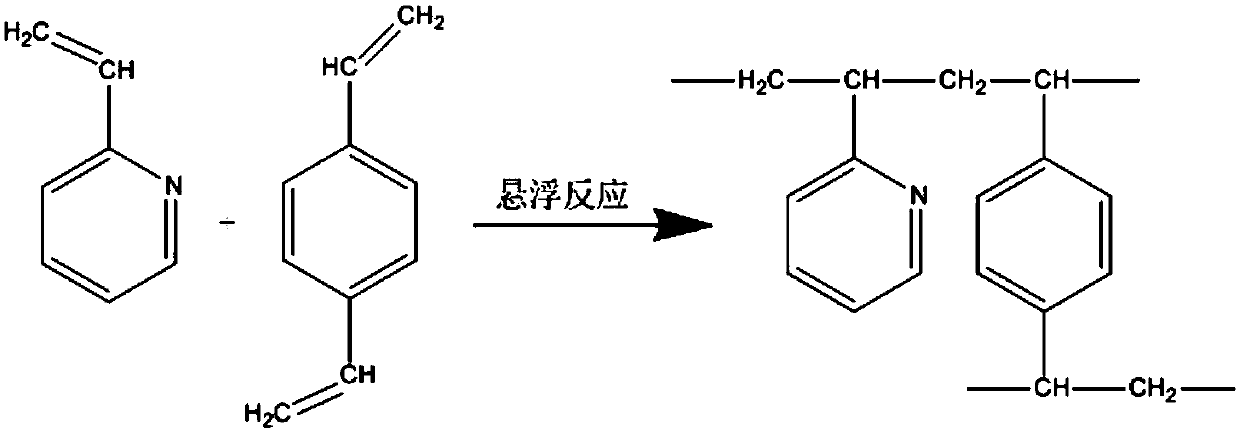

Macroporous weak-base anion-exchange resin and preparation method thereof

A weakly basic anion and exchange resin technology, applied in the chemical industry, can solve the problems of reducing the exchange capacity and adsorption selectivity of the ion exchange resin, poor heat resistance of the resin, and short service life, so as to improve the agglomeration phenomenon and prolong the service life , the effect of high adsorption selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

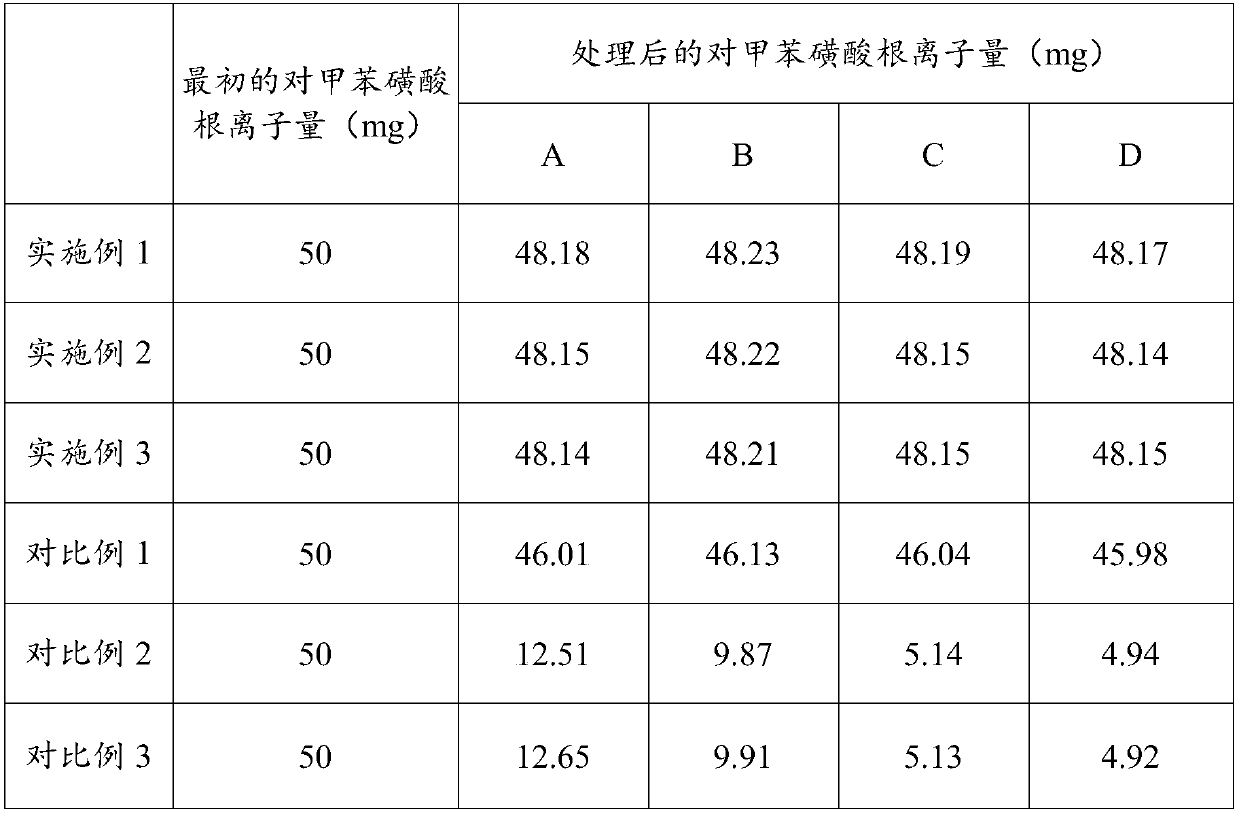

Examples

Embodiment 1

[0031] In the present embodiment, a kind of preparation method of macroporous weakly basic anion exchange resin is provided, it comprises the following steps:

[0032] Step 1: Remove the polymerization inhibitor in 2-vinylpyridine: Add 2-vinylpyridine to anhydrous calcium carbide powder, place it for 24 hours, and distill under reduced pressure at a temperature of 60-70°C and a pressure of 3.8-4KPa to obtain 2-vinylpyridine containing a polymerization inhibitor;

[0033] Step 2: remove the polymerization inhibitor in 2-vinylpyridine: wash divinylbenzene with 8% sodium hydroxide solution and dry under anhydrous calcium chloride desiccant to obtain divinylbenzene without polymerization inhibitor ;

[0034] Step 3: Weigh 60g 2-vinylpyridine monomer, 25g divinylbenzene crosslinking agent, 20g polyurethane and 40g modified hydroxymethyl cellulose as mixed porogen, 0.225g benzoyl peroxide and 0.675g of azobisisobutyronitrile is a mixed initiator, mixed to obtain an oil phase;

[...

Embodiment 2

[0039] In the present embodiment, a kind of preparation method of macroporous weakly basic anion exchange resin is provided, it comprises the following steps:

[0040] Step 1: Remove the polymerization inhibitor in 2-vinylpyridine: Add 2-vinylpyridine to anhydrous calcium carbide powder, place it for 24 hours, and distill under reduced pressure at a temperature of 60-70°C and a pressure of 3.8-4KPa to obtain 2-vinylpyridine containing a polymerization inhibitor;

[0041] Step 2: remove the polymerization inhibitor in 2-vinylpyridine: wash divinylbenzene with 8% sodium hydroxide solution and dry under anhydrous calcium chloride desiccant to obtain divinylbenzene without polymerization inhibitor ;

[0042] Step 3: Weigh 70g of 2-vinylpyridine monomer, 30g of divinylbenzene crosslinking agent, 43.75g of polyurethane and 43.75g of modified hydroxymethyl cellulose as the mixed porogen, 0.7g of benzyl peroxide Acyl and 0.7g azobisisobutyronitrile are mixed initiators, mixed to obt...

Embodiment 3

[0047] In the present embodiment, a kind of preparation method of macroporous weakly basic anion exchange resin is provided, it comprises the following steps:

[0048] Step 1: Remove the polymerization inhibitor in 2-vinylpyridine: Add 2-vinylpyridine to anhydrous calcium carbide powder, place it for 24 hours, and distill under reduced pressure at a temperature of 60-70°C and a pressure of 3.8-4KPa to obtain 2-vinylpyridine containing a polymerization inhibitor;

[0049]Step 2: remove the polymerization inhibitor in 2-vinylpyridine: wash divinylbenzene with 8% sodium hydroxide solution and dry under anhydrous calcium chloride desiccant to obtain divinylbenzene without polymerization inhibitor ;

[0050] Step 3: Weigh 80g 2-vinylpyridine monomer, 35g divinylbenzene crosslinking agent, 40g polyurethane and 80g modified hydroxymethyl cellulose as mixed porogen, 1.8g benzoyl peroxide and 0.6g of azobisisobutyronitrile is a mixed initiator, mixed to obtain an oil phase;

[0051]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com