Laser reinforcing technological method for circular saw bit

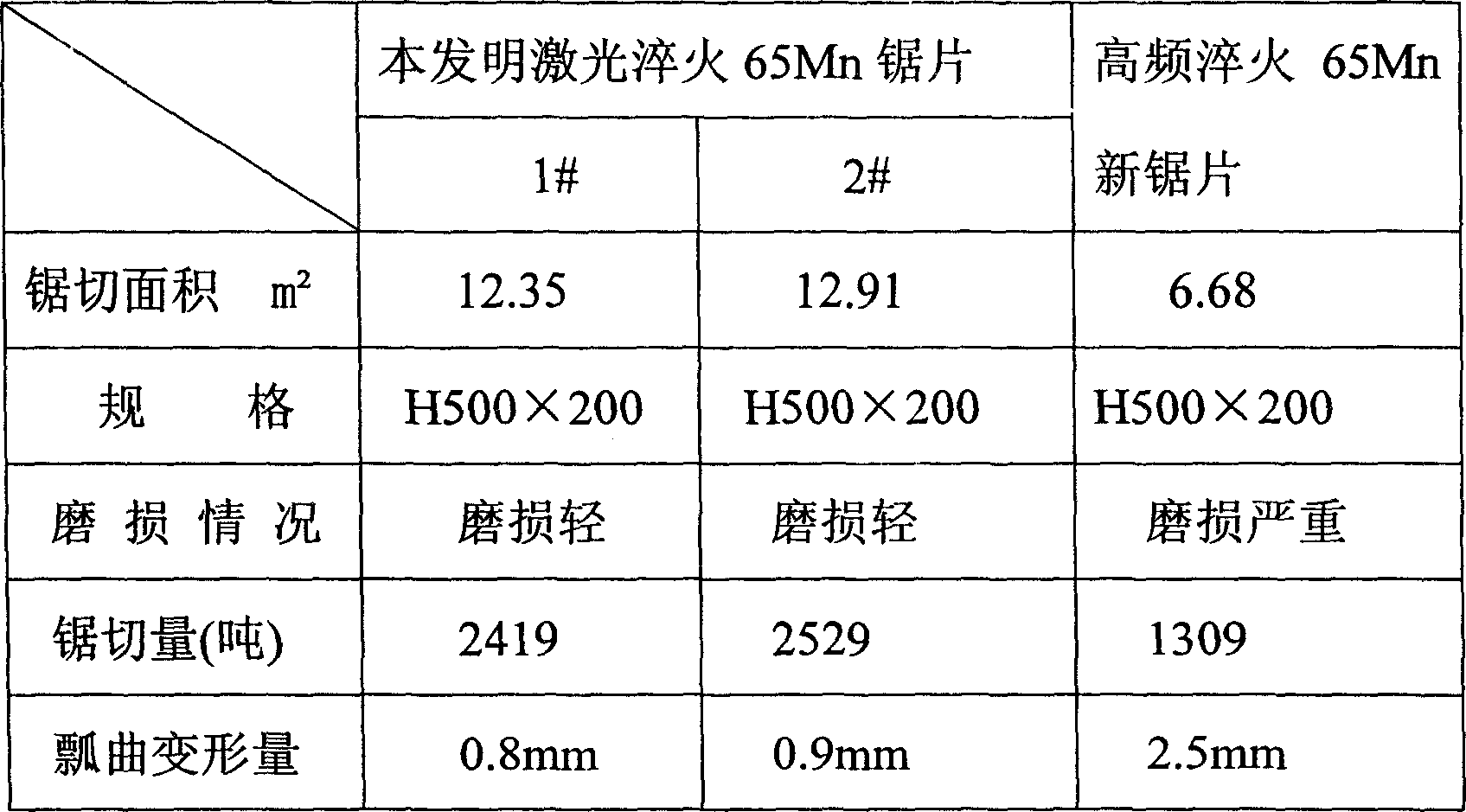

A circular saw blade and laser strengthening technology, which is applied to manufacturing tools, heat treatment equipment, furnaces, etc., can solve the problems of easy cracking, large deformation of heating furnace quenched saw blades, and poor wear resistance of high frequency quenched saw blades. Not easy to crack, long service life, good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0020] To strengthen the circular saw blade with a thickness of 16mm and a diameter of Φ2100mm for cutting H-shaped steel, the steps are as follows:

[0021] (1) Deformation detection of saw blades entering the site;

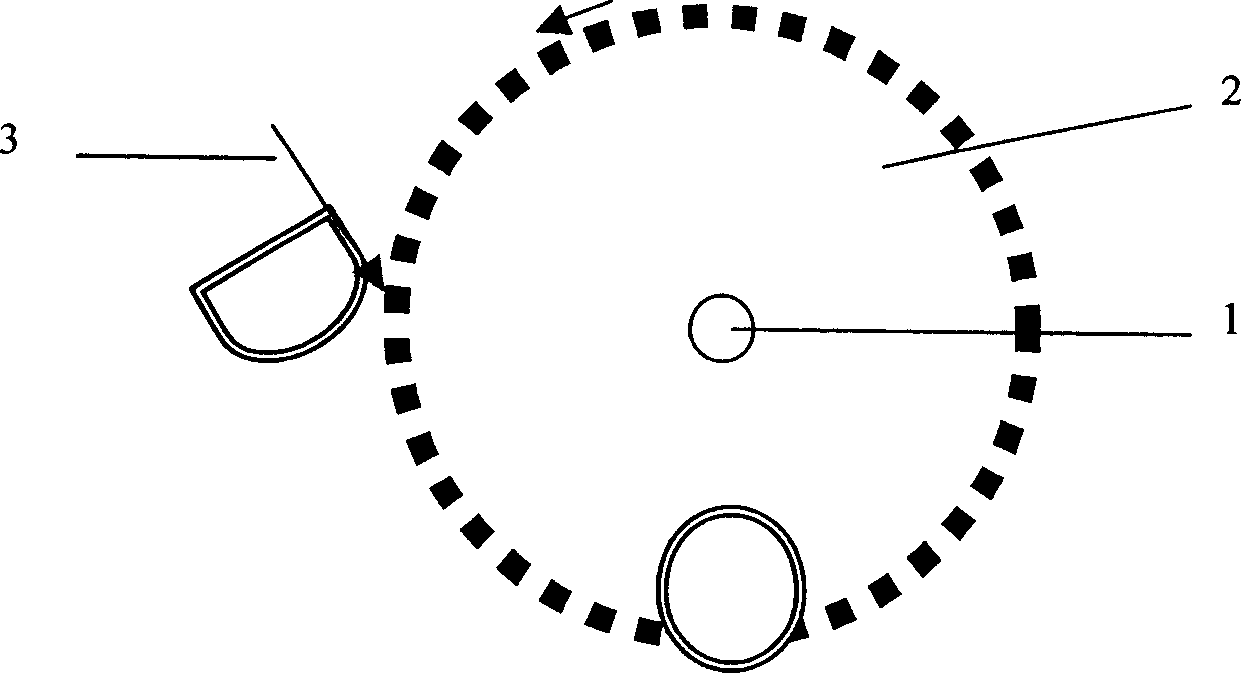

[0022] (2) Press figure 1 As shown, install the saw blade to be processed on the spindle of the machine tool, and adjust the swing to less than 1mm;

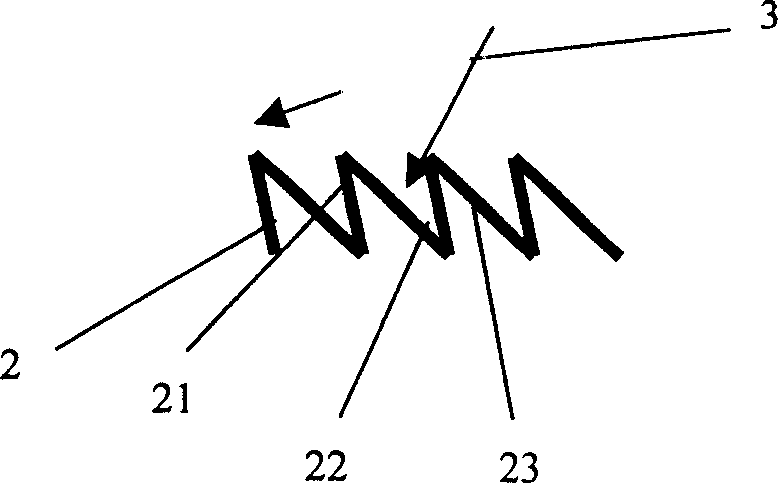

[0023] (3) Adopt broadband integral lens, H=20mm;

[0024] (4) Apply black light-absorbing paint to the teeth, and then wipe off the tooth tip paint;

[0025] (5) The light spot irradiates the circular saw blade radially, and the rotation direction of the main shaft is counterclockwise (such as figure 1 Arrow), where the lens angle α=45. , power N=2900W, outer circle speed V=800mm / min;

[0026] (7) Process quality monitoring, observe whether the beam irradiated surface is slightly melted, whether the non-irradiated surface (front) is gray-white quenching trace, and adjust the power and speed in time.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com