Metal glaze as well as preparation method and application method thereof

An application method, the technology of metal glaze, applied in the field of ceramic glaze, can solve the problems of difficult appearance of metal luster, poor stability of metal effect, poor metal effect, etc., and achieve the effect of improving the excellent rate, showing stability, and reducing crystallization conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

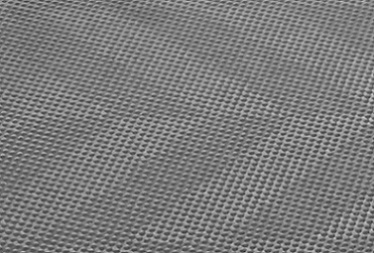

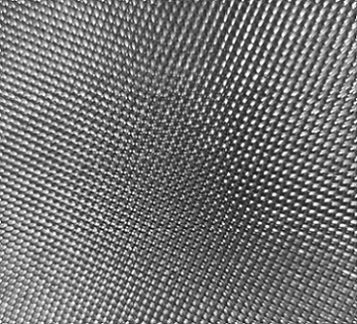

Image

Examples

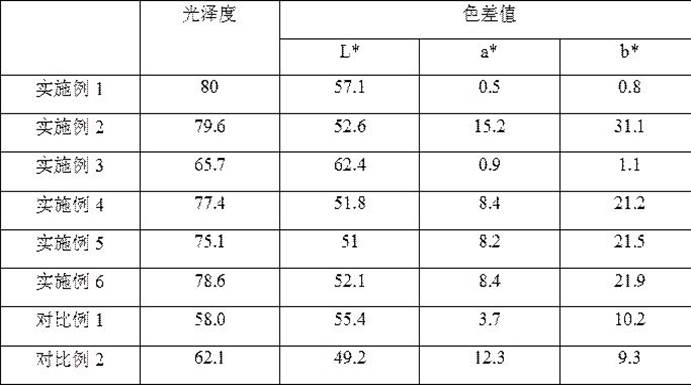

Embodiment 1

[0047] A kind of metallic glaze of the present embodiment, the weight percent of its each raw material is:

[0048] Albite 37%, quartz 15%, wollastonite 2%, calcined kaolin 9%, calcined zinc oxide 4%, calcined iron phosphate 19%, self-made high phosphorus frit powder 14%.

[0049] Among them, the weight percentage of each raw material in the self-made high phosphorus frit powder is: aluminum dihydrogen phosphate 40%, phosphate rock powder 15%, sodium carbonate 12%, calcined kaolin 9%, potassium carbonate 13%, alumina 11%.

[0050] The preparation method of this metallic glaze comprises the following steps:

[0051] Step S11, preparing self-made high-phosphorus frit powder: weighing according to the above formula of self-made high-phosphorus frit powder, mixing the weighed raw materials evenly in a mixer, and then melting in a high-temperature frit furnace, the melting process The heating rate in the medium is 10°C / min, the maximum temperature is 1000°C, and the holding time i...

Embodiment 2

[0057] A kind of metallic glaze of the present embodiment, the weight percent of its each raw material is:

[0058] Albite 35%, quartz 8%, wollastonite 4%, calcined kaolin 11%, calcined zinc oxide 4%, calcined iron phosphate 23%, self-made high phosphorus frit powder 15%.

[0059] Among them, the weight percentage of each raw material in the self-made high phosphorus frit powder is: aluminum dihydrogen phosphate 48%, phosphate rock powder 10%, sodium carbonate 11%, calcined kaolin 5%, potassium carbonate 12%, alumina 14%.

[0060] The preparation method of this metallic glaze comprises the following steps:

[0061] Step S11, preparing self-made high-phosphorus frit powder: weighing according to the above formula of self-made high-phosphorus frit powder, mixing the weighed raw materials evenly in a mixer, and then melting in a high-temperature frit furnace, the melting process The heating rate in the medium is 10°C / min, the maximum temperature is 1050°C, and the holding time i...

Embodiment 3

[0067] A kind of metallic glaze of the present embodiment, the weight percent of its each raw material is:

[0068] Albite 34%, quartz 10%, calcined kaolin 16%, calcined zinc oxide 4%, calcined iron phosphate 23%, homemade high phosphorus frit powder 13%.

[0069] Among them, the weight percentage of each raw material in the self-made high phosphorus frit powder is: aluminum dihydrogen phosphate 30%, phosphate rock powder 25%, sodium carbonate 15%, calcined kaolin 5%, potassium carbonate 15%, alumina 10%.

[0070] The preparation method of this metallic glaze comprises the following steps:

[0071] Step S11, preparing self-made high-phosphorus frit powder: weighing according to the above formula of self-made high-phosphorus frit powder, mixing the weighed raw materials evenly in a mixer, and then melting in a high-temperature frit furnace, the melting process The heating rate in the medium is 10°C / min, the highest temperature is 1060°C, and the holding time is 5h. After stopp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com