Manufacturing method of Aluminumaluminum-plastic plate engraving artwork manufacturing method and finished products thereof

A manufacturing method and technology of aluminum-plastic panels, applied in the field of handicrafts, can solve the problems of weak three-dimensional effect of handicrafts, simple patterns and patterns, and damage to the main body of aluminum-plastic panels.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

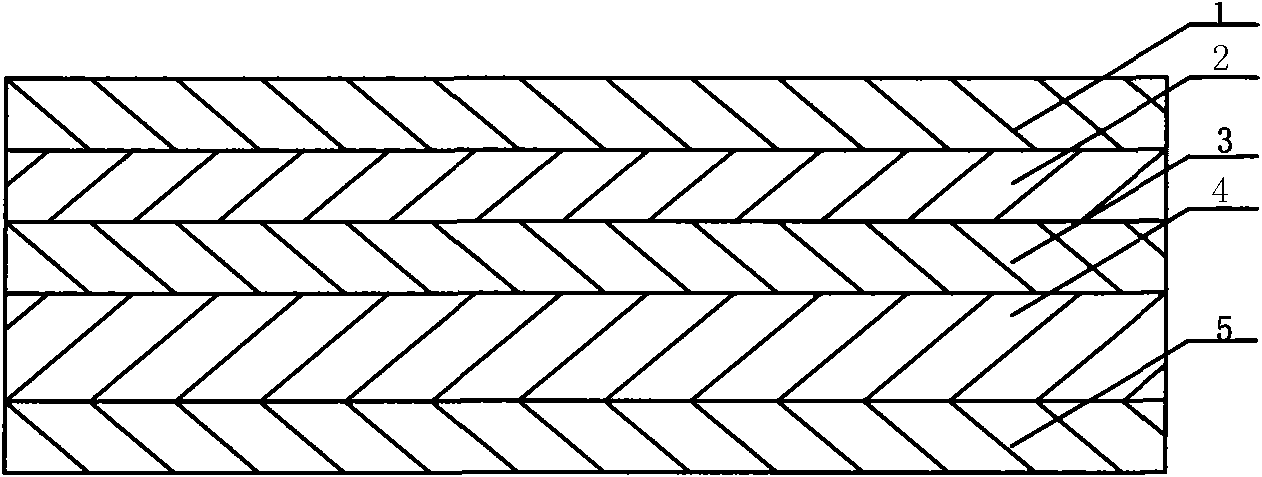

[0021] figure 1 The basic structure of the aluminum-plastic panel shown is composed of a coating 1, a surface color layer 2, an upper aluminum alloy layer 3, a plastic layer 4, and a lower aluminum alloy layer 5 from top to bottom. Wherein the plastic layer 4 is the main support of the whole board. On the basis of not destroying the plastic layer, this process uses a special tool to scrape and carve lines on the surface color layer 2 until the metallic luster of the upper aluminum alloy layer 3 is revealed.

[0022] A method for manufacturing an aluminum-plastic panel handicraft, comprising the following steps:

[0023] 1. Remove the top film of the aluminum-plastic panel to reveal the color of the surface paint;

[0024] 2. Carry the knife manually, use a special knife to scratch the dents in different directions and sequences on the surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com