Arsenic sulfide waste residue recycling treatment method and device thereof

A treatment method and treatment device technology, applied in the direction of solid waste removal, etc., can solve the problems of secondary pollution, long operation time, high consumption, etc., achieve no secondary wastewater pollution, avoid secondary hazardous waste, and low energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

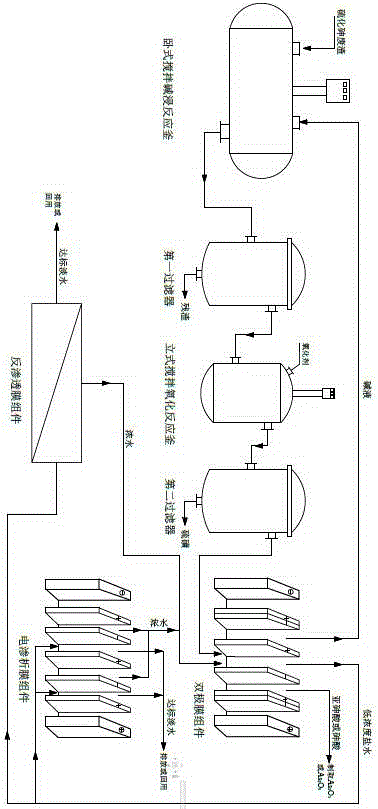

Image

Examples

Embodiment 1

[0054] As produced in the production process of a phosphoric acid plant 2 S 3 Slag, the arsenic content is 10%.

[0055] (1) Take 1000g of the above As 2 S 3 The slag is placed in a horizontal stirring leaching reactor, and then 2% NaOH solution is added for leaching to obtain a solution containing thioarsenite, n(OH - ): n(As)=4, the leaching temperature is 25°C, the leaching time is 10min, and the leaching rate is above 99.999995%;

[0056] (2) The solution obtained after alkaline leaching enters the first precision filter to separate and obtain 3% alkaline leaching solution and residue;

[0057] (3) 3% alkaline leaching solution enters the vertical stirring oxidation reaction kettle, and then passes through pure oxygen for oxidative desulfurization, and completely oxidizes the thioarsenite in it to arsenite ion;

[0058] (4) The oxidized solution from the vertical stirring oxidation reactor enters the second precision filter to separate and obtain the sulfur product an...

Embodiment 2

[0062] As produced in the production process of a sulfuric acid plant 2 S 5 Slag, the arsenic content is 25%.

[0063] (1) Take 1000g of the above As 2 S 5 The slag is placed in a horizontal stirring leaching reactor, and then a 5% NaOH solution is added for leaching to obtain a solution containing thioarsenate, n(OH - ): n(As)=5, the leaching temperature is 30°C, the leaching time is 20min, and the leaching rate is over 99.999996%;

[0064] (2) The solution obtained after alkaline leaching enters the first precision filter to separate and obtain 5.4% alkaline leaching solution and residue;

[0065] (3) The 5.4% alkaline leaching solution enters the vertical stirring oxidation reaction kettle, and then passes through pure oxygen for oxidative desulfurization, and completely oxidizes the thioarsenate in it to arsenate ion;

[0066] (4) The oxidized solution from the vertical stirring oxidation reactor enters the second precision filter to separate and obtain the sulfur pro...

Embodiment 3

[0070] As produced in the production process of a copper company 2 S 2 and As 2 S 3 Slag, the arsenic content is 50%.

[0071] (1) Take 1000g of the above As 2 S 2 and As 2 S 3 The slag is placed in a horizontal stirring leaching reactor, and then a 6% NaOH solution is added for leaching to obtain a solution containing thioarsenite, n(OH -): n(As)=5, the leaching temperature is 40°C, the leaching time is 25min, and the leaching rate is over 99.999997%;

[0072] (2) The solution obtained after alkaline leaching enters the first precision filter to separate and obtain 6.5% alkaline leaching solution and residue;

[0073] (3) 6.5% alkaline leaching solution enters the vertical stirring oxidation reaction kettle, and then passes through pure oxygen for oxidative desulfurization, and completely oxidizes the thioarsenite in it to arsenite ion;

[0074] (4) The oxidized solution from the vertical stirring oxidation reactor enters the second precision filter to separate and o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com