Material for purication anion polluted water

A purification material and anion technology, applied in the direction of ion exchange water/sewage treatment, water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of high price, limited application, difficult fluoride ion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) 246g (1.6mol) of Mg(NO 3 ) 2 and 85g (0.4mol) of Al(NO 3 ) 3 Disperse in 0.36L (20mol) of water.

[0024] (2) 128g (3.2mol) of NaOH and 35g (0.4mol) of NaNO 3 Evenly dispersed in 0.36L (20mol) of water. The solution obtained in (2) was quickly added into the solution of (1), and the stirring was continued for 120 hours. The obtained solution was suction-filtered at normal temperature to obtain a white powder, which was washed with water and dried at 50°C to obtain a white composite material.

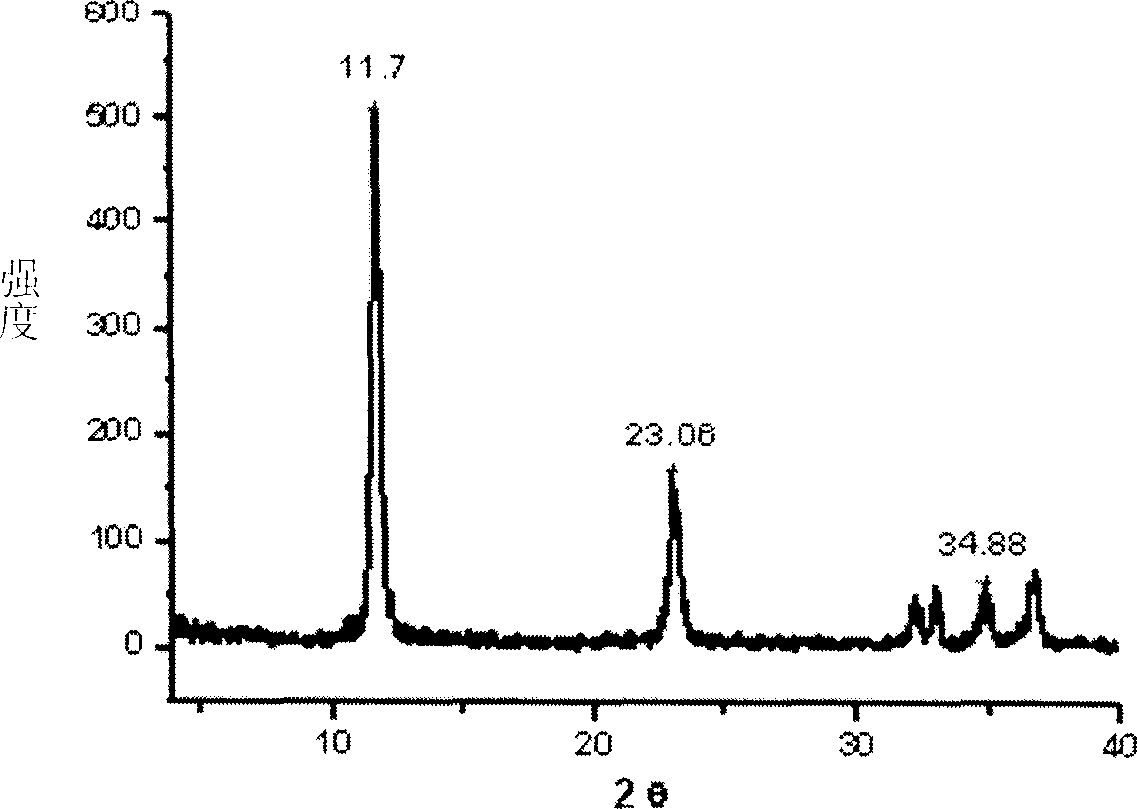

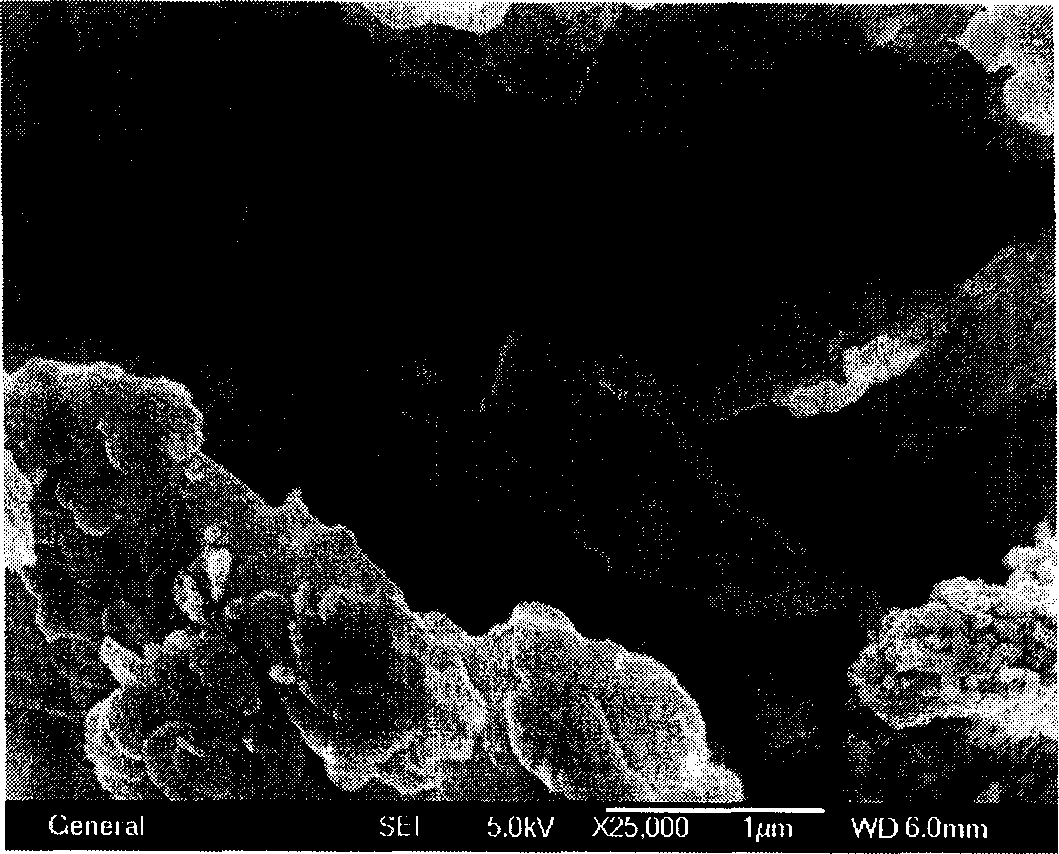

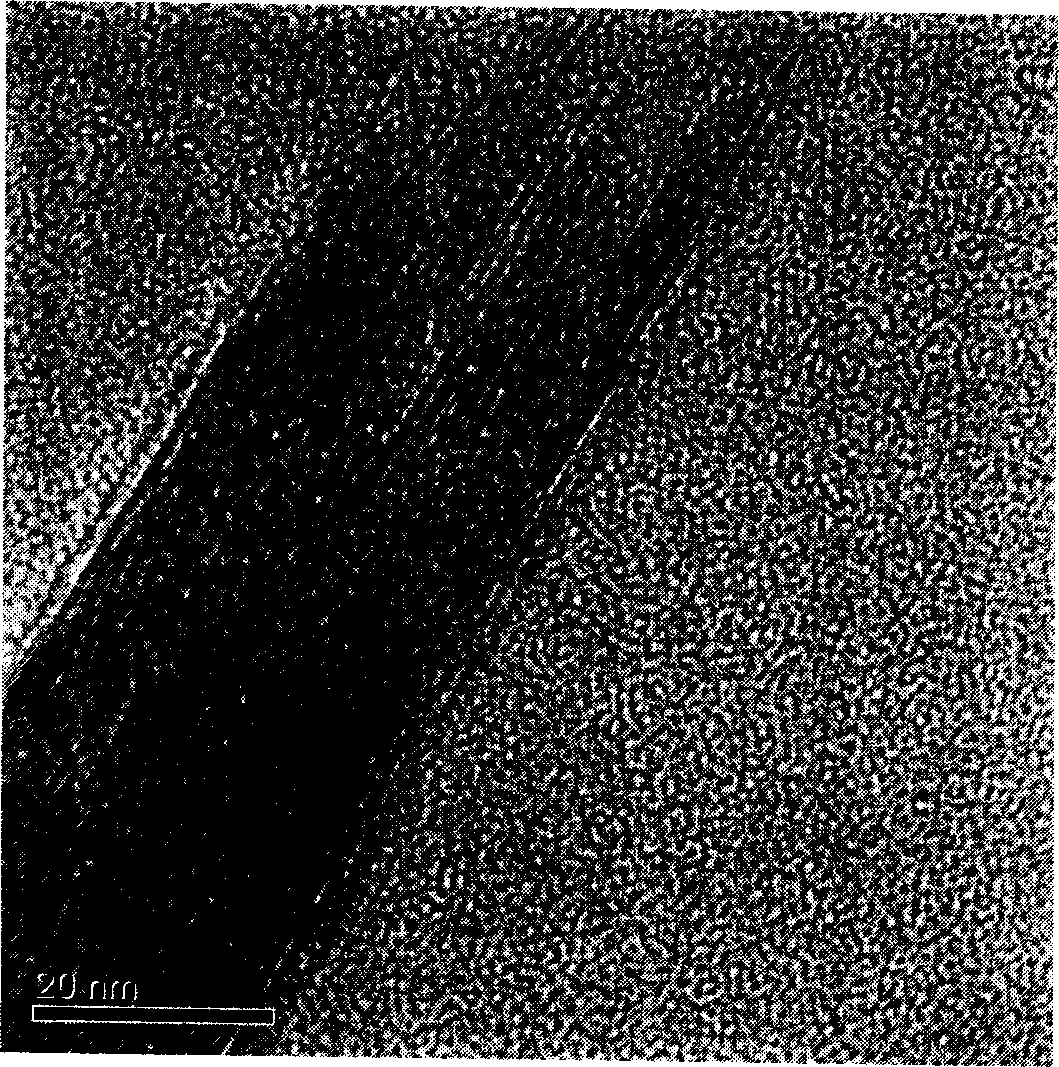

[0025] like figure 1 As shown, it can be seen from the X-ray diffraction spectrum that the characteristic diffraction peak of the composite material is 2θ=11.7°, and three characteristic diffraction peaks with relatively high diffraction intensity appear, corresponding to the interlayer spacing d003 and two advanced reflections d006 , d009, the composite material presents an obvious layered structure. For the interlayer distance d003 of 0.756nm, the thickness of the la...

Embodiment 2

[0029] (1) 246g (1.6mol) of Mg(NO 3 ) 2 and 113.5g (0.533mol) of Al(NO 3 ) 3 Disperse in 0.36L (20mol) of water.

[0030] (2) 128g (3.2mol) of NaOH and 48g (0.533mol) of NaNO 3Evenly dispersed in 0.36L (20mol) of water. The solution obtained in (2) was quickly added to the solution of (1), and the stirring was continued for 120d. The obtained solution was suction-filtered at normal temperature to obtain a white powder, which was washed with water and dried at 50° C. to obtain a white composite material.

[0031] X-ray diffraction, SEM and TEM analysis are consistent with the results in Example 1. ICP elemental analysis shows that the compound contains 26.7% of magnesium, 10% of aluminum, 53.3% of oxygen, 2.2% of hydrogen and 5.2% of nitrogen in the substance content of the compound. It is basically consistent with the theoretical calculation, and also contains a very small amount of water and trace impurities.

Embodiment 3

[0033] (1) 246g (1.6mol) of Mg(NO 3 ) 2 and 170g (0.80mol) of Al(NO 3 ) 3 Disperse in 0.36L (20mol) of water.

[0034] (2) 128g (3.2mol) of NaOH and 70g (0.80mol) of NaNO 3 Evenly dispersed in 0.36L (20mol) of water. The solution obtained in (2) was quickly added to the solution of (1), and the stirring was continued for 144 hours. The obtained solution was suction-filtered at normal temperature to obtain a white powder, which was washed with water and dried at 50° C. to obtain a white composite material.

[0035] X-ray diffraction, SEM and TEM analysis are consistent with the results in Example 1. ICP elemental analysis shows that the compound contains 26.6% of magnesium, 15% of aluminum, 44.4% of oxygen, 1.1% of hydrogen and 7.8% of nitrogen in the substance content of the compound. It is basically consistent with the theoretical calculation.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com