An air monitoring device and an exhaust gas treatment line provided with the air monitoring device

A technology for air monitoring and waste gas treatment, which is applied in the measurement of color/spectral properties, separation of dispersed particles, chemical instruments and methods, etc. It can solve problems such as manual sampling and achieve good treatment effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

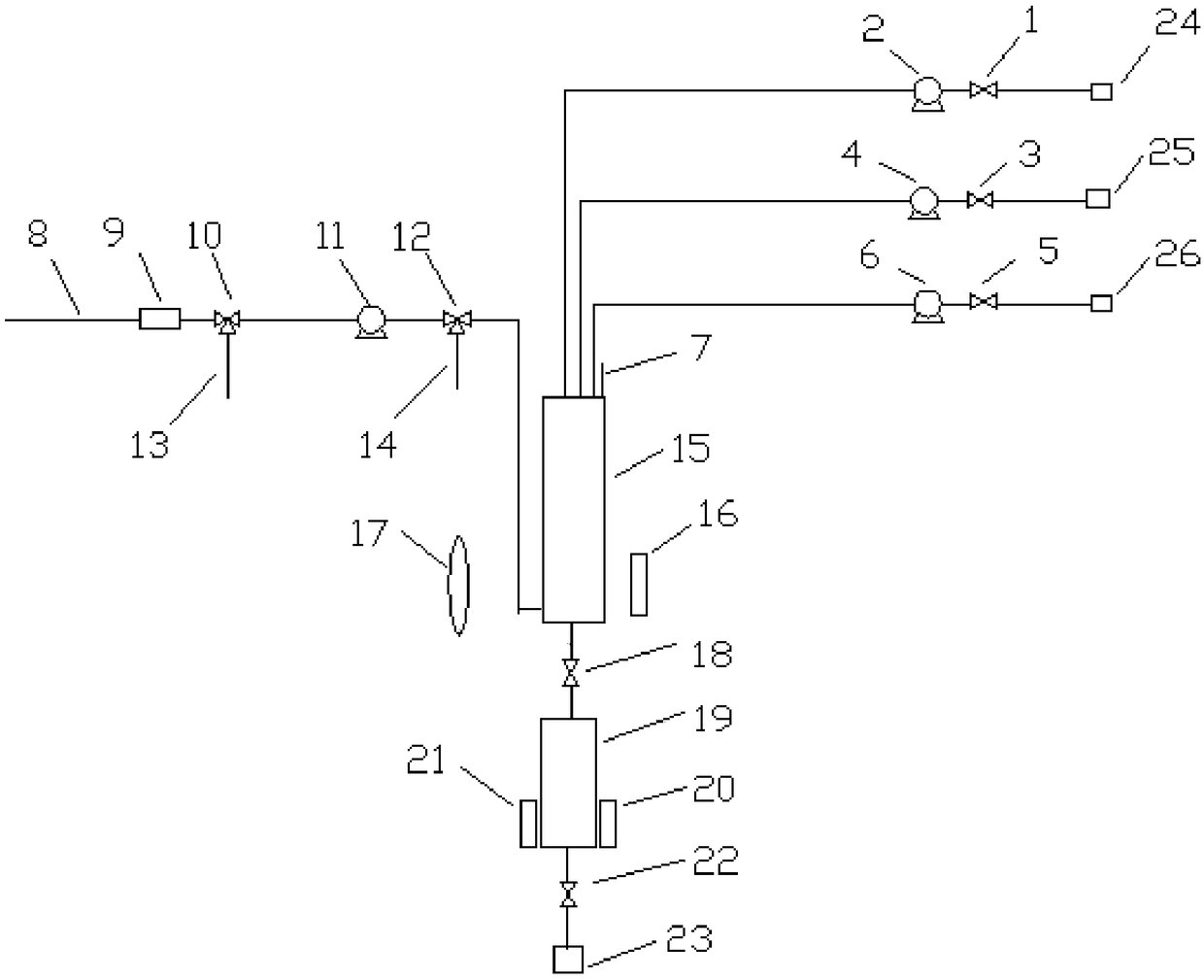

[0024] The air monitoring device provided in Embodiment 1 includes a mixing chamber 15, in which an anti-overflow sensor 7 is arranged, and a fan 17 and a heater 16 are respectively arranged on both sides of the mixing chamber 15. The mixing chamber 15 is connected with a plurality of liquid inlet assemblies, and each liquid inlet assembly includes liquid storage tanks 24, 25, 26, liquid inlet valves 1, 3, 5 and metering pumps 2, 4, 6 connected in sequence, and each metering The outlet pipes of the pumps 2, 4 and 6 are all connected to the mixing chamber 15. The mixing chamber 15 is also communicated with an air inlet pipe 8 , and an air flow meter 9 and an air pump 11 are arranged on the air inlet pipe 8 . The intake pipes 8 on both sides of the air pump are also respectively connected with a clean air pipeline 13 and an emptying pipeline 14, and the clean air pipeline 13 and the emptying pipeline 14 are equipped with air delivery valves 10, 12 respectively. The lower part o...

Embodiment 2

[0028] This embodiment provides the method of using the air monitoring device in Example 1. There should be at least three liquid inlet components, and the liquid storage barrels 24, 25, and 26 of each liquid inlet component store the absorption liquid, acetylacetone liquid and formaldehyde standard liquid respectively. Absorbent can be depurified water:

[0029] (1) Rinse the liquid pipeline and the mixing chamber 15 with clean water.

[0030] (2) Turn on the metering pump 2 of the pipeline connected to the absorption liquid to pump the absorption liquid.

[0031] (3), open the metering pump of the pipeline connected to the formaldehyde standard solution to pump a certain amount of formaldehyde standard solution.

[0032] (4), open the metering pump 6 of the pipeline connected to the acetylacetone liquid to pump a certain amount of acetylacetone liquid.

[0033] (5) Mix the various reagents in the mixing chamber 15 uniformly by feeding clean air bubbles or other stirring de...

Embodiment 3

[0052] This embodiment provides an exhaust gas treatment line equipped with an air monitoring device. The exhaust gas treatment line includes exhaust gas treatment components connected in series. The exhaust gas treatment components are also connected to monitoring exhaust gas treatment equipment, and a switching valve is set at the collection pipe of the monitoring exhaust gas treatment equipment. A chimney is connected to the end of the waste gas treatment assembly, and the exhaust pipeline 14 of the air monitoring device is connected to the chimney. The signal output end of the colorimeter is connected with an exhaust gas treatment equipment controller and an audible and visual alarm, and the exhaust gas treatment equipment controller is connected with a switch and a switching valve for monitoring the exhaust gas treatment equipment.

[0053] Further, the exhaust gas treatment component includes condensation equipment, spray equipment, photocatalytic oxidation equipment, hig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com