Method for separating and extracting protein and/or enzyme from ion liquid

A technology of ionic liquid and protein, which is applied in the field of protein and/or enzyme extraction and separation, can solve the problems of rare separated protein and/or enzyme, toxicity of fermenting microorganisms, immiscibility, etc., and achieve wide thermal stability temperature range and strong matching Effect of bit activity and high viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

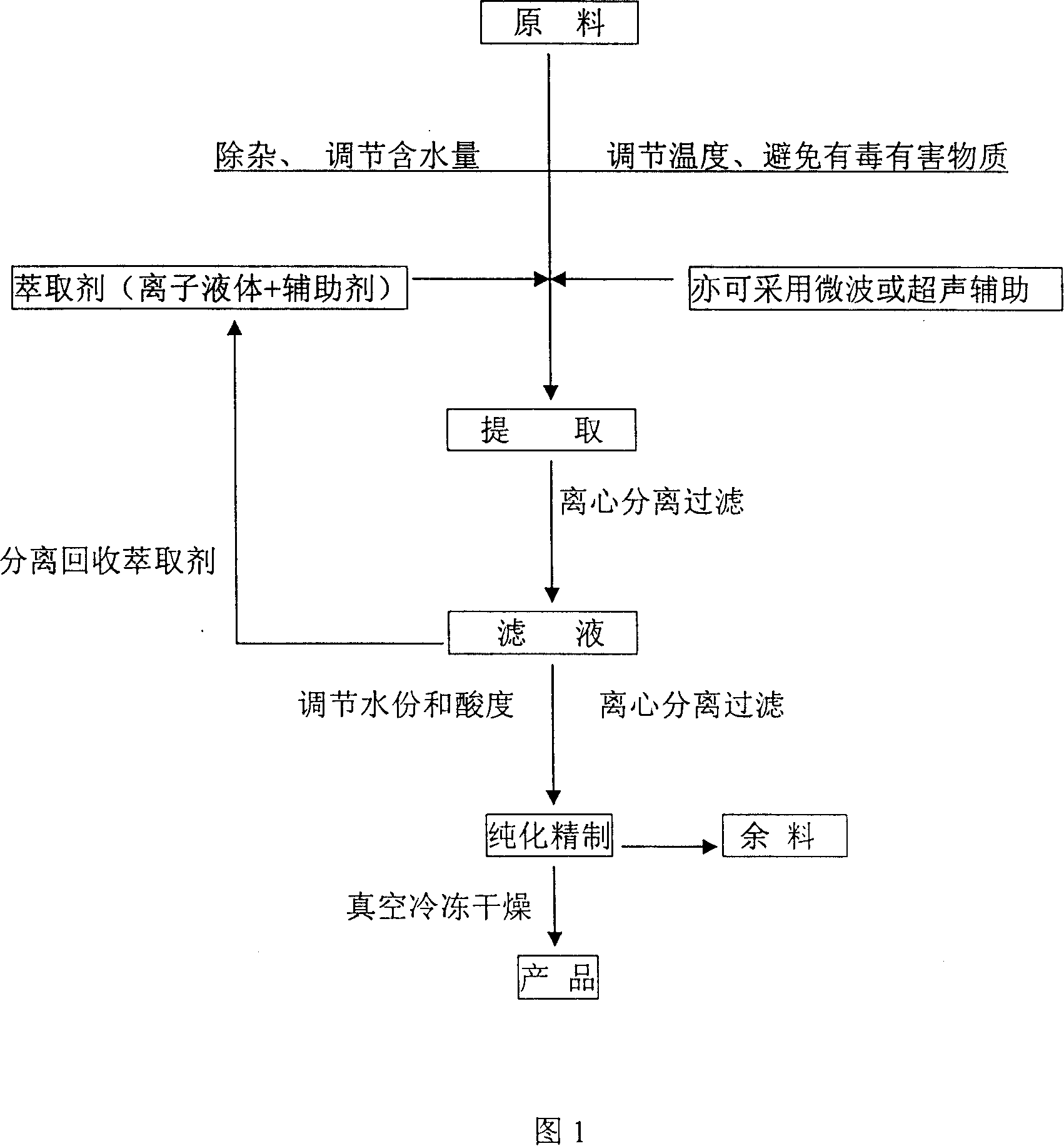

Method used

Image

Examples

Embodiment 1

[0031] Extract plant protein. Using 1000g soybean meal as raw material, the raw material is pretreated, including crushing, sieving, and impurity removal. The water content of the raw material is adjusted to 1.0%-3.0% (w / w) with distilled water, the temperature is controlled at 15℃~45℃, and carbonic acid is used. Adjust the pH to 6.5-9.5 with sodium hydrogen. Pay attention that the environment does not contain toxic and harmful substances and avoid sunlight, so as not to affect the protein activity. Add the extractant (in terms of weight percentage, the extractant is composed of 88.5% of the total weight of the extractant, hexaalkylguanidine fluoroborate, 4% ethyl butyrate, 5% ethanol and 2.5% acetic acid. Mix well before use. ) 5000g (extract in 3 times, the amount of extractant in the first time is 40% of the total, and the second and third times are 30%), extract 3~5h under the shaking of a shaker, and then in a centrifuge at 5000r / Centrifugal separation for about 10 minutes a...

Embodiment 2

[0033] Extract plant protein. Using 1000g wheat as raw material, the pretreatment includes crushing, sieving, adjusting the water content of the raw material to 60±5% (w / w) with distilled water, controlling the temperature to 40±5°C, and adjusting the pH to 6.5~9.5 with sodium hydrogen phosphate , Note that the environment does not contain toxic and hazardous substances and avoid sunlight. Add the extractant (in terms of weight percentage, the extractant consists of 88.5% of the total weight of the extractant hexaalkylguanidine fluorophosphate ionic liquid, 10% methyl propionate, 1% hexane and 0.5% butyric acid, before use Mix well and reserve) 4000g (extract in 3 times, the amount of extractant for the first time is 40% of the total amount, the second and third times are 30%), extract 3~5h under shaker shaking, and then put on the centrifuge Centrifuge at 5000r / min for 10 minutes, filter, adjust the water content of the filtrate to 5±1%, pH 4.5±1, and then centrifuge and filter. ...

Embodiment 3

[0035] Extract animal protein. Take 500g pig blood meal as raw material, remove impurities first, then ultrasonically break, adjust pH 7.5~9.0 with sodium bicarbonate, adjust water content 0.1%~2.0% (w / w), temperature 10℃~15℃, pay attention to the environment does not contain toxic Harmful substances and avoid sunlight. Add extractant (by weight percentage, the extractant consists of 25% of the total weight of the extractant, 1-methyl-3-butylimidazole tetrafluoroborate and 55% of 1-methyl-3-octylimidazole hexafluoroborate Ionic liquid composed of fluorophosphate, 3% sodium dihydrogen phosphate, 7% ammonium bisulfate, 1% ethyl formate, 9% acetone, mix well before use, and use it for use. The amount of extractant is 10 times the quality of the raw material ( The extraction is carried out in 3 times. The amount of the extractant in the first time is 40% of the total amount, and the second and third times are both 30%). The extraction is performed under ultrasonic vibration for 20 min...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com