Resourceful treatment method of industrial wastewater containing chlorine and arsenic

A technology for industrial wastewater and treatment methods, applied in water/sewage treatment, water treatment parameter control, chemical instruments and methods, etc., can solve the problems of not considering recycling and high consumption of precipitants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

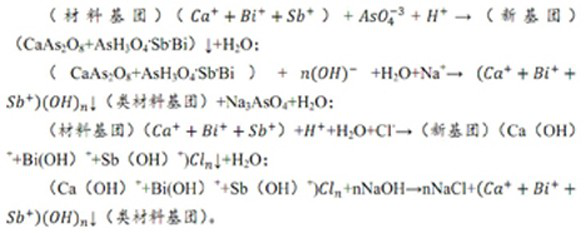

[0065] The invention provides a preparation method of an active calcium bismuth antimony-based combined group inorganic adsorption material.

[0066] In one embodiment of the present invention, the preparation method of the active calcium bismuth antimony-based combination group inorganic adsorption material comprises the following steps:

[0067] S1, calcium oxide, bismuth oxide and antimony oxide; mixed according to the ratio of 1:1:8~1:3:20 to form a solid mixture; wherein, the calcium oxide can be CaO or Ca(OH ) 2 ; The bismuth oxide can be Bi 2 o 3 or Bi 2 o 4 ; The antimony oxide can be Sb 2 o 5 , Sb 2 o 3 or Sb 2 o 4 .

[0068] S2, mixing the solid mixture with clear water according to a solid-to-liquid ratio of 1:2 and adding to the agitator;

[0069] S3, at a temperature of 25° C. to 55° C., start the agitator to stir for 2 to 3 hours; and, during stirring, add dilute sulfuric acid with a concentration of 1% to 5% every 20 to 30 minutes to to the role of ...

Embodiment 1

[0076] S10, take 1L of chlorine-containing wastewater discharged from the iron and steel plant, detect that the chloride ion contains 25g / l of chlorine, and the pH is 6; take 100g of the adsorbent material prepared according to the aforementioned method, and add it to the chlorine-containing wastewater;

[0077] Heating and stirring the wastewater solution at the same time, the stirring time is 1.5 hours, the stirring speed is 300 rpm; the heating temperature is 40°C;

[0078] S20, filtering out the adsorption residue in the stirred solution;

[0079] S30, adding a preset amount of sulfuric acid into the filtered solution, adding a preset amount of the adsorption material again, and simultaneously starting a heating operation and a stirring operation;

[0080] S40, filtering out the adsorption residue in the stirred solution;

[0081] S50, detecting the concentration of chloride ions in the filtered solution, and judging whether the detection result meets the processing requi...

Embodiment 2

[0095] S10, take 1 liter of arsenic-containing wastewater discharged from a gold smelting company, and detect that the concentration of arsenic acid ions in it is 20.3 g / l, and the pH is 1;

[0096] Take 25 g of the adsorbent material that was analyzed and regenerated in the first step, add 35 g of the adsorbent material prepared according to the above preparation method, and add it to the arsenic-containing wastewater;

[0097] While heating the solution to 55°C, stir for about 100 minutes at a speed of 400 rpm;

[0098] S20, filtering out the adsorption residue in the stirred solution;

[0099] S30, adding a preset amount of sulfuric acid into the filtered solution, adding a preset amount of the adsorption material again, and simultaneously starting a heating operation and a stirring operation;

[0100] S40, filtering out the adsorption residue in the stirred solution;

[0101] S50, detecting the concentration of arsenate ions in the filtered solution, and judging whether ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com