Patents

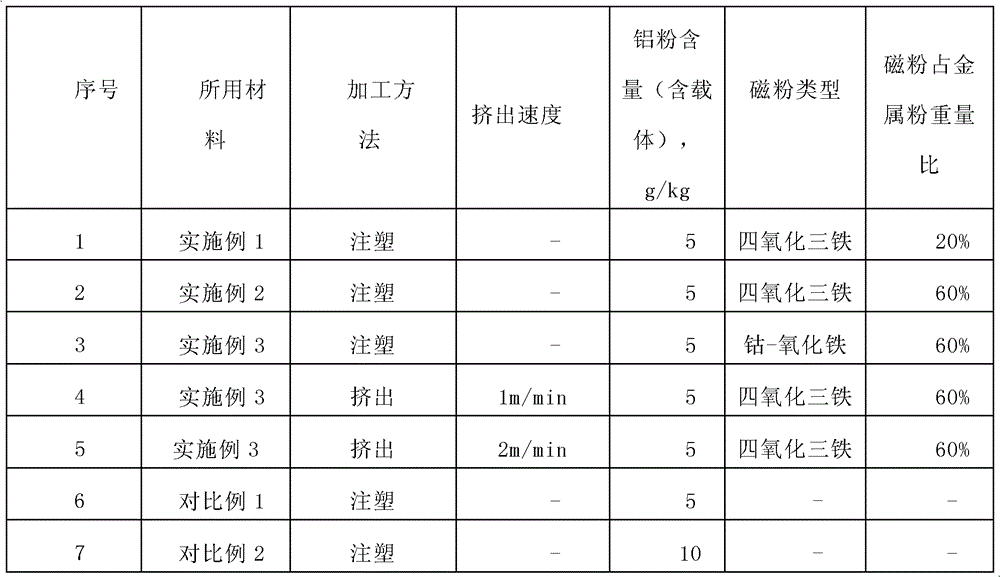

Literature

78results about How to "Improve metal performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

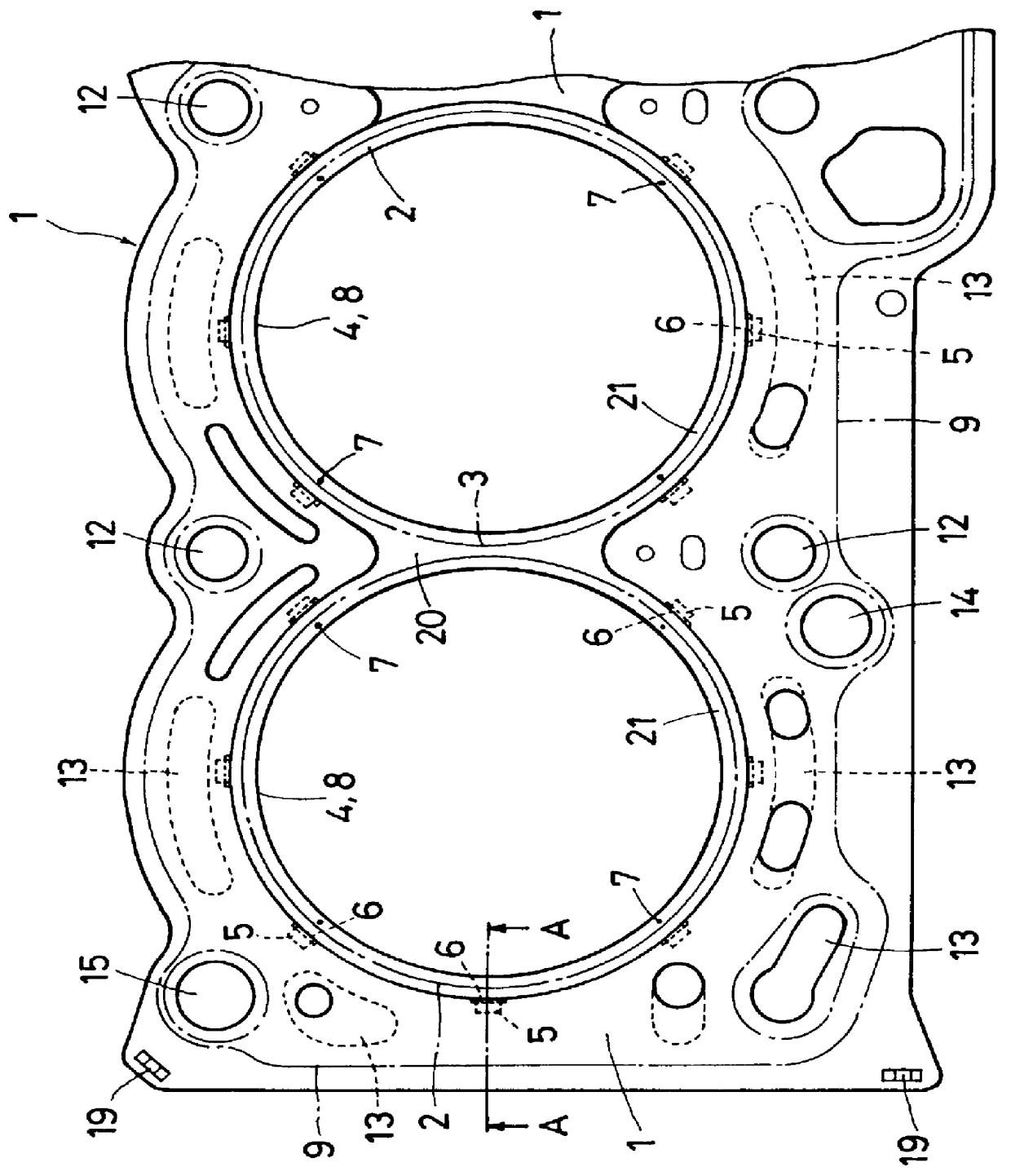

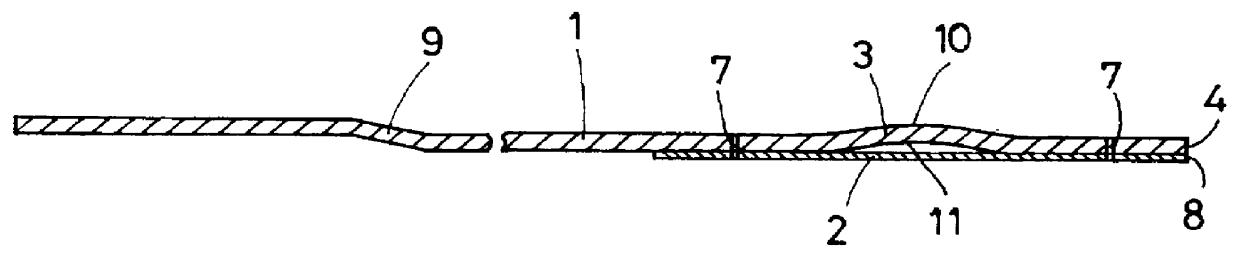

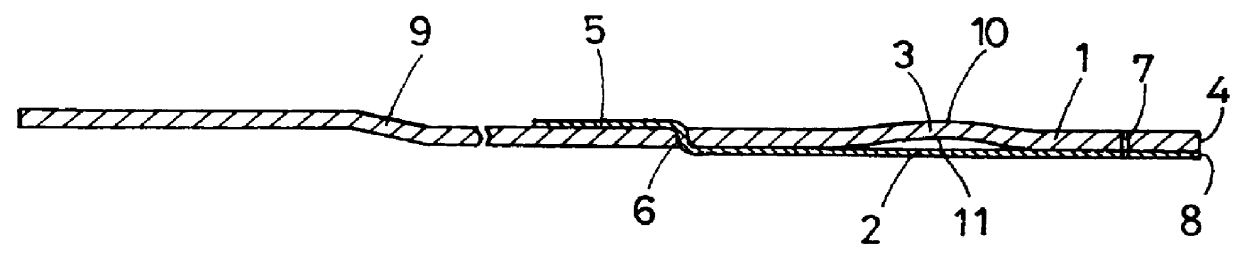

Metal gasket

InactiveUS6027124AImprove sealingImprove balanceEngine sealsSealing arrangements for enginesThin metalCombustion chamber

A metal gasket in which a thin metal plate for reinforcing the beads of an elastic metal plate is laminated on bead regions only of the elastic metal plate, whereby a stable sealing performance is secured for a long period of time. This metal gasket comprises a thin metal plate provided with beads extending around the circumferences of parallel arranged combustion chamber holes, and an elastic metal plate having combustion chamber holes and extending with a predetermined width and laminated on the portions of the thin metal plate which are around the combustion chamber holes so as to be opposed to valley portions of the beads. The thickness of the thin metal plate is set smaller than that of the elastic metal plate. The thin metal plate is fixed to the elastic metal plate with locking portions formed at the outer circumference of the former engaged with slits formed in the regions of the latter which are on the outer sides of the beads, the thin metal plate being combined with the elastic metal plate at joint portions thereof by spot welding or laser welding.

Owner:NIPPON GASKET CO LTD

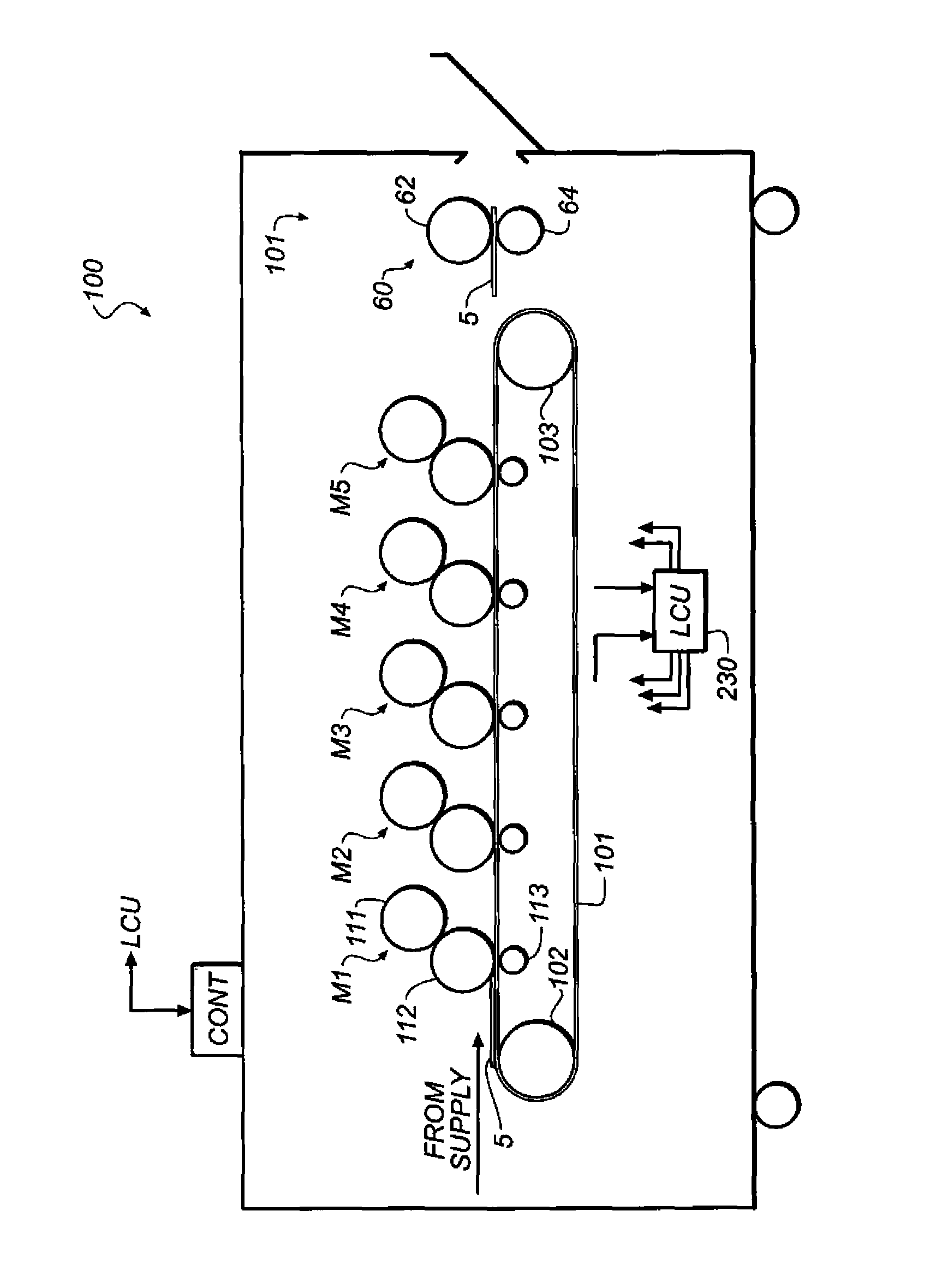

Preparing color toner images with metallic effect

ActiveUS9323169B2Highly uniform dispersionMinimize shearLayered productsDevelopersLatent imageEngineering

A color toner image with a metallic effect can be prepared by forming one or more latent images and developing them with metallic dry toner particles and color toner particles. The developed color toner image can be transferred to a receiver material, and fixed to provide a color toner image with a metallic effect. The metallic dry toner particles have a polymeric binder phase and non-conductive metal oxide particles dispersed therein. Before fixing, the metallic dry toner particle has a mean volume weighted diameter (Dvol) 15-40 μm and the non-conductive metal oxide particles are present in an amount of at least 20-50 weight % based on total metallic dry toner particle weight. The ratio of the metallic dry toner particle Dvol to the average equivalent circular diameter (ECD) of the non-conductive metal oxide particles in the metallic dry toner particles is greater than 0.1 and up to and including 10.

Owner:EASTMAN KODAK CO

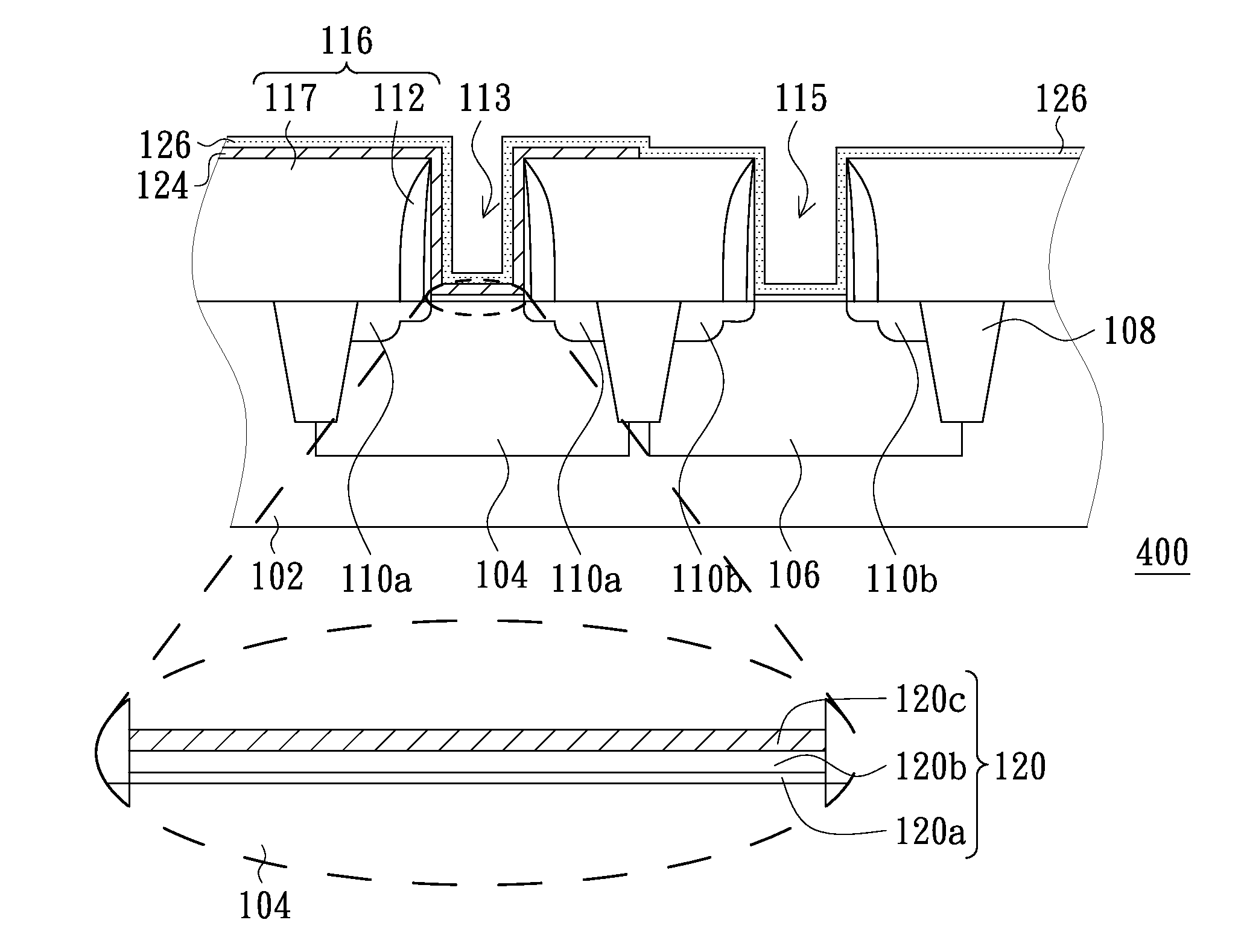

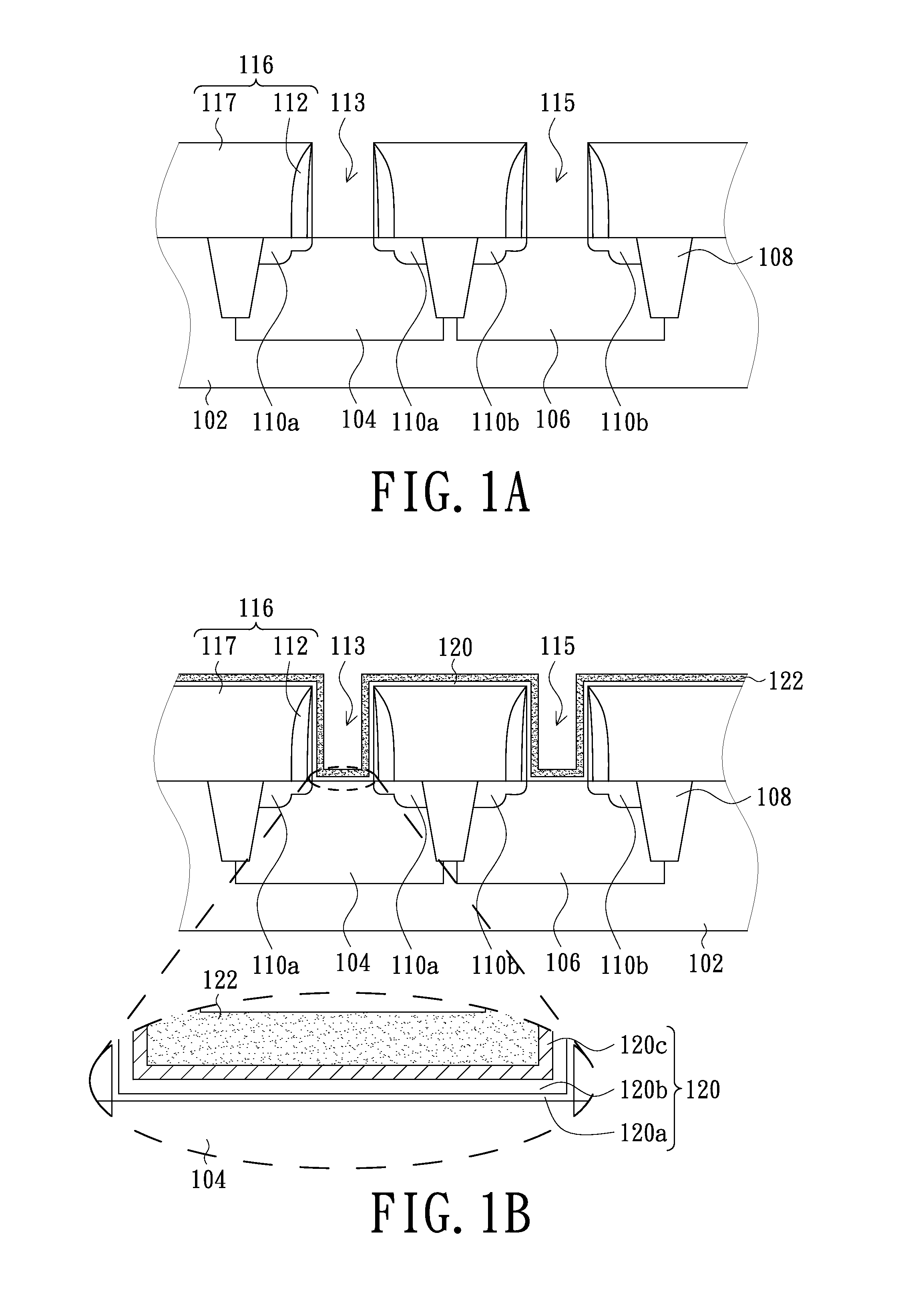

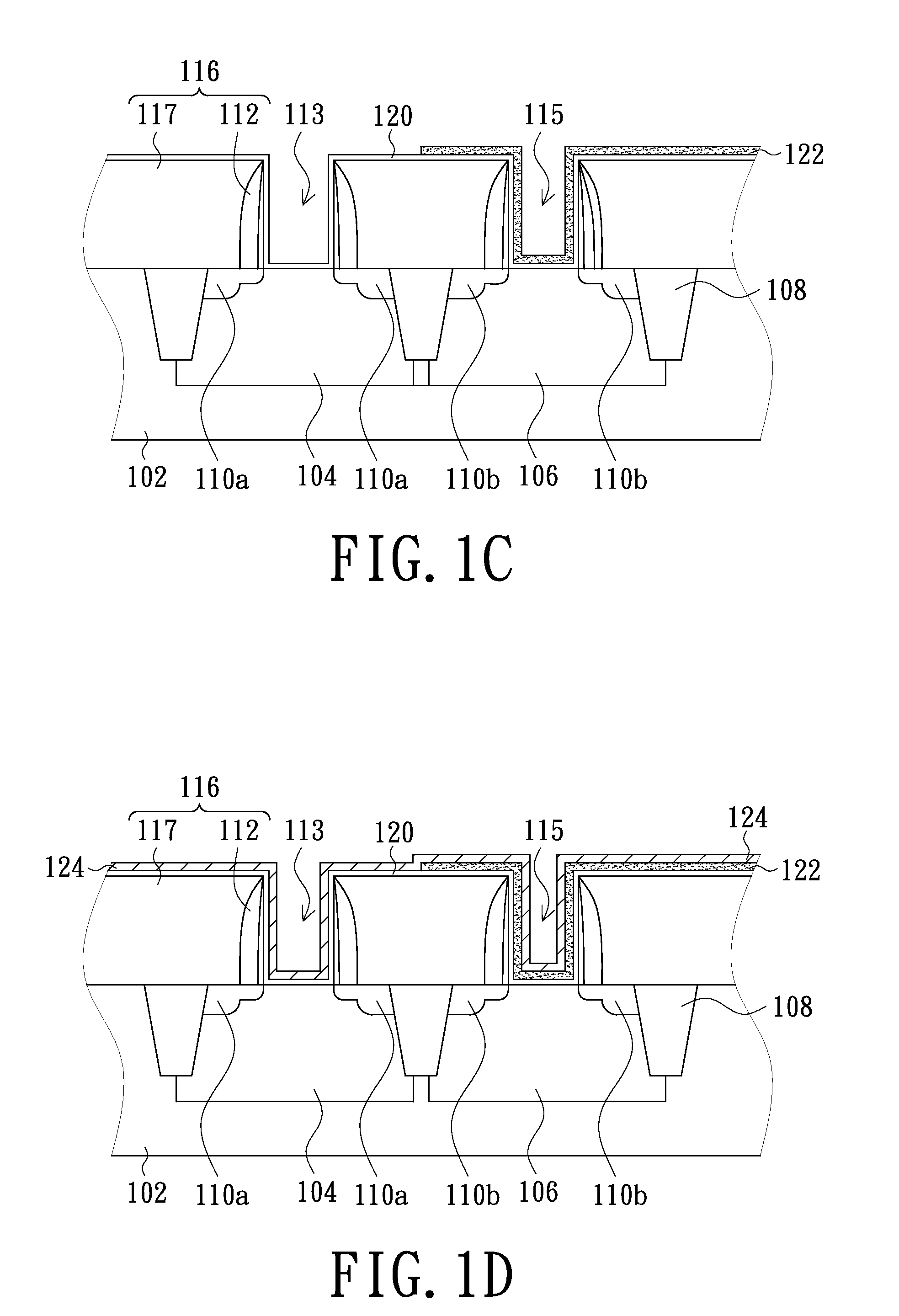

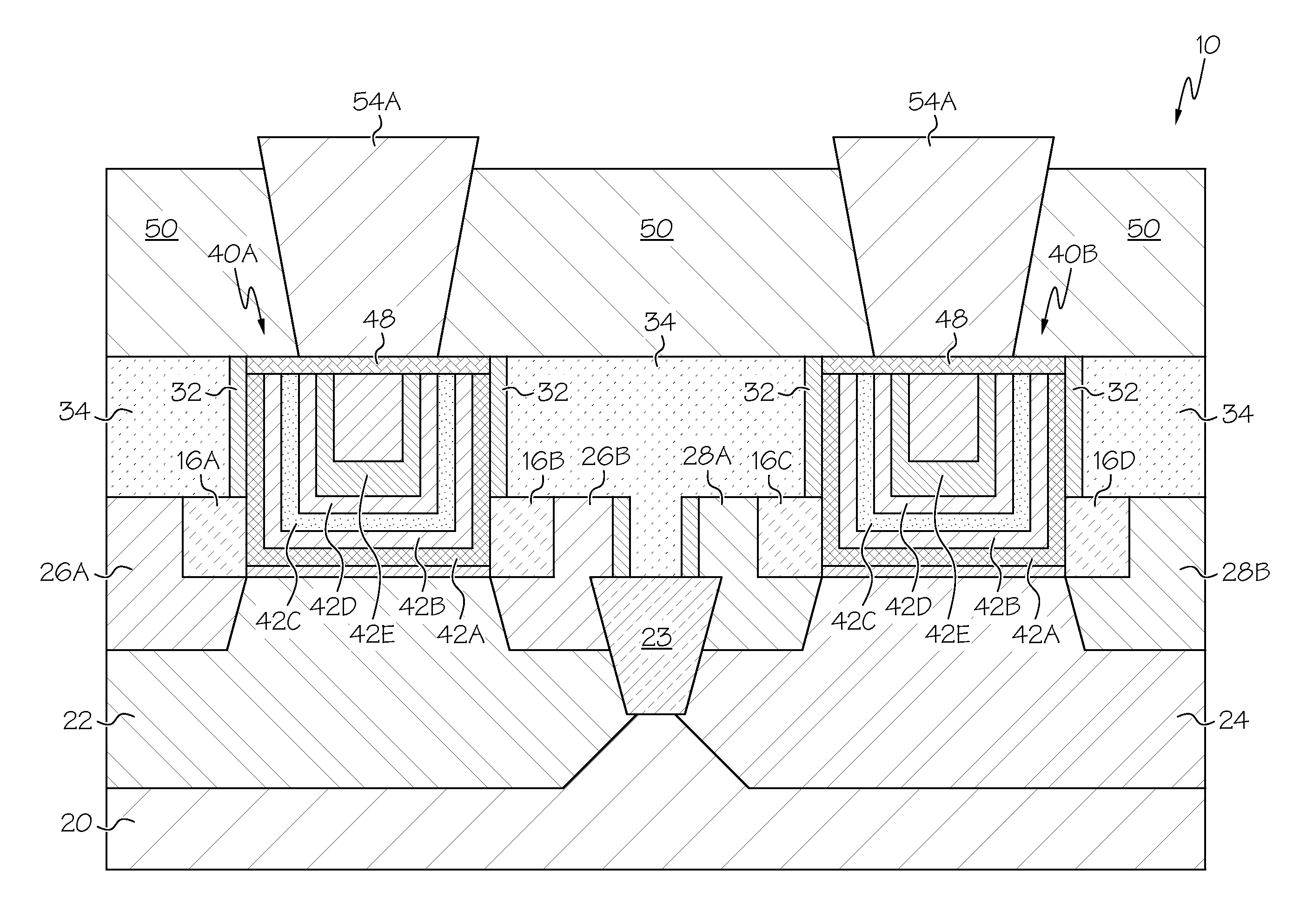

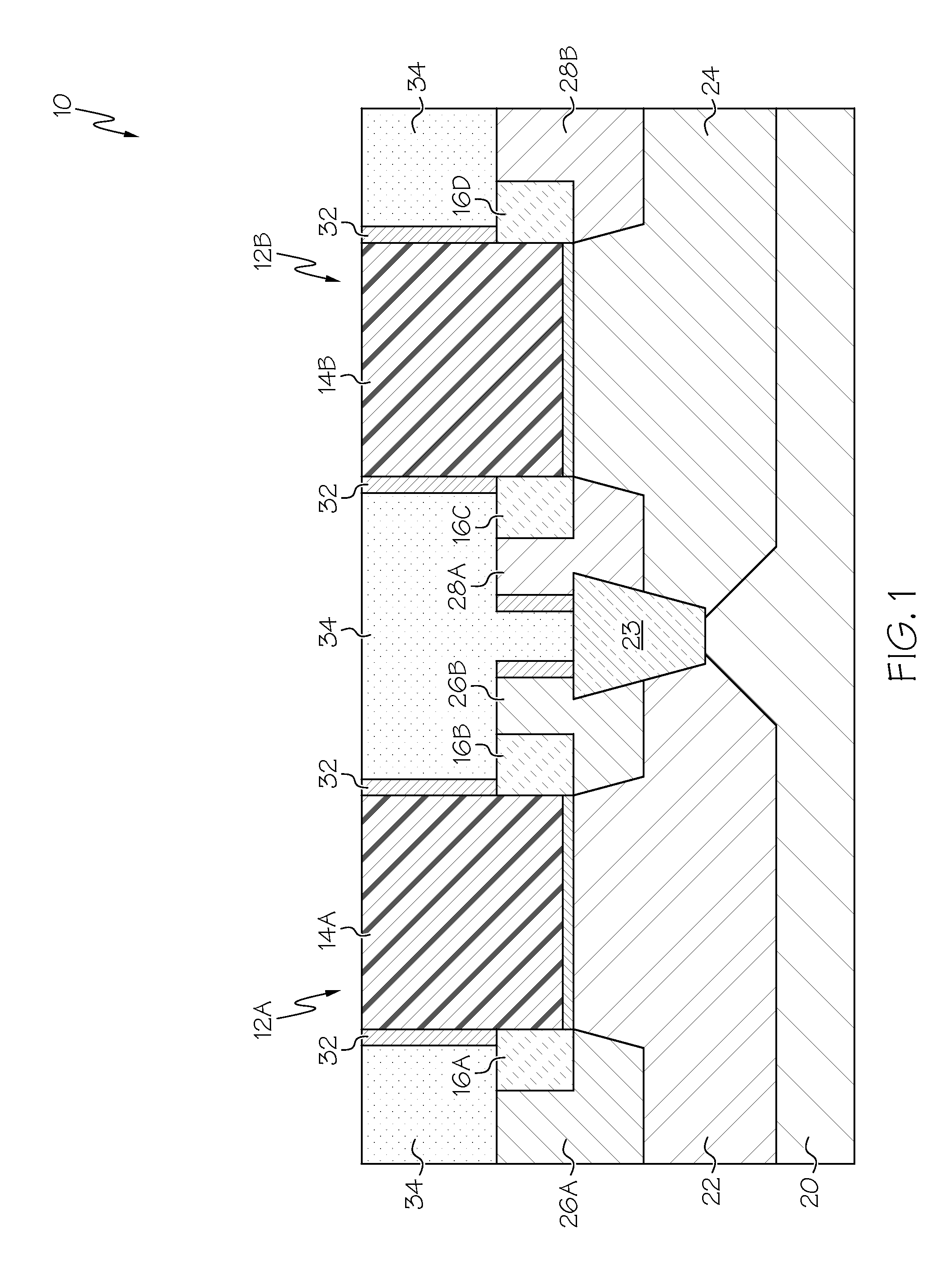

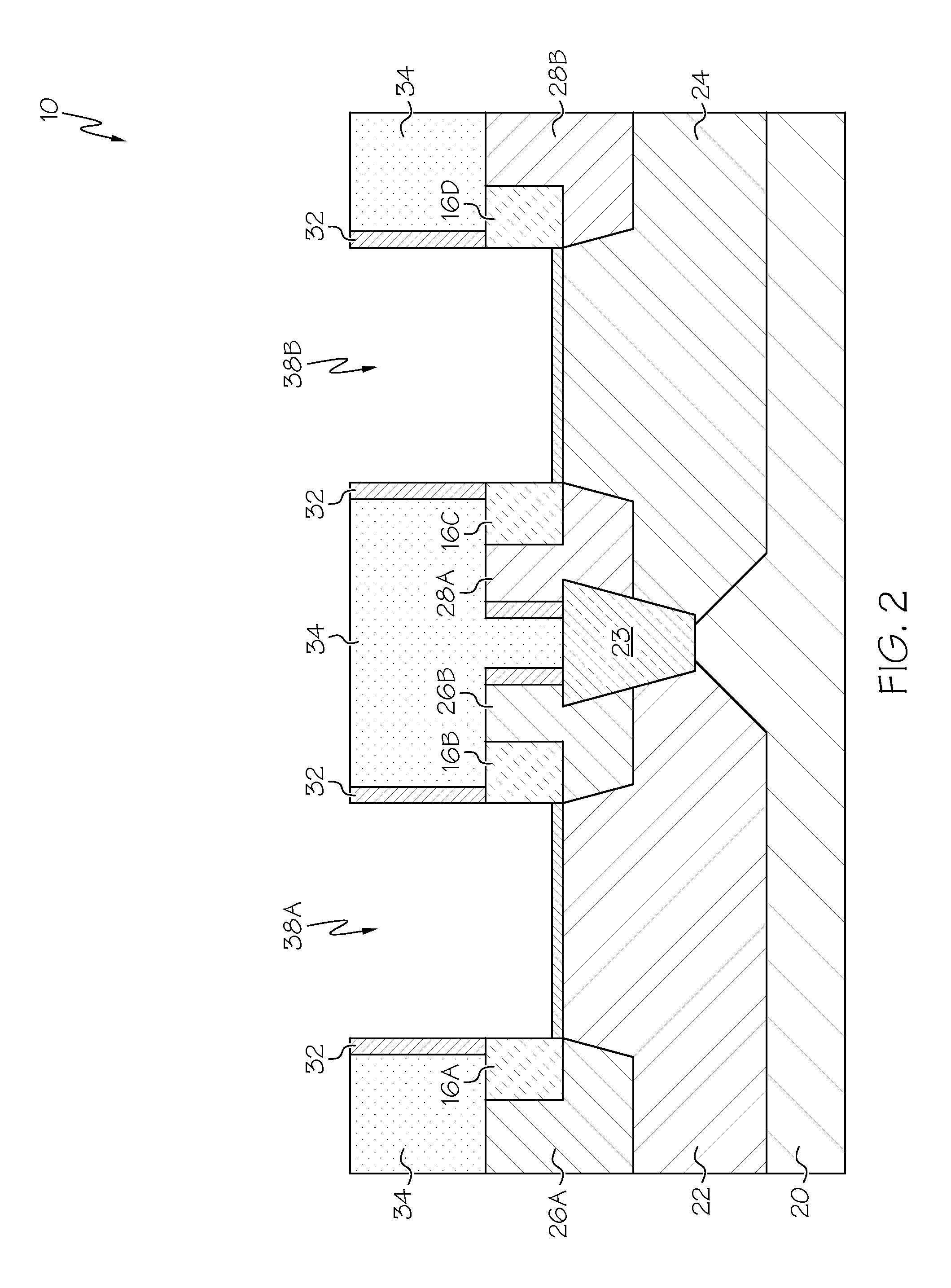

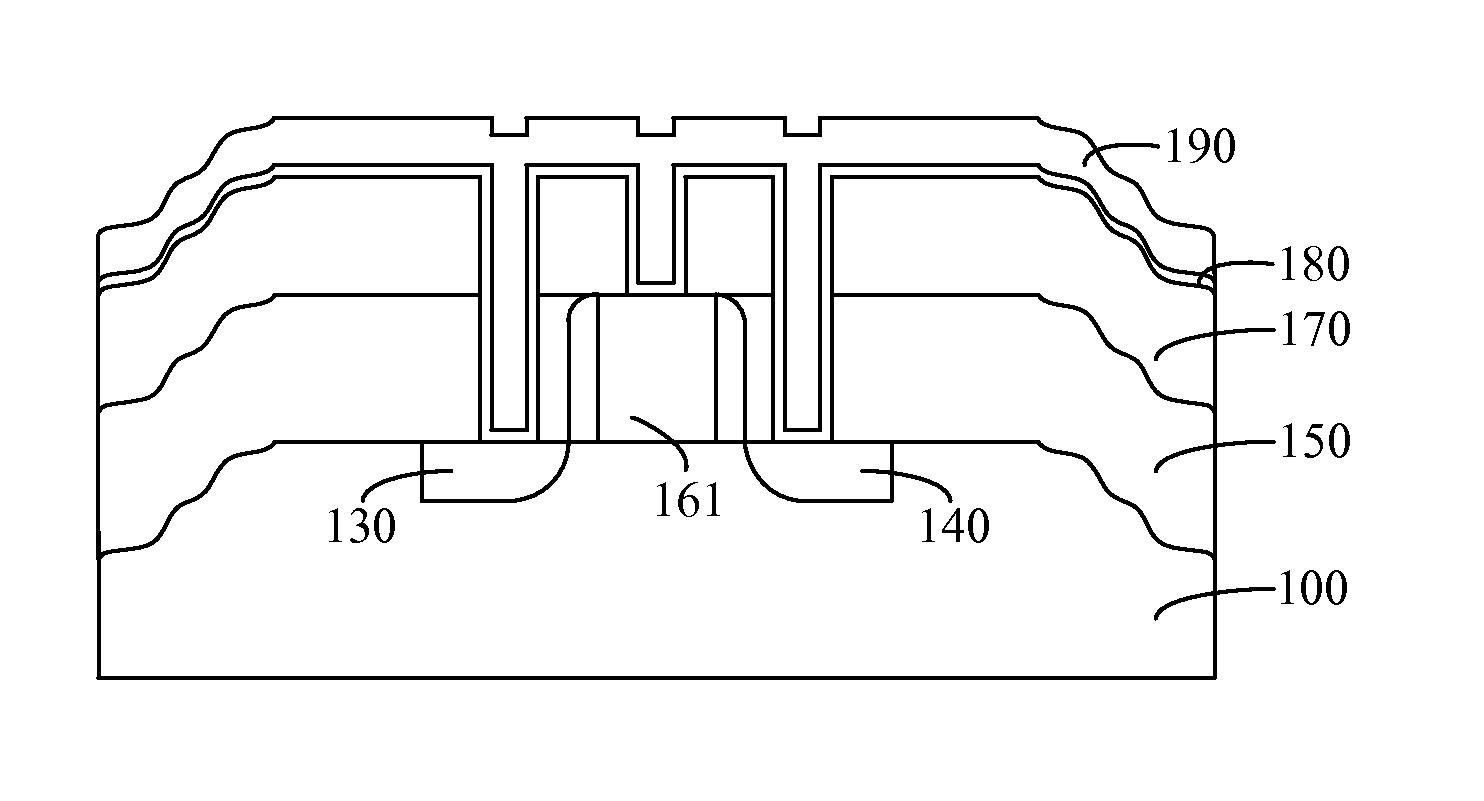

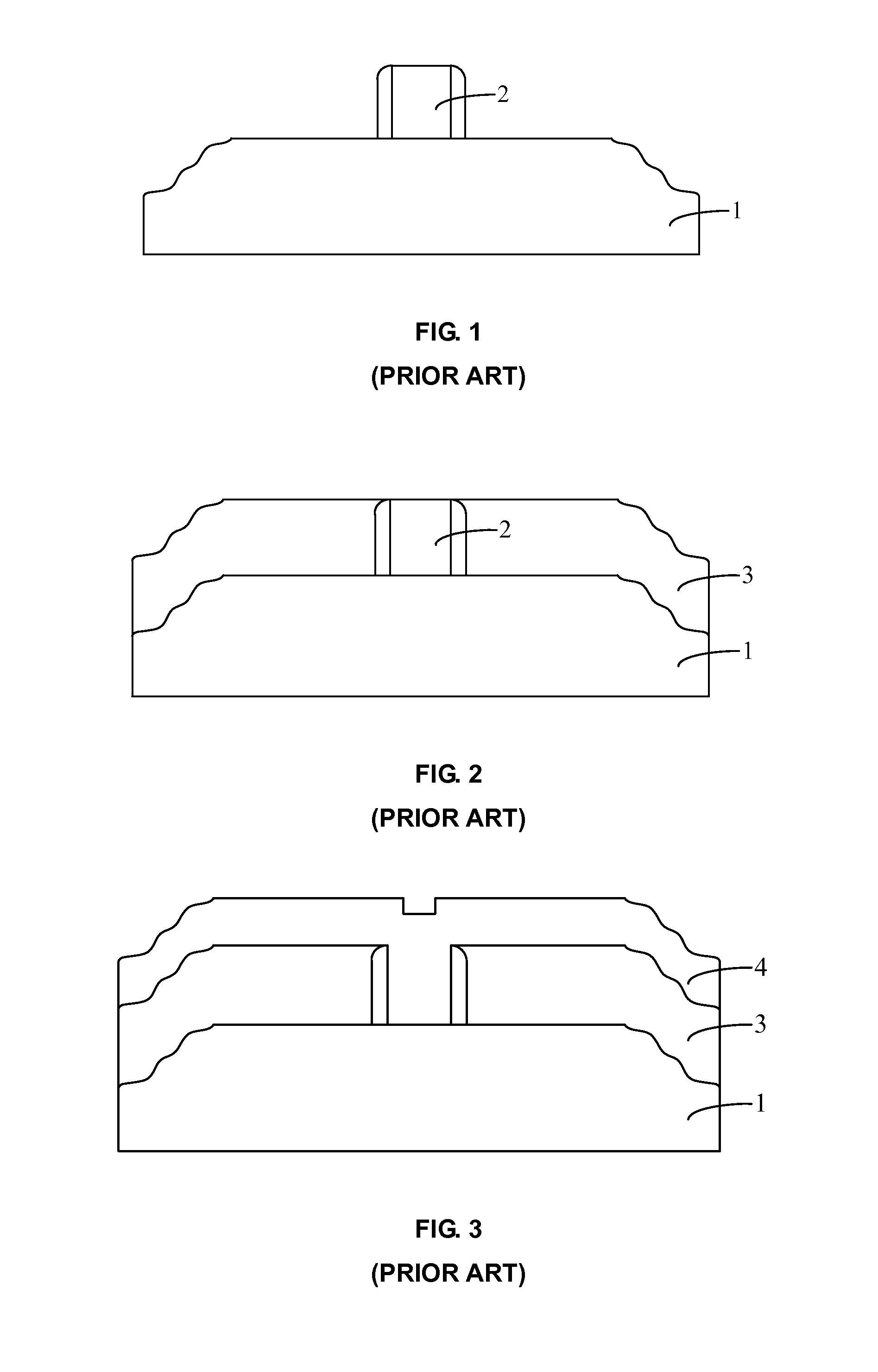

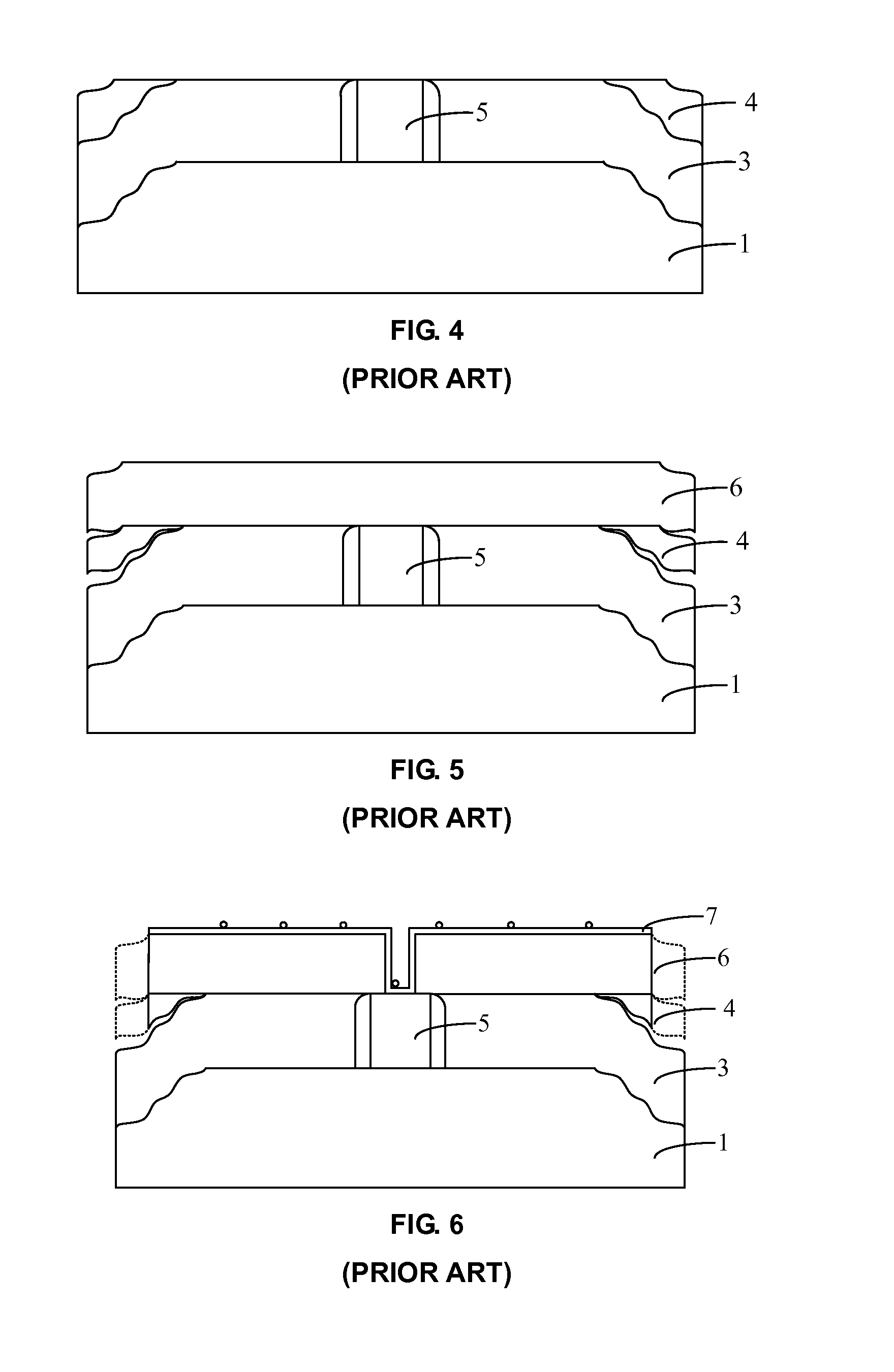

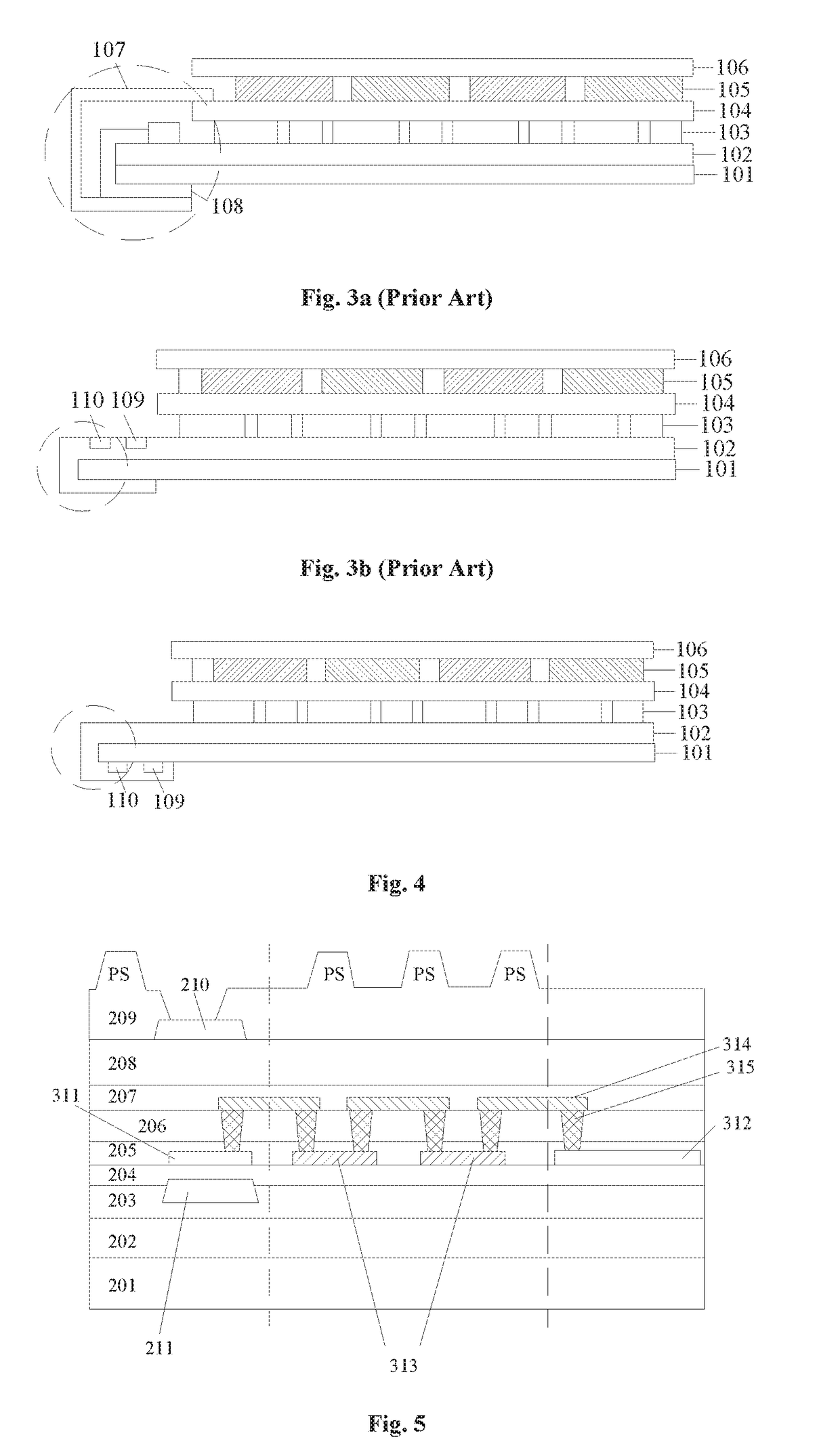

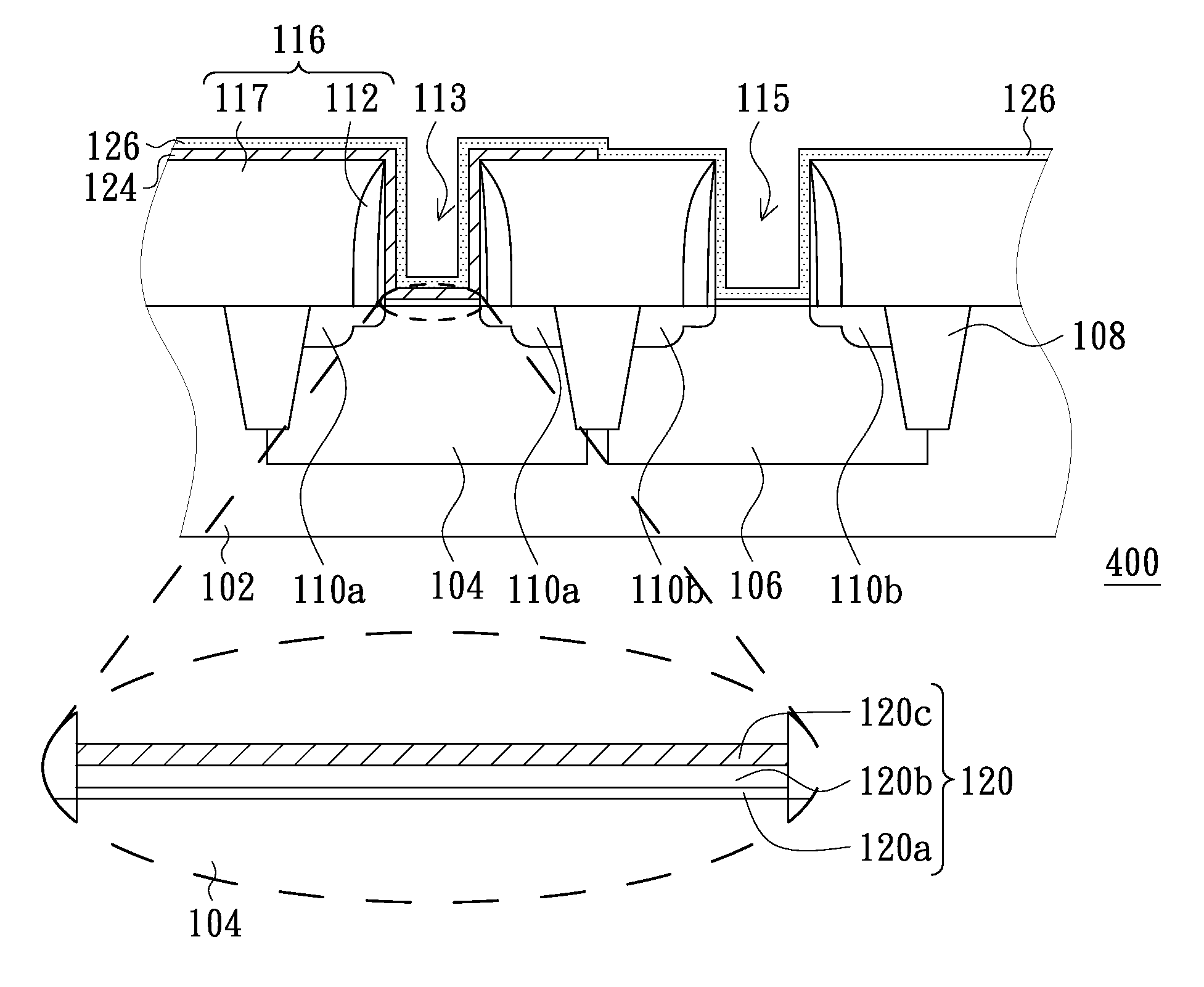

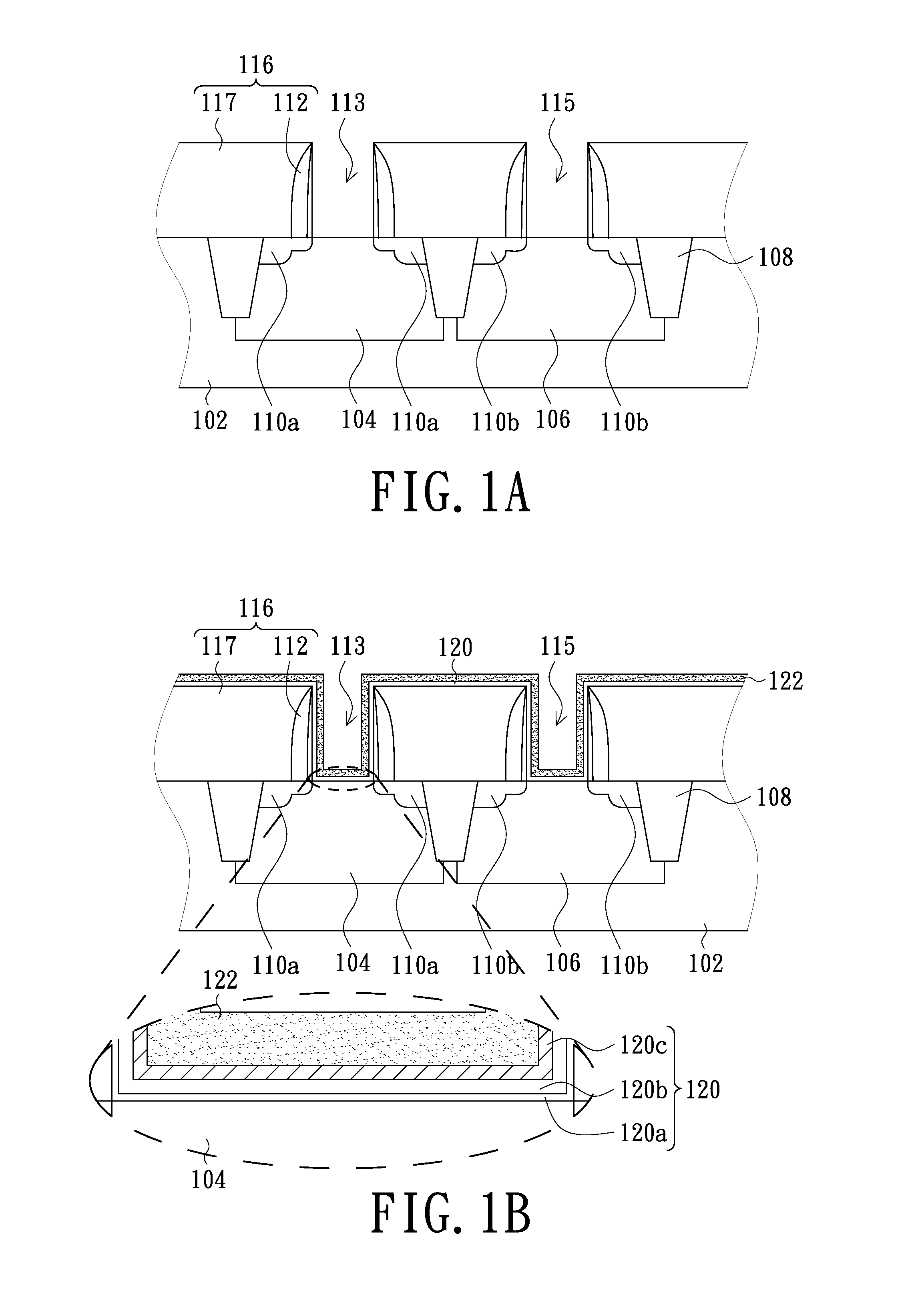

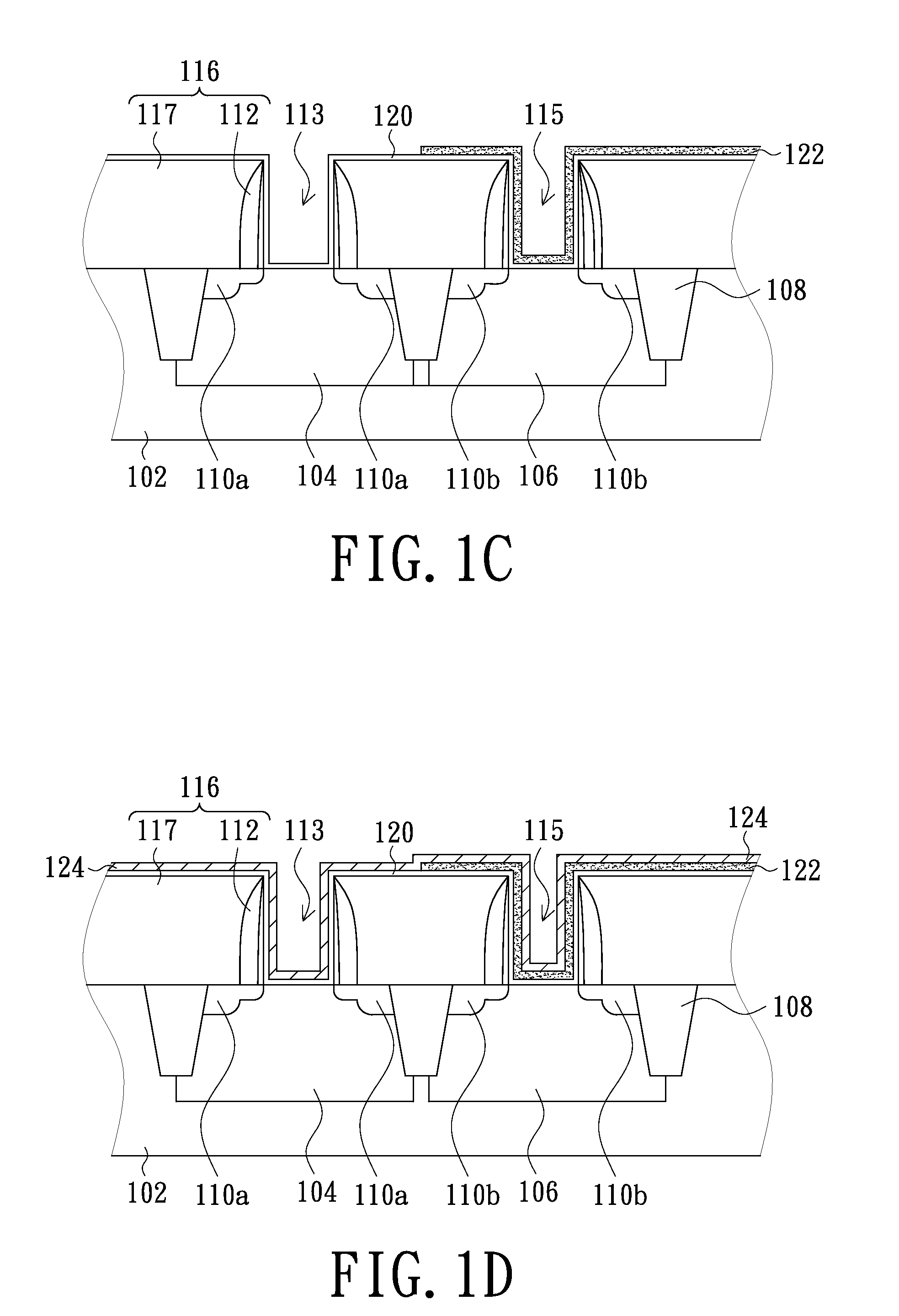

Semiconductor structure and fabricating method thereof

ActiveUS20130037889A1Prevent be damageImproved transistor performanceTransistorSolid-state devicesSemiconductor structureMaterials science

A fabricating method of semiconductor structure is provided. First, a substrate with a dielectric layer formed thereon is provided. The dielectric layer has a first opening and a second opening exposing a portion of the substrate. Further, a gate dielectric layer including a high-k dielectric layer and a barrier layer stacked thereon had been formed on the bottoms of the first opening and the second opening. Next, a sacrificial layer is formed on the portion of the gate dielectric layer within the second opening. Next, a first work function metal layer is formed to cover the portion of the gate dielectric layer within the first opening and the sacrificial layer. Then, the portion of the first work function metal layer and the sacrificial layer within the second opening are removed.

Owner:UNITED MICROELECTRONICS CORP

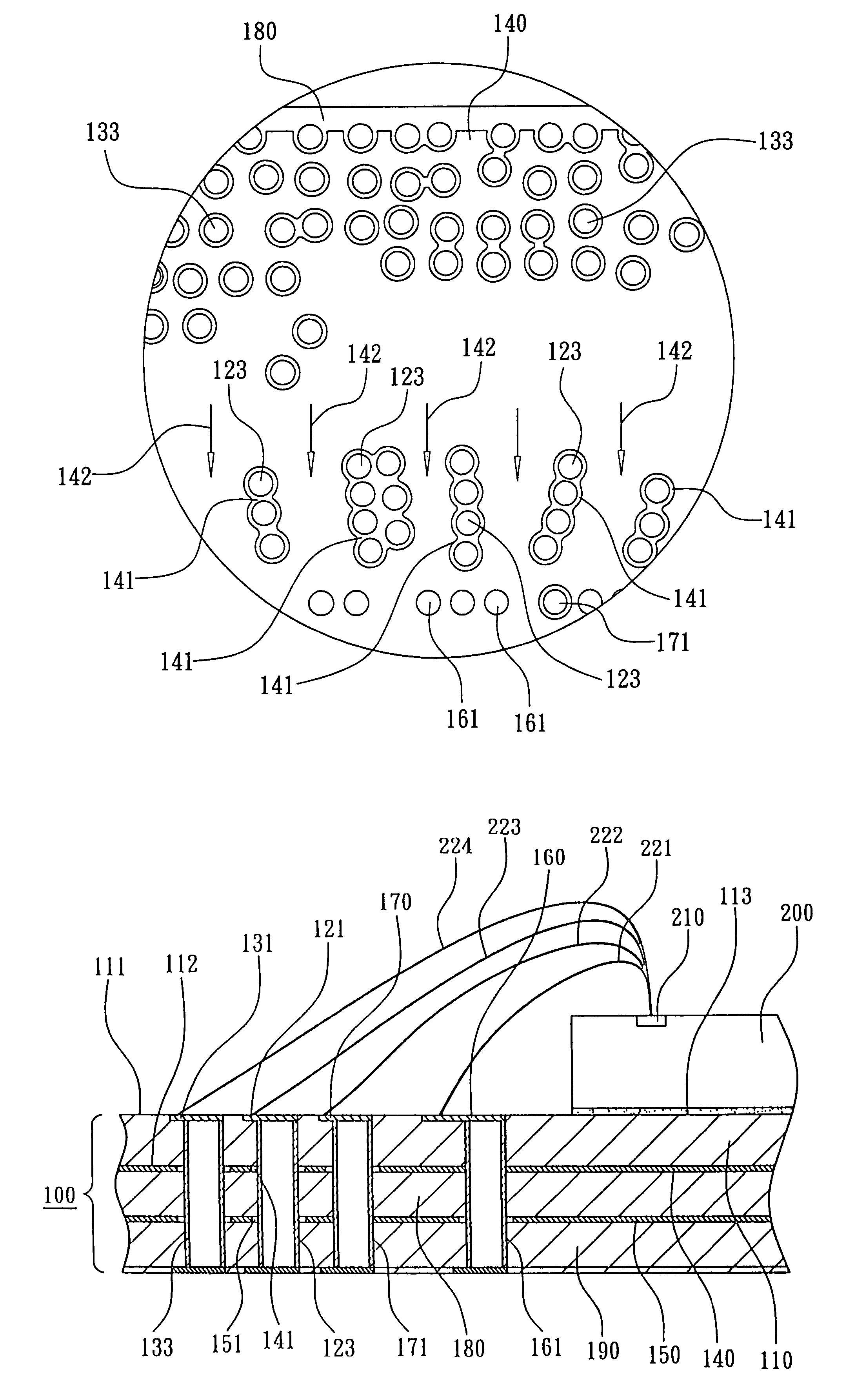

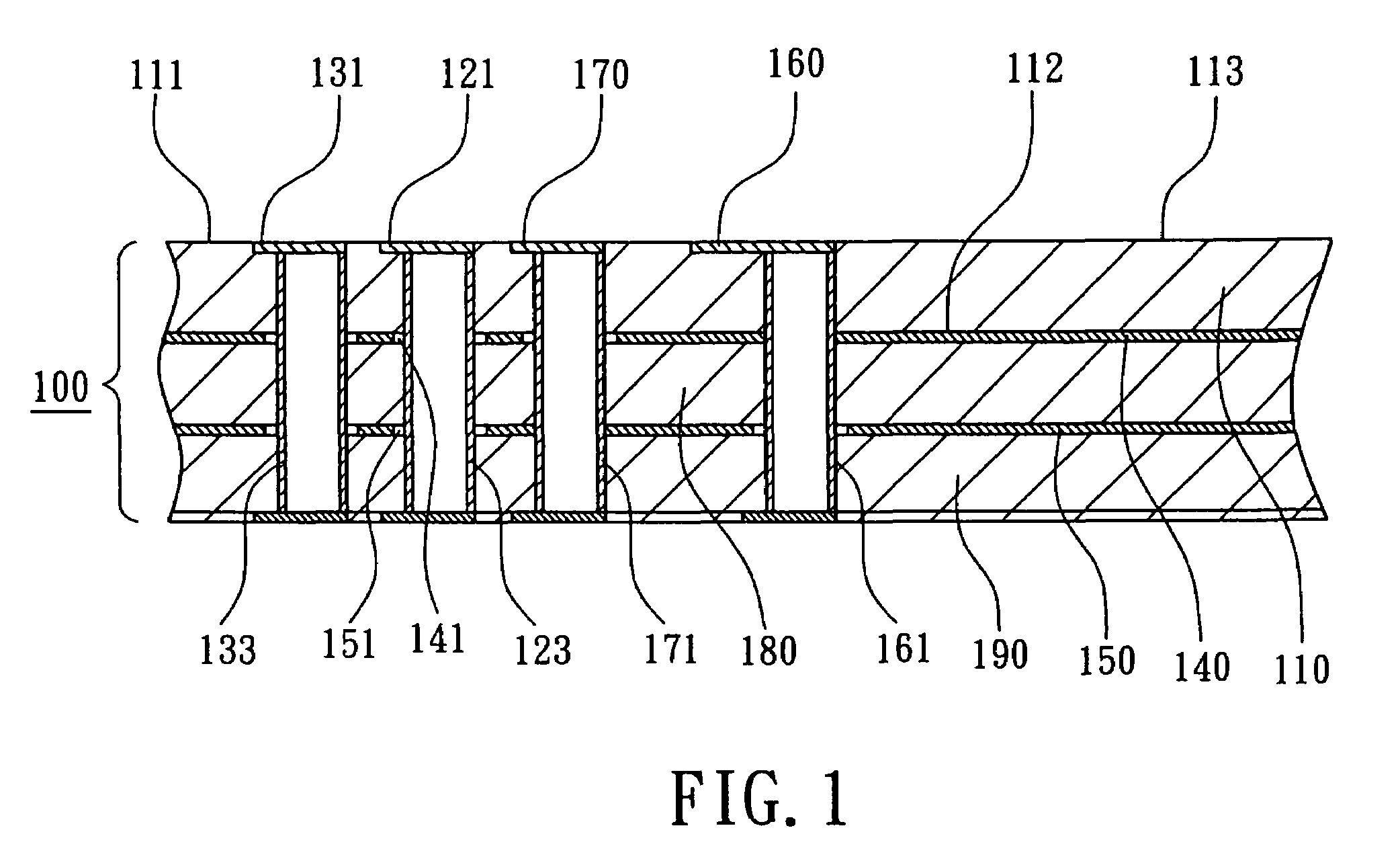

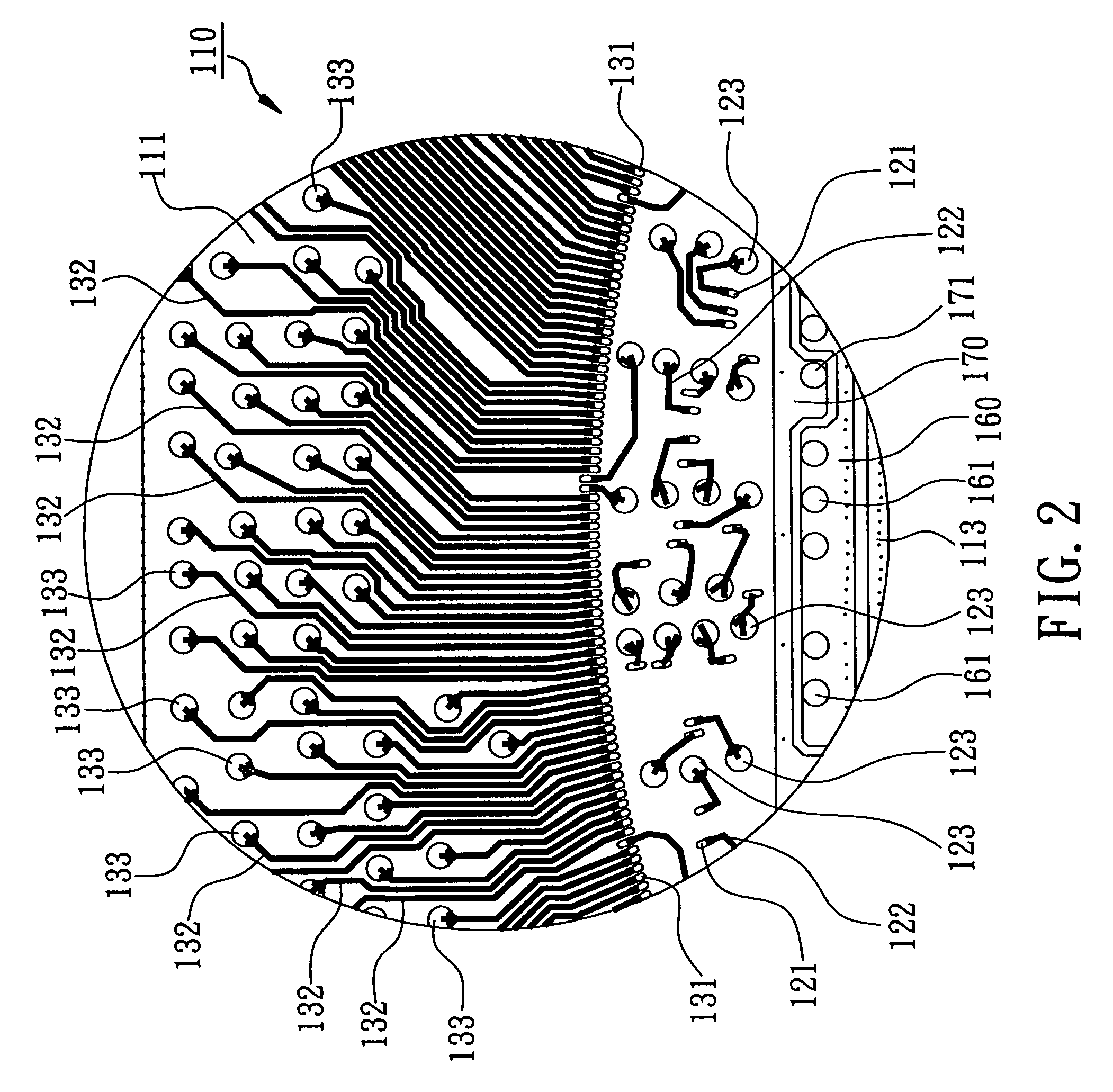

Package substrate for improving electrical performance

ActiveUS6979897B2Well formedThe location is limitedSemiconductor/solid-state device detailsSolid-state devicesElectrical performanceMetal

A package substrate for improving electrical performance includes at least an insulating layer, a wiring layer and a ground / power layer. The wiring layer is formed on a top surface of the insulating layer, and includes a plurality of inner fingers, a plurality of outer fingers and a metal ring. A plurality of inner through holes are formed through the insulating layer to electrically connect corresponding inner fingers to bottom surface of the insulating layer. The ground / power layer has a plurality of openings formed on a bottom surface of the insulating layer. The plurality of inner through holes are crowded in groups to pass through the openings which are electrically isolated from the ground / power layer. Each group of the inner through holes are arranged in grid array or radial arrangement so that a distance between two adjacent openings not less than 0.2 mm for improving electrical performance of the ground / power layer.

Owner:ADVANCED SEMICON ENG INC

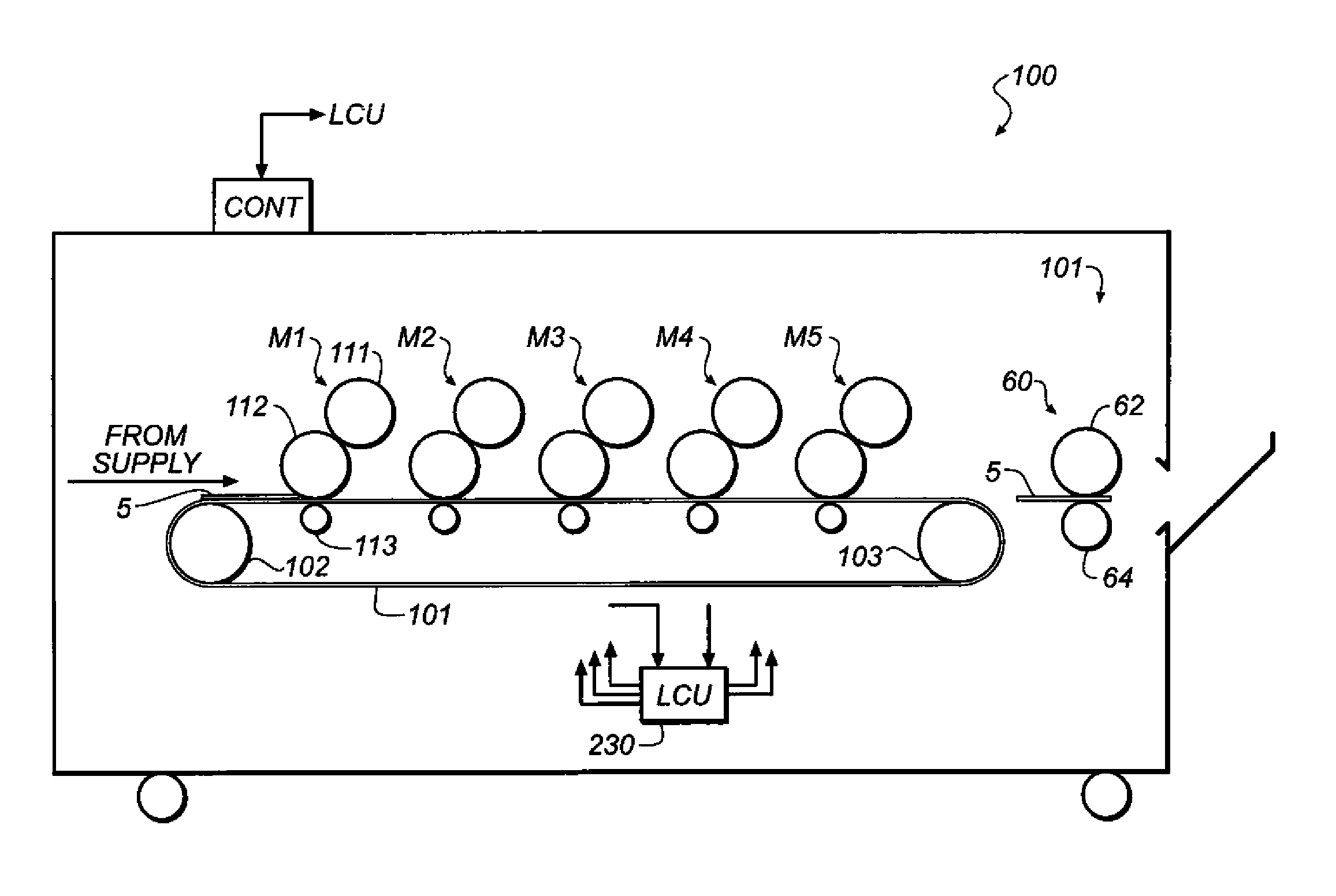

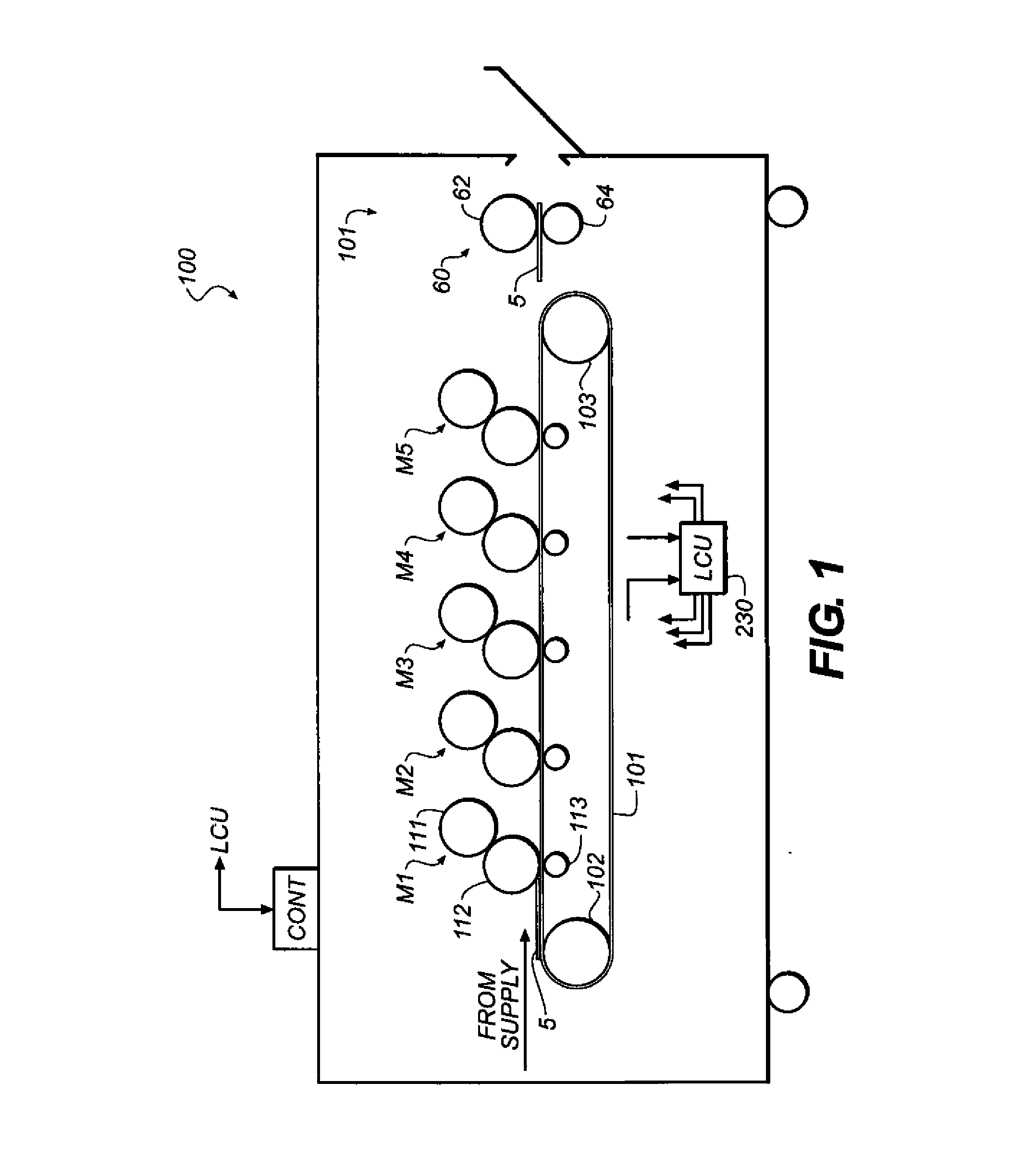

Preparing toner images with metallic effect

InactiveUS20130295502A1Enhance original colorHigh glossDevelopersElectrographic process apparatusLatent imagePolymer

A method is used to provide a toner image with a metallic effect. After forming a latent image, it is developed with metallic dry toner particles to form a developed toner image that is transferred and fixed to a receiver material. Each metallic dry toner particle consists essentially of a polymeric binder phase and non-conductive metal oxide particles. Before fixing, the metallic dry toner particle has a mean volume weighted diameter (Dvol) of at least 15 μm and up to and including 40 μm. The non-conductive metal oxide particles are present in an amount of 20-50 weight %. The ratio of the metallic dry toner particle Dvol to the average equivalent circular diameter (ECD) of the non-conductive metal oxide particles in the metallic dry toner particles, before fixing, is greater than 0.1 and up to and including 10.

Owner:EASTMAN KODAK CO

De-oxidation of metal gate for improved gate performance

ActiveUS20150270142A1Improve metal performanceTransistorSemiconductor/solid-state device manufacturingField-effect transistorImproved performance

Aspects of the present invention relate to approaches for forming a semiconductor device such as a field-effect-transistor (FET) having a metal gate with improved performance. A metal gate is formed on a substrate in the semiconductor device. Further processing can result in unwanted oxidation in the metal that forms the metal gate. A reducing agent can be used to de-oxidize the metal that forms the metal gate, leaving a substantially non-oxidized surface.

Owner:GLOBALFOUNDRIES US INC

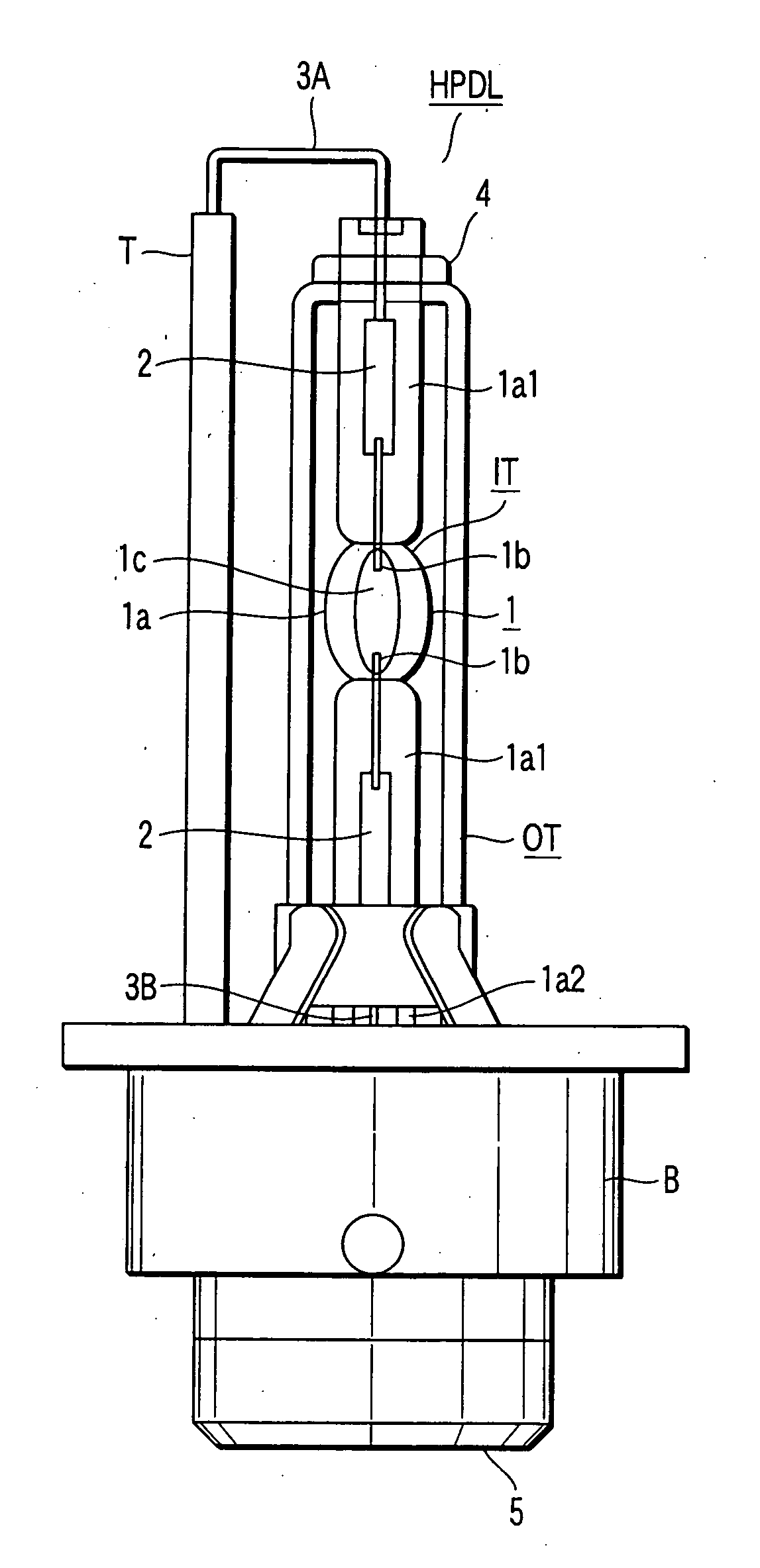

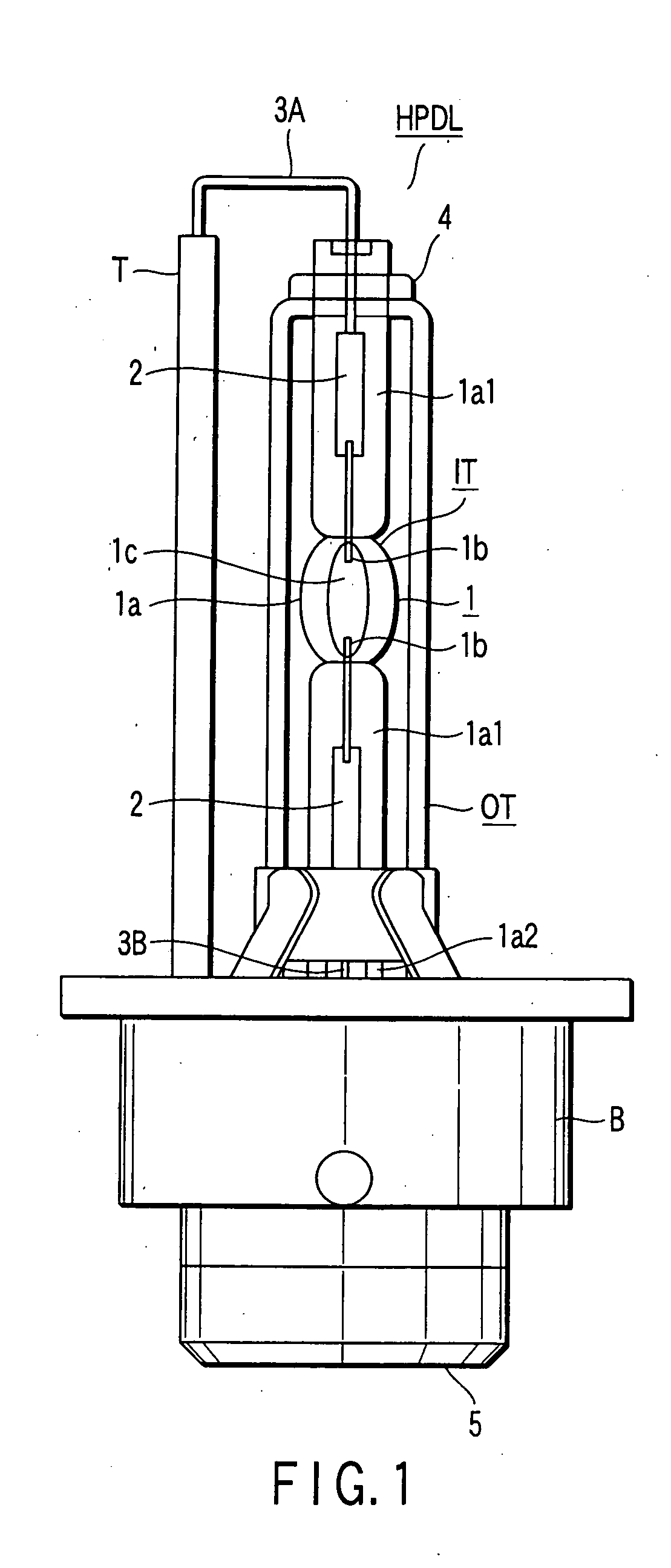

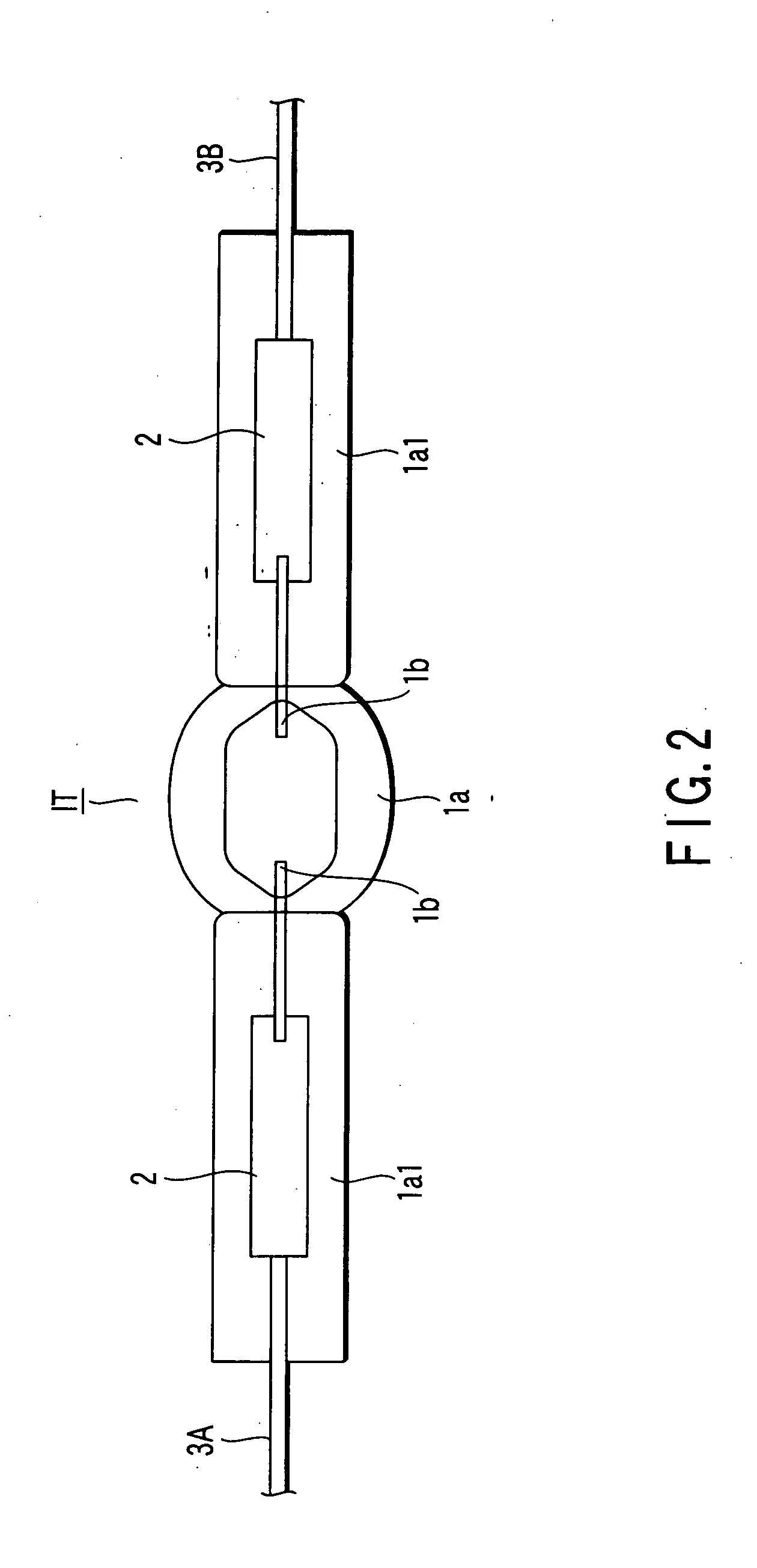

Metal halide lamp and lighting device

InactiveUS20050082987A1Improve metal performanceFunction increaseElectroluminescent light sourcesVessels or leading-in conductors manufactureIndiumNoble gas

A metal halide lamp comprises a refractory, light-transmitting airtight container defining therein a discharge space with an internal volume of not more than 0.1 cc, electrodes sealed in the container, opposing each other with a distance of not more than 5 mm interposed, and a discharge medium sealed in the container and including a metal halide material and a rare gas. The metal halide includes first and second halide materials. The first halide material contains scandium (Sc) and sodium (Na) halides. The second halide material contains at least one of indium (In) and zinc (Zn) halides. The discharge medium contains substantially no mercury. The load on the wall of the container in a stable state is 50 W / cm2 or more. A / B≦0.21 where A represents the intensity of an impurity chromium (Cr) spectrum in lighting spectra, and B represents the intensity of a scandium (Sc) spectrum.

Owner:HARISON TOSHIBA LIGHTING CORP

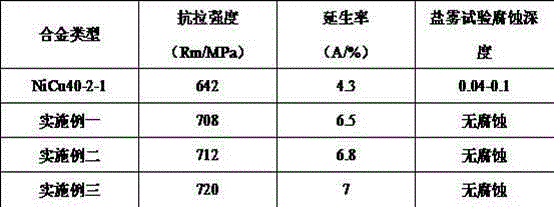

Nickel-copper alloy with high strength and high corrosion resistance and manufacturing method thereof

The invention discloses a nickel-copper alloy with high strength and high corrosion resistance and a manufacturing method thereof. The method takes electrolytic copper and electrolytic nickel as major components, a small amount of manganese, iron, silicon, metal magnesium and metal titanium is added, and the impurity accounts for less than or equal to 0.5%. According to the invention, the components are sequentially put into a smelting furnace and subjected to the steps of smelting, stirring and slag extraction, refining, casting formation and the like to obtain a finished product of the nickel-copper alloy. Through the invention, the tensile strength is 670-720Rm / MPa, the elongation is 6-7.5, the strength is improved by 15% over the existing domestic nickel-copper alloy, and the corrosion resistance is improved by about twice. The nickel-copper alloy disclosed by the invention is widely applicable, has long service life and the like, can be used for producing plates, belts, pipes, rods, lines and forgings, and is applied to the industries such as shipbuilding, chemical industry, machinery manufacturing, aerospace, electronics and the like. The manufacturing method disclosed by the invention changes the original vacuum casting process, adopts a semi-continuous smelting method and reduces the production cost.

Owner:沈阳有色金属研究所有限公司

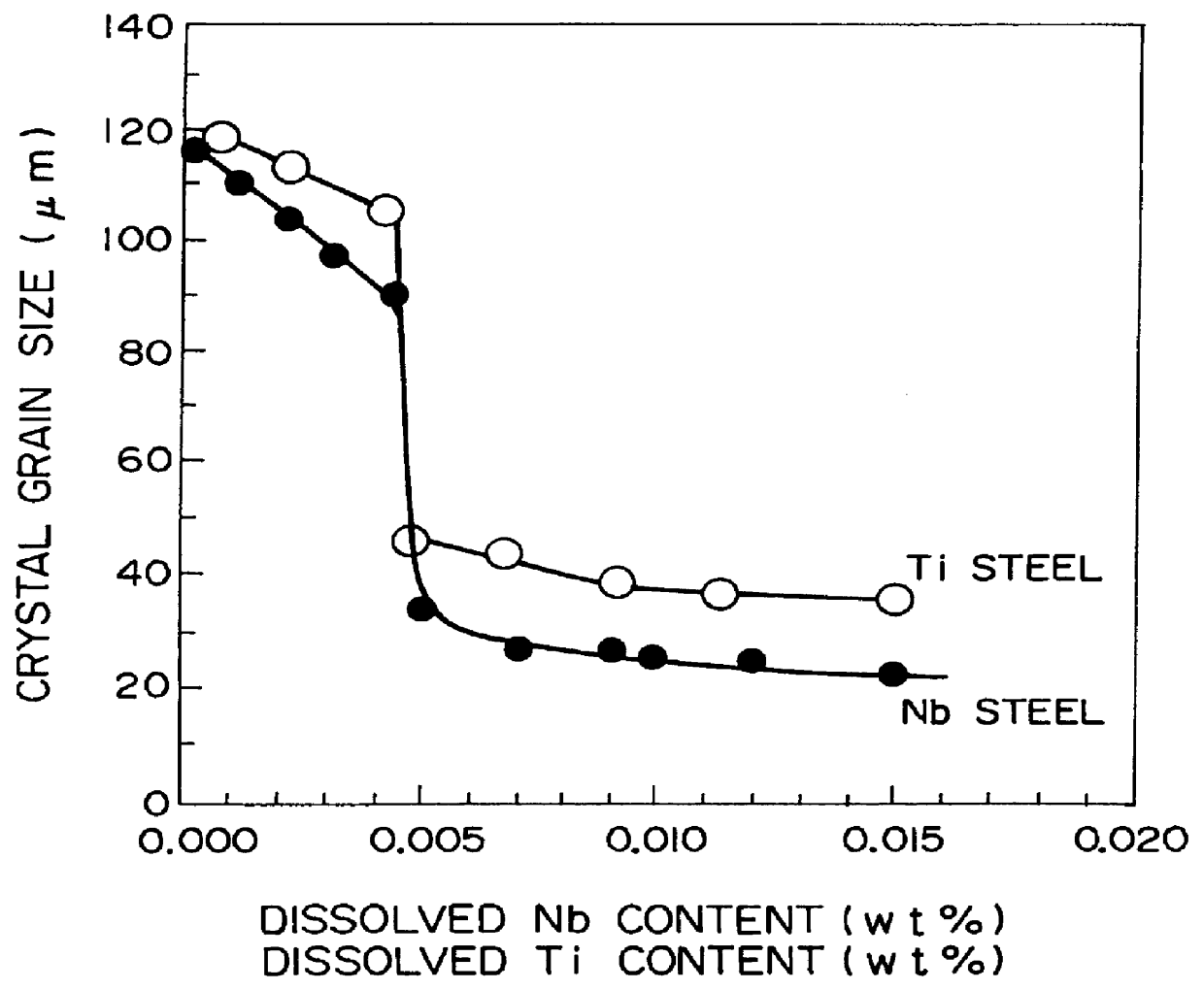

Steel sheet for double wound pipe and method of producing the pipe

InactiveUS6110299AImprove metal performanceGood molding effectFurnace typesHeat treatment furnacesReduction rateSheet steel

PCT No. PCT / JP97 / 04289 Sec. 371 Date Jun. 24, 1998 Sec. 102(e) Date Jun. 24, 1998 PCT Filed Nov. 25, 1997 PCT Pub. No. WO98 / 24942 PCT Pub. Date Jun. 11, 1998A steel sheet for double-rolled tubes has excellent formability, and excellent strength and toughness after forming and heat treatment of a tube because of suppressed coarsening of the ferrite grain size and a method for making the same comprises: hot finish-rolling of a steel material containing C: 0.0005-0.020 wt %, and one or two of Nb: 0.003-0.040 wt %, and Ti: 0.005-0.060 wt % at a final temperature of 1,000-850 DEG C., coiling at 750 DEG C. or less, cold rolling, continuous annealing at 650 DEG C.-850 DEG C. for 20 seconds or less, and second cold-rolling at a rolling reduction rate of 20% or less, so that at least one of Nb and Ti is present in a solid solution state in an amount of 0.005 wt % or more, and the crystal grain size in the ferrite structure is in the range of 5 to 10 mu m.

Owner:KAWASAKI STEEL CORP

Metal gate transistor and method for forming the same

ActiveUS20140361384A1Improve metal performanceFirmly attachedSemiconductor/solid-state device manufacturingSemiconductor devicesEngineeringElectrical and Electronics engineering

Various embodiments provide metal gate transistors and methods for forming the same. In an exemplary method, a substrate having a top surface and a back surface can be provided. A dummy gate can be formed on the top surface. A first interlayer dielectric layer can be formed on the top surface and planarized to expose the dummy gate. The dummy gate can be removed to form a trench. A metal gate stack can be formed to cover the first interlayer dielectric layer and to fill the trench. The metal gate stack can be planarized to remove a portion of the metal gate stack from the first interlayer dielectric layer to form a metal gate electrode in the trench. A remaining edge portion of the metal gate stack can exist over an annular region of the substrate and can be removed from the annular region by an edge cleaning process.

Owner:SEMICON MFG INT (SHANGHAI) CORP

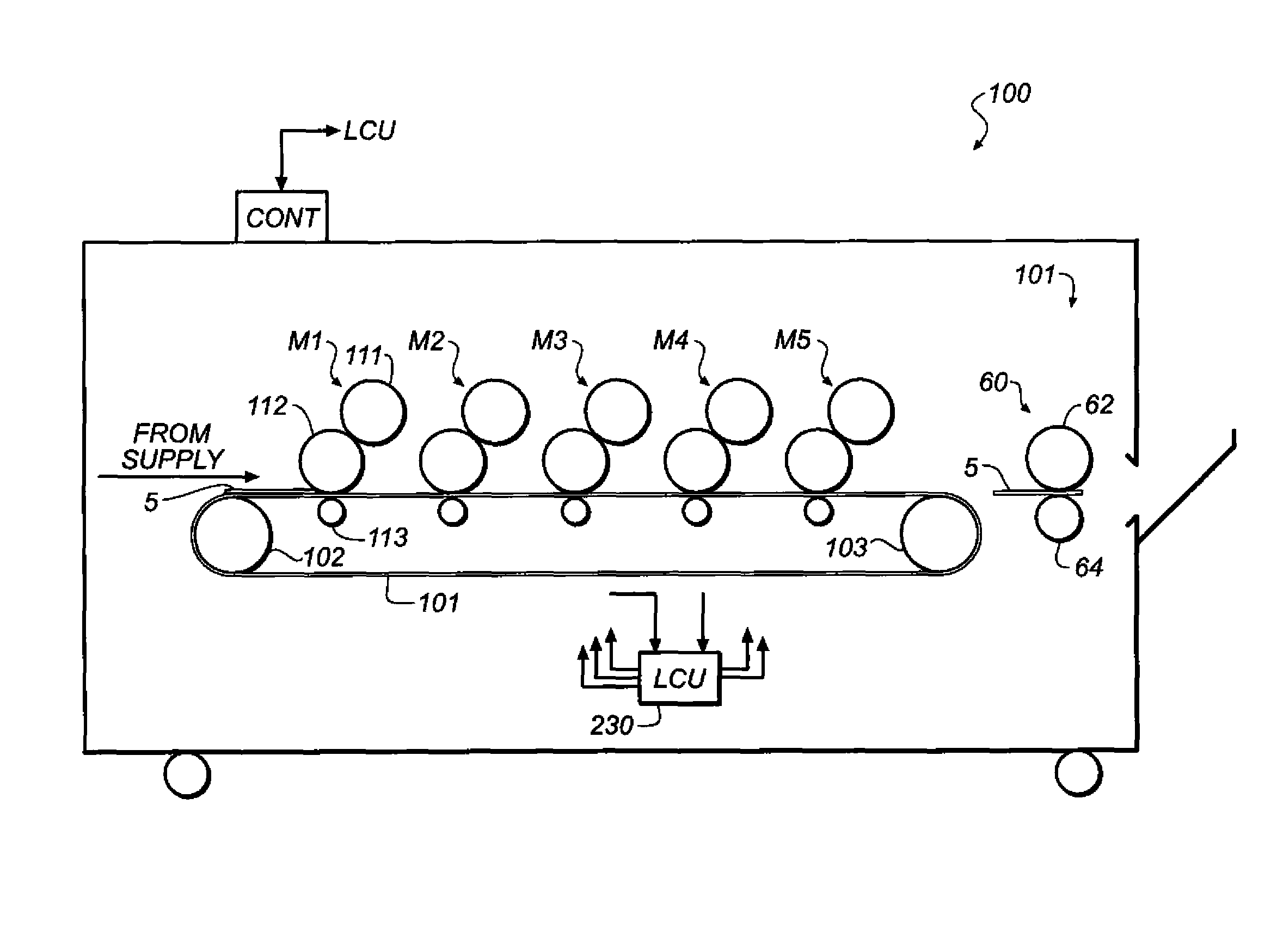

Preparing dry toner particles for metallic effect

Metallic dry toner particles are prepared by dry blending resin particles with non-conductive metal oxide particles to form a dry blend. This dry blend is melt extruded under low shear conditions to form an extruded composition that is broken up into metallic dry toner particles. Each metallic dry toner particle consists essentially of a polymeric binder phase formed from the resin particles, and the non-conductive metal oxide particles dispersed within the polymeric binder phase. The metallic dry toner particles have a mean volume weighted diameter (Dvol) before fixing of 15 μm to 40 μm, and the non-conductive metal oxide particles are present in an amount of 20 to 50 weight %. The ratio of the metallic dry toner particle Dvolto the average equivalent circular diameter (ECD) of the non-conductive metal oxide particles in the metallic dry toner particles is greater than 0.1 and to 10.

Owner:EASTMAN KODAK CO

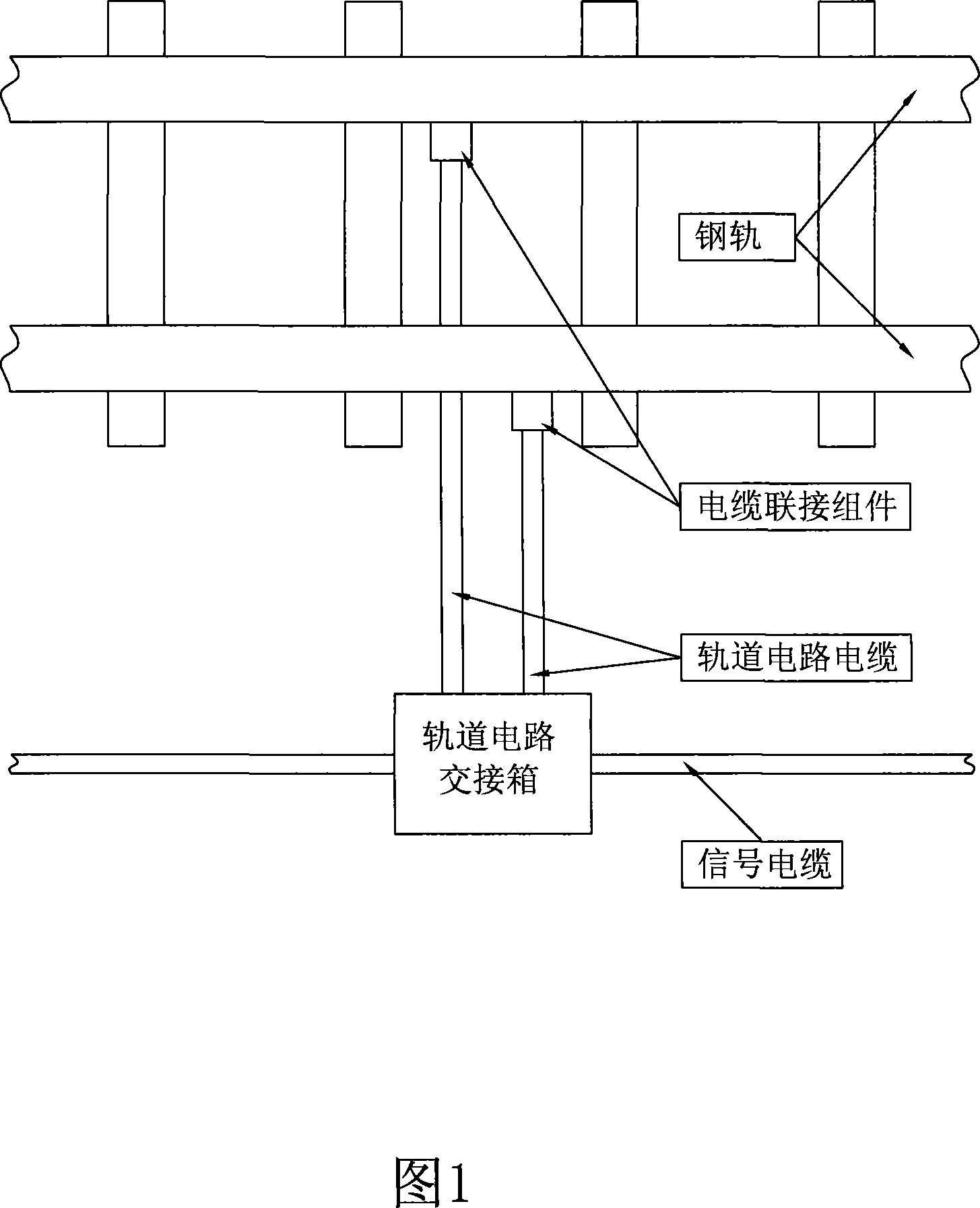

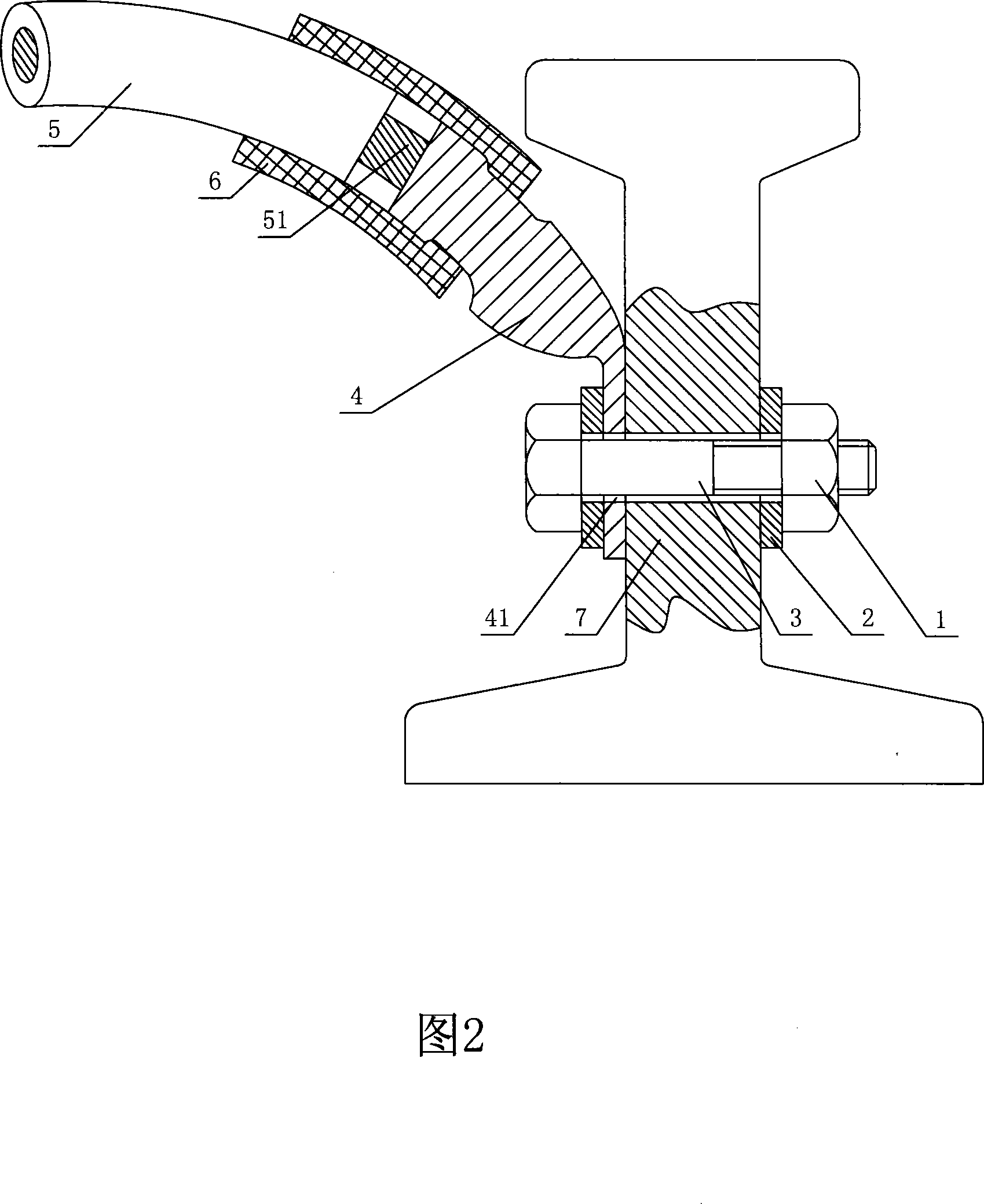

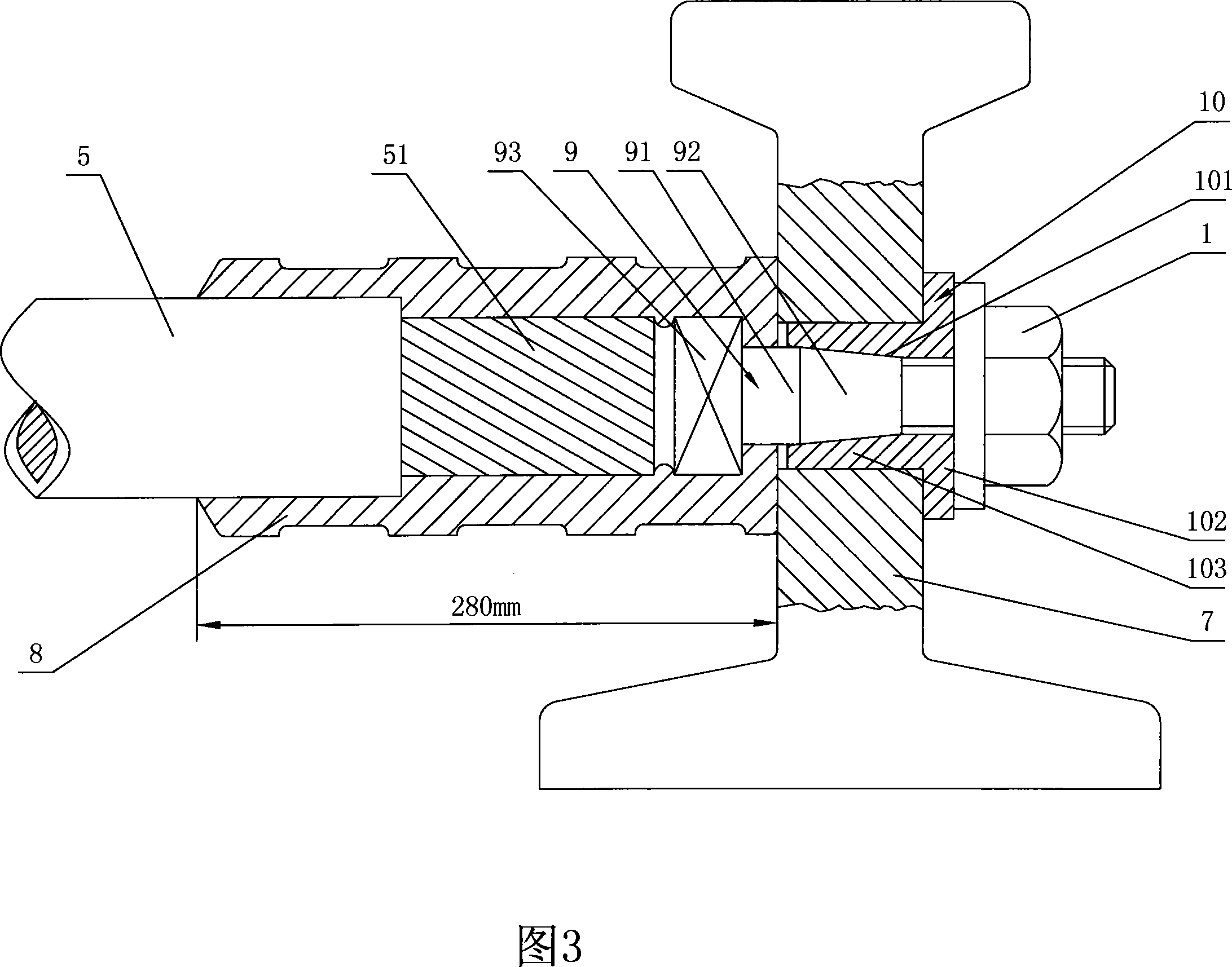

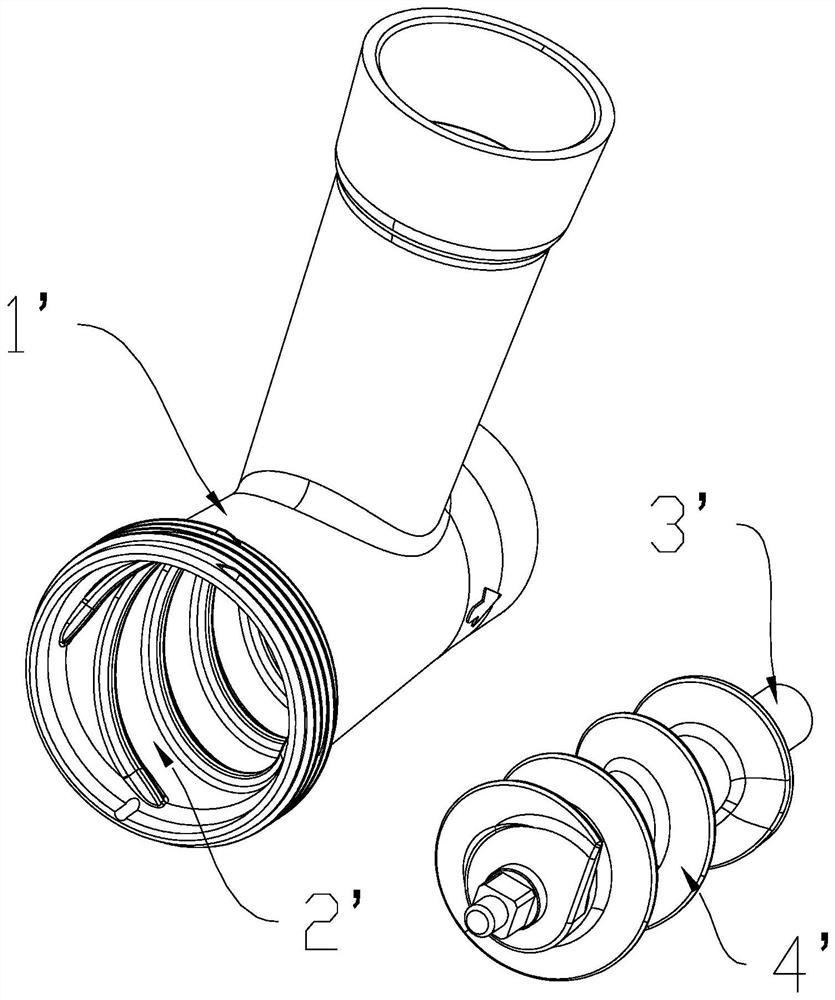

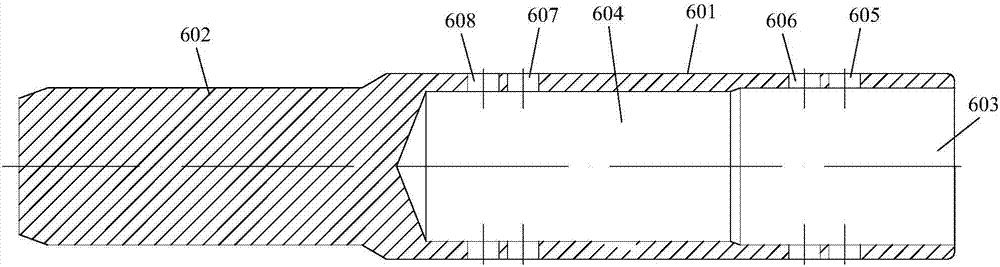

Cable coupling component and method for jointing steel rail with cable using the cable coupling component

ActiveCN101252230ANot easy to rustSoft textureVehicle route interaction devicesElectric connection basesCouplingEngineering

The invention discloses a cable connecting component and a method of connecting cables with rails by using the same. The cable connecting component comprises a tapered bolt of which the head is connected with a track circuit cable and of which a shaft is provided with a cone part with a gradually reduced diameter from the head to the shaft; the cable connecting component also comprises a flexible sheath inserted on a rail web and a taper hole which can accommodate the cone part is arranged on the inner wall of the flexible sheath; one end t of the shaft of the tapered bolt far away from the head is through an inner hole of the flexible sheath, the outer wall of the cone part is held against the inner wall of the taper hole tightly, and the end of the shaft of the tapered bolt far away from the head is also locked with a nut. The cable connecting component and the method enable the tapered bolt, the flexible sheath and the end face of the rail web to stick tightly without gaps, which ensure that the cable connecting component can keep stable metallic performance and be not easy to rust during the long-term application.

Owner:TONGDING INTERCONNECTION INFORMATION CO LTD

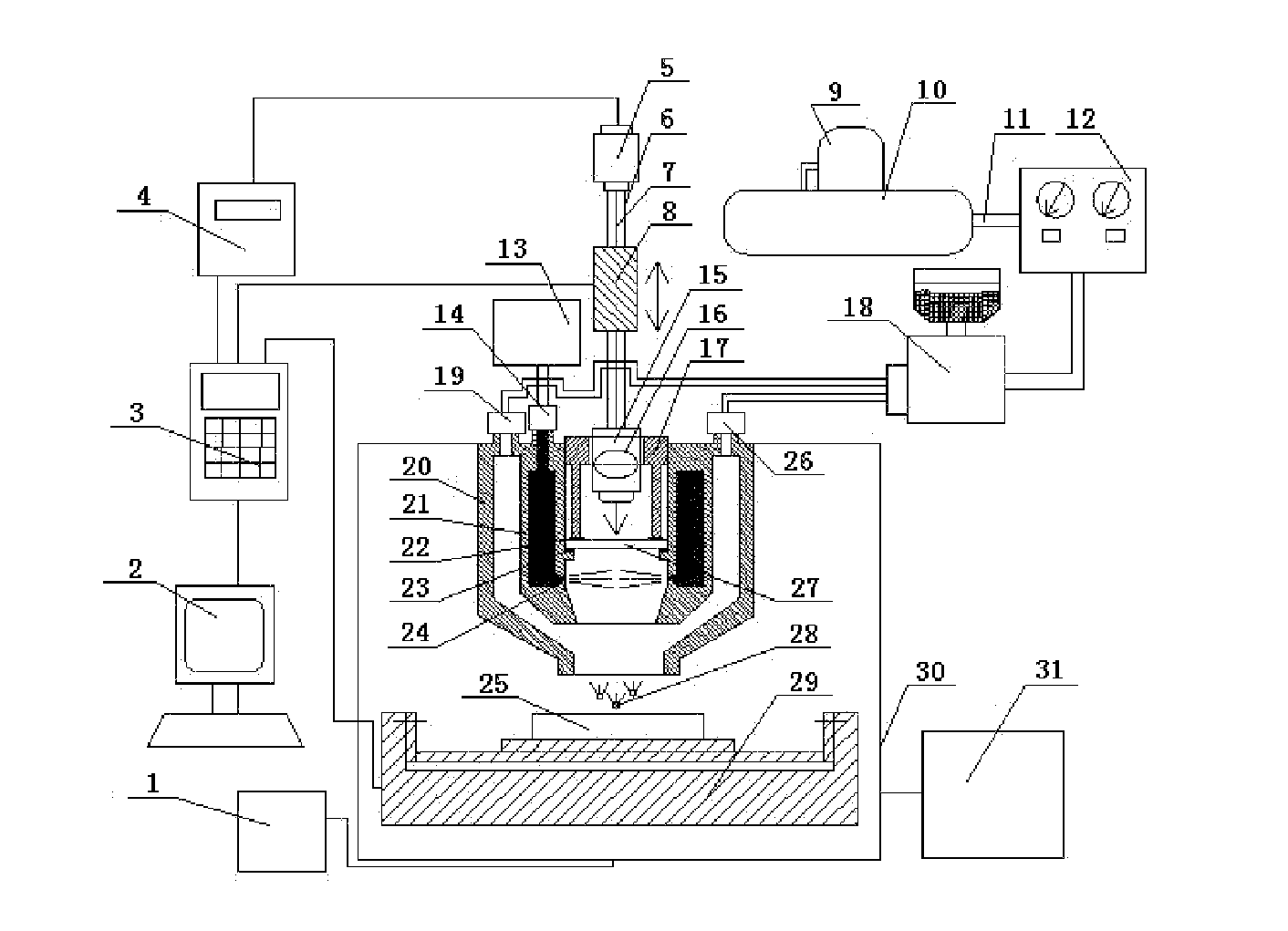

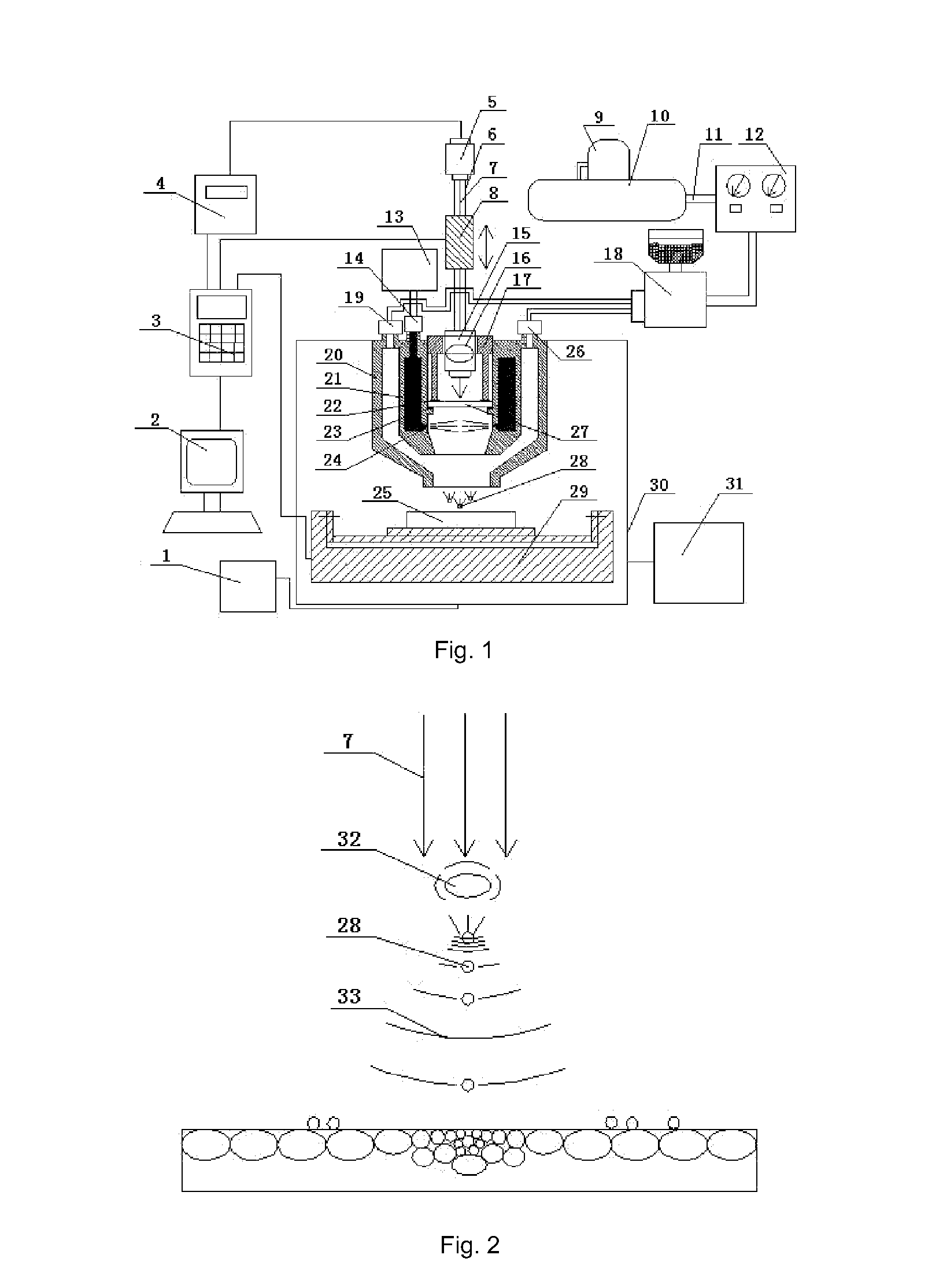

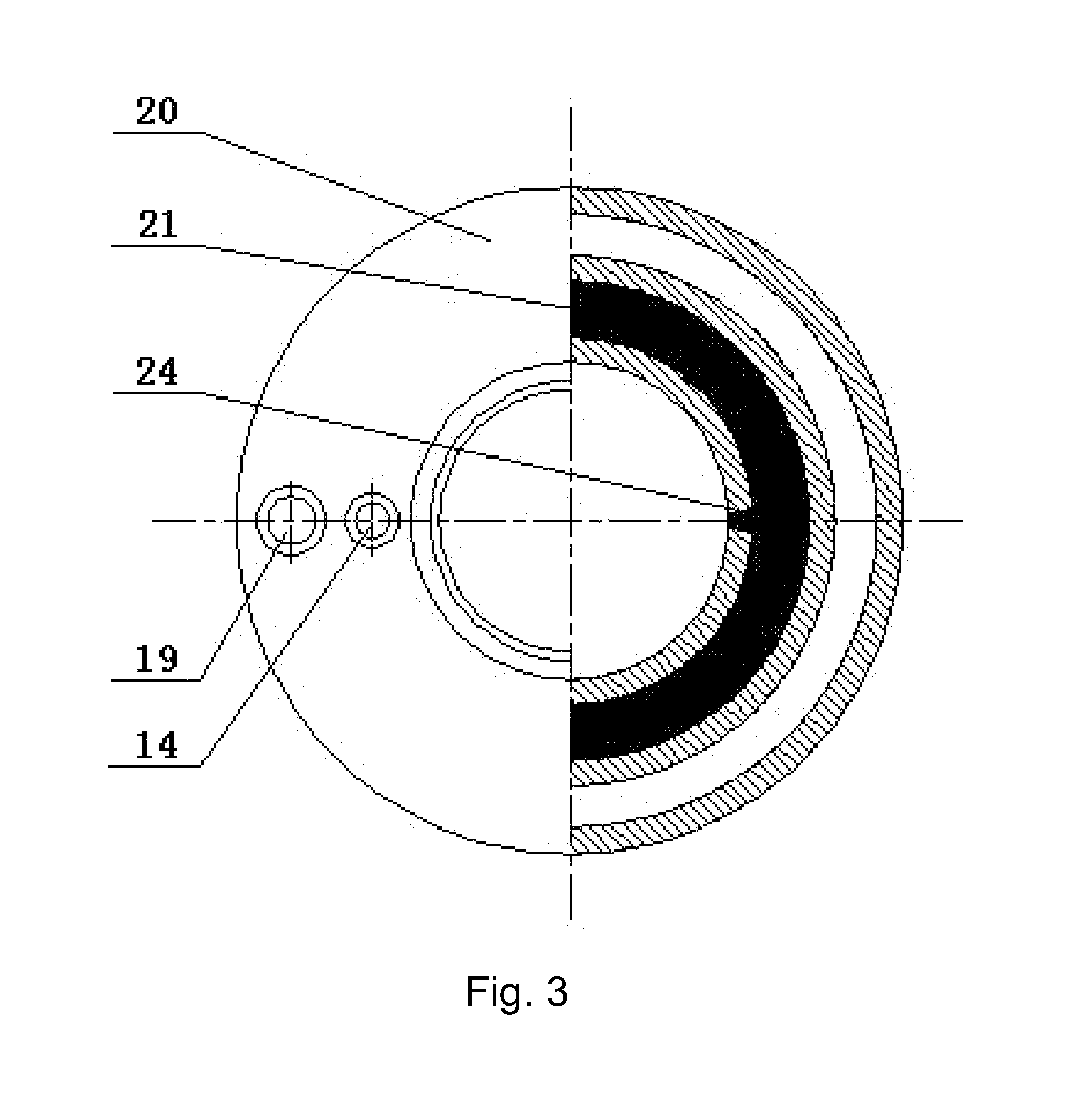

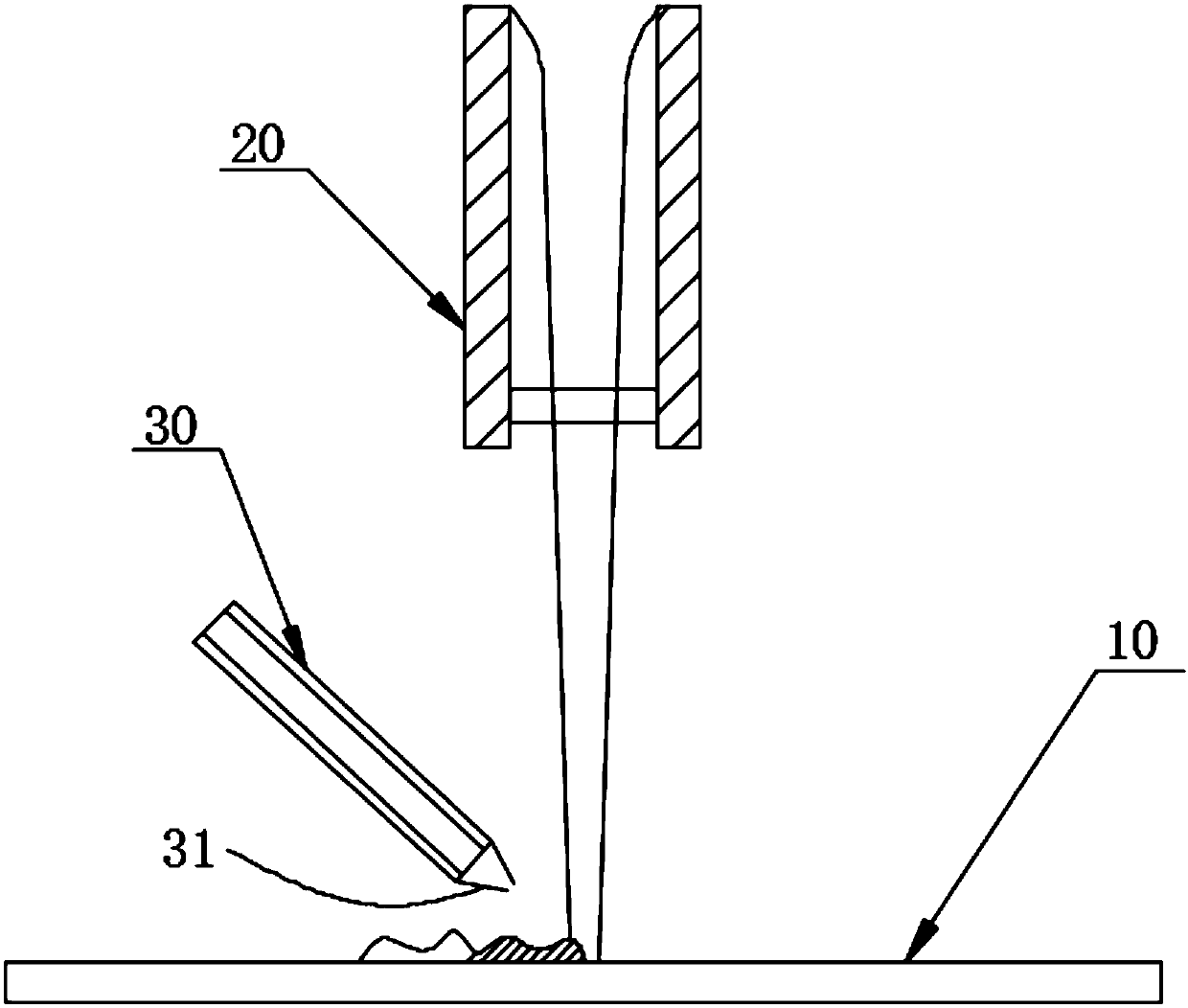

Method and apparatus for nanocrystallizing a metal surface by shock wave-accelerated nanoparticles

ActiveUS20140178593A1Improve metal performanceExtended service lifeLiquid surface applicatorsMolten spray coatingShock waveBlack paint

A method and apparatus for nanocrystallizing a metal surface by laser-induced shock wave-accelerated nanoparticles. The apparatus comprises a control system, a light guiding system, a workbench control system and an auxiliary system, wherein the auxiliary system comprises an air compressor, a paint feeder device, a nanoparticle nozzle, a powder feeder device, an exhaust, a sealed working chamber and a metal nanoparticle recycler device. The method comprises the following steps: pre-processing and fixing a workpiece; activating the air compressor to feed a powder; controlling and adjusting the paint feeder device to eject a black paint; transmitting a high-power pulse laser beam; recycling excess metal nanoparticles; and rinsing non-vaporized / ionized black paint off a surface of the workpiece.

Owner:JIANGSU UNIV

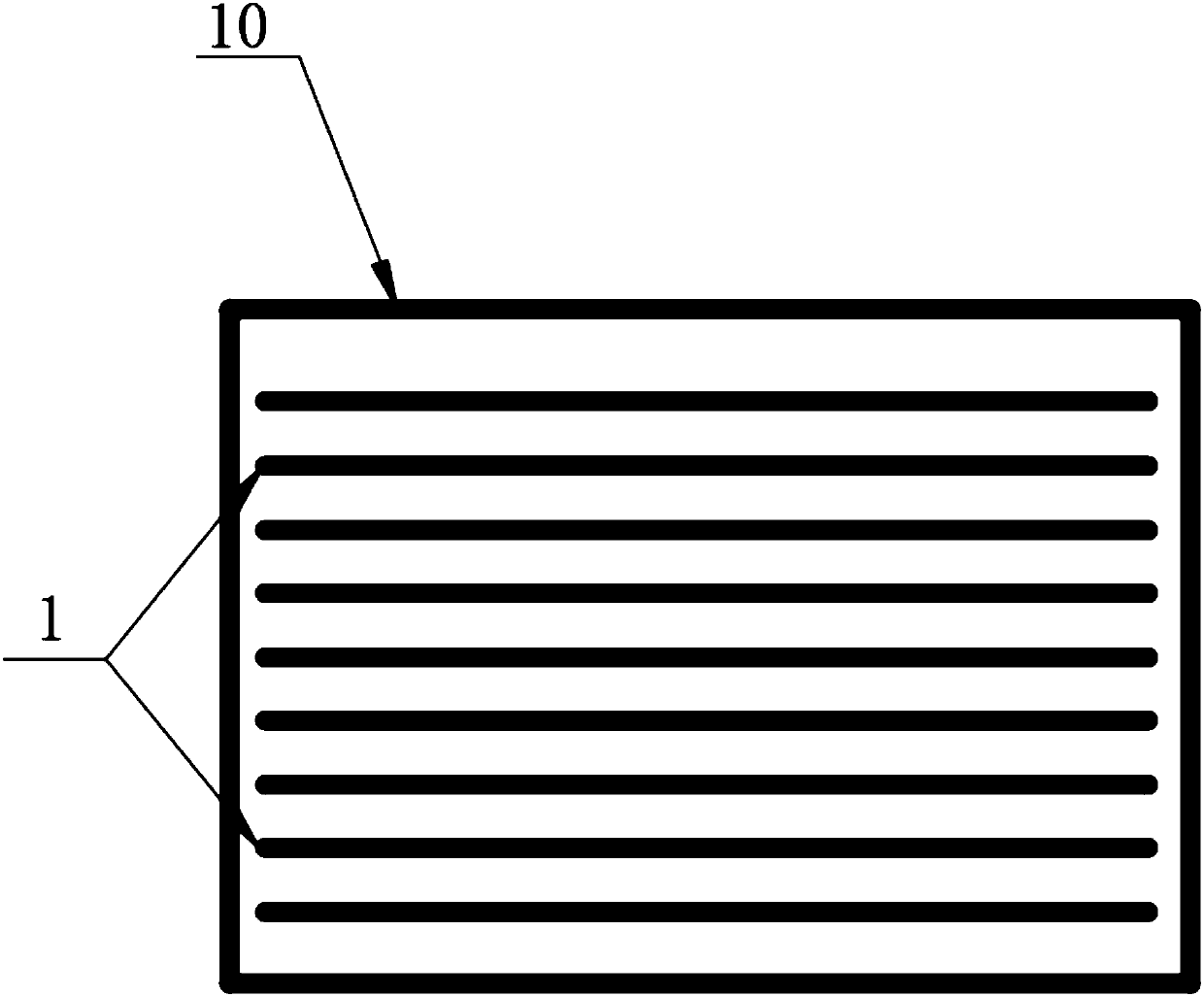

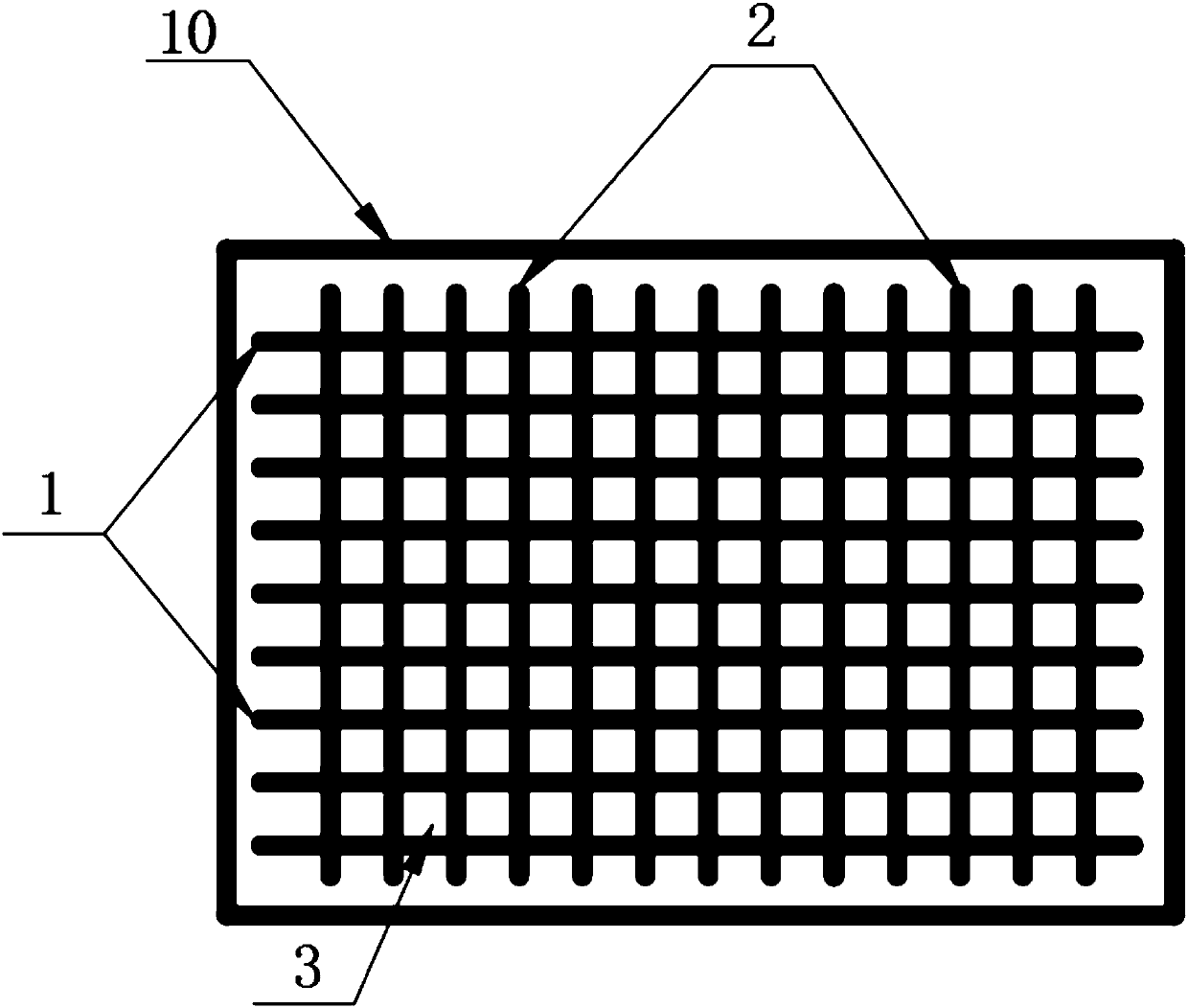

Manufacturing method of laser additive for porous aluminum alloy

InactiveCN107737926AReduce porosityDense tissue structureAdditive manufacturing apparatusIncreasing energy efficiencyPorosityHardness

The invention relates to a manufacturing method of a laser additive for a porous aluminum alloy. The method comprises the following steps that first layer alloy powder is laid on a base plate uniformly; a laser device focuses the first layer alloy powder to carry out scanning, and a plurality of first linear tracks are formed; the first linear tracks are arranged at intervals and in parallel; second layer alloy powder is laid on the first layer alloy powder uniformly; the laser device focuses the second layer alloy powder to carry out scanning, and a plurality of second linear tracks are formed; the second linear tracks are arranged at intervals and in parallel and are perpendicular to the first linear tracks to form a plurality of holes; according to the principle that (N+1) linear tracksof (N+1) layer alloy powder are perpendicular to N linear tracks of the Nth alloy powder, layer-by-layer stacking is achieved, and laser additive manufacturing of the porous aluminum alloy is achieved. The size of the formed holes is controlled by accurately controlling the intervals of the linear tracks, then the porosity of the aluminum alloy is controlled, and in this way, and the aluminum alloy with compact organization structure, large hardness and high metal performance can be obtained.

Owner:HANS LASER TECH IND GRP CO LTD

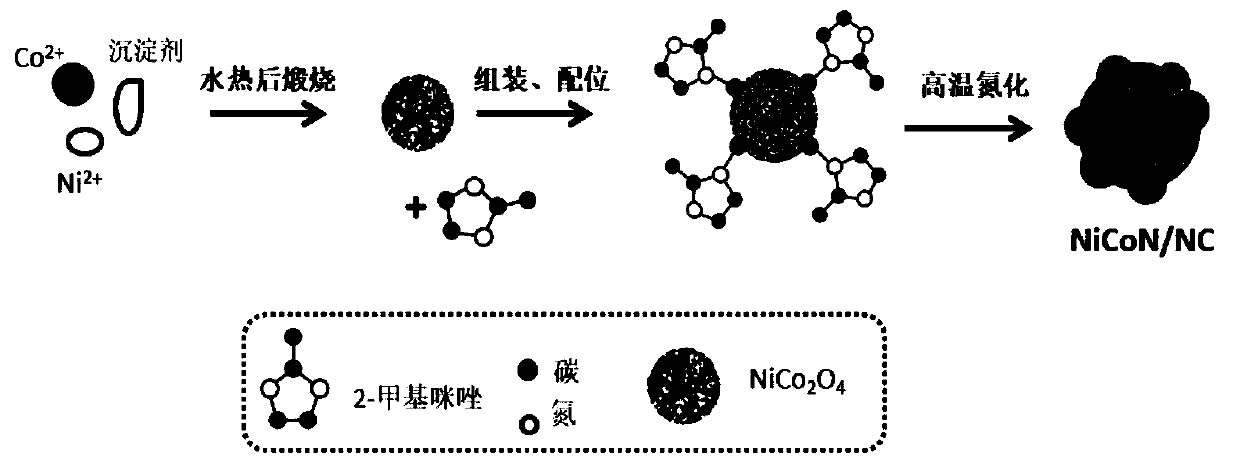

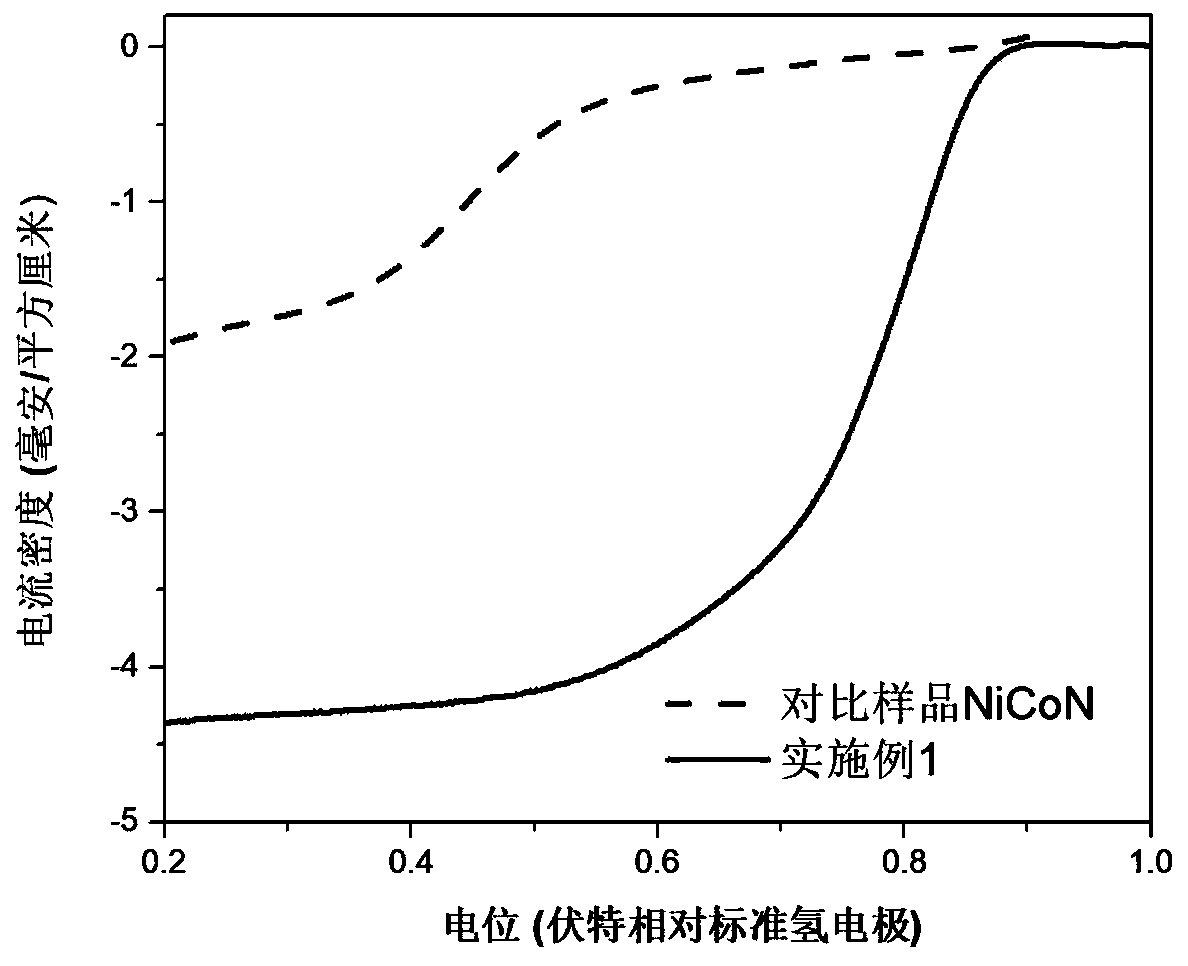

ZIFs derived metal nitride/carbon composite material and preparation method and application thereof

ActiveCN110350205AAvoid reunionPrevent structural collapseCell electrodesCarbon compositesMetal particle

The invention discloses a ZIFs derived metal nitride / carbon composite material and a preparation method and application thereof. The method comprises the steps: NiCo2O4 nano-spheres and 2-methylimidazole are mixed and ground and sintered at the temperature of 700-900 DEG C in the mixture gas of ammonia and inert gas so as to obtain the composite material; or a zinc salt and the 2-methylimidazole are added to a methanol solution to obtain a ZIFs precursor, the ZIFs precursor is added the methanol solution of the NiCo2O4 -spheres and the dispersant to be stirred and separated to obtain the solid, the solid is heated to 700-900 DEG C under the protection of the inert gas and sintered in the mixture gas of ammonia and the inert gas and then cooled under the protection of the inert gas after sintering and thus the composite material is obtained. The method effectively avoids the agglomeration of metal particles and the structural collapse of ZIFs in the nitriding process, significantly speeds up the electron conduction rate and improves the reaction efficiency.

Owner:SICHUAN UNIV

Coating method

ActiveUS20110159197A1Increase speedGood coating effectMovable spraying apparatusSpray nozzlesMaterials sciencePigment

A coating method of coating a surface of an object with a paint containing a glitter pigment, including: spraying the paint onto the surface of the object; and controlling a color shade of the paint on the object by adjusting a particle size of paint particles to be sprayed according to a spray width indicating a width of a spread of the paint particles.

Owner:NISSAN MOTOR CO LTD

Manufacturing technique of nickel-copper alloy

The invention discloses a manufacturing technique of a nickel-copper alloy. The invention is characterized in that the nickel-copper alloy mainly comprises the following components in percentage by weight: 35-50% of copper, 8-15% of iron, 10-15% of chromium, 0.5-2% of rhenium, 1.25-2.25% of manganese, 0.15-0.2% of silicon, 0.05-0.1% of magnesium, 0.1-0.15% of titanium, at most 0.5% of other components and the balance of nickel. The manganese can improve the metallurgical structure of the material, improve the as-cast structure of the alloy, enhance the compactness of the material and promote the combination of the base, thereby effectively enhancing the high-temperature oxidation resistance and corrosion resistance, enhancing the strength, prolonging the service life of the material product and lowering the cost. The magnesium, which is used as a fluxing agent, can absorb abundant oxygen, hydrogen, nitrogen and other gases in the heating process, and thus, is an ideal degasser. The titanium has favorable corrosion resistance, and can further enhance the corrosion resistance of the material. The silicon is beneficial to enhancing and refining the grains by solid solution, thereby enhancing the metallic properties.

Owner:JIANGSU LEAP MACHINE

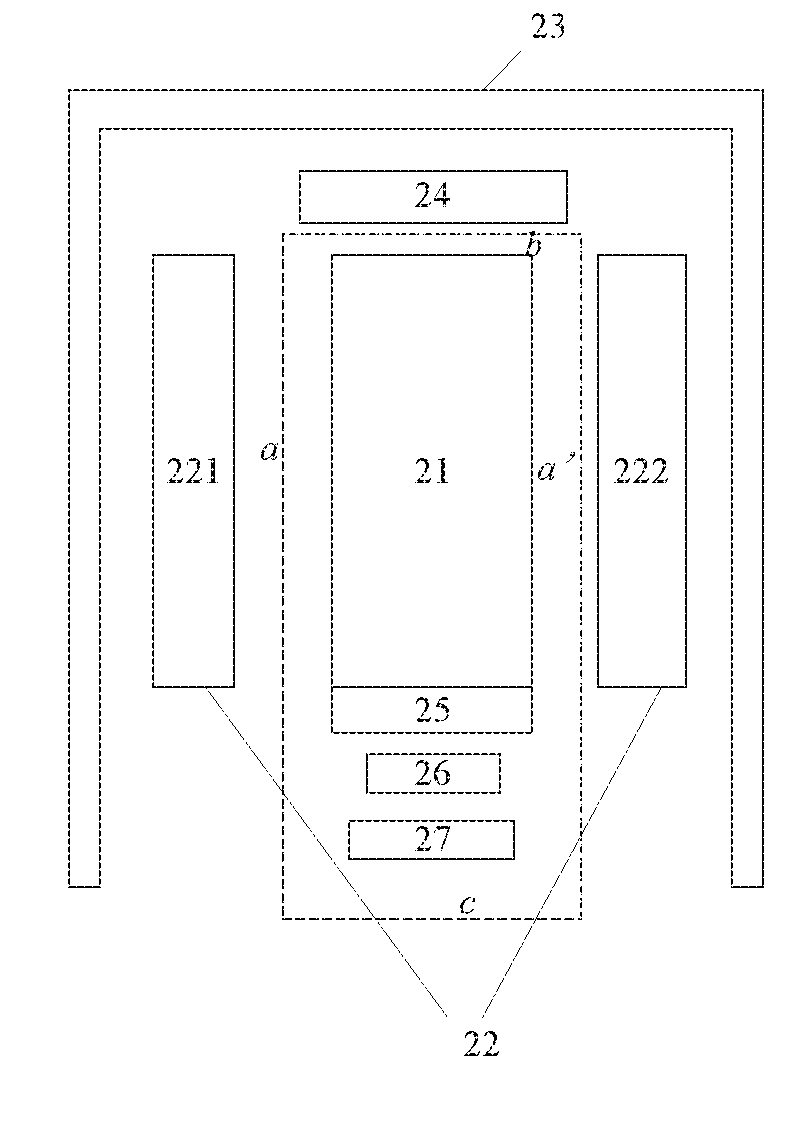

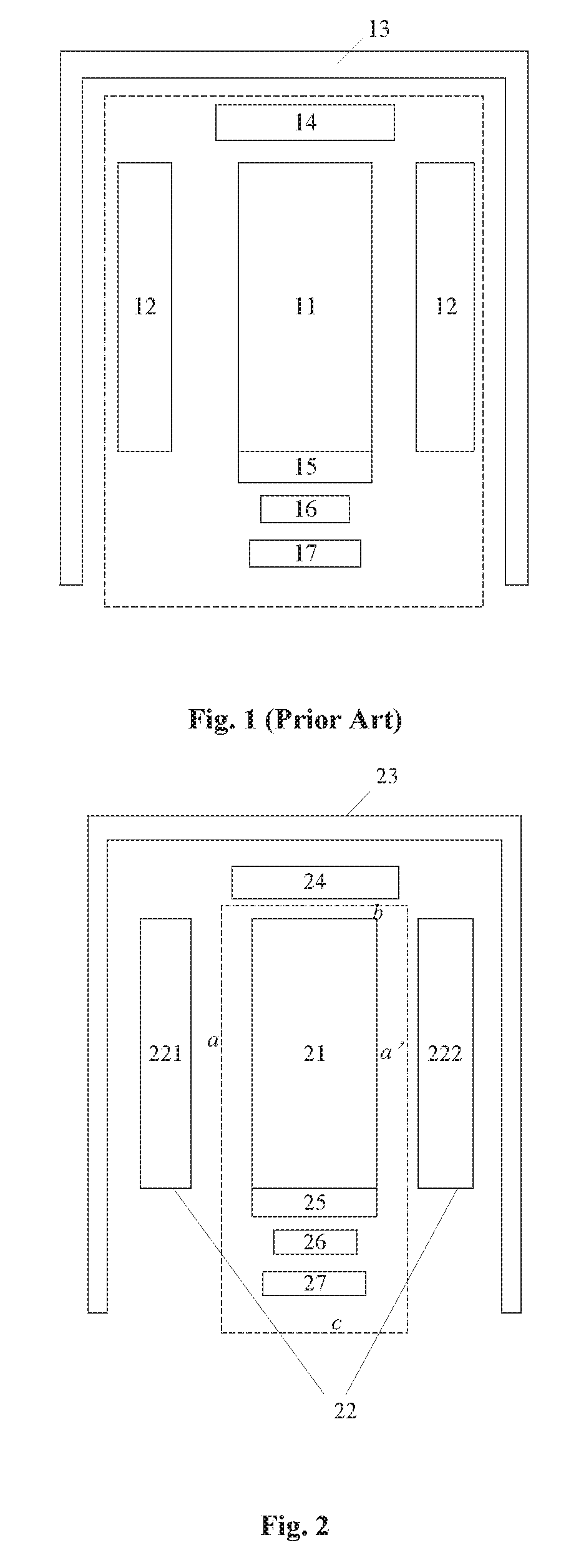

Display panel and display device

ActiveUS20180212015A1Improve metal performanceImprove performanceSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceDriving circuit

Disclosed are a display panel and a display device. The display panel includes an active area and two GOA driving circuit areas which are respectively arranged on a right side and a left side of the active area, wherein the display panel is bent along bending positions formed by gaps between the active area and each of the GOA driving circuit areas. Performance of metal lines at the bending positions can be improved and the display panel has an ultra-narrow frame.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

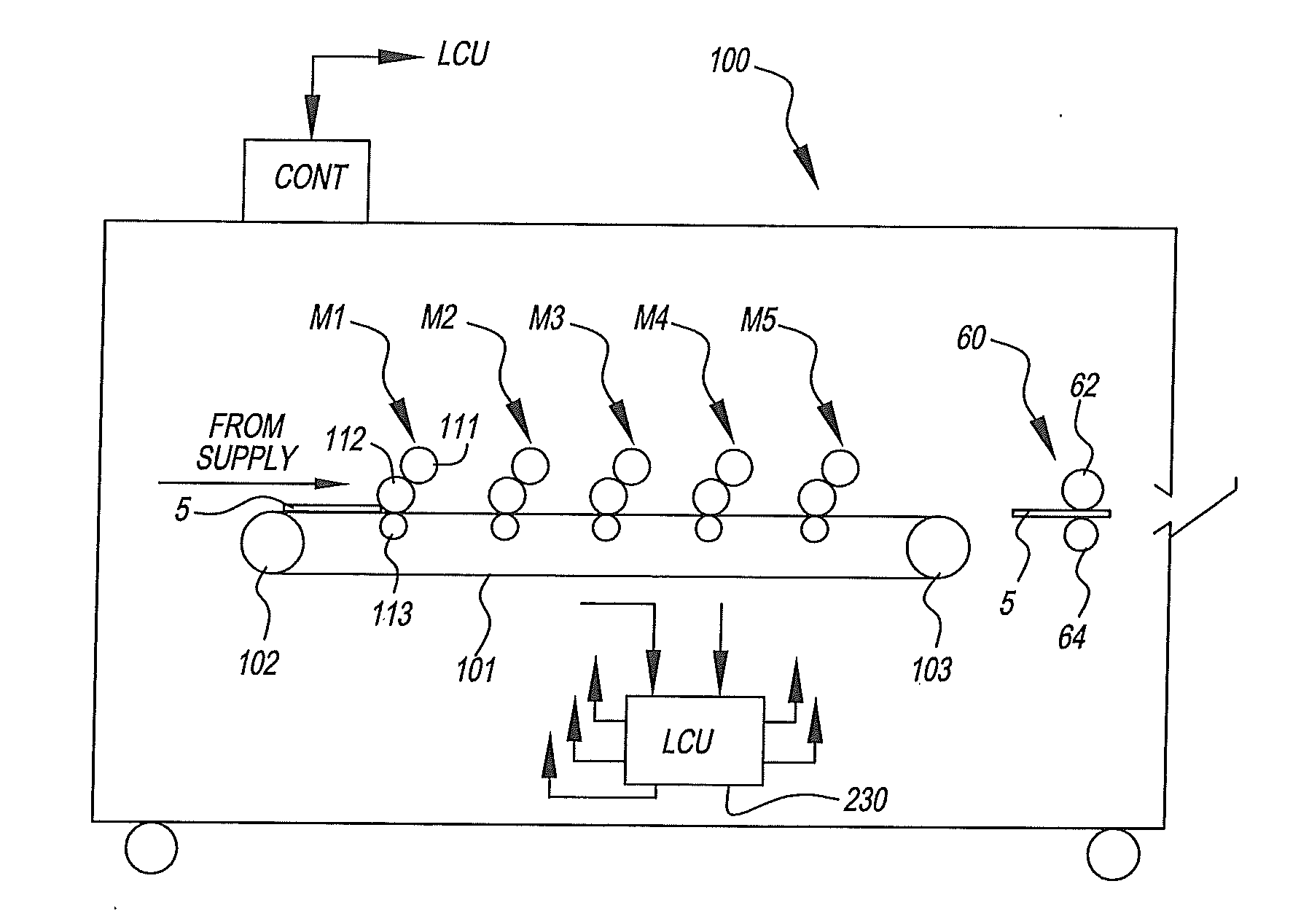

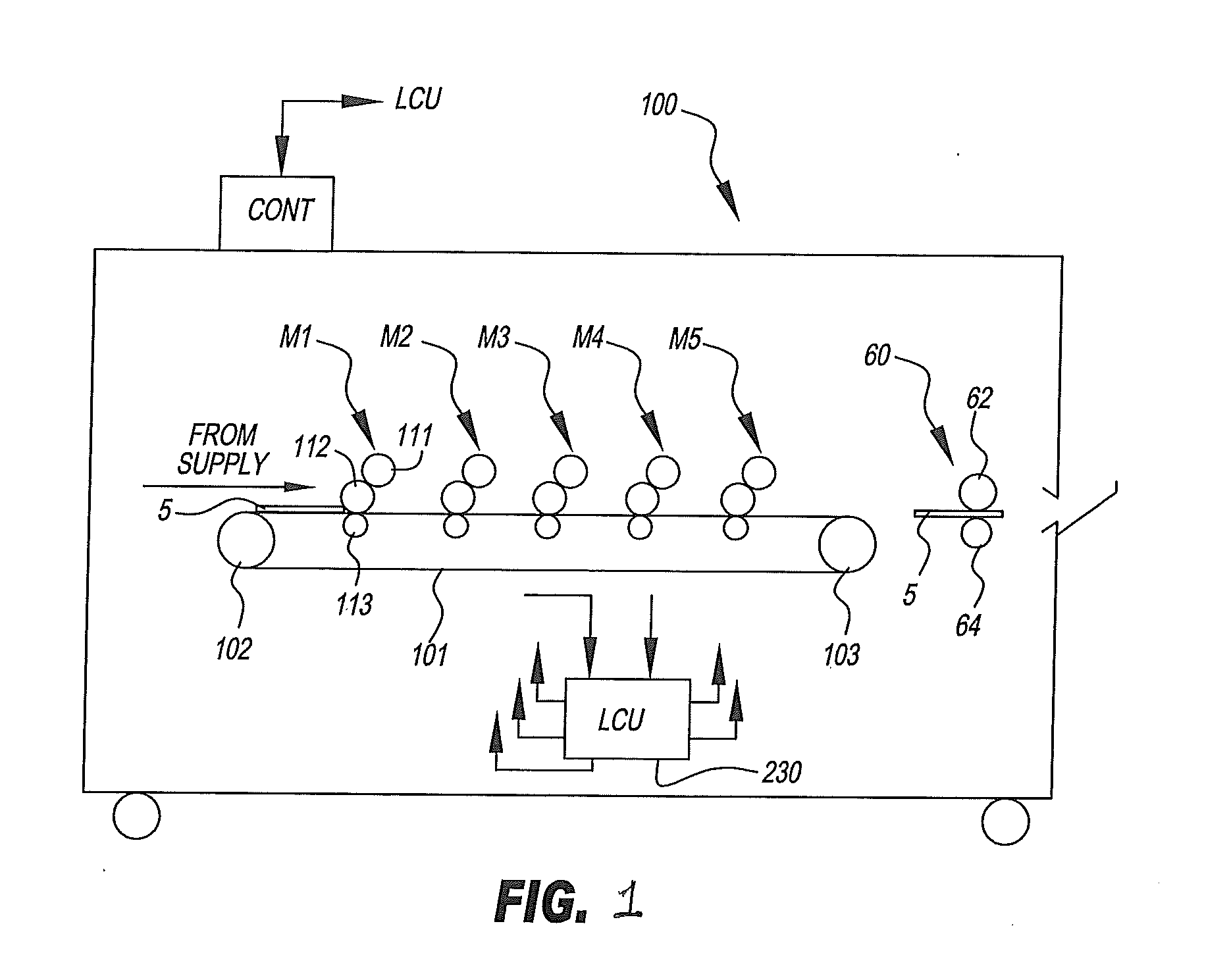

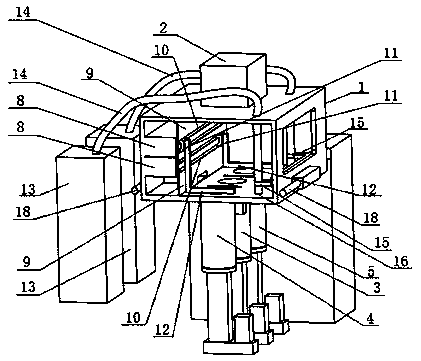

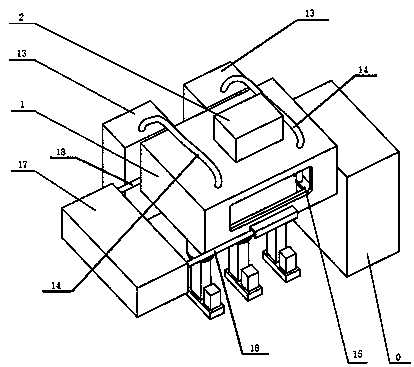

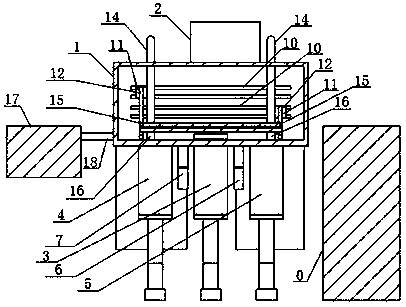

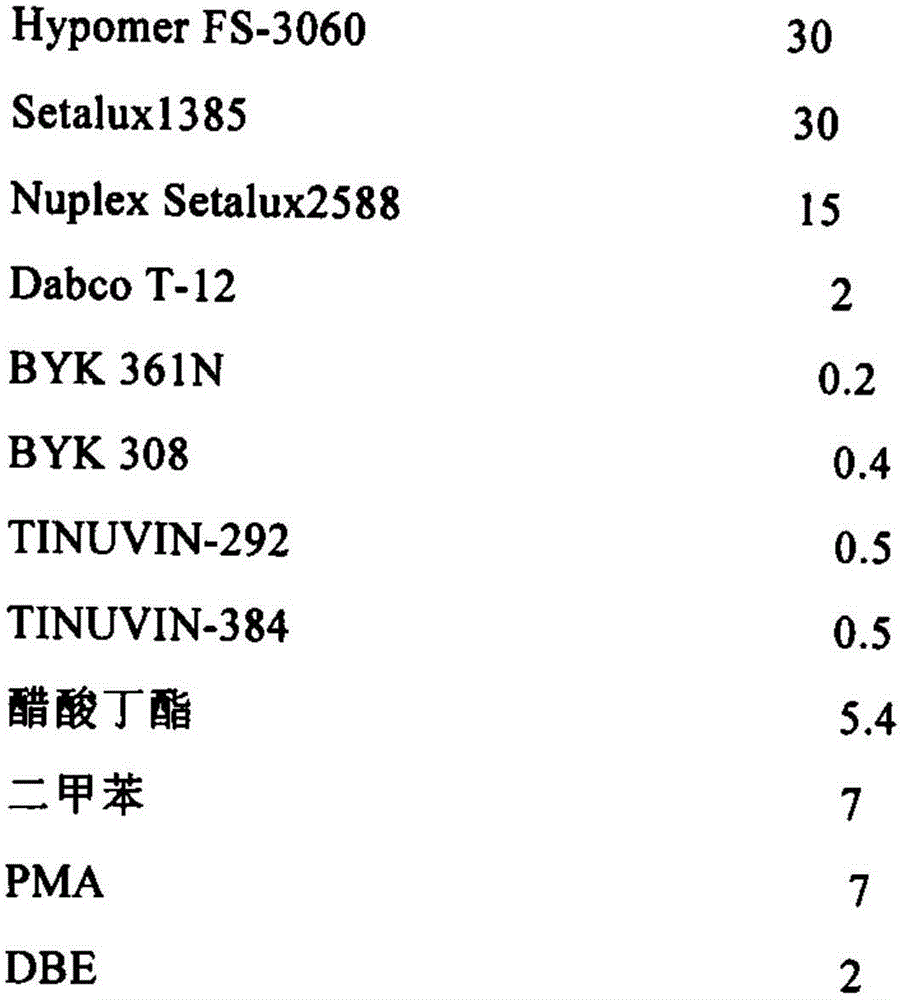

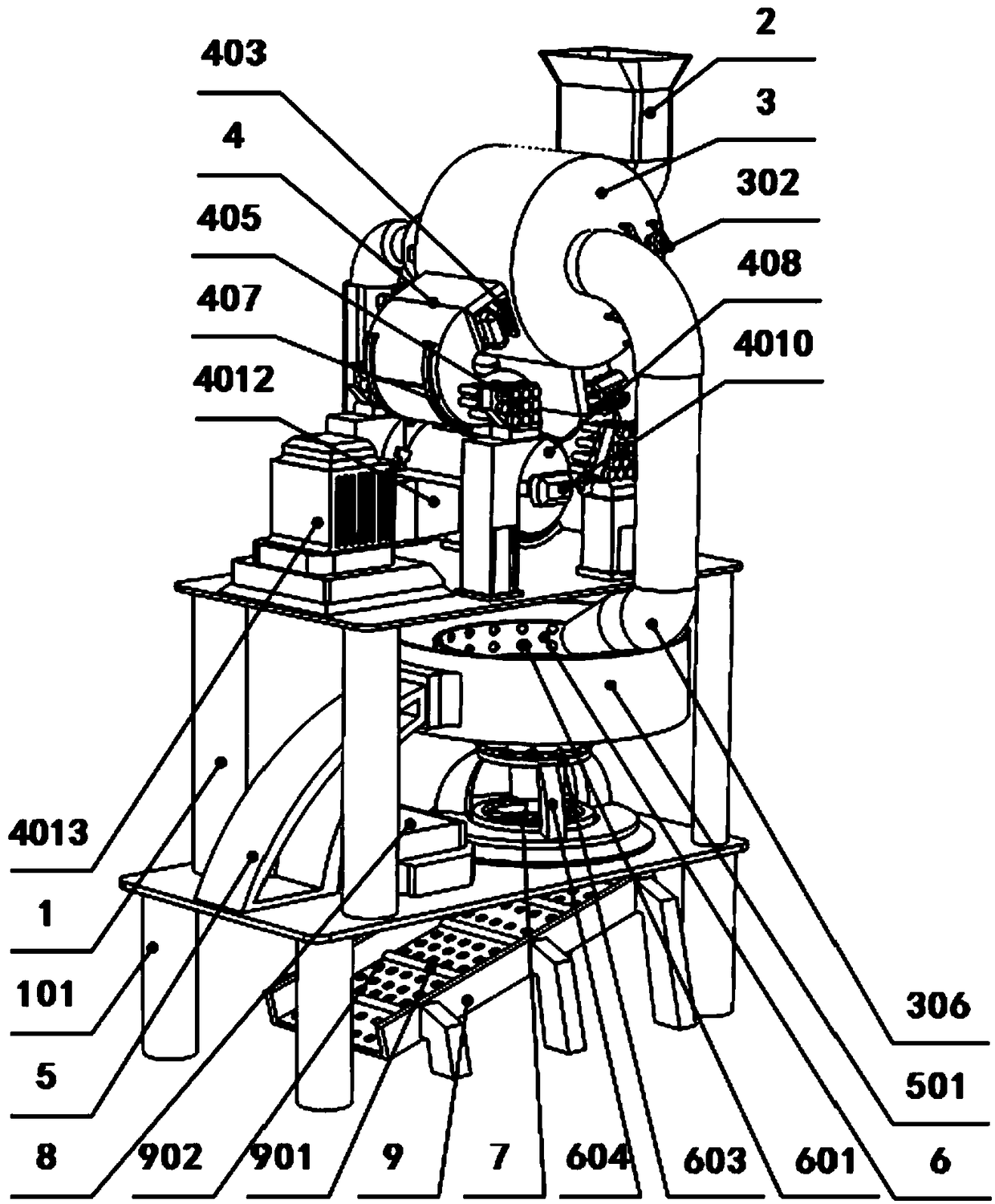

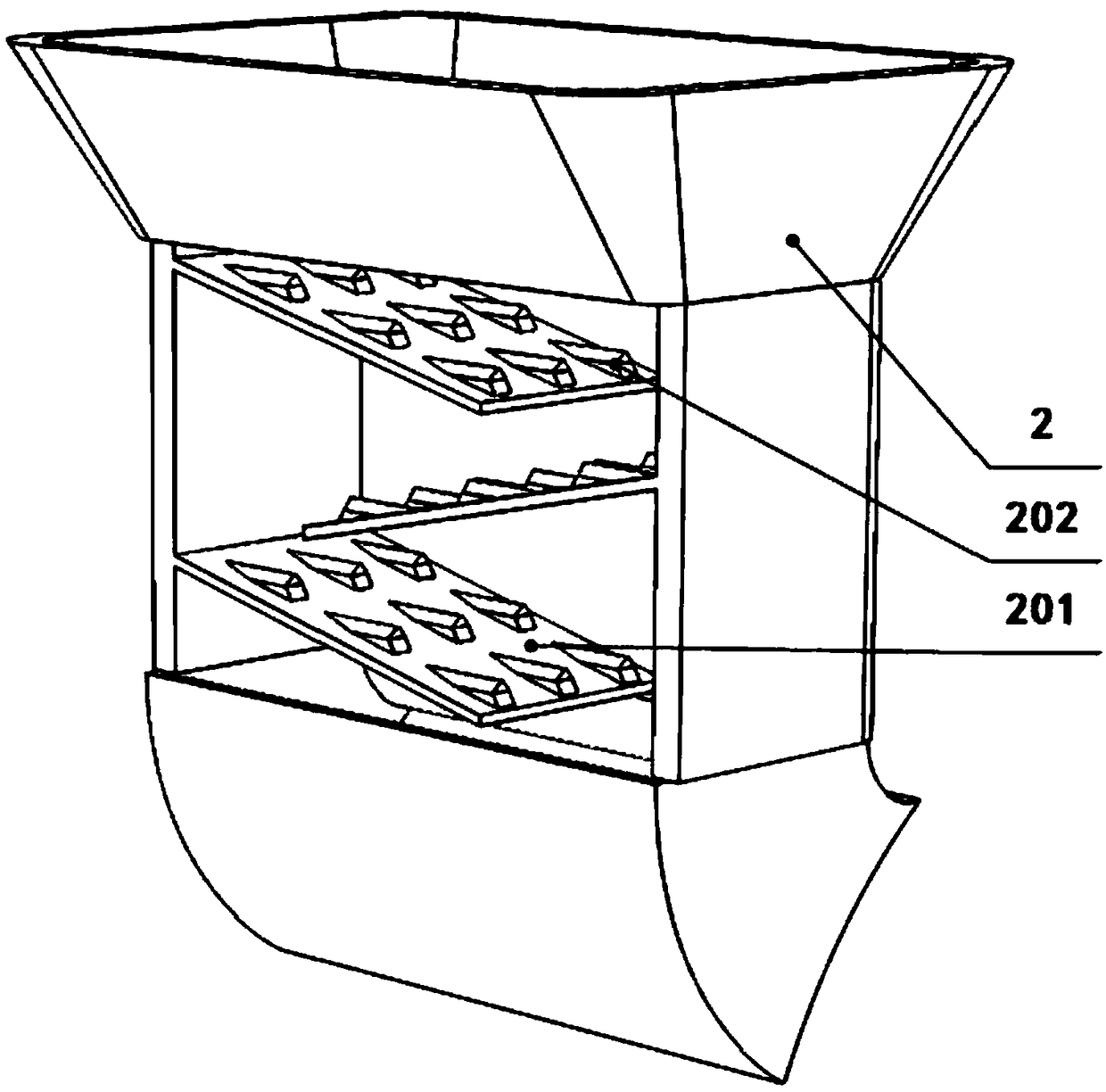

Dual-powder mixing printing system for 3D printing

PendingCN110605394AAchieve recyclingNo confusionAdditive manufacturing apparatusIncreasing energy efficiencySystems designEngineering

The invention relates to a dual-powder mixing printing system for 3D printing. For an existing 3D printing system, a powder A cylinder (4) and a powder B cylinder (5) are arranged at the two sides ofa forming cylinder (3) in a sealing box (1) respectively, in cooperation with scraper systems designed for the powder cylinders respectively, on the basis of a laser device (2), alternate 3D printingbetween two kinds of powder is achieved, meanwhile, a powder A collecting cylinder (6) is introduced at the position between the powder A cylinder (4) and the forming cylinder (3), and a powder B collecting cylinder (7) is introduced at the position between the powder B cylinder (5) and the forming cylinder (3), the powder in the corresponding powder cylinders is scraped into the forming cylinder(3) through scrapers (12) in the scraper systems, and then surplus powder is scraped into the corresponding powder collecting cylinders; the surplus powder can be recycled, the powder obtained after layers of 3D printing is not mixed, the powder can be used secondarily, the advantages of the two kinds of powder are achieved, and the metal performance of forming materials is effectively improved.

Owner:NANJING CHAMLION LASER TECH CO LTD

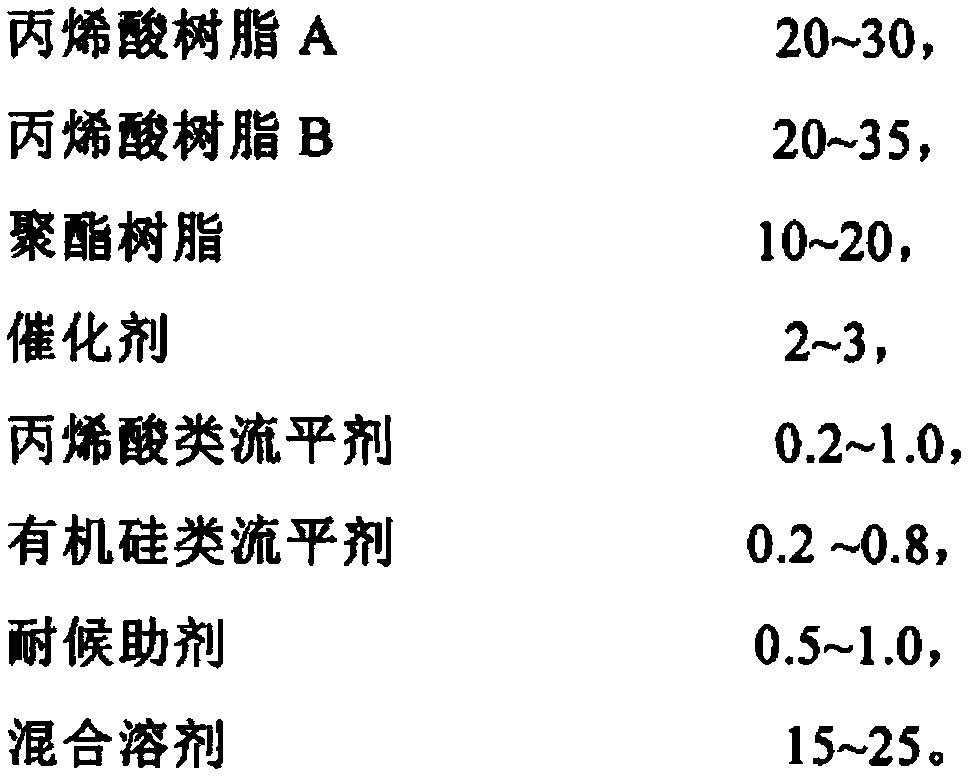

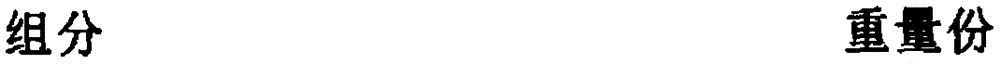

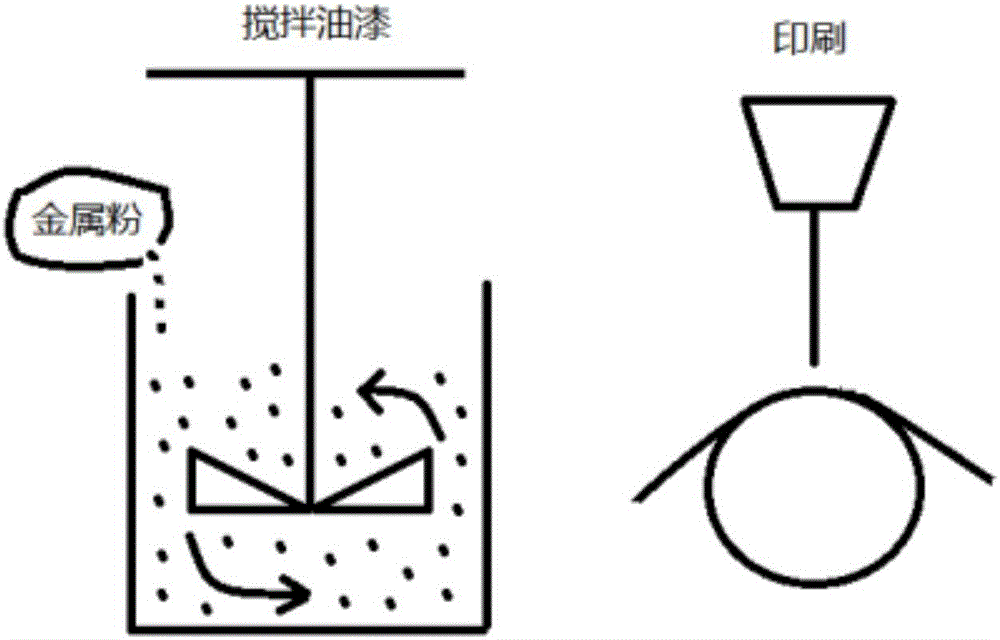

High-temperature-resistant high-metal-effect plastic paint and preparation method thereof

InactiveCN104559556AIncrease polarityGood compatibilityPolyester coatingsAcrylic resinPolyester resin

The invention relates to a high-temperature-resistant high-metal-effect plastic paint and a preparation method thereof. The preparation method comprises the following steps: sequentially adding 20-30 wt% of acrylic resin A, 20-35 wt% of acrylic resin B, 10-20 wt% of polyester resin, 2-3 wt% of catalyst, 0.2-1.0 wt% of acrylic leveling agent, 0.2-0.8 wt% of organic silicon leveling agent, 0.5-1.0 wt% of weather-resistant assistant and 15-25 wt% of mixed solvent, slowly stirring, and stirring at the high speed of 600-800 rpm for 15 minutes to obtain the high-temperature-resistant high-metal-effect plastic paint. Compared with the prior art, the method enhances the high temperature resistance, high metal effect, wear resistance and other properties of the plastic paint.

Owner:DONGLAI COATING TECH SHANGHAI

Ore dressing device

ActiveCN108855436ANot prone to damageImprove securityMagnetic separationGrain treatmentsEngineeringMachining process

The invention discloses an ore dressing device. The ore dressing device comprises a first worktable and a second worktable, and also comprises a primary crushing mechanism, a cutting crushing mechanism, a magnetic separation mechanism and a screening mechanism. The ore dressing device crushes, cuts, magnetically separates and screens minerals to obtain the needed ore by virtue of the primary crushing mechanism, the cutting crushing mechanism, the magnetic separation mechanism and the screening mechanism, the situation that the machine is seized and damaged in the crushing processing process can be completely avoided, the safety is high, the ore dressing period is short, and the efficiency is high. The ore dressing device can perform the heavy-wind cutting for the minerals by virtue of thecutting crushing mechanism, so that not only can the crushing effect be realized, but also a drying impurity removal effect can be realized, and the useless dust in the dressed ore is less; and by virtue of the magnetic separation mechanism, the high-value ore of the metal property can be separated from the impurity minerals with no metal property, and the ores can be collected in a classifying manner according to the size of the ore by virtue of the screening mehcainsm.

Owner:YUNNAN YUANKUANG TECH DEV CO LTD

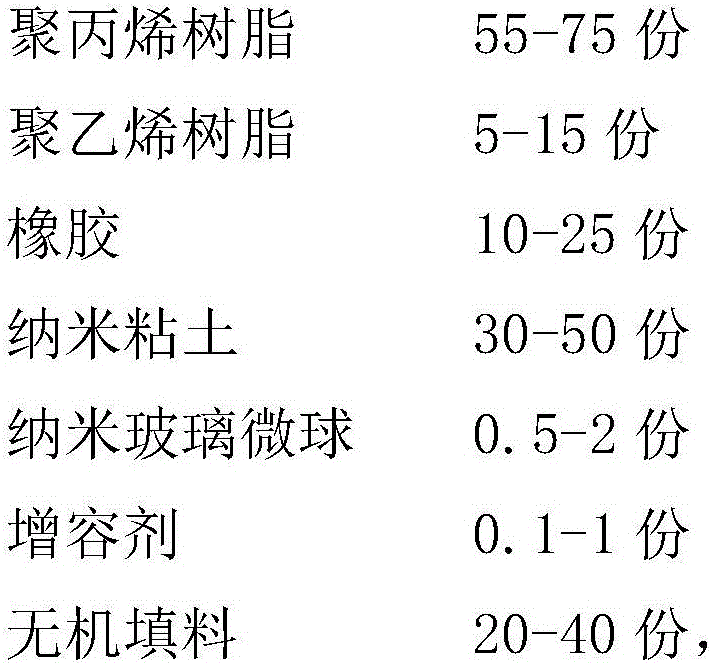

Automobile interior material being suitable for vacuum molding and achieving pearlescent appearance

InactiveCN106280000AImprove metal performanceNew Visual EnjoymentPolyurea/polyurethane coatingsSilicon dioxideMetal

The invention discloses an automobile interior material being suitable for vacuum molding and achieving pearlescent appearance. The automobile interior material comprises a TPO surface and waterborne paint which is uniformly applied to the TPO surface, and the waterborne paint is waterborne polyurethane paint which is prepared from 60-75 parts of waterborne polyurethane dispersoid, 0.5-1.5 parts of a polyurethane thickening agent, 0.1-0.5 part of an isocyanate curing agent, 30-60 parts of water and 0.5-2 parts of silicon dioxide. According to the automobile interior material, the metal effect of TPO is enhanced, the metal-color appearance is given to the TPO surface, and then the automobile interior material achieves the unique effect different from the effect generated when dye is used in the past; brand new visual enjoyment is provided for a user, the interior material with the metal pearlescent appearance gives the high-end feeling to the user, the status symbol of the user is improved, and the requirement of existing automobile interior material development is met.

Owner:BENECKE CHANGSHUN AUTO TRIMZHANGJIAGANG

Easy-to-cut titanium alloy

The invention discloses easy-to-cut titanium alloy, which comprises the following components in percentage by weight: 3 percent to 6.1 percent of chromium, 1 percent to 4 percent of manganese, 5.1 percent to 8 percent of aluminum, 0.4 percent to 1.3 percent of silicon, 3.7 percent to 7 percent of magnesium, 1.3 percent to 2.7 percent of lead, and the balance titanium. According to the easy-to-cut titanium alloy provided by the invention, the manganese, the aluminum, a small amount of lead and other metals are added, a vacuum consumable-electrode arc melting technology is adopted for melting for three times repeatedly, and degassing, deoxidizing and impurity removing processes are better realized for the metal materials, so that a pure metal material billet is acquired; due to high melting rate and the accurate control of an electric arc heating area, the consistency of a melting metal solidification direction is ensured, a metal performance of the material is greatly improved, and the titanium alloy can be easily cut; and later, double annealing is carried out, so that recrystallization is fully carried out without increasing crystal particles in the titanium alloy, the plasticity and the structure stability of the titanium alloy are improved, the machinability of the titanium alloy is improved, and meanwhile, the high strength and the stability of the titanium alloy are further maintained.

Owner:ANHUI YINLONG PUMP VALVE

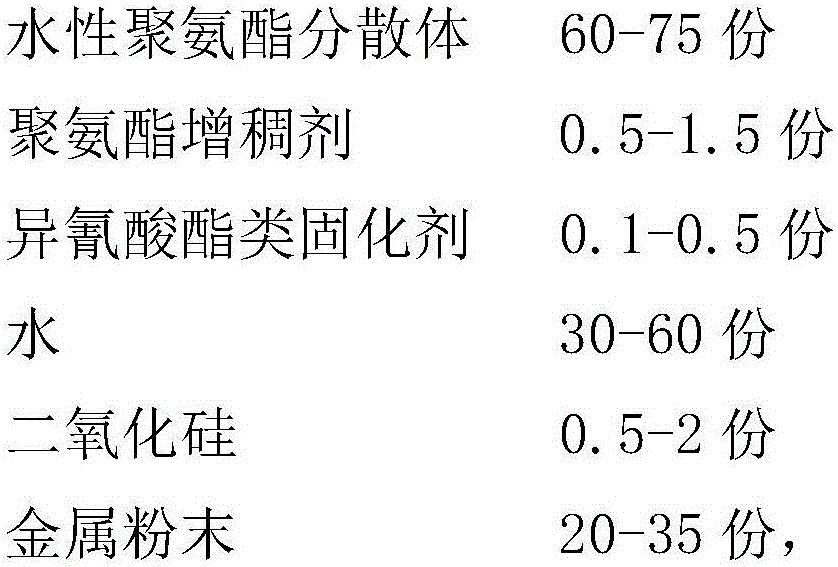

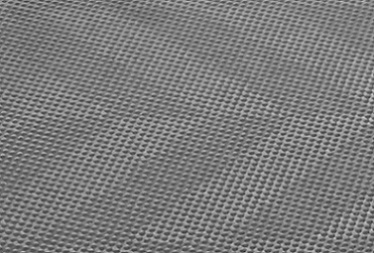

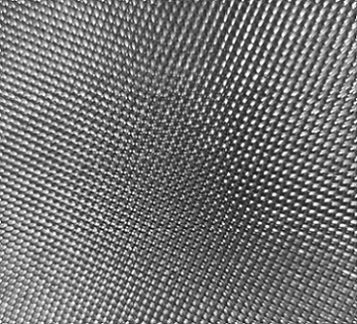

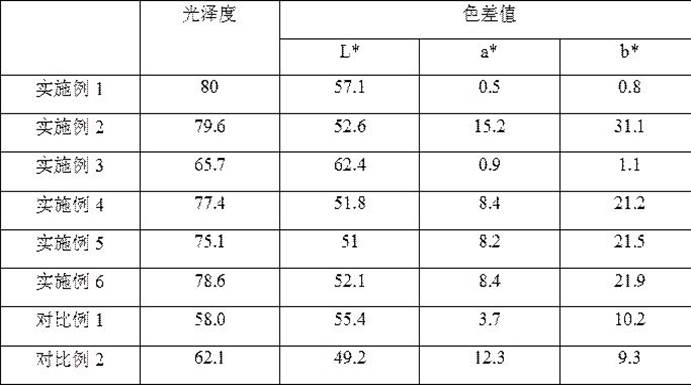

Appearance-improving spraying-free aesthetic resin and its preparation method

Owner:SHANGHAI KUMHO SUNNY PLASTICS

Metal glaze as well as preparation method and application method thereof

The invention belongs to the technical field of ceramic glaze, and relates to metal glaze as well as a preparation method and an application method thereof. The metal glaze comprises the following raw materials in percentage by weight: 30-37% of albite, 8-15% of quartz, 0-4% of wollastonite, 9-16% of calcined kaolin, 4-6% of calcined zinc oxide, 19-23% of calcined iron phosphate and 13-20% of self-made high-phosphorus frit powder. On the basis of calcined iron phosphate, self-made high-phosphorus frit powder is added as a crystallization accelerant into the metal glaze, so that the metal luster is more easily presented. The element P is introduced into the self-made high-phosphorus frit powder in a frit form, and compared with a high-phosphorus raw material system, the self-made high-phosphorus frit powder has a wider firing temperature range, and the metal effect is more stably presented. By finely adjusting the ratio of the self-made high-phosphorus frit powder to the silicon-aluminum of the metal glaze, the adjustment of metal to different colors can be realized. In addition, the metal glaze is combined with a roller printing process, so that the glaze surface can present a good three-dimensional effect.

Owner:FOSHAN SANSHUI CREATE TIDE

Semiconductor structure and fabricating method thereof

ActiveUS8507338B2Improve metal performanceImprove electrical performanceTransistorSolid-state devicesGate dielectricSemiconductor structure

A fabricating method of semiconductor structure is provided. First, a substrate with a dielectric layer formed thereon is provided. The dielectric layer has a first opening and a second opening exposing a portion of the substrate. Further, a gate dielectric layer including a high-k dielectric layer and a barrier layer stacked thereon had been formed on the bottoms of the first opening and the second opening. Next, a sacrificial layer is formed on the portion of the gate dielectric layer within the second opening. Next, a first work function metal layer is formed to cover the portion of the gate dielectric layer within the first opening and the sacrificial layer. Then, the portion of the first work function metal layer and the sacrificial layer within the second opening are removed.

Owner:UNITED MICROELECTRONICS CORP

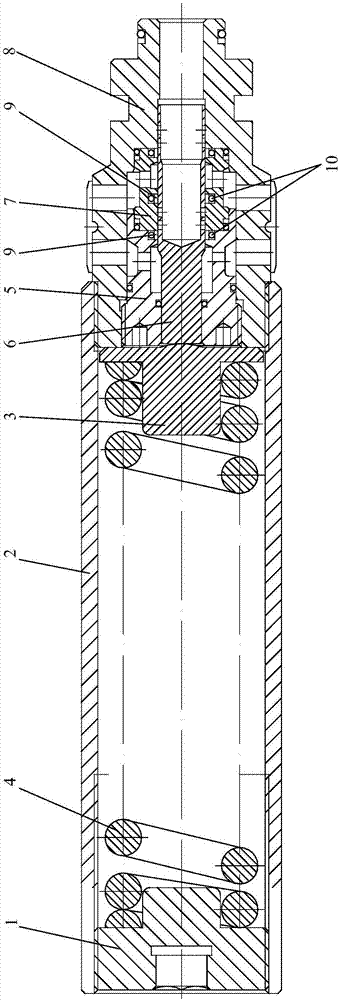

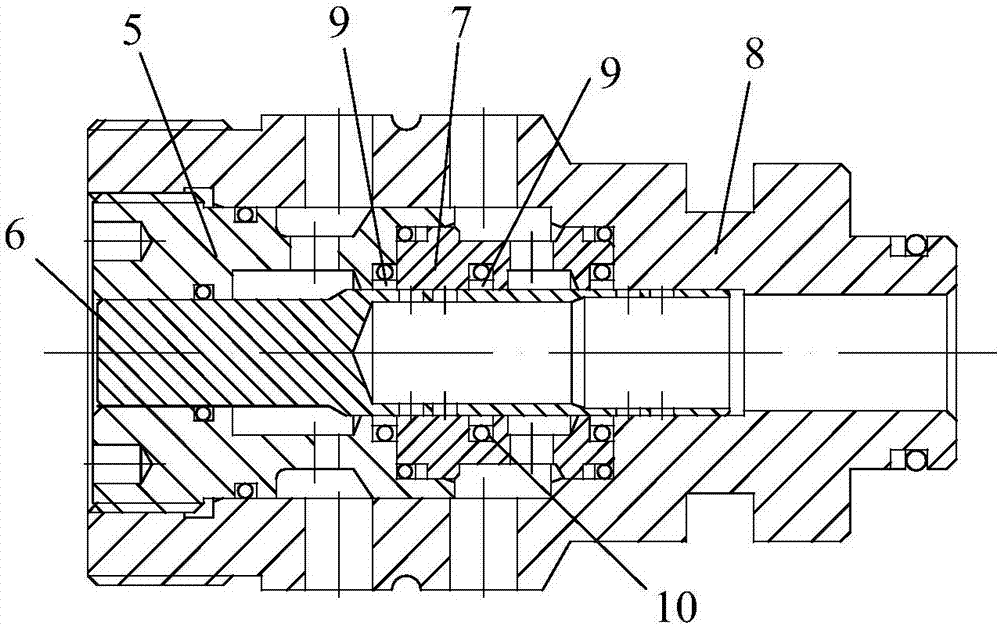

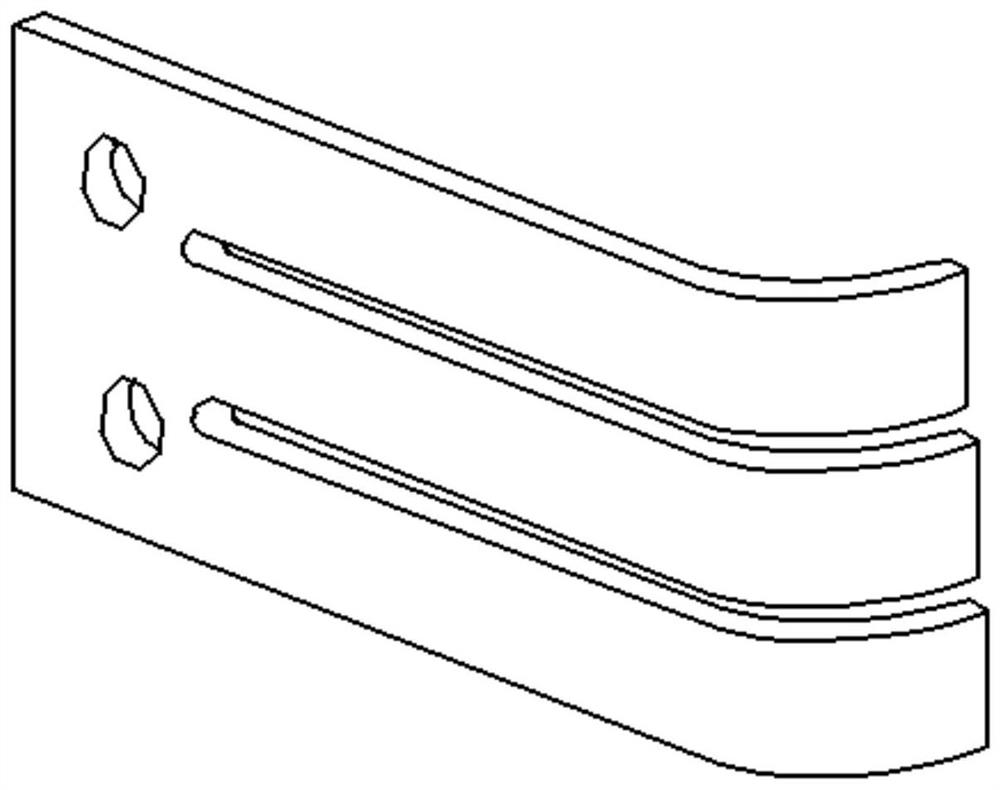

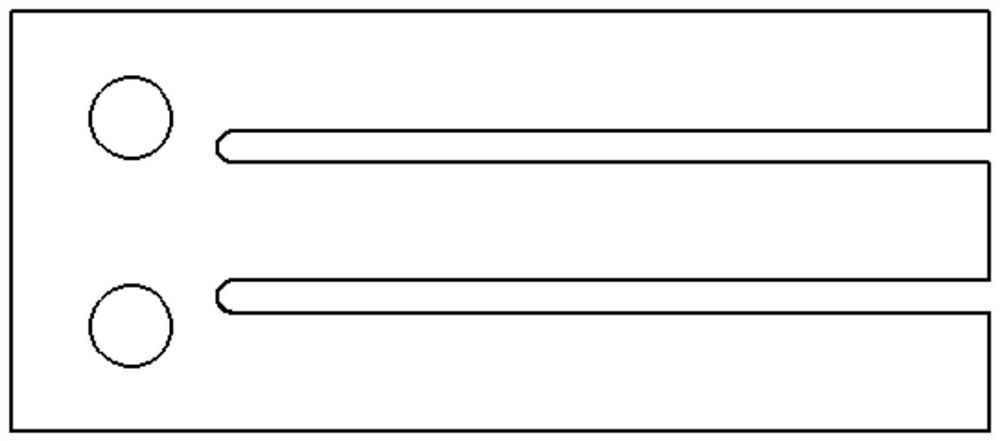

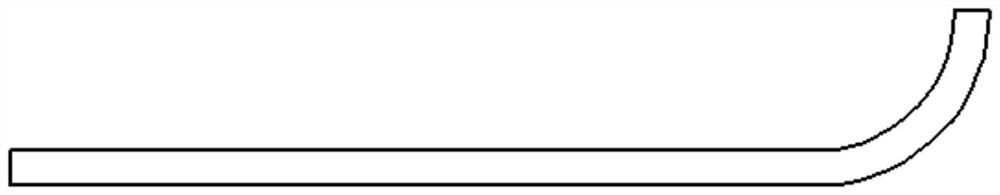

Production process of thin-wall boosting extruded tube and thin-wall boosting extruded tube

The invention discloses to a production process of a thin-wall boosting extruded tube and thin-wall boosting extruded tube, and belongs to the technical field of food processing equipment. The production process comprises the steps that after a high-quality pipe is selected and cut, a pipe blank with a boosting groove is formed in a bulging mode through a water swelling process, and then an annular pipe of an integrated structure used for welding a feeding pipe is drawn out; compared with a traditional metal casting process, a thin-wall boosting extrusion pipe manufactured through the production process has the advantages that the thickness of a pipe wall is greatly reduced, the thin-wall boosting extrusion pipe is light in weight, the energy consumption of the production process is low, the production cost is low, the process steps are simple, the production period is shortened, the production efficiency is improved, and the production cost is reduced, and continuous production can be realized.

Owner:杜亚玲

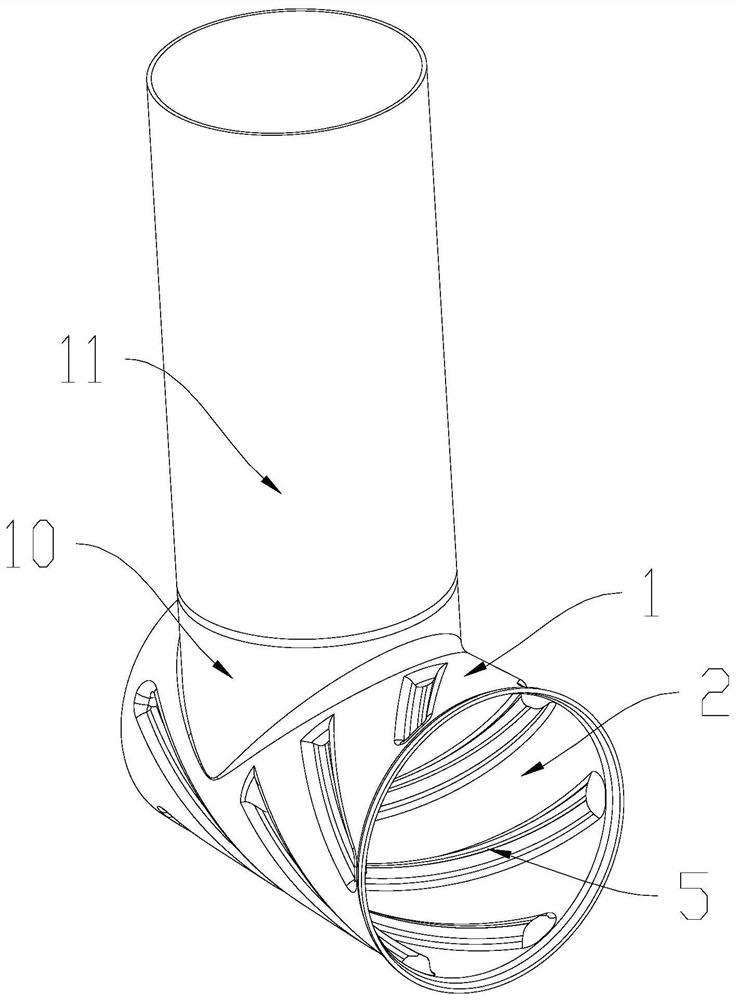

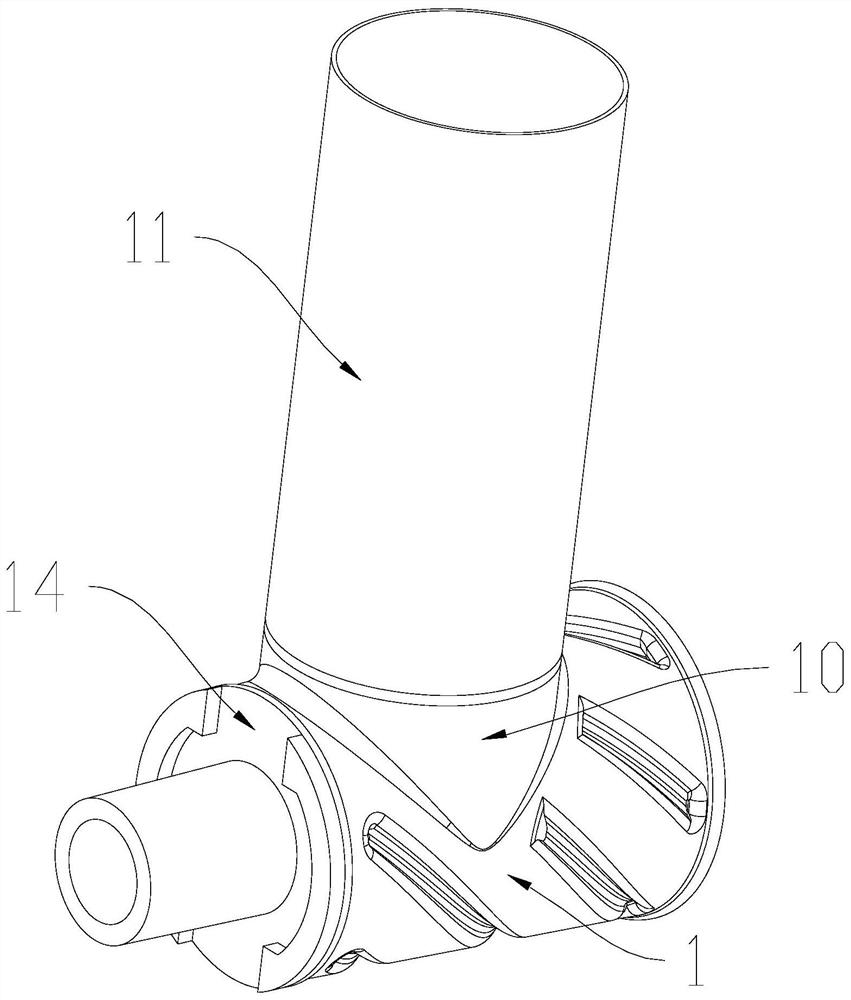

Valve element of safety valve

InactiveCN107503783AIncrease drainage flowImprove unloading capacityMine roof supportsEngineeringSafety valve

The invention discloses a valve element of a safety valve. The valve element comprises a liquid incoming section and a guide section which are axially arranged sequentially, a first liquid passing hole, a second liquid passing hole, a third liquid passing hole and a fourth liquid passing hole which are axially arranged sequentially are formed in the liquid incoming section, the first liquid passing hole and the second liquid passing hole are used for guiding liquid entering the valve element to a second liquid discharging hole of the safety valve, and the third liquid passing hole and the fourth liquid passing hole are in staggered arrangement. The first liquid passing hole, the second liquid passing hole, the third liquid passing hole and the fourth liquid passing hole are in staggered arrangement, so that liquid passing flow is increased, metal performance of the valve element is improved, rigidity of the valve element is improved, so that the valve element is less prone to breaking; the valve element is large in liquid passing flow, so that increasing of liquid discharging flow of the safety valve is facilitated, and unloading capacity of the safety valve is improved.

Owner:HONGDA INTELLIGENT MACHINERY CO LTD

Preparation method of CuCrZr alloy material self-operated contact finger product

ActiveCN111799117AImprove metal performanceReduce thicknessElectric switchesSolution treatmentPunching

The invention provides a preparation method of a CuCrZr alloy material self-operated contact finger product. The preparation method comprises the following steps: S1, taking raw materials including achromium block, a copper-zirconium 40 intermediate alloy, rare earth and an electrolytic copper plate for later use; S2, smelting the raw materials in a vacuum medium-frequency induction furnace, andobtaining a uniform alloy solution; S3, refining the alloy solution obtained in the S2, degassed and deoxidized and then introducing the solution into a mold for cooling crystallization, and obtainingan alloy ingot after demolding; S4, the alloy ingot obtained in S3 being subjected to extrusion, solution treatment, multi-pass drawing and aging treatment, and obtaining a treated profile; S5, conducting blanking, punching, bending and groove milling on the profile obtained in the S4, and obtaining a contact finger; and S6, performing surface deburring and overall shape correction on the contactfinger obtained in the step S5, and plating a nano-silver layer on the electric contact surface of the contact finger to obtain a self-operated contact finger product with the electric conductivity of greater than 85% IACS, the hardness HB of greater than 155 and the tensile strength of greater than 480MPa.

Owner:SIRUI ADVANCED COPPER ALLOY CO LTD

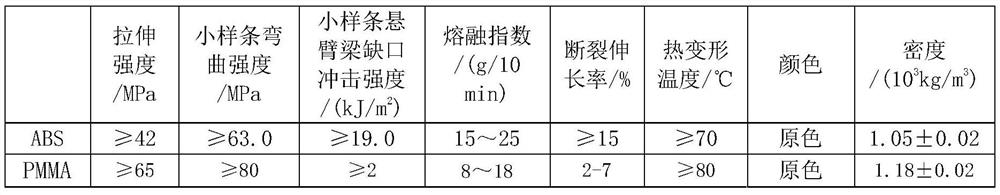

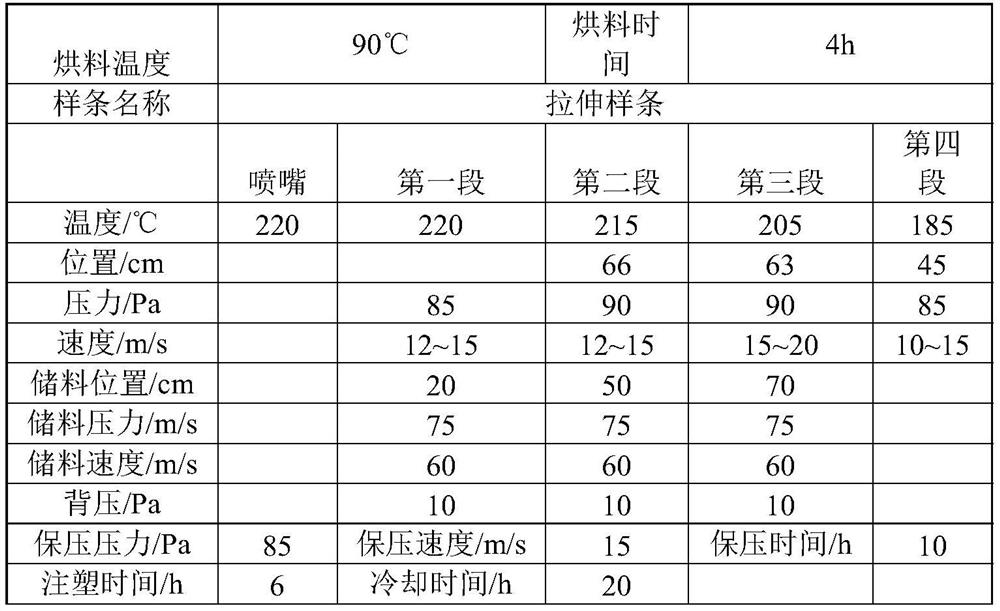

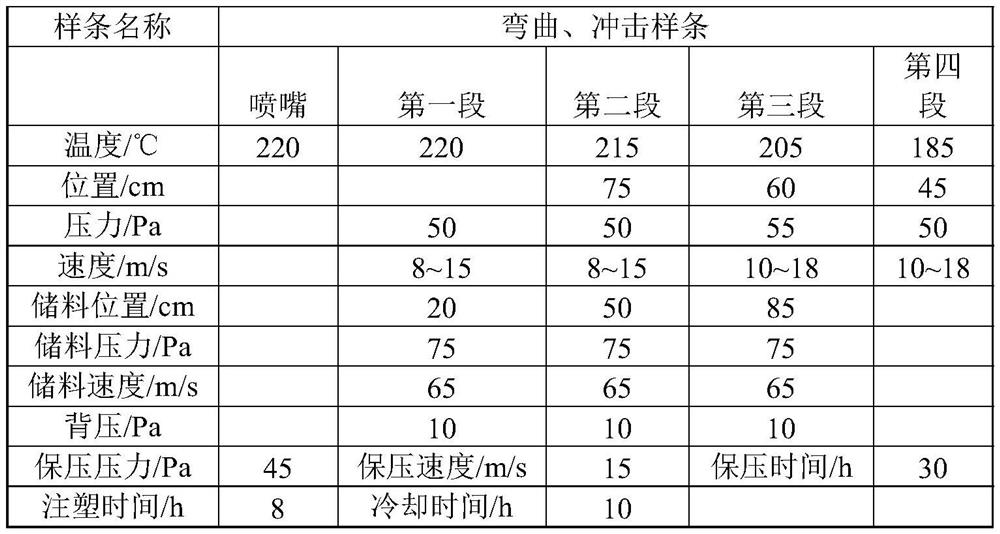

ABS-PMMA composite material as well as preparation method and application thereof

The invention discloses an ABS-PMMA composite material as well as a preparation method and application thereof. Based on the total weight, the composite material is prepared from the following materials: 65 to 85 weight percent of ABS resin, 5 to 25 weight percent of PMMA resin, 0.1 to 0.6 weight percent of antioxidant, 4 to 7 weight percent of lubricant, 0.5 to 3.5 weight percent of metal powder, 1.6 to 3 weight percent of pearlescent pigment and 0.2 to 0.8 weight percent of white oil. The composite material is relatively good in mechanical property, has high flowability and metal effect, and can be directly used for injection molding to obtain different appearance shapes, so that the material cost and the labor cost brought by a traditional spraying process are saved, and the pollution to the environment and the harm to a human body in the spraying process are avoided.

Owner:GREE ELECTRIC APPLIANCES INC +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com