Chitosan and chitosan quaternary ammonium salt composite magnetic microspheres and preparation method thereof

A chitosan quaternary ammonium salt, composite magnetic technology, applied in chemical instruments and methods, alkali metal compounds, alkali metal oxides/hydroxides, etc., can solve the problems of low degree of protonation and easy solubility in water, etc. , to achieve the effect of large ion exchange capacity, easy separation and high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

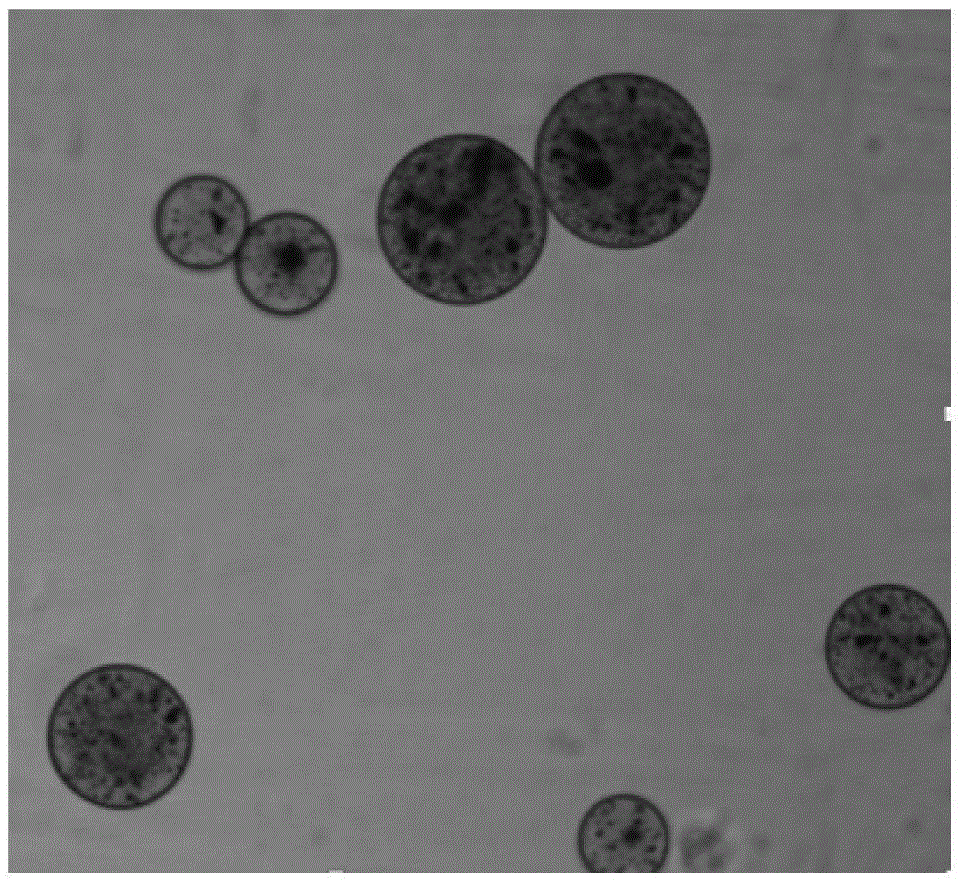

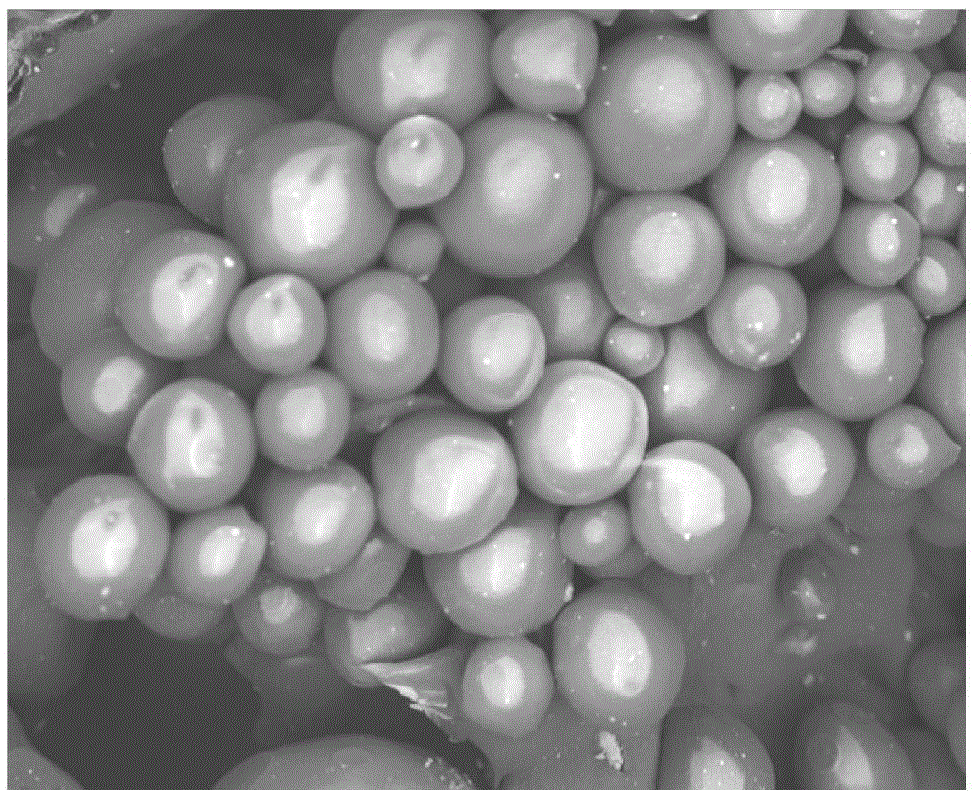

[0035] A preparation method of chitosan and chitosan quaternary ammonium salt composite magnetic microspheres, comprising the steps of:

[0036] (1) prepare water phase, claim 0.6g chitosan, 1.8g chitosan quaternary ammonium salt, 0.4g porogen PEG600, stirring and dissolving in 40mL volume concentration is in the acetic acid aqueous solution of 2%, add 0.6g particle diameter 0.01~1μm Fe 3 o 4 Magnetic particles, stir and add ultrasound (40kHz, 300W) for 20min to obtain the water phase; the molecular weight of chitosan is 2.0×10 4 -2.0×10 5 , the degree of deacetylation is 80.0%-85.0%; the molecular weight of chitosan quaternary ammonium salt is 1.0×10 5 -3.0×10 5 , the degree of substitution is 95%;

[0037] (2) To prepare the oil phase, take 100mL of liquid paraffin and 1mL of Span80, stir at 40°C at a speed of 200rpm for 40min to obtain the oil phase;

[0038] (3) Add the water phase to the oil phase dropwise under stirring, and stir for 60 min at 360 rpm to obtain a l...

Embodiment 2

[0042] A preparation method of chitosan and chitosan quaternary ammonium salt composite magnetic microspheres, comprising the steps of:

[0043] (1) Prepare the water phase, claim 1.2g chitosan, 1.2g chitosan quaternary ammonium salt, 0.4g PEG2000, stir and dissolve in 40mL volume concentration of 2% acetic acid aqueous solution, add 0.6g particle diameter is 0.1~10μm γ-Fe 2 o 3 Magnetic particles, stir and add ultrasound (40kHz, 300W) for 20min to obtain the water phase; the molecular weight of chitosan is 2.0×10 5 -3.0×10 5 , the degree of deacetylation is 85.0%-95.0%; the molecular weight of chitosan quaternary ammonium salt is 3.0×10 5 -5.0×10 5 , the degree of substitution is 103%;

[0044](2) To prepare the oil phase, take 200 mL of n-hexane and 4 mL of Span80, and stir at 40° C. at a speed of 200 rpm for 40 min to obtain the oil phase;

[0045] (3) Add the water phase to the oil phase dropwise under stirring, and stir for 60 min at 360 rpm to obtain a liquid mixtu...

Embodiment 3

[0049] A preparation method of chitosan and chitosan quaternary ammonium salt composite magnetic microspheres, comprising the steps of:

[0050] (1) Prepare the water phase, claim 1.8g chitosan, 0.6g chitosan quaternary ammonium salt, 0.6g PEG4000, stir and dissolve in 40mL volume concentration of 2% acetic acid aqueous solution, add 0.6g particle diameter of 1-10 μm Stainless steel powder magnetic particles, stirring and ultrasonic (40kHz, 300W) for 10min to obtain the water phase; the molecular weight of chitosan is 2.0×10 4 -2.0×10 5 , the degree of deacetylation is 80.0%-85.0%; the molecular weight of chitosan quaternary ammonium salt is 3.0×10 5 -5.0×10 5 , the degree of substitution is 80%;

[0051] (2) Prepare the oil phase, take 100mL corn oil, 2mL Span80, stir at 40°C at a speed of 200rpm for 40min to obtain the oil phase;

[0052] (3) Add the water phase to the oil phase dropwise under stirring, and stir for 40 min at 400 rpm to obtain a liquid mixture;

[0053]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com