A kind of macroporous cross-linked adsorption resin containing tertiary amine hydrochloride functional group and preparation method thereof

A technology containing tertiary amine hydrochloride and tertiary amine hydrochloride, which is applied in chemical instruments and methods, and other chemical processes, can solve the problems of strong fluidity and difficult removal of toxic oxyacid anions, and achieve low price , The effect of easy access to raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

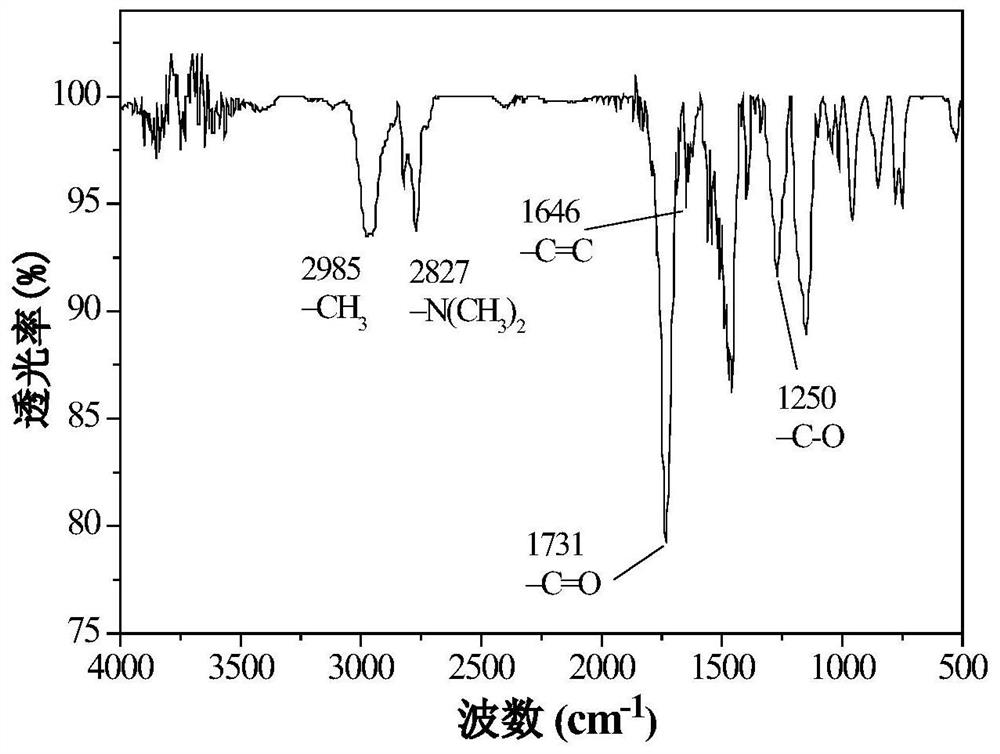

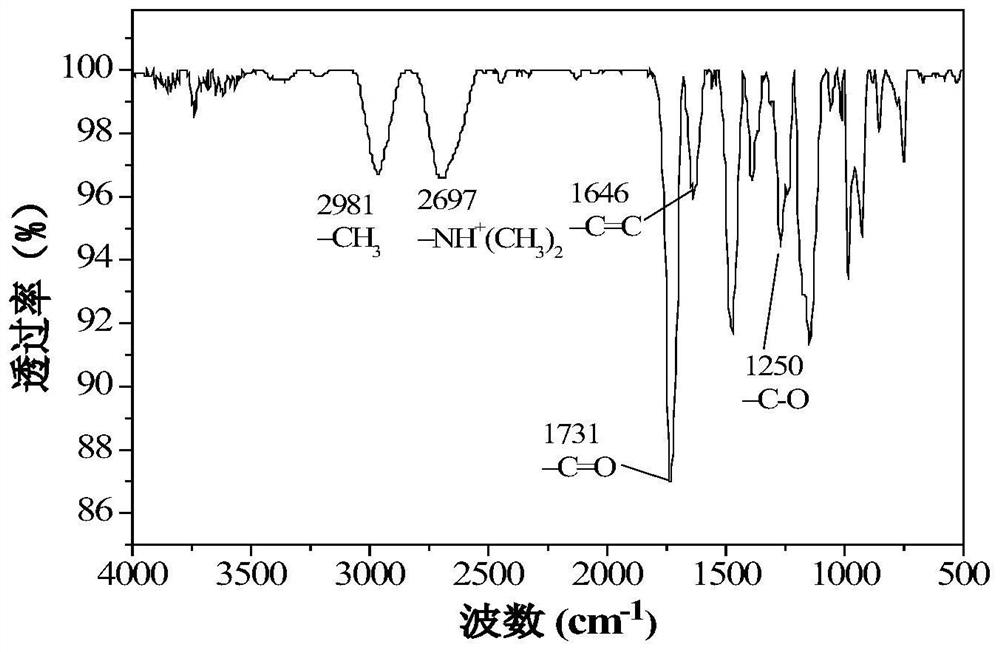

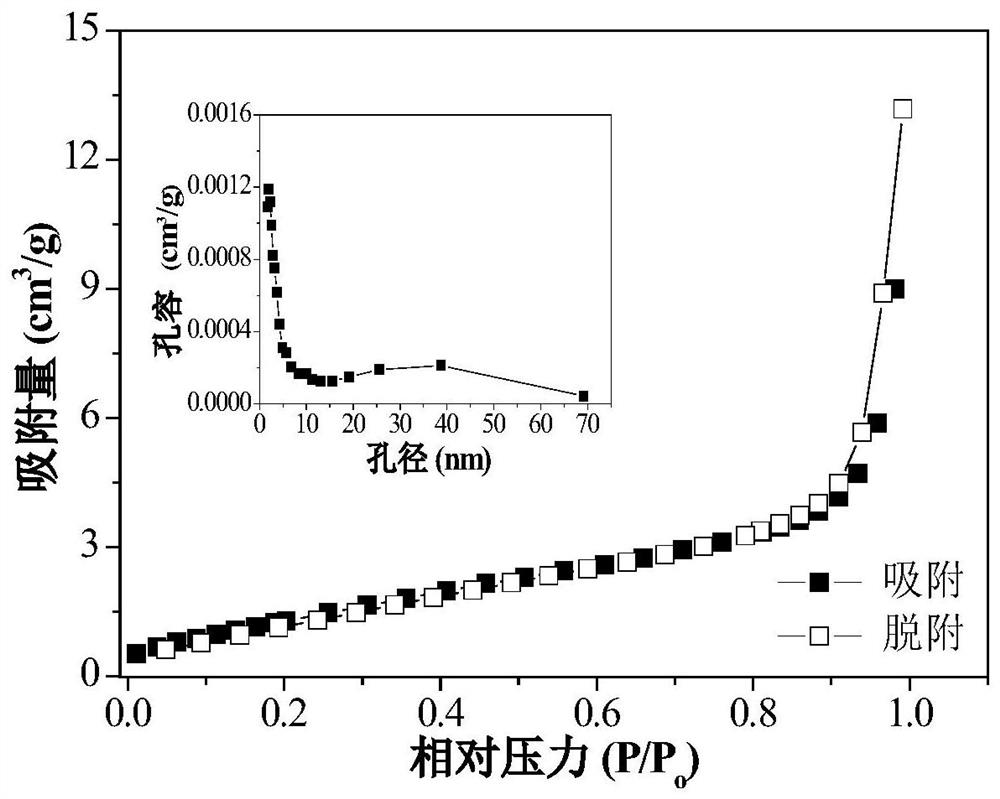

[0038] 1. Preparation of trimethylolpropane trimethacrylate-dimethylaminoethyl methacrylate macroporous adsorption resin

[0039] In a three-neck round bottom flask, add 60mL distilled water, 0.04g polyvinyl alcohol, 0.04g sodium dodecylsulfonate dispersant and 0.05g bentonite, install a stirrer, water separator, reflux condenser and thermometer, and stir Under certain conditions, heat to 100°C to dissolve it completely, then cool to room temperature to form a homogeneous aqueous phase.

[0040]In addition, take 4g of trimethylolpropane trimethacrylate, 8g of dimethylaminoethyl methacrylate, 40mL of toluene and 4mL of liquid paraffin as porogens, ultrasonically dissolve them completely, and then add 1g of azobisisobutyl Nitrile is used as an initiator, and ultrasonic waves disperse it to form a uniform organic phase.

[0041] Slowly add the fully dissolved organic phase to the water phase at a constant stirring speed, pre-disperse for 5 minutes, then slowly raise the temperat...

Embodiment 2

[0047] 1. Preparation of trimethylolpropane trimethacrylate-dimethylaminoethyl methacrylate macroporous adsorption resin

[0048] In a three-neck round bottom flask, add 60mL distilled water, 0.05g polyvinyl alcohol, 0.05g sodium dodecylsulfonate dispersant and 0.06g bentonite, install a stirrer, a water separator, a reflux condenser and a thermometer, and stir Under certain conditions, heat to 100°C to dissolve it completely, then cool to room temperature to form a homogeneous aqueous phase.

[0049] In addition, take 6g of trimethylolpropane trimethacrylate, 6g of dimethylaminoethyl methacrylate, 40mL of toluene and 4mL of liquid paraffin as porogens, ultrasonically dissolve them completely, and then add 0.9g of azobisiso Butyronitrile is used as an initiator, and it is dispersed by ultrasonic waves to form a uniform organic phase.

[0050] Slowly add the fully dissolved organic phase to the water phase at a constant stirring speed, pre-disperse for 5 minutes, then slowly r...

Embodiment 3

[0055] 1. Preparation of trimethylolpropane trimethacrylate-dimethylaminoethyl methacrylate macroporous adsorption resin

[0056] In a three-neck round bottom flask, add 60mL distilled water, 0.06g polyvinyl alcohol, 0.06g sodium dodecylsulfonate dispersant and 0.07g bentonite, install a stirrer, water separator, reflux condenser and thermometer, and stir Under certain conditions, heat to 100°C to dissolve it completely, then cool to room temperature to form a homogeneous aqueous phase.

[0057] In addition, take 5g of trimethylolpropane trimethacrylate, 7g of dimethylaminoethyl methacrylate, 20mL of toluene and 2mL of liquid paraffin as porogens, ultrasonically dissolve them completely, and then add 1.1g of azobisiso Butyronitrile is used as an initiator, and it is dispersed by ultrasonic waves to form a uniform organic phase.

[0058] Slowly add the fully dissolved organic phase to the water phase at a constant stirring speed, pre-disperse for 5 minutes, then slowly raise t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com