Adsorbent for removing toxic element arsenic in water and application thereof

An adsorbent and water removal technology, which is applied in the field of water treatment, can solve the problems of poor treatment effect and low saturated adsorption capacity, and achieve the effects of low cost, strong adsorption capacity, and simple and easy preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

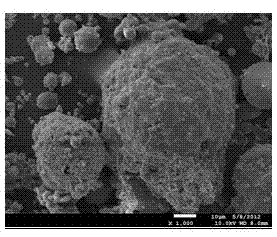

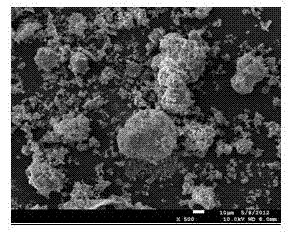

Image

Examples

Embodiment 1

[0017] Embodiment 1 pickling fly ash

[0018] Take 10g of fly ash in a 500 mL large beaker, add 400 mL of deionized water, place it on a magnetic stirrer and stir vigorously, then adjust the pH of the solution to 2 with 2mol / L nitric acid, and stir for 1 hour. Ensure pH=2. The stirring was stopped, and the fly ash was washed repeatedly with deionized water until the washed water was neutral (pH 6.5-7.5), and dried at 105°C for 6 h to obtain the pickled fly ash.

Embodiment 2

[0019] Example 2 Preparation of fly ash material modified by zirconium manganese composite oxide

[0020] Add 200mL of deionized water to a 250mL Erlenmeyer flask, and then add 4.028g of ZrOCl 2 ·8H 2 O and 8.451g MnSO 4 ·H 2 O, the molar ratio of zirconium to manganese (Zr:Mn=1:4) was placed on a magnetic stirrer and stirred vigorously. Add 1mol / L NaOH solution to the solution to adjust pH=7.5. In order to ensure that the zirconium manganese oxide fully reacted, the solution was vigorously stirred for 1 h, and at the same time, the pH of the solution was adjusted with 1 mol / L NaOH, so that the pH was always 7.5.

[0021] Add 10 g of the acid-washed fly ash prepared in Example 1 into the solution, and stir thoroughly for 0.5 h. Then leave it to age for 24 hours. Rinse the fly ash repeatedly with deionized water until the filtrate is clear and the pH is 7-8. The fly ash after the reaction was collected and dried under vacuum at 80°C for 4 hours to prepare the zirconium m...

Embodiment 3

[0022] Example 3 Preparation of zirconium manganese oxide modified fly ash composite material

[0023] Add 200mL of deionized water to a 250mL Erlenmeyer flask, and then add 12.084g of ZrOCl 2 ·8H 2 O and 4.226g MnSO 4 ·H 2 O, the molar ratio of zirconium to manganese (Zr:Mn=3:2) was placed on a magnetic stirrer and stirred vigorously.

[0024] Other conditions are with embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com