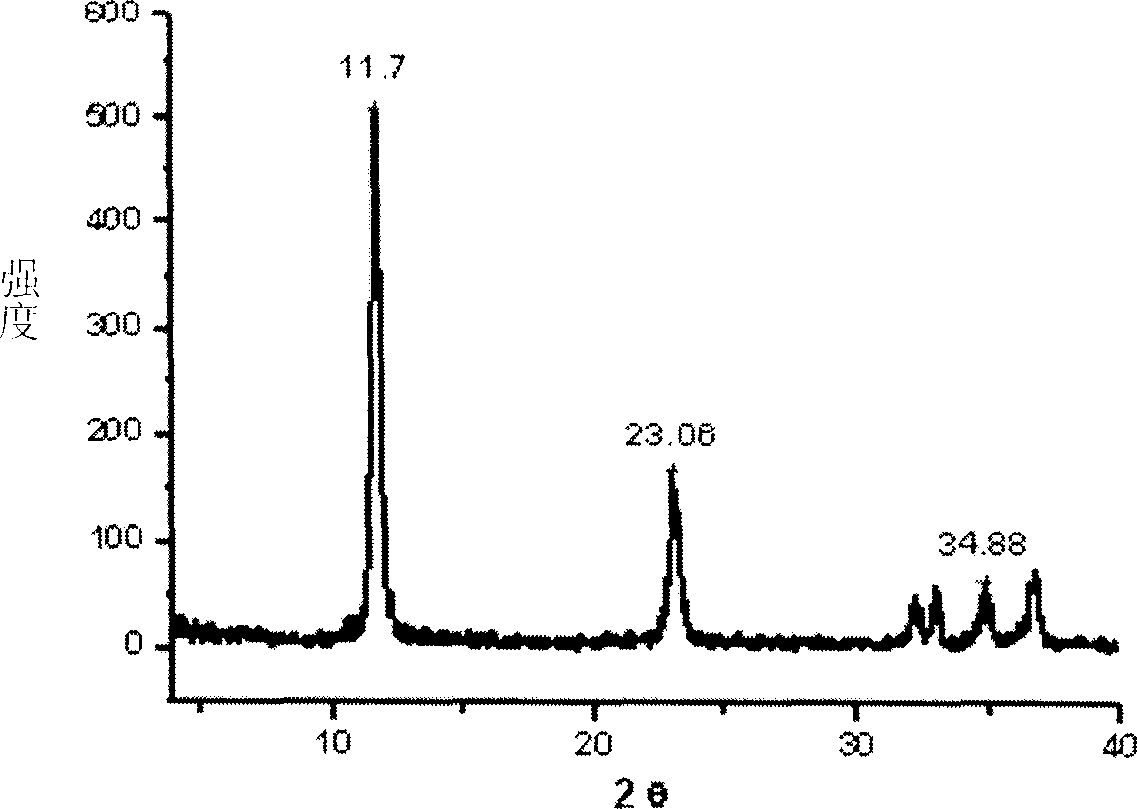

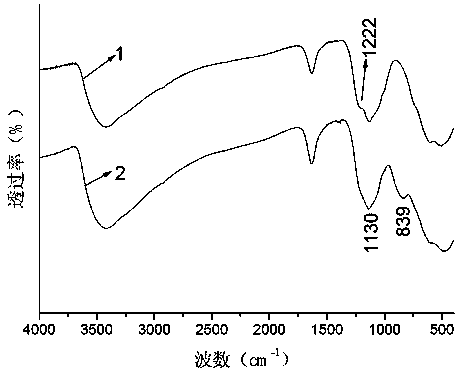

Method for treating arsenic pollutants with calcic aluminiferous material

InactiveCN103058338AHigh cost of solutionWater/sewage treatment by flocculation/precipitationAluminum IonArsenic pollution

The invention relates to a method for treating arsenic pollutants with a calcic aluminiferous material, belonging to the technical fields of waste material recycling and arsenic pollutant stabilization. The calcic aluminiferous material used as a stabilizer contains abundant calcium and aluminum: in the arsenic pollutant stabilization process, the calcium directly precipitates with (AsO4)3<->; the (AsO4)3 intercalation forms hydrotalcite-like calcium aluminum-LDH and surface adsorption action with calcium and aluminum in the system; and under the coagulation precipitation actions of the aluminum ions on the arsenate radical, the goal of arsenic pollutant stabilization is achieved. The method comprises the following steps: taking a certain amount of arsenic pollutants, dispersing the arsenic pollutants in a water solution, and adding the calcic aluminiferous material, wherein the dry weight proportion of the calcic aluminiferous material to the arsenic pollutants is 1:10-1:20; and oscillating at room temperature for 12-24 hours, standing for aging, filtering, and carrying out solid-liquid separation. The stabilizer calcic aluminiferous material is cheap, accessible and stable, is used for arsenic pollutant stabilization, and has important economic, environmental and social meanings.

Owner:SHANGHAI UNIV +1

Method for treating arsenic contaminants by using material containing calcium and aluminum

InactiveCN104801527AHigh reusabilitySolid waste disposalWater/sewage treatment by flocculation/precipitationArsenic pollutionAqueous solution

The present invention discloses a method for treating arsenic contaminants by using a material containing calcium and aluminum. The method comprises: grinding a material containing calcium and aluminum and arsenic contaminants into powder, weighing the material containing calcium and aluminum and the arsenic contaminants according to a dry weight ratio of 1:20-1:40, dispersing the arsenic contaminants in an aqueous solution, adding the material containing calcium and aluminum to the arsenic contaminant dispersing solution, stirring for 24 h at a room temperature, carrying out placing aging, and carrying out solid-liquid separation so as to obtain the arsenic or arsenate ion-fixed Ca-Al-LDHs capable of carrying out a stabilizing treatment on arsenic contaminants. The method of the present invention has the following advantages that: the used stabilizer material containing calcium and aluminum is cheap, easily-available and stable and is used for stably treating the arsenic contaminants, and the important economic, environmental and social significance is provided.

Owner:江苏佳源铝业有限公司

Material for purication anion polluted water

InactiveCN1830822AEfficient removalStrong exchange abilityWater/sewage treatment by ion-exchangeWhite powderIon

A laminar material for cleaning the anion-polluted water by removing the anions (F ions, arsenous radicals, or arsenic radicals) is prepared through proportionally dissolving Mg (or Zn) source and Al source in water, dissolving alkali and anions in water, quickly mixing them, stirring for 48-144 hr, pump filtering, water washing and baking to obtain white powder.

Owner:JILIN UNIV

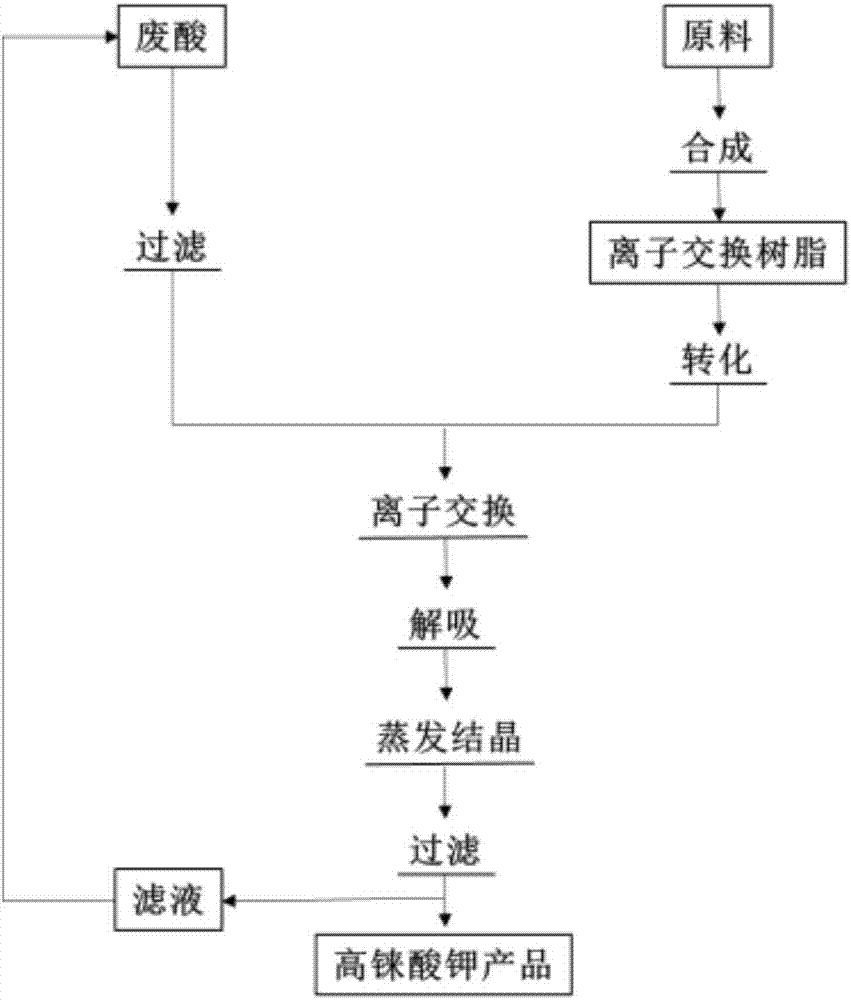

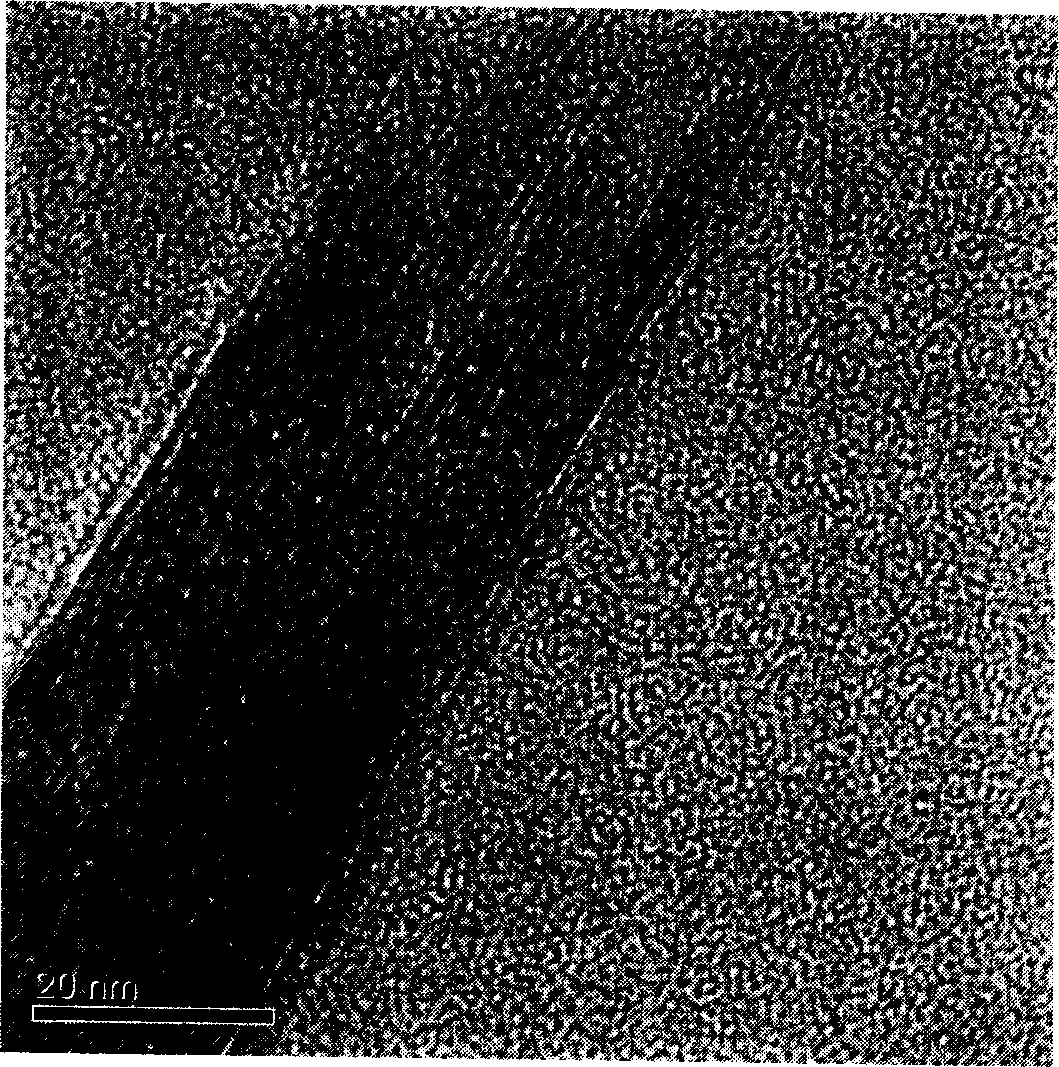

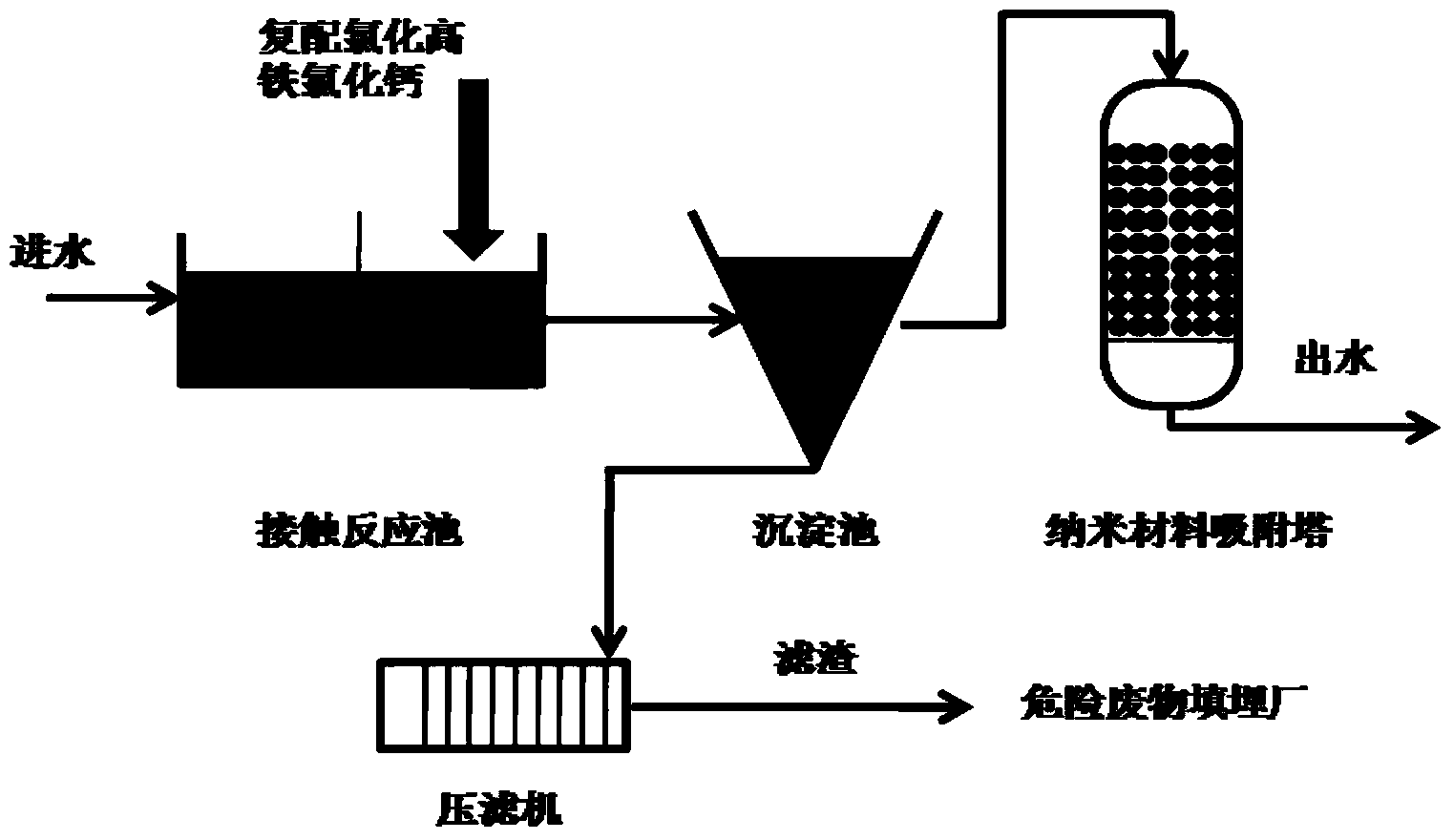

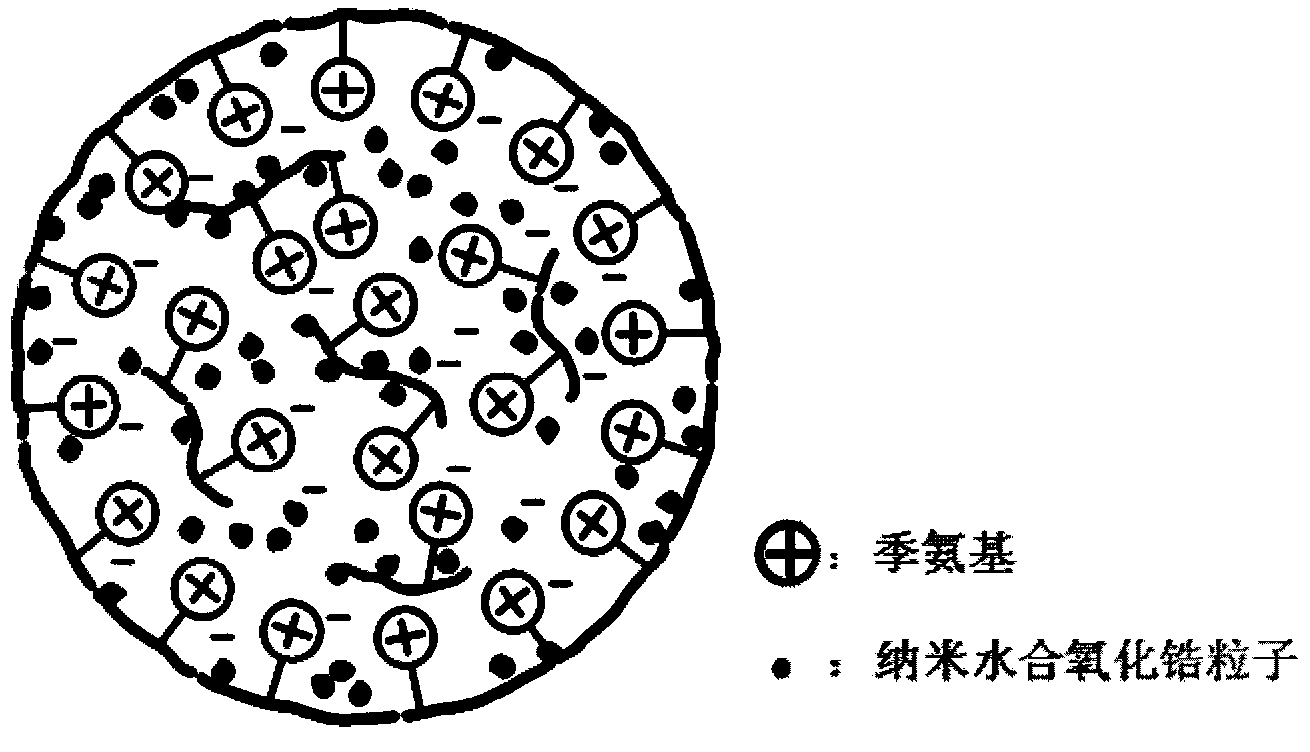

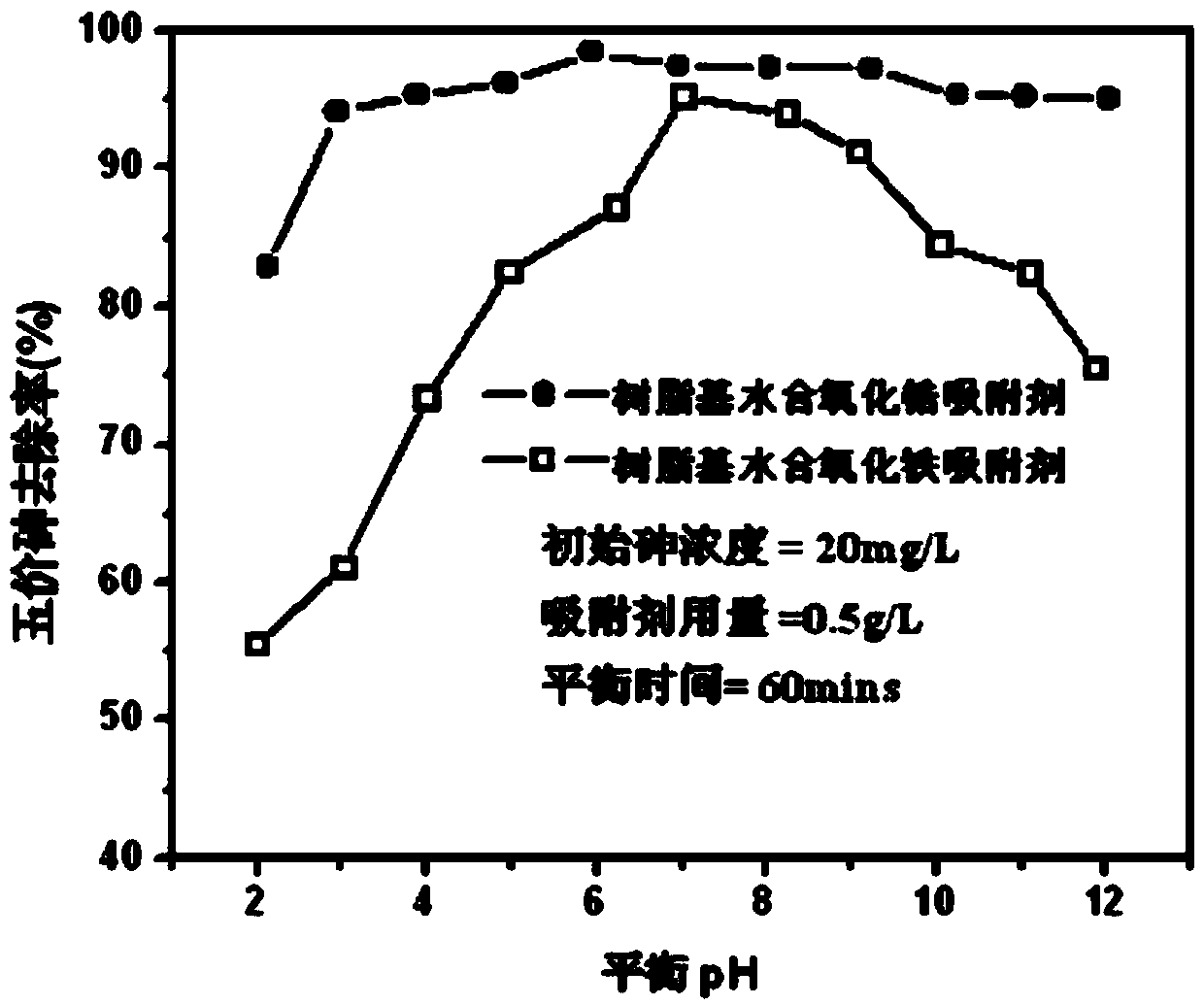

Method for treating high-concentration alkaline arsenic mining and metallurgy wastewater by coprecipitation-ion exchange compound technology

ActiveCN103626338AEasy to produce secondary pollutionLow costWaste water treatment from ceramic industriesWater contaminantsHigh concentrationTreatment effect

The invention discloses a method for treating high-concentration alkaline arsenic mining and metallurgy wastewater by coprecipitation-ion exchange compound technology, belonging to the technical field of wastewater treatment. The method comprises the following steps: (A) controlling the raw water of the arsenic mining and metallurgy wastewater to flow into a pH regulating tank, and regulating the pH of the raw water; (B) adding a mixture of ferric chloride and calcium chloride as well as polyacrylamide to carry out coprecipitation reaction; (C) enabling the coprecipitation reaction mixed liquid obtained in the step (B) to flow into a precipitation tank to undergo solid-liquid separation; (D) passing the supernatant obtained in the step (C) through an adsorption tower filled with nanocomposite materials; (E) stopping adsorption when the arsenate ions adsorbed by the nanocomposite materials reach the breakthrough point, and desorbing and regenerating the nanocomposite materials; (F) concentrating the desorption liquid obtained in the step (E), and then sending the precipitate outwards for incineration or reducing the precipitate for producing pesticides. The method can be used for advanced treatment of the high-concentration alkaline arsenic mining and metallurgy wastewater, and has good treatment effects.

Owner:NANJING UNIV

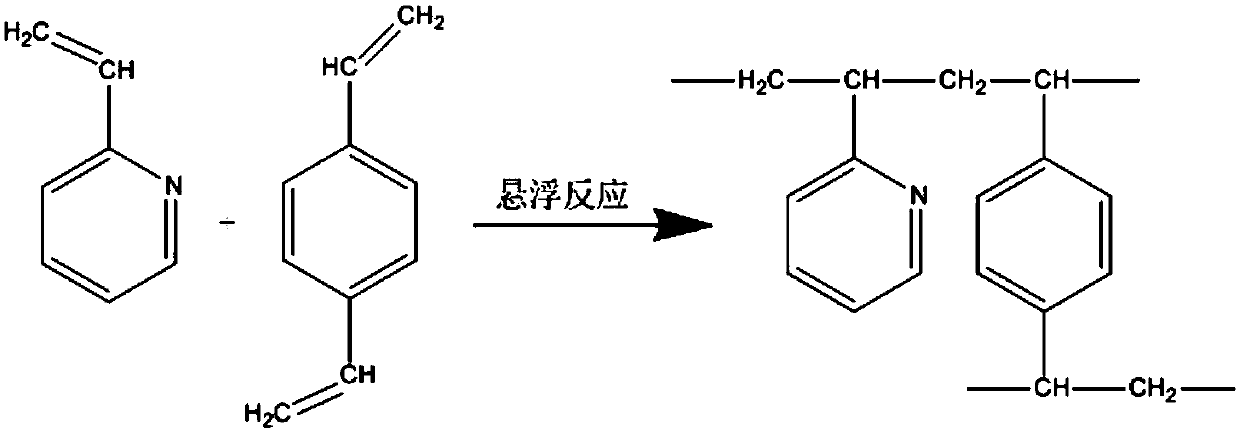

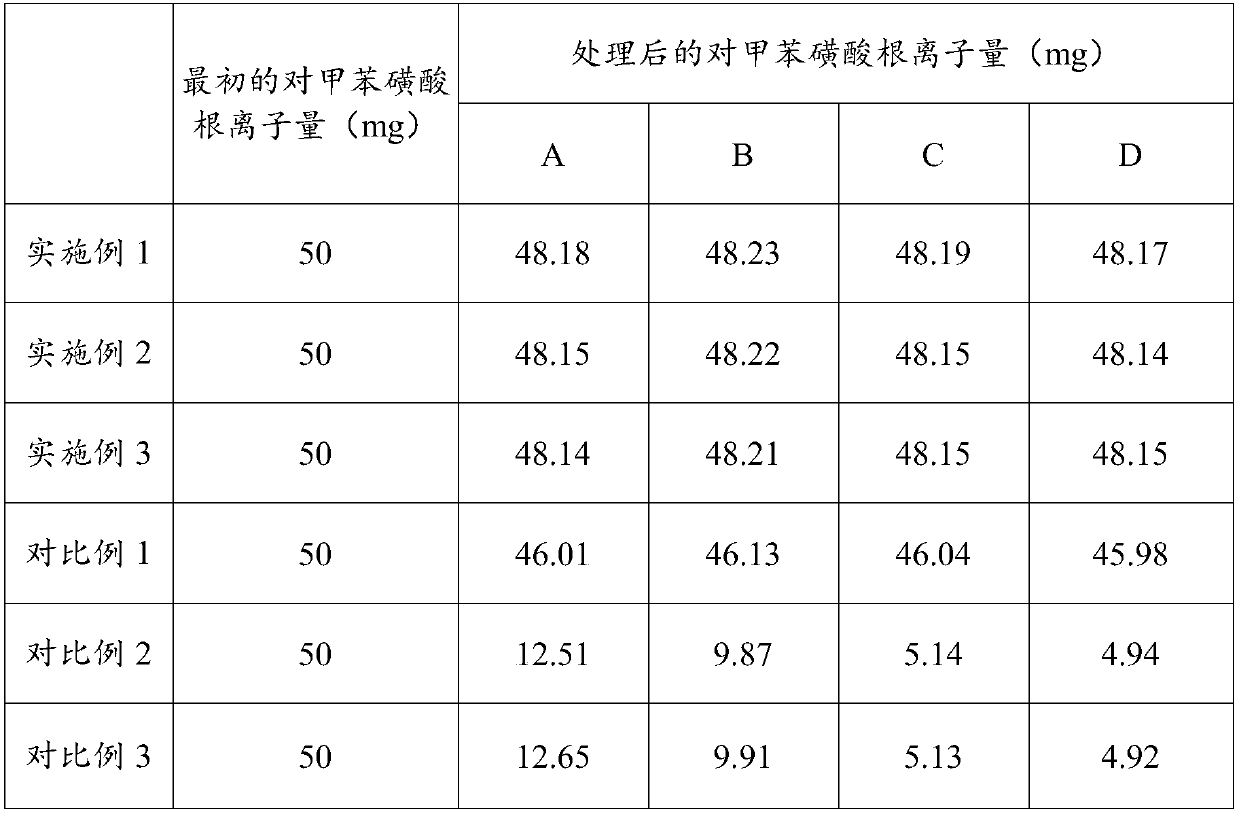

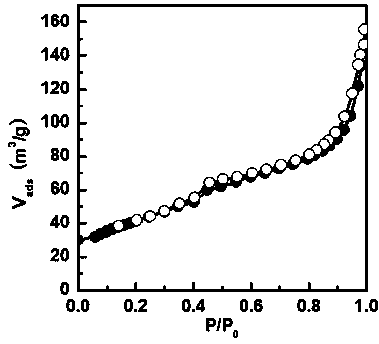

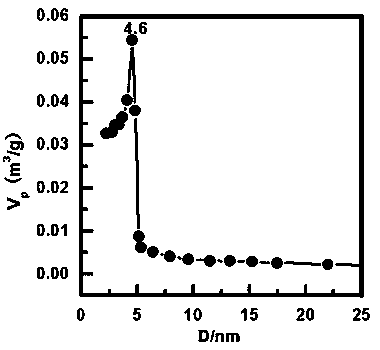

Macroporous weak-base anion-exchange resin and preparation method thereof

InactiveCN109575186AHigh selectivityEfficient removalAnion exchangers2-VinylpyridineBenzoyl peroxide

The invention discloses macroporous weak-base anion-exchange resin and a preparation method thereof. The macroporous weak-base anion-exchange resin comprises the following components: an oil phase anda water phase, wherein the oil phase is 60-80 parts of a 2-vinylpyridine monomer, 25-35 parts of a divinylbenzene cross-linking agent, 100-150% of polyurethane and modified hydroxymethyl cellulose asa mixed pore-foaming agent by monomer weight, and 1.5-3% of benzoyl peroxide and azodiisobutyronitrile as a mixed initiator by monomer weight; and the water phase is 480-600 parts of deionized water,2-3 parts of a hydroxypropyl methyl cellulose dispersing agent, and 38-42 parts of a sodium nitrite salting-out agent. The preparation method thereof comprises the following steps: adding the oil phase to the water phase, stirring, varying a temperature, and performing a curing reaction. The prepared macroporous weak-base anion-exchange resin has higher adsorptive selectivity, larger adsorptioncapacity and good heat resistance, and is capable of efficiently removing harmful or degradation-resistant anions of an arsenate ion, an aromatic sulfonate ion, a fumaric acid radical ion and the like, and prolonging service life thereof.

Owner:ANHUI SANXIN RESIN TECH

Method for preparing arsenic adsorbent and method for treating waste water

InactiveCN102698703BImprove adsorption capacityThe synthesis method is simpleOther chemical processesWater/sewage treatment by sorptionSorbentWastewater

The invention provides a method for preparing an arsenic adsorbent. The arsenic adsorbent has zirconium oxide of nano-pore structure. The material can effectively treat arsenate and arsenite in the waste water, and can be recycled after waste water treatment. Another objective of the invention is to provide a method for treating waste water containing arsenate or arsenite ions by the arsenic adsorbent prepared by the method. The method contains a 'regeneration' step, so that the arsenic adsorbent can be reused cyclically.

Owner:CHONGQING THREE GORGES UNIV

Resourceful treatment method of industrial wastewater containing chlorine and arsenic

InactiveCN111620481ASolve the purification problemFlexible adjustment of process flowWater treatment parameter controlSpecific water treatment objectivesIndustrial waste waterDesorption

The invention discloses a resourceful treatment method of industrial wastewater containing chlorine and arsenic. The method comprises the following steps: adding a preset amount of adsorbing materialinto a wastewater solution, and starting heating operation and stirring operation at the same time; filtering out the adsorption residues in the stirred solution; adding a preset amount of sulfuric acid into the filtered solution, adding a preset amount of the adsorbing material again, and starting heating operation and stirring operation at the same time; filtering out the adsorption residues inthe stirred solution; detecting the concentration of chloride ions and / or arsenate ions in the filtered solution, and judging whether the detection result meets the treatment requirement or not; whenthe detection result meets the treatment requirement, recycling the filtered solution or discharging after reaching the standard; collecting the adsorption residues in the previous step, adding a preset amount of desorption solution, and stirring while adding an alkaline material until the pH value is kept alkaline and does not drop any more; and filtering out the desorbed and regenerated adsorbing material so as to realize the cyclic utilization of the adsorbing material.

Owner:湖南大青生态科技有限公司

Chitosan and chitosan quaternary ammonium salt composite magnetic microspheres and preparation method thereof

ActiveCN104258822BImprove adsorption capacityStrong pH adaptabilityOther chemical processesAnion exchangersPhosphate ionMicrosphere

The invention discloses a chitosan and chitosan quaternary ammonium salt composite magnetic microsphere and a preparation method thereof. The method comprises the steps of preparing a water phase, stirring and dissolving chitosan, chitosan quaternary ammonium salt and a pore-foaming agent PEG or PVP according to a ratio in an acetic acid aqueous solution, and adding magnetic particles for stirring and ultrasonic treatment; preparing an oil phase, and stirring liquid paraffin and Span80 to obtain the oil phase; gradually adding the water phase into the oil phase drop by drop while stirring is carried out to obtain a liquid mixture; adding a sodium polyphosphate aqueous solution into the liquid mixture drop by drop, carrying out stirring, and adding a glutaraldehyde aqueous solution for reaction; carrying out centrifugation and washing to obtain the chitosan and chitosan quaternary ammonium salt composite magnetic microsphere. The composite magnetic microsphere disclosed by the invention is higher in adsorption to electronegative materials such as humic acid, anionic dyes, arsenate ions, phosphate anions and nitrate ions, is higher in pH adaptability, magnetic separation property and regeneration performance, and is high in exchange capacity, high in adsorption speed and easy to separate.

Owner:TIANJIN POLYTECHNIC UNIV

Application of porous cationic polymer in removal of dyes or heavy metals in wastewater

ActiveCN111470576AHigh density of surface active sitesHigh densityOther chemical processesWater contaminantsIndustrial waste waterCongo red

The invention discloses an application of a porous cationic polymer in removal of dyes or heavy metals in wastewater. The concentration range of the heavy metal acid radical ions in the wastewater is0-200mg / L; the concentration of the dye in the wastewater ranges from 0 mg / L to 500 mg / L, the concentration of the porous cationic polymer in the wastewater ranges from 0.5 mg / mL to 1.5 mg / mL, heavy metal acid radical ions in the wastewater are dichromate, permanganate and arsenate, and the dye in the wastewater is methyl orange, methylene blue, rhodamine B, Congo red and chrome black T. The porous cationic polymer disclosed by the invention is high in surface active site density, can be used for rapidly, efficiently and synergistically removing dyes and heavy metal ions in wastewater, and isan efficient and cheap adsorbent for synergistically removing dyes and heavy metals in industrial wastewater.

Owner:EAST CHINA UNIV OF SCI & TECH

Magnesium ion-containing non-aqueous electrolyte and a production process thereof, as well as electrochemical device

ActiveUS8691434B2Effective resourcesEfficient use ofNon-aqueous electrolyte accumulatorsCell electrodesAluminum IonPhosphate ion

Owner:MURATA MFG CO LTD

A compound aminovinyl weakly basic anion exchange resin and a method for recovering rhenium from copper smelting waste acid

The invention relates to a composite vinylamine-series weakly-basic anion exchange resin and a method for recovering rhenium from waste acid produced in copper smelting, belonging to the technical field of recycling of metallic rhenium. The composite vinylamine-series weakly-basic anion exchange resin is prepared by swelling chloromethylated polystyrene microspheres in an organic solvent for 4 to 10 h; then slowly adding a mixture of dicyclohexylamine, pyridine and N-methylcyclohexylamine and carrying out a reaction at room temperature for 1 to 6 h; then carrying out heating to 40 to 90 DEG C and continuing the reaction for 6 to 18 h; and then carrying out vacuum pumping filtration. The composite vinylamine-series weakly-basic anion exchange resin provided by the invention has good adsorptive selectivity on low-concentration rhenium (2 to 10 mg / L) under the conditions of high acidity and existence of high-concentration impurity ions, and almost does not adsorb impurity ions, especially toxic arsenate ions; waste acid directly enters an arsenate after filtering; so process flow is simplified and the recovery rate of rhenium is increased.

Owner:ZHENGZHOU MINERALS COMPOSITIVE UTILIZATION RES INST CHINESE GEOLOGICAL ACAD +1

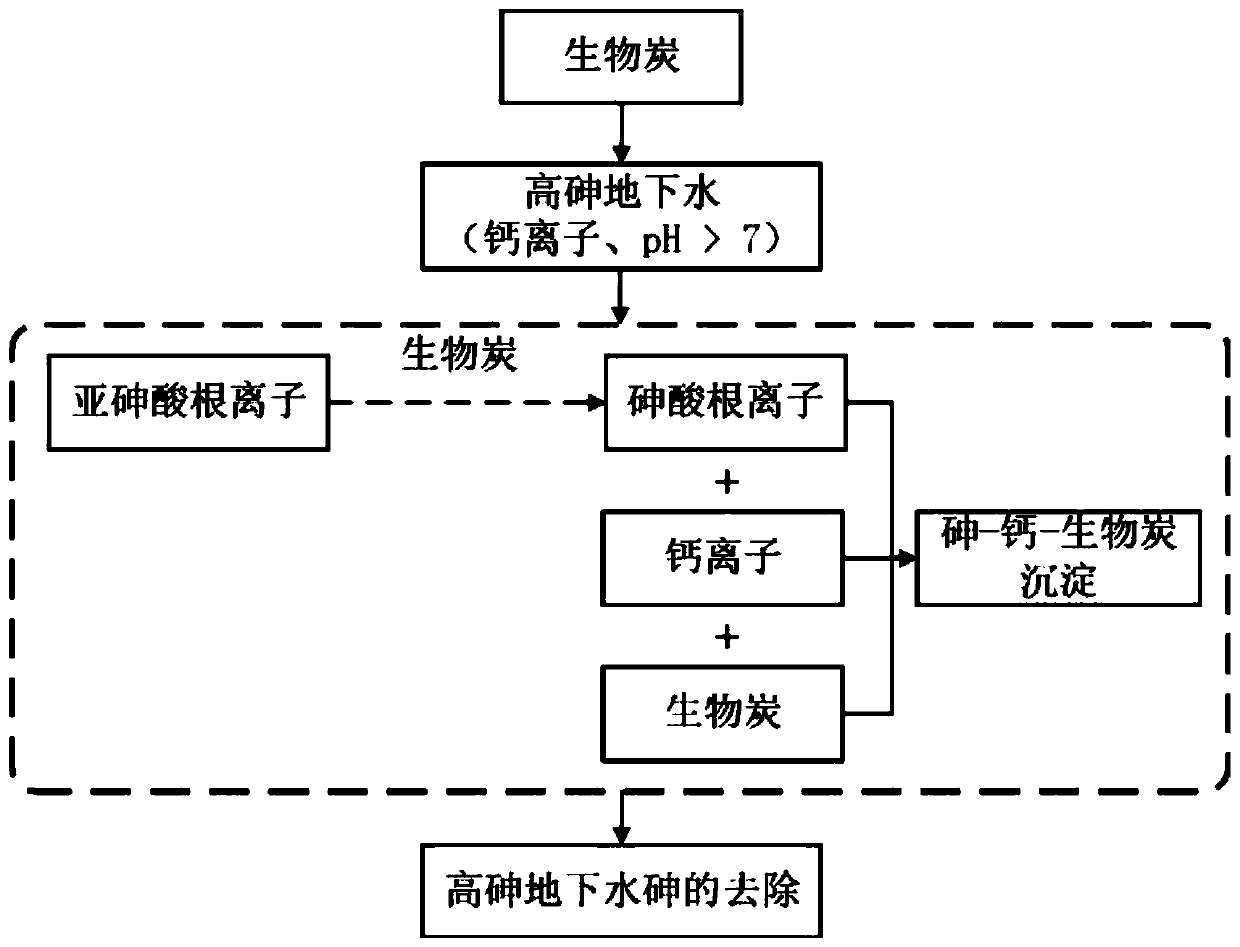

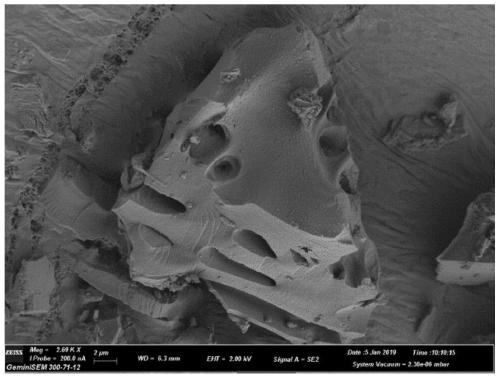

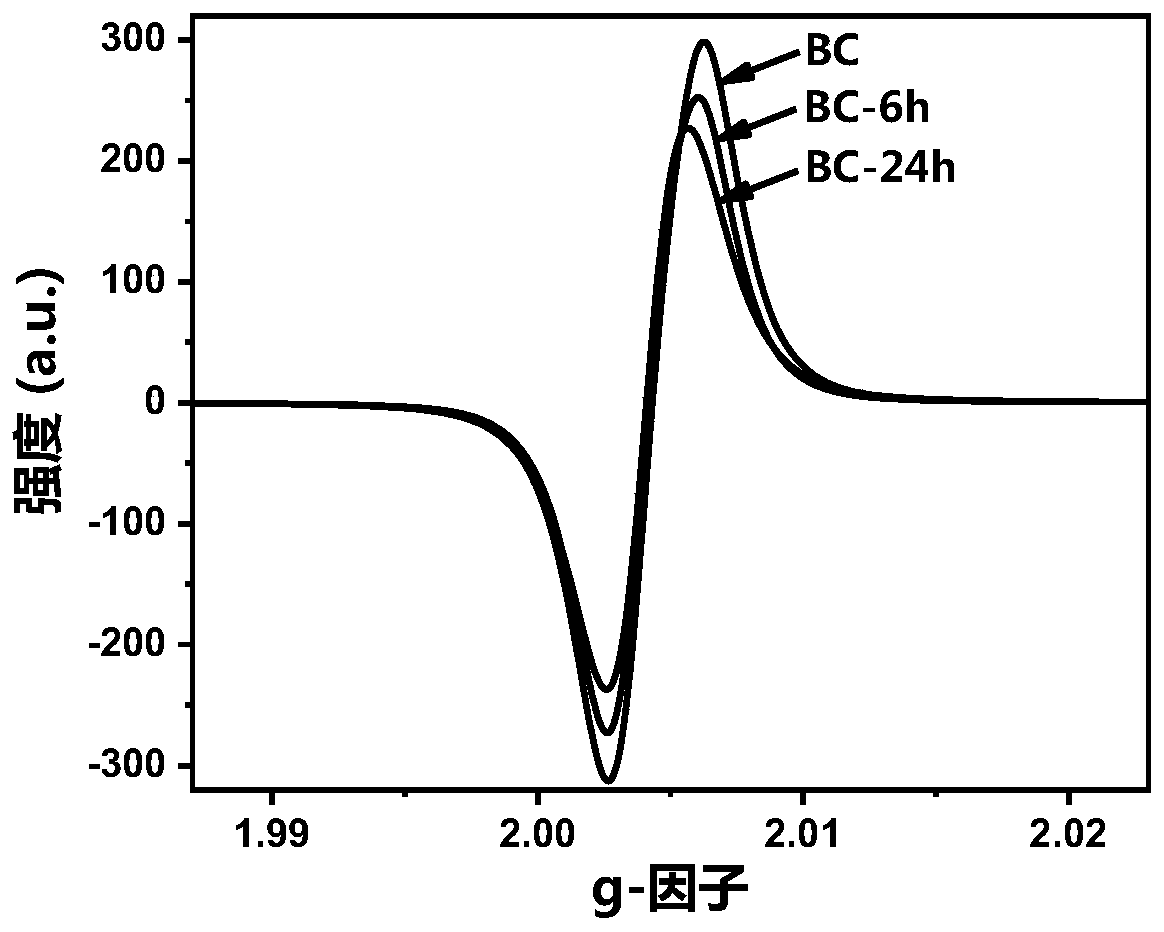

A method for removing arsenic from calcium-rich and high-arsenic groundwater by using biochar

ActiveCN110143661BImprove adsorption capacityReduce secondary pollutionWater contaminantsContaminated soil reclamationSoil scienceArsenic pollution

The invention discloses a method for removing arsenic in calcium-rich high-arsenic groundwater by using biochar, belonging to the field of arsenic pollution treatment for groundwater. The method comprises the following steps: adding biochar into alkaline calcium-rich high-arsenic groundwater, and carrying out a stirring reaction for at least 4 hours to remove arsenic dissolved in the groundwater,wherein the concentration of arsenic contained in the groundwater is 0.1-10 mg / L, and the concentration of calcium ions is 20-2000 mg / L. According to the invention, the specific calcium-rich high-arsenic groundwater is used as the object in which arsenic is to be removed; oxidizing active groups on the surface of the biochar are employed to oxidize low-valent arsenite in the groundwater into high-valent arsenate, and the generated arsenate reacts with the calcium ions and biochar to formation an arsenic-calcium-biochar precipitate; so the characteristic that the groundwater is rich in calciumand is alkaline is fully utilized, oxidation and adsorption means are organically combined to achieve the purpose of integrated removal of arsenic from the groundwater, and the method can effectivelysolve the common problems of low efficiency, high operating cost, complicated operation and the like in conventional methods for removing arsenic in groundwater.

Owner:HUAZHONG UNIV OF SCI & TECH

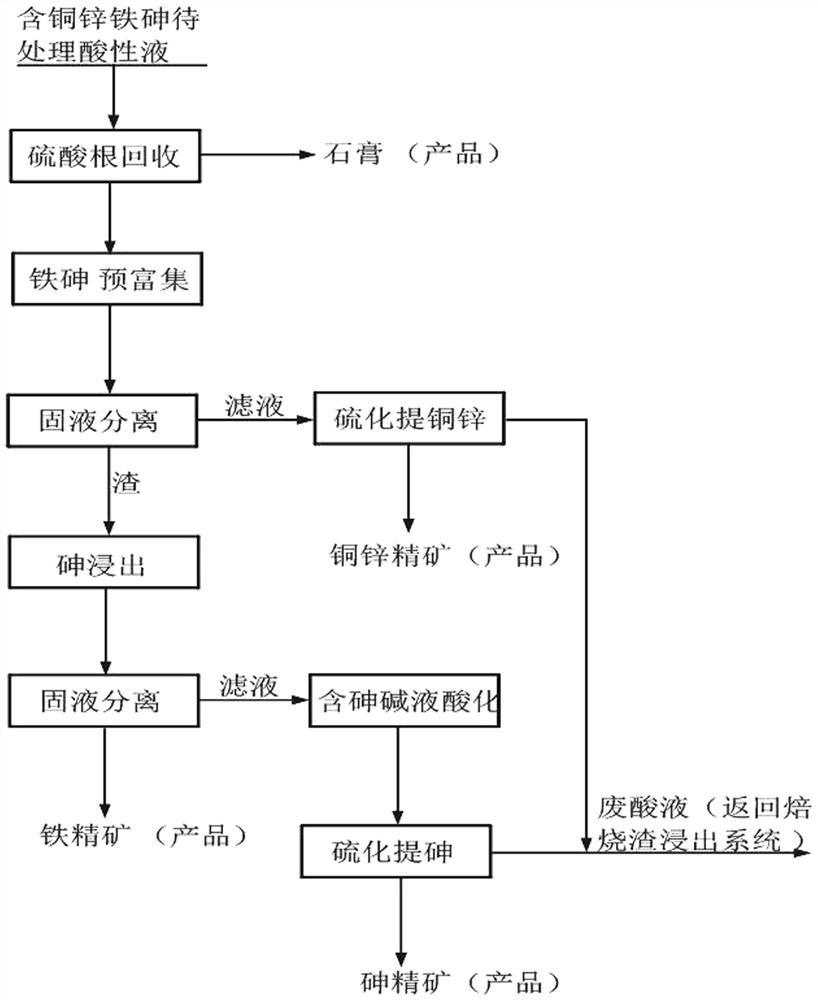

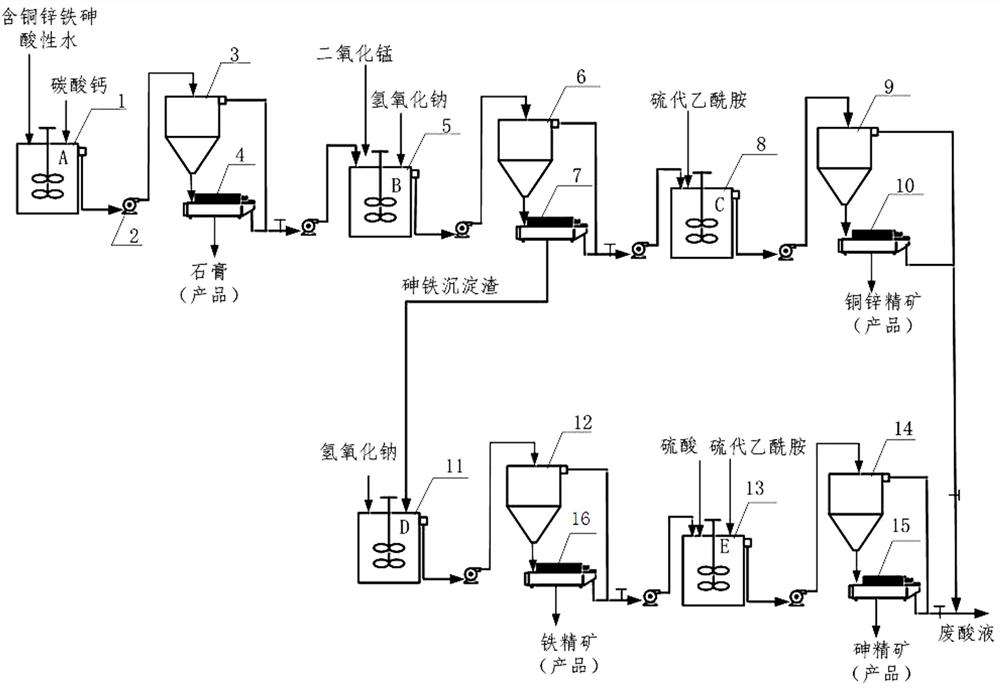

Method for recovering valuable elements from gold-containing sulfur concentrate roasting slag pickle liquor

ActiveCN113088702AEfficient separation and extractionReduce typesIron oxides/hydroxidesCalcium/strontium/barium sulfatesSulfate radicalsSlag

The invention relates to a method for recovering valuable elements from gold-containing sulfur concentrate roasting slag pickle liquor, and belongs to the field of chemical beneficiation. The method comprises the following steps that (1) the contents and acidity of copper, zinc, iron, arsenic and sulfate radicals in acidic waste liquor are measured; (2) calcium carbonate or lime is added, concentrating and filtering are carried out to obtain a gypsum product and an acidic solution; (3) an oxidizing agent is added, then a sodium hydroxide solution is added, the pH value is 2.7-3.7 after the slurry reaction is finished, and arsenic-containing iron ore concentrate and copper-zinc-containing filtrate are obtained through concentration and filtration; (4) an arsenic precipitator is added, reacting is carried out for 30 minutes, concentrating, and filtering are carried out to obtain copper-zinc concentrate and acid-containing waste liquid; (5) the concentration of ore pulp is adjusted to be 50%, a sodium hydroxide solution is added, and then filtering and washing are carried out to obtain iron ore concentrate and arsenate-containing alkali liquor; and (6) sulfuric acid is added, the pH value of the solution is adjusted to 1, then the arsenic precipitator is slowly added, and then concentrating and filtering are carried out to obtain arsenic concentrate and acid-containing waste liquid. The arsenic-containing wastewater can be treated, and valuable elements in the arsenic-containing wastewater can be recycled.

Owner:YUNNAN GOLD MINING GRP

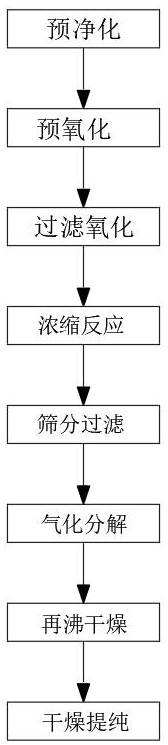

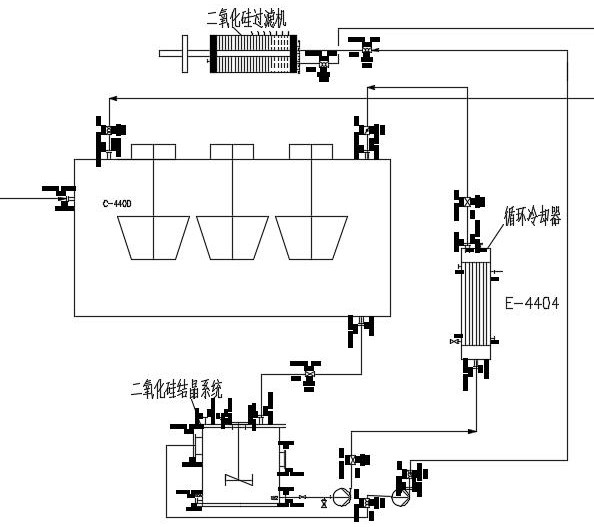

Process for removing arsenic in process of preparing anhydrous hydrogen fluoride by fluosilicic acid method

The invention relates to the technical field of arsenic removal of anhydrous hydrogen fluoride, in particular to a process for removing arsenic in the process of preparing anhydrous hydrogen fluorideby a fluosilicic acid method, which comprises the following steps of: 1, pre-purifying fluosilicic acid; 2, pre-oxidizing trivalent arsenic in fluosilicic acid; 3, carrying out further catalytic oxidation on trivalent arsenic by using microporous filtration II hydrogen peroxide; 4, treating the materials with a concentration and reaction system; 5, screening silicon dioxide; 6, gasifying and decomposing the material; 7, treating the material through a hydrogen fluoride reboiling system and a drying separation system. The method has the beneficial effects that hydrogen peroxide and manganese dioxide can be added as catalysts under the conditions of normal temperature and acidity to oxidize arsenic in fluosilicic acid into pentavalent arsenic; since a small amount of trivalent arsenic cannotreact with hydrogen fluoride to generate arsenic trifluoride difficult to separate under the condition that the boiling point of arsenate is 160 DEG C, the oxidation operation and cost are low, large-batch production is facilitated, and the obtained anhydrous hydrogen fluoride is high in purity and small in harm.

Owner:福建瓮福蓝天氟化工有限公司

Arsenic contaminated soil remediation method

InactiveCN109304355AEasy to prepareThe preparation method is feasibleContaminated soil reclamationCrusherHydrogen iodide

The invention discloses an arsenic contaminated soil remediation method. The method comprises steps as follows: firstly, soil of arsenic contaminated land parcel is digged out and treated by a crusher, and soil particles with size being 2-5 mm are obtained; a sodium citrate solution is prepared, the prepared sodium citrate solution is added to the soil particles in a ratio being 1L / kg, mixing andstirring are performed for 30 min, and a soil and solution mixture is obtained; a hydrogen iodide solution is added to the soil and solution mixture and stirred sufficiently, arsenate ions in the soilor arsenic acid and iodide ions react under the acidic condition to generate iodine and arsenious acid or arsenite; the obtained soil is filtered, fed into a vacuum heat treatment device, heated to 460 DEG C or higher and subjected to heat insulation for 30 min, arsenious acid or arsenite in the soil are converted into arsenious oxide, elementary iodine and arsenious oxide in the soil are volatilized from the soil and separated from the soil, then the soil is cooled to the room temperature, and remediated clean soil is obtained. The method has the advantages of being simple, feasible and goodin remediation effect, and arsenic can be removed from the soil.

Owner:CHANGSHA HUIJU ENVIRONMENTAL TECH CO LTD

A resourceful treatment method and device for arsenic sulfide waste residue

ActiveCN104438287BEffluent water quality is stable and up to standardAvoid secondary hazardous wasteSolid waste disposalThio-Reverse osmosis

Owner:BEIJING CYCLE COLUMBUS ENVIRONMENTAL SCI & TECH

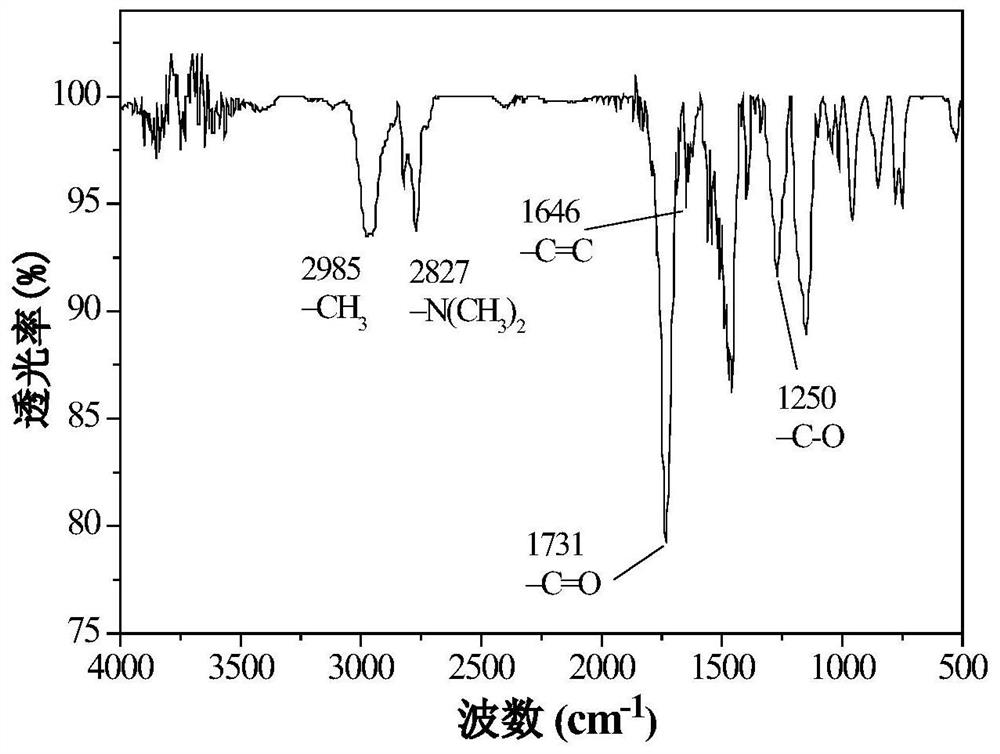

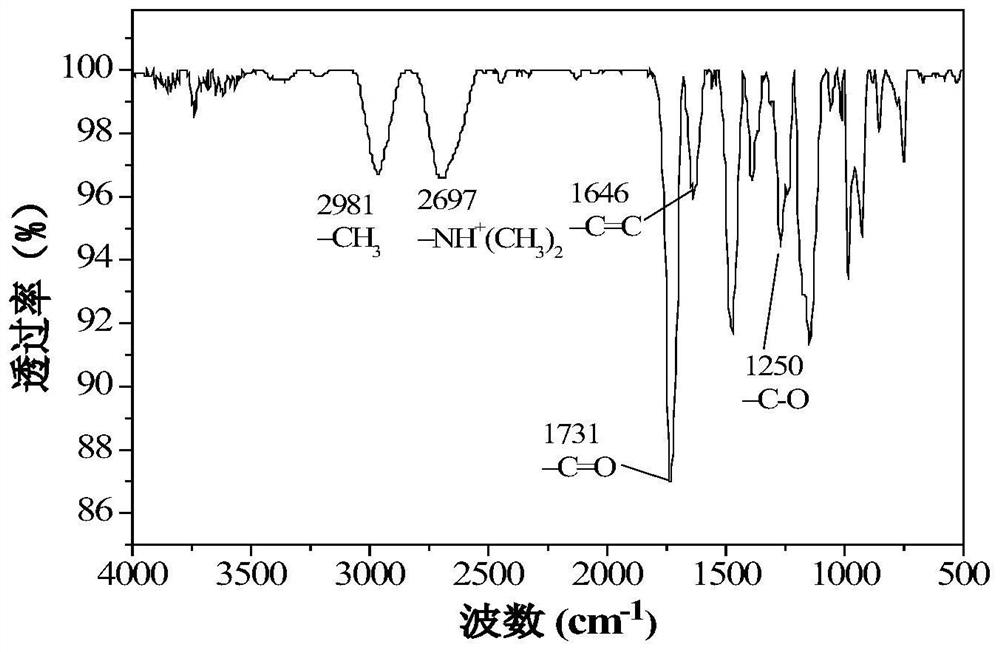

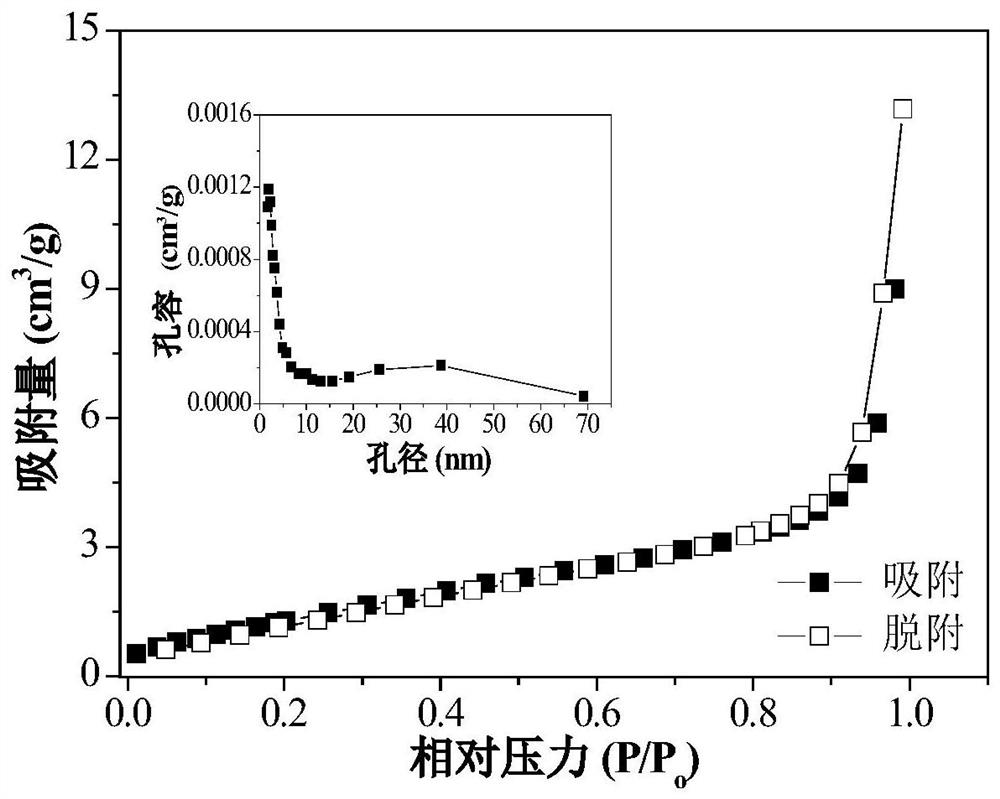

A kind of macroporous cross-linked adsorption resin containing tertiary amine hydrochloride functional group and preparation method thereof

ActiveCN112898481BRaw materials are easy to getAdsorption safetyOther chemical processesMethacrylatePolymer science

The invention discloses a macroporous cross-linked adsorption resin containing tertiary amine hydrochloride functional groups and a preparation method thereof. The present invention uses a trifunctional group crosslinking agent (trimethylolpropane trimethacrylate) and a functional monomer (dimethylaminoethyl methacrylate) as raw materials to prepare trimethylolpropane trimethacrylate through free radical suspension polymerization. Methacrylate tertiary amine resin, after soaking and modifying its tertiary amine group ‑N(CH3)2 with hydrochloric acid, a macroporous cross-linked resin containing tertiary amine hydrochloride functional groups can be obtained, which can be used for toxic and Adsorption removal of oxoacid anions (perchlorate, bromate, arsenite and arsenate). The novel adsorption resin developed by the present invention has the characteristics of environmental protection, high efficiency and wide adaptability, etc., and is used to solve the safety problem of drinking water, so as to realize the production of safe, environment-friendly and clean drinking water.

Owner:GUANGXI UNIV FOR NATITIES

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com