Preparation method of gravure bronze powder

A technology of copper gold powder and copper block, which is applied in the field of chemical material preparation technology, can solve the problems of weak metallic luster, high oxygen content of copper gold powder, unstable product quality, etc., and achieve high stability of production process and low oxygen content. The effect of low and high fine powder rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

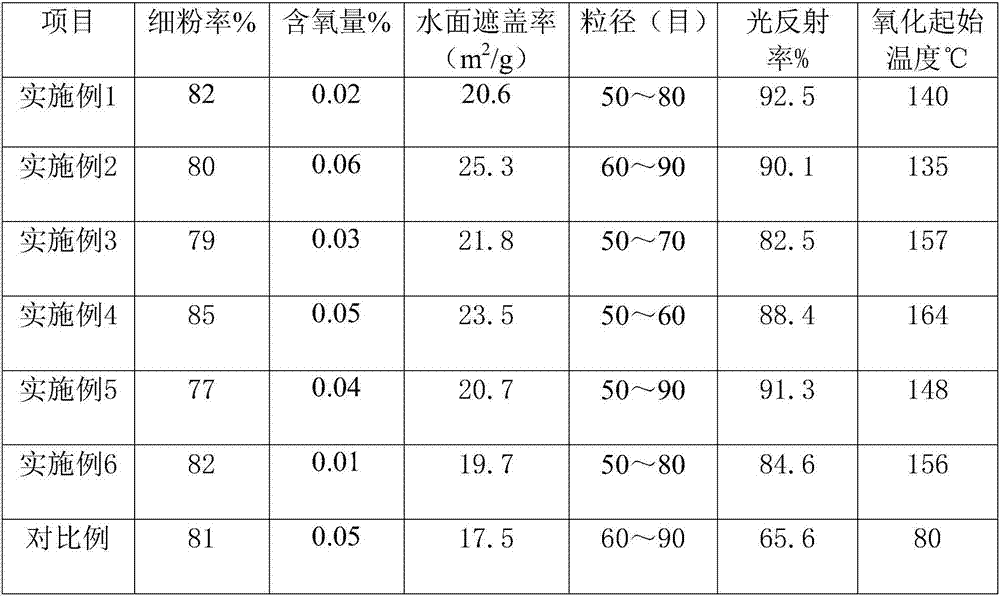

Examples

Embodiment 1

[0022] Step 1: Weigh raw materials: Weigh 85kg copper block, 10kg zinc block and 5kg aluminum block;

[0023] Step 2: Melting of raw materials: first place the zinc block and 0.03kg of sodium metal in a melting furnace and heat to 450°C to completely melt the zinc block, then preheat the aluminum block and 0.015kg of sodium metal at 500°C and add them to the melting furnace and add 0.05kg of sodium bicarbonate, raise the temperature of the furnace to 750°C to completely melt the aluminum block, then preheat the copper block and 0.255kg of sodium metal at 800°C and add to the melting furnace, and add 0.45kg of carbonic acid Sodium hydrogen, raise the temperature of the smelting furnace to 1250°C to completely melt the copper block to obtain a molten metal mixture.

[0024] Step 3: Water atomization powder making: Atomization is carried out twice, the nozzle used for the second atomization is located 0.5cm below the nozzle used for the first atomization, and the spray top angle ...

Embodiment 2

[0030] Step 1: Weigh raw materials: Weigh 70kg copper block, 25kg zinc block and 5kg aluminum block;

[0031] Step 2: Melting of raw materials: first place the zinc block and 0.15kg of sodium metal in a melting furnace and heat to 500°C to completely melt the zinc block, then preheat the aluminum block and 0.03kg of sodium metal at 600°C and add them to the melting furnace and add 0.07kg of sodium bicarbonate, raise the temperature of the furnace to 800°C to completely melt the aluminum block, then preheat the copper block and 0.42kg of sodium metal at 900°C and add to the melting furnace, and add 0.63kg of carbonic acid Sodium hydrogen, raise the temperature of the smelting furnace to 1300°C to completely melt the copper block to obtain a molten metal mixture.

[0032] Step 3: Water atomization powder making: Atomization is carried out twice, the nozzle used for the second atomization is located 0.8cm below the nozzle used for the first atomization, and the spray top angle is...

Embodiment 3

[0038] Step 1: Weigh raw materials: Weigh 75kg copper block, 24kg zinc block and 1kg aluminum block;

[0039] Step 2: Melting of raw materials: first place the zinc block and 0.168kg of sodium metal in a melting furnace and heat to 520°C to completely melt the zinc block, then preheat the aluminum block and 0.007kg of metal sodium at 630°C and add them to the melting furnace and add 0.05kg of sodium bicarbonate, raise the temperature of the furnace to 780°C to completely melt the aluminum block, then preheat the copper block and 0.525kg of sodium metal at 850°C and add to the melting furnace, and add 0.45kg of carbonic acid Sodium hydrogen, raise the temperature of the smelting furnace to 1280°C to completely melt the copper block to obtain a molten metal mixture.

[0040] Step 3: Water atomization powder making: Atomization is carried out twice, the nozzle used for the second atomization is located 0.9cm below the nozzle used for the first atomization, and the spray top angle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com