Arsenic removing water purification treatment method

A treatment method and arsenic water purification technology, which are applied in the fields of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

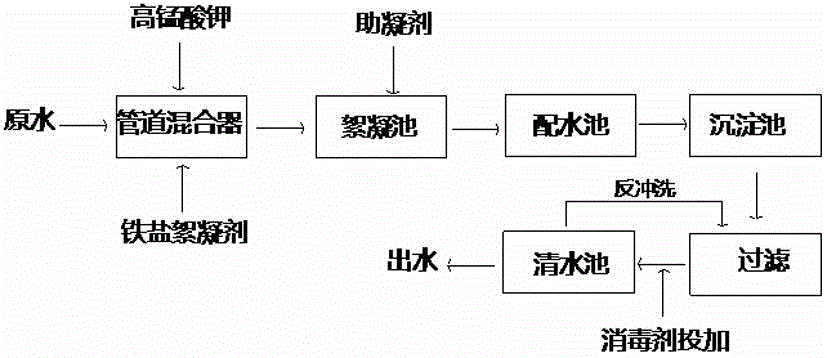

[0033] Such as figure 1 Shown, a kind of arsenic removal water purification treatment method comprises steps:

[0034] 1) Put the raw water to be treated into the raw water pipeline, and add potassium permanganate into the pipeline mixer installed on the raw water pipeline according to the trivalent arsenic content, and mix evenly;

[0035] 2) Add polymeric ferric sulfate flocculant to the pipeline mixer and mix evenly; among them, the dosage of polymeric ferric sulfate flocculant is 10 mg / L;

[0036] 3) After mixing, transport it to the flocculation tank for full reaction to form alum flowers; add polyacrylamide coagulant aid to the flocculation tank, as the reaction progresses, the alum flowers become larger and larger, after 40 minutes of flocculation reaction, Large alum flowers are formed in the flocculation tank; among them, the dosage of coagulant aid is 1.5 mg / L;

[0037] 4) Step 3) After fully reacting, the water and alum flowers in the flocculation tank are evenly ...

Embodiment 2

[0043] Such as figure 1 Shown, a kind of arsenic removal water purification treatment method comprises steps:

[0044] 1) Put the raw water to be treated into the raw water pipeline, and add potassium permanganate into the pipeline mixer installed on the raw water pipeline according to the trivalent arsenic content, and mix evenly;

[0045] 2) Add polymeric ferric sulfate flocculant to the pipeline mixer and mix evenly; among them, the dosage of polymeric ferric sulfate flocculant is 12 mg / L;

[0046] 3) After mixing, transport it to the flocculation tank for full reaction to form alum flowers; add polyacrylamide coagulant aid to the flocculation tank, as the reaction progresses, the alum flowers become larger and larger, after 40 minutes of flocculation reaction, Large alum flowers are formed in the flocculation tank; among them, the dosage of coagulant aid is 2 mg / L;

[0047] 4) Step 3) After fully reacting, the water and alum flowers in the flocculation tank are evenly di...

Embodiment 3

[0053] Such as figure 1 Shown, a kind of arsenic removal water purification treatment method comprises steps:

[0054] 1) Put the raw water to be treated into the raw water pipeline, and add potassium permanganate into the pipeline mixer installed on the raw water pipeline according to the trivalent arsenic content, and mix evenly;

[0055] 2) Add polymeric ferric sulfate flocculant to the pipeline mixer and mix evenly; among them, the dosage of polymeric ferric sulfate flocculant is 8 mg / L;

[0056] 3) After mixing, it is transported to the flocculation tank for full reaction to form alum flowers; adding polyacrylamide coagulant aid to the flocculation tank, as the reaction progresses, the alum flowers become larger and larger. After 35 minutes of flocculation reaction, Large alum flowers are formed in the flocculation tank; among them, the dosage of coagulant aid is 1.0 mg / L;

[0057] 4) Step 3) After fully reacting, the water and alum flowers in the flocculation tank are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com