A water-based roll-spray paint with water washability and high metallic luster and preparation method thereof

A high-metal, water-resistant technology, applied in the field of roller spray paint, can solve the problems of oily roller spray paint, which is not environmentally friendly, and the surface quality of unsafe products, and achieve the effects of less environmental pollution, excellent hiding power, and improved film forming speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

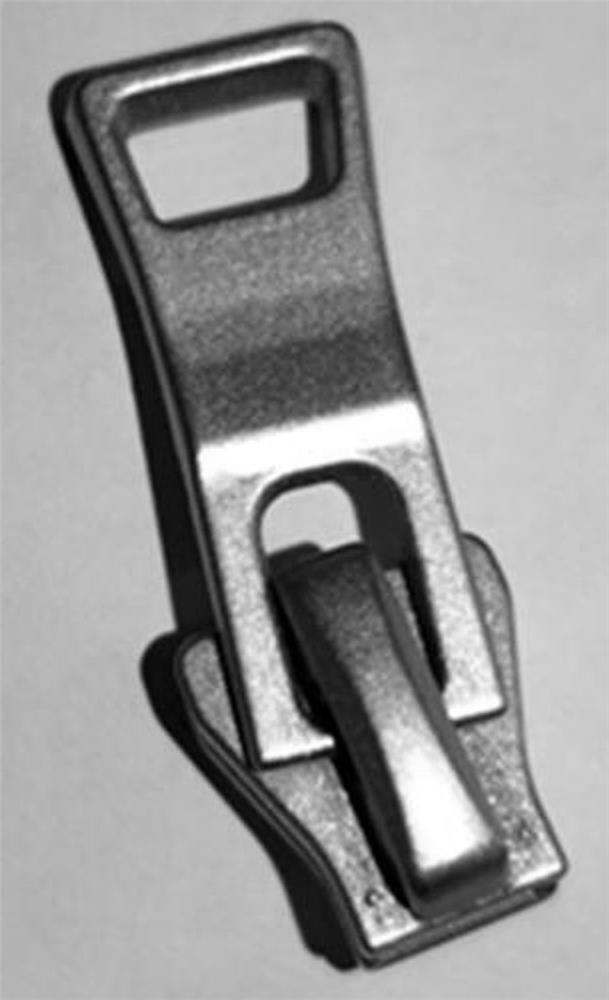

Image

Examples

Embodiment Construction

[0020]The invention will be further described below with reference to the examples.

[0021]The present invention provides a water-resistant, high metal glossy aqueous roll paint, which is mixed by the following weight percentage content: acrylic resin 30% -40%, aqueous polyurethane 7% -9%, aqueous aluminum pigment 7% -9%, water-based transparent color slurry 5% -7%, coupling agent 1% -2%, surface slip agent 1% -2%, diethylene glycol butyl ether 14% -18%, deionized water 25% -33%.

[0022]Wherein, the acrylic resin is a silicone modified acrylic resin; aqueous polyurethane is an anionic aqueous polyurethane; aqueous aluminum pigment is the company's product, there is related patent document disclosure; water-based transparent slurry is a laboratory; coupling agent is silane Coupling agent; surface skilled agent is a fluorinated wax; diethylene glycol butyl ether is purchased in laboratory; deionized water is a pure water machine.

[0023]As needed, different raw materials can be used to prep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com