Vermiculite plate with sound insulation and fire protection functions and preparation method of vermiculite plate

A vermiculite board and functional technology, applied in the field of vermiculite board and its preparation, can solve the problems of complicated manufacturing process, low production efficiency, and non-environmental protection, and achieve the effects of simple manufacturing process, improved production efficiency, and good weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

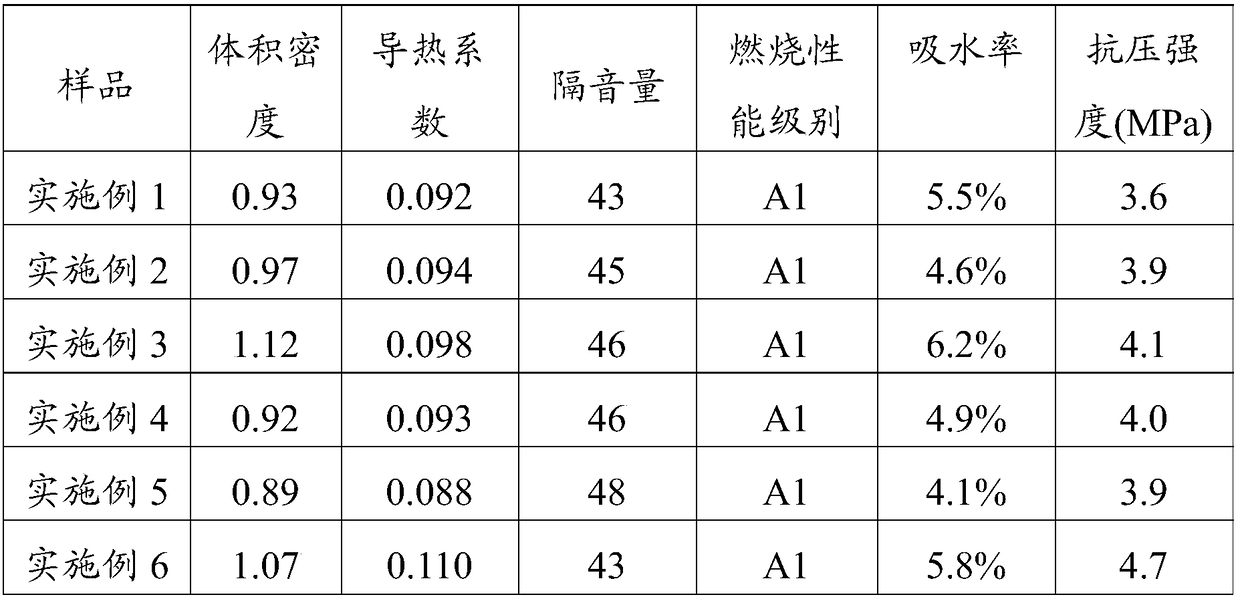

Examples

Embodiment 1

[0044] The raw materials of vermiculite board are: 20 parts of expanded vermiculite, 5 parts of magnesium aluminum silicate, 5 parts of expanded perlite, 45 parts of modified water glass (the degree of Baume is 40°Bé), 10 parts of glyoxal and 15 parts of water .

[0045] Preparation of modified water glass: Weigh 100kg of water glass and pour it into the heating reflux device, then add 10kg of KH560 organic silicon coupling agent, stir and heat to 85°C, keep at this temperature for 60min, then stop heating, after cooling Modified water glass can be obtained.

[0046] Follow the steps below to prepare a vermiculite board:

[0047] S1. Measure and weigh the required materials according to the proportion of each component, and slowly add them to the stirring container in batches according to the order of modified water glass, glyoxal, water, expanded vermiculite, magnesium aluminum silicate and expanded perlite, and add While stirring, a premix is formed;

[0048]S2. Then us...

Embodiment 2

[0052] The raw materials of vermiculite board are: 20 parts of expanded vermiculite, 10 parts of magnesium aluminum silicate, 5 parts of expanded perlite, 40 parts of modified water glass (the degree of Baume is 40°Bé), 10 parts of glyoxal and 15 parts of water .

[0053] Preparation of modified water glass: Weigh 100kg of water glass and pour it into a heating reflux device, then add 5kg of KH560 organic silicon coupling agent, stir and heat to 90°C, keep at this temperature for 60min, then stop heating, after cooling Modified water glass can be obtained.

[0054] Follow the steps below to prepare a vermiculite board:

[0055] S1. Measure and weigh the required materials according to the proportion of each component, and slowly add them to the stirring container in batches in the order of modified water glass, glyoxal, water, expanded vermiculite, magnesium aluminum silicate, and expanded perlite, and add While stirring, a premix is formed;

[0056] S2. Then use the stir...

Embodiment 3

[0060] The raw materials of vermiculite board are: 20 parts of expanded vermiculite, 15 parts of magnesium aluminum silicate, 5 parts of expanded perlite, 40 parts of modified water glass (the degree of Baume is 40°Bé), 10 parts of glyoxal and 10 parts of water .

[0061] Preparation of modified water glass: Weigh 100kg of water glass and pour it into a heating reflux device, then add 20kg of KH560 organic silicon coupling agent, stir and heat to 80°C, keep at this temperature for 60min, then stop heating, after cooling Modified water glass can be obtained.

[0062] Follow the steps below to prepare a vermiculite board:

[0063] S1. Measure and weigh the required materials according to the proportion of each component, and slowly add them to the stirring container in batches in the order of modified water glass, glyoxal, water, expanded vermiculite, magnesium aluminum silicate, and expanded perlite, and add While stirring, a premix is formed;

[0064] S2. Then use the sti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| flame retardant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com