Method for treating high-concentration alkaline arsenic mining and metallurgy wastewater by coprecipitation-ion exchange compound technology

A technology of ion exchange and composite process, which is applied in the field of sewage treatment, can solve the problems that arsenic-containing mining and metallurgy wastewater cannot be discharged up to the standard, the performance of arsenic removal is easily affected by impurity ions, and secondary pollution of sediments, etc., to achieve environmental benefits and Social benefits, enhanced deep removal effect, and large adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

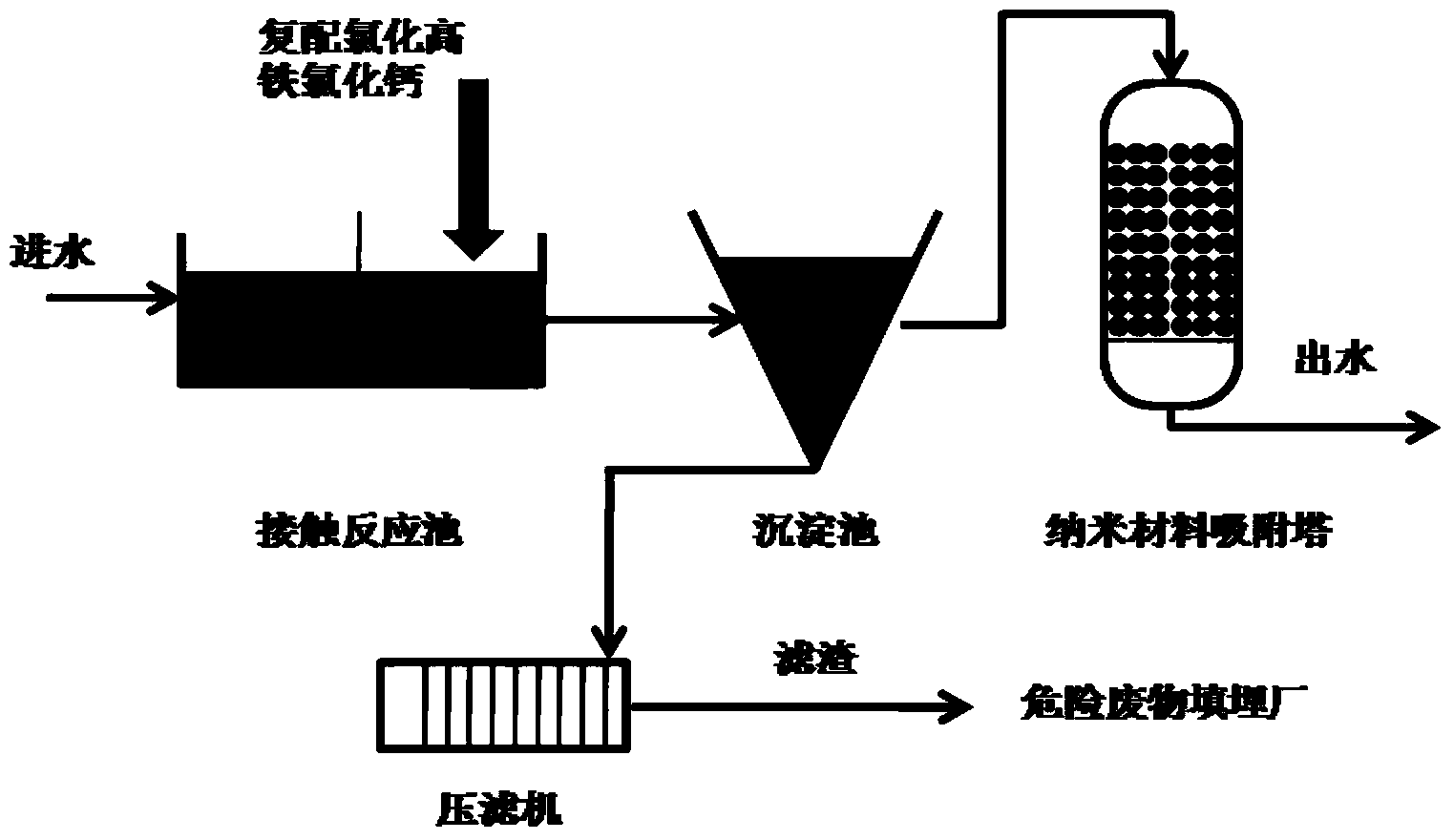

[0039]In conjunction with the accompanying drawings, a co-precipitation-ion exchange composite process of this embodiment is a method for treating high-concentration alkaline arsenic-containing mining and metallurgy wastewater, which is especially suitable for treating high arsenic-containing concentration, strong alkalinity, and a large number of coexisting ions (such as Ca 2+ , Mg 2+ , SiO 3 2- etc.) arsenic-containing mining and metallurgy wastewater. The steps are:

[0040] (A) Control the flow of high-concentration alkaline arsenic-containing mining and metallurgy wastewater raw water into the pH adjustment pool. In this embodiment, the arsenic content in the arsenic-containing mining and metallurgy wastewater is 15 mg / L. Use a metering pump to add sulfuric acid solution to neutralize the alkalinity of the raw water. The mass percentage concentration of sulfuric acid in the added sulfuric acid solution is 40%, and the dosage of sulfuric acid solution is 5L / m 3 , the ...

Embodiment 2

[0049] The method for treating high-concentration alkaline arsenic-containing mining and metallurgy wastewater by a co-precipitation-ion exchange composite process in this embodiment is basically the same as that in Embodiment 1, except that some parameters have been adjusted, and the same effect can still be achieved. details as follows:

[0050] The mass percent concentration of sulfuric acid in the sulfuric acid solution added in step (A) is 70%, and the dosage of sulfuric acid solution is 10L / m 3 , adjust the pH to 6.

[0051] In the step (B), the stirring speed is 20-100 rpm, and the reaction time of the waste water in the contact reaction tank is 30-90 minutes. The dosage of compound ferric chloride and calcium chloride mixed solution is 20L / m 3 , the mass percentage concentration of ferric chloride in the mixed solution is 10%, the mass percentage concentration of calcium chloride is 0.05%; the dosage of polyacrylamide solution is 10L / m 3 , the mass percent concentra...

Embodiment 3

[0057] The method for treating high-concentration alkaline arsenic-containing mining and metallurgy wastewater by a co-precipitation-ion exchange composite process in this embodiment is basically the same as that in Embodiment 1, except that some parameters have been adjusted, and the same effect can still be achieved. details as follows:

[0058] The mass percent concentration of sulfuric acid in the sulfuric acid solution added in step (A) is 40%, and the dosage of sulfuric acid solution is 5L / m 3 , adjust PH to be 8.

[0059] In step (B), the stirring speed is 20 rpm, and the reaction time of the wastewater in the contact reaction tank is 30 minutes. The dosage of compound ferric chloride and calcium chloride mixed solution is 5L / m 3 , the mass percentage concentration of ferric chloride in the mixed solution is 5%, the mass percentage concentration of calcium chloride is 0.01%; the dosage of polyacrylamide solution is 2L / m 3 , the mass percent concentration of the polya...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com