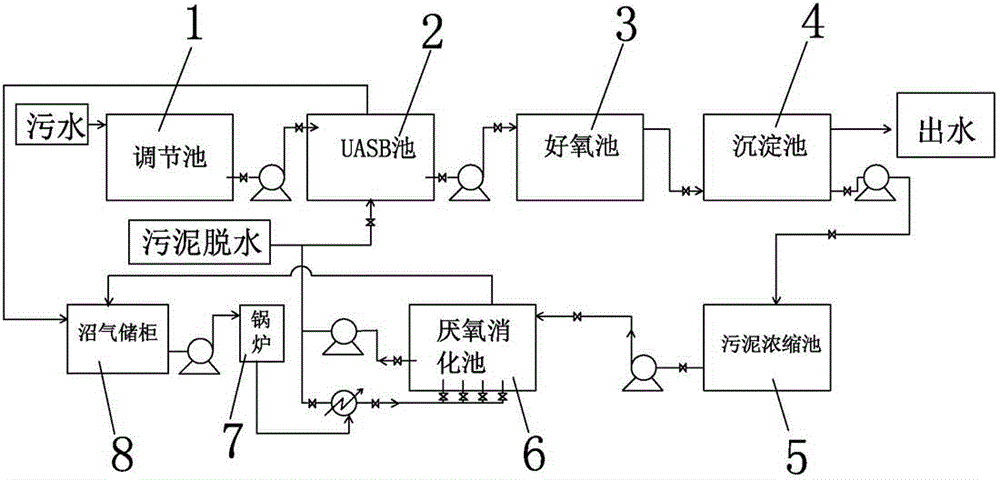

Method for reducing sludge and recycling sludge in UASB (upflow anaerobic sludge blanket) system and sludge treatment system

A sewage treatment system and sludge reduction technology, applied in water/sludge/sewage treatment, sludge treatment, sludge treatment, etc., can solve the problems of loss of granular sludge, poor effluent quality, poor sedimentation, etc. Achieve the effect of reducing nitrogen and phosphorus consumption, improving treatment rate and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Example 1: The wastewater treatment capacity of a chemical enterprise is 2wt / d, and the sludge treatment system with sludge reduction and reuse functions according to the present invention is constructed by rebuilding the old device. The amount of digested sludge that can be obtained in one month is 662m 3 , the sludge concentration is 30000mg / L, then 19.86t of sludge (calculated as dry sludge) is replenished to the UASB pool every month to supplement the flocculent sludge lost by UASB and provide a sludge source for sludge granulation. The cost of purchasing mud sources. After analyzing the water quality of the sludge supernatant, the COD, NH3-N, TN, and TP of the concentrated sludge before digestion were 183, 0.2, 0.52, and 2.5 mg / L, respectively. TP were 969, 3.7, 10.66, and 4.8 mg / L, respectively. It can be seen that during the anaerobic digestion process of sludge microorganisms, extracellular polymer (EPS) was dissociated and released, cells entered endogenous re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com