Method for recovering valuable elements from gold-containing sulfur concentrate roasting slag pickle liquor

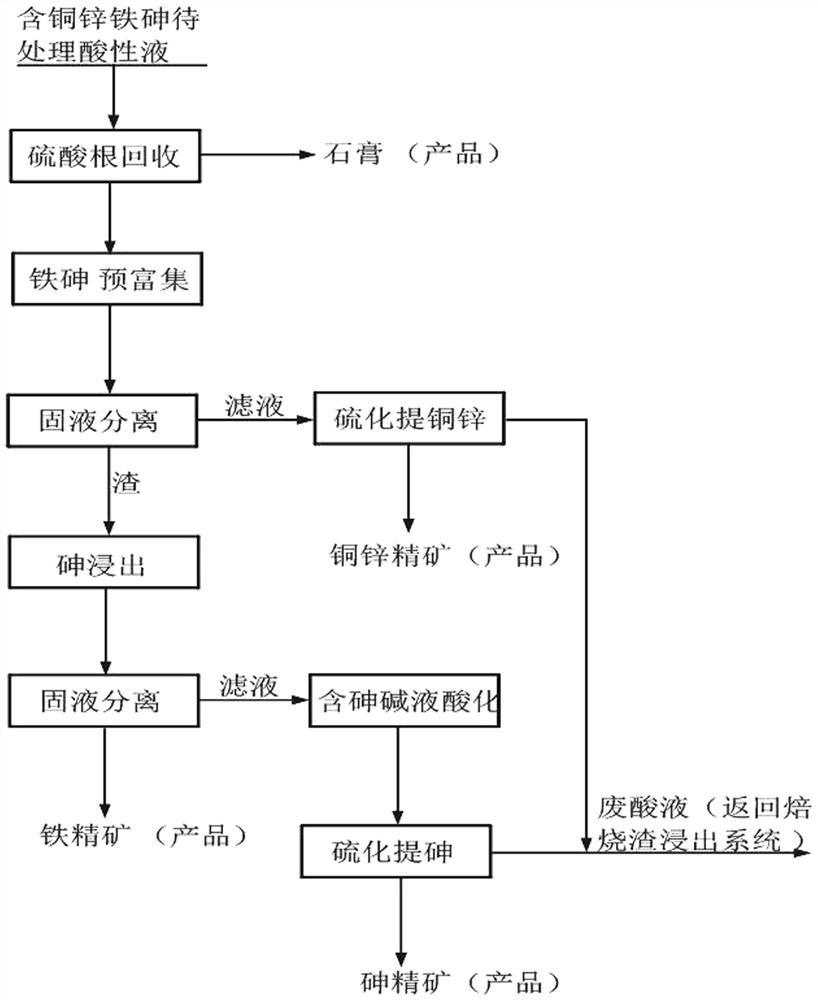

A valuable element, roasting slag technology, applied in the direction of calcium/strontium/barium sulfate, process efficiency improvement, iron oxide/iron hydroxide, etc., can solve the problems of high processing cost, high processing cost, secondary pollution and so on , to achieve the effect of simple process flow, stable production indicators, and avoidance of potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

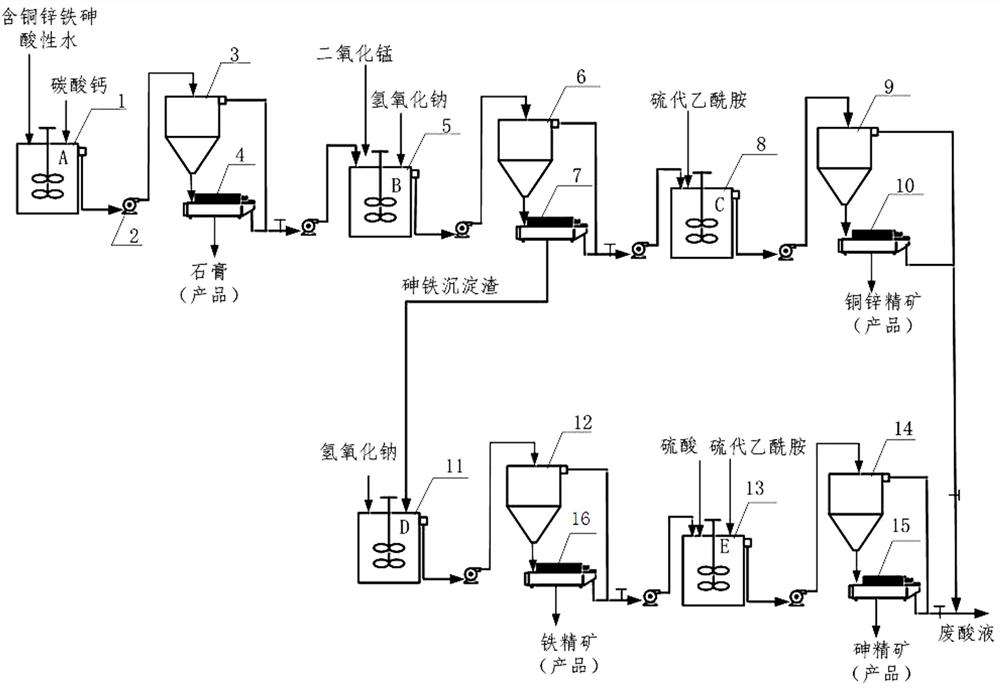

Embodiment 1

[0050] An acid leaching solution containing gold-sulfur concentrate roasting slag, the pH of the solution is about 0.6, the main element analysis results are: copper 3130mg / L, zinc 160mg / L, iron 19210mg / L, arsenic 2325mg / L Contains a certain amount of calcium, magnesium and other elements.

[0051] Adopt the present invention to implement this gold-containing sulfur concentrate roasting slag acid leaching solution, technical step comprises:

[0052] (1) Determination of acid waste liquid copper, zinc, iron, arsenic, sulfate content and acidity (pH). Take a certain amount of acid waste liquid to be treated, and analyze the content and acidity of copper, zinc, ferrous, total iron, arsenic, total arsenic, sulfate, etc.;

[0053] (2) Sulfate recovery. The acid waste liquid to be treated is transported to the mixing tank A, and calcium carbonate is added to make gypsum. In this process, the amount of calcium carbonate or lime is added according to the theoretical calculation of ...

Embodiment 2

[0060] A gold-containing sulfur concentrate roasting slag acid leaching solution, the pH of the solution is about 1, the main element analysis results are: copper 4520mg / L, zinc 135mg / L, iron 19480mg / L, arsenic 2035mg / L Contains a certain amount of calcium, magnesium and other elements.

[0061] Adopt the present invention to implement this gold-containing sulfur concentrate roasting slag acid leaching solution, technical step comprises:

[0062] (1) Determination of acid waste liquid copper, zinc, iron, arsenic, sulfate content and acidity (pH). Take a certain amount of acid waste liquid to be treated, and analyze the content and acidity of copper, zinc, ferrous, total iron, arsenic, total arsenic, sulfate, etc.;

[0063](2) Sulfate recovery. The acid waste liquid to be treated is transported to the mixing tank A, and lime is added to make gypsum. In this process, the amount of calcium carbonate or lime is added according to the theoretical calculation of the chemical reac...

Embodiment 3

[0070] An acid leaching solution containing gold-sulfur concentrate roasting slag, the pH of the solution is about 2, the main element analysis results are: copper 3683mg / L, zinc 384mg / L, iron 18792mg / L, arsenic 2163mg / L Contains a certain amount of calcium, magnesium and other elements.

[0071] Adopt the present invention to implement this gold-containing sulfur concentrate roasting slag acid leaching solution, technical step comprises:

[0072] (1) Determination of acid waste liquid copper, zinc, iron, arsenic, sulfate content and acidity (pH). Take a certain amount of acid waste liquid to be treated, and analyze the content and acidity of copper, zinc, ferrous, total iron, arsenic, total arsenic, sulfate, etc.;

[0073] (2) Sulfate recovery. The acid waste liquid to be treated is transported to the mixing tank A, and calcium carbonate is added to make gypsum. In this process, the amount of calcium carbonate or lime is added according to the theoretical calculation of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com