Method and apparatus for producing hard particle abrasion resistant composite steel board

A composite steel plate and hard point technology, which is applied to other manufacturing equipment/tools, manufacturing tools, etc., can solve the problem of not being able to manufacture large-area composite steel plates, ceramic composite layer steel plates, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

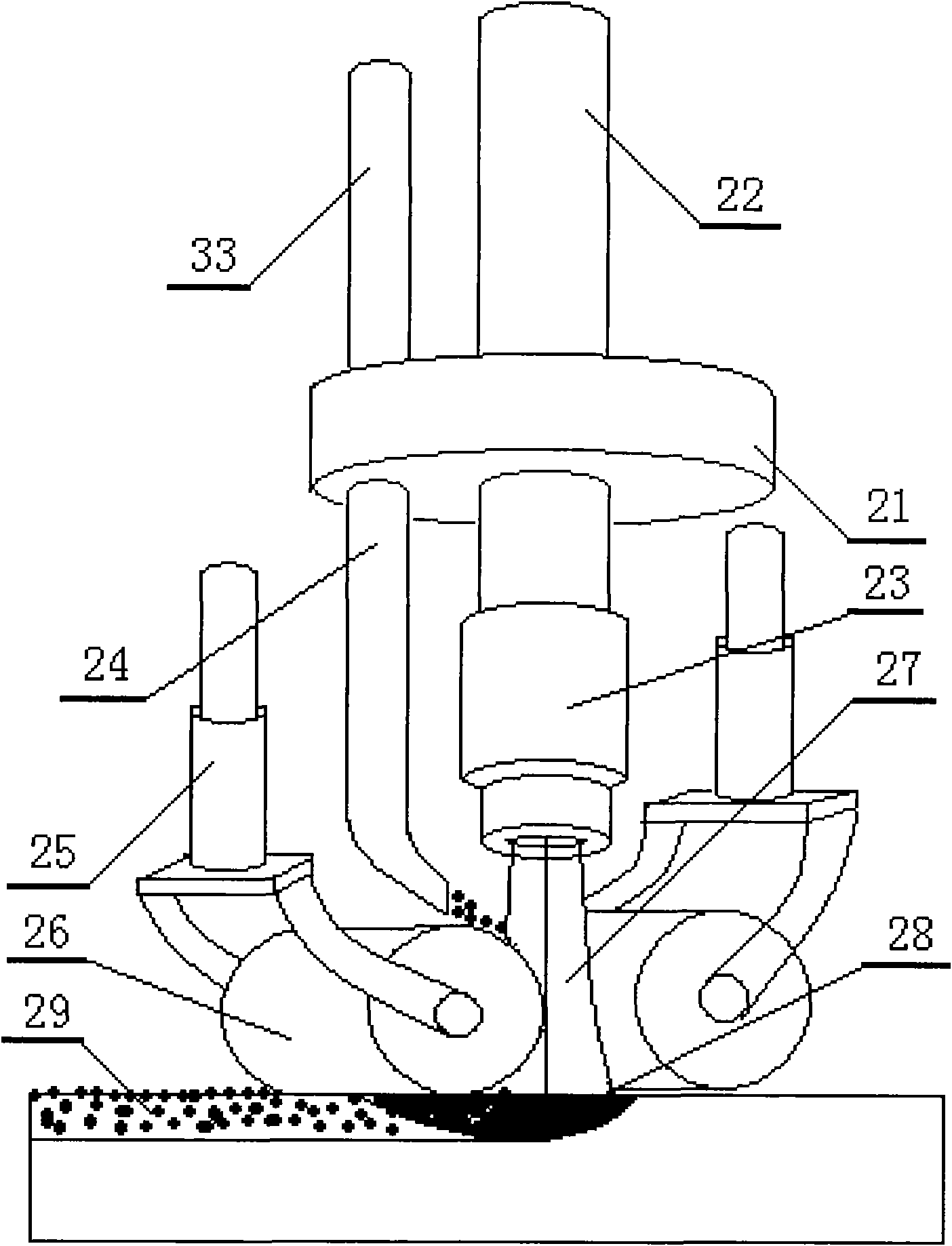

[0032] Technical key of the present invention:

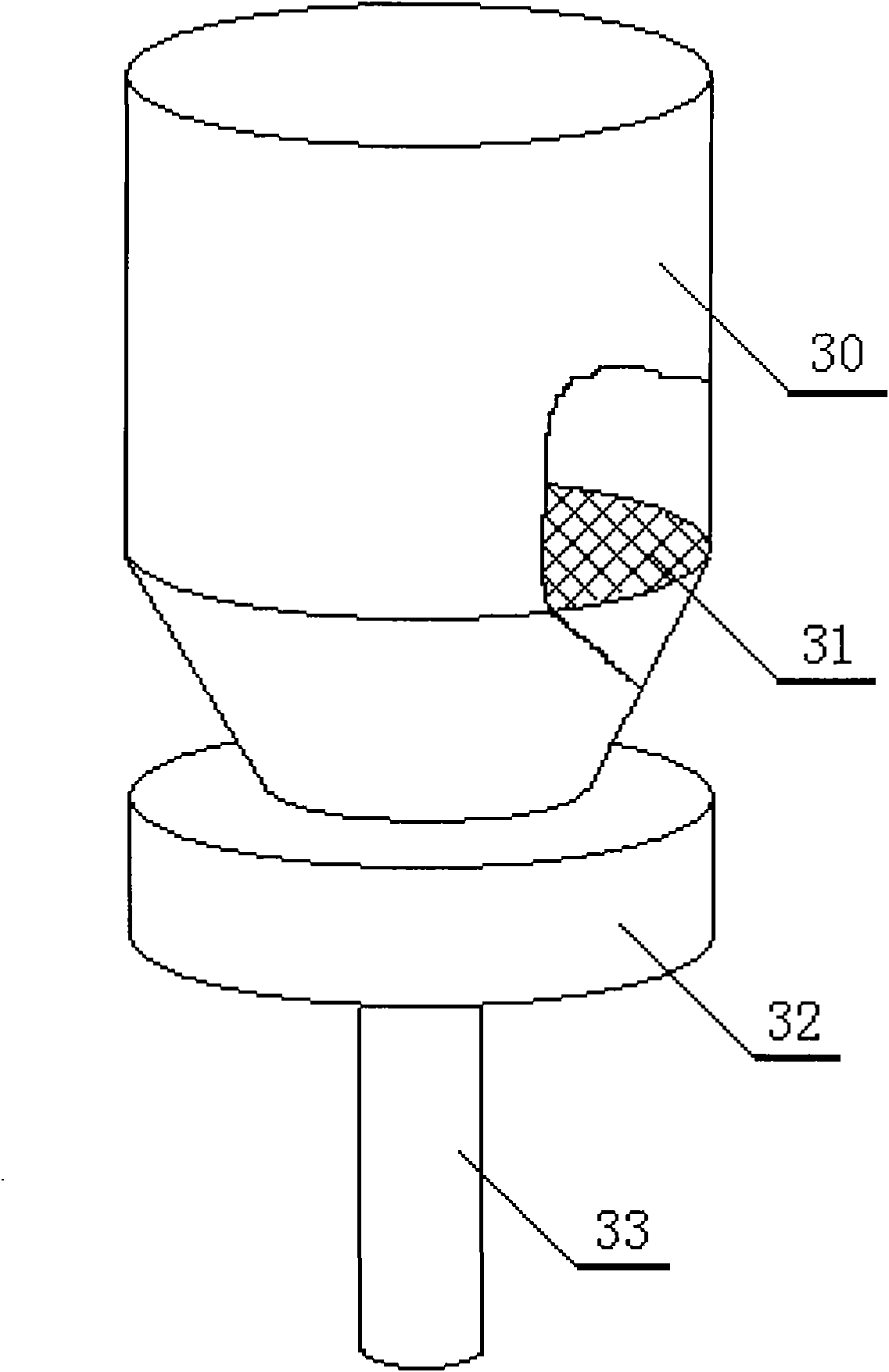

[0033] ① It can evenly sprinkle the hard point material on the molten pool according to the required quantity.

[0034] ②Ability to roll hard materials into the molten pool or firmly stick to the surface of the molten pool.

[0035] ③ It can control the deformation of the clad steel plate during the fusion welding process.

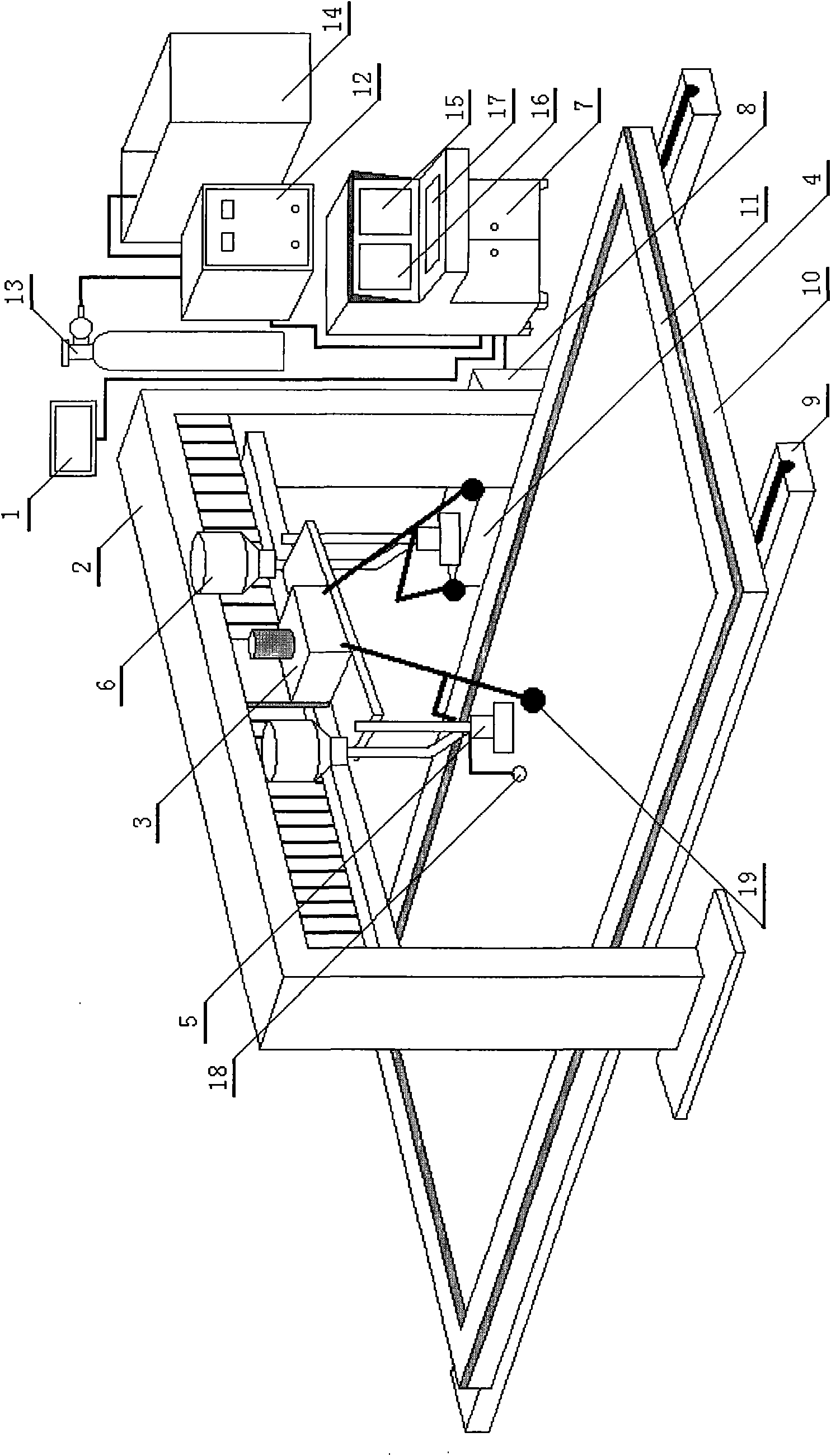

[0036] 1. The design requirements of the special equipment for manufacturing hard point composite steel plates of the present invention:

[0037] ① It can control and adjust the process parameters of fusion welding clad steel plate; it can realize the automatic production process of hard point clad steel plate.

[0038] ②Meet the specifications and dimensions of composite steel plates: thickness: 4mm-200mm; width: 10mm-2000mm; length: 100mm-3000mm.

[0039] ③ It can be applied to a variety of automatic welding methods and supporting corresponding welding equipment.

[0040] ④ It can directly melt the base ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com