Manufacturing technique of nickel-copper alloy

A manufacturing process and technology of nickel-copper alloy, applied in the field of nickel-copper alloy and its manufacturing process, can solve the problems of inability to achieve corrosion resistance effect, unsatisfactory effect of nickel-copper alloy, etc., and improve high-temperature oxidation resistance and corrosion resistance. , The effect of improving the metallographic structure and enhancing the compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

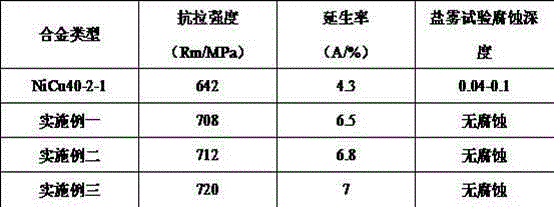

Examples

Embodiment 1

[0017] A manufacturing process of nickel-copper alloy, which mainly includes the following components, expressed in weight percentage: 35% copper, 15% iron, 15% chromium, 2% rhenium, 2.25% manganese, and 0.2% silicon , magnesium is 0.1%, titanium is 0.15%, nickel is 30%, and the rest is other ingredients.

[0018] The specific manufacturing process is as follows:

[0019] (1) Retrieving materials: select nickel, copper, iron, chromium, rhenium, manganese, silicon, magnesium and titanium as raw materials to prepare alloy materials according to the stated ratio;

[0020] (2) Smelting: Put nickel, copper, iron, chromium, rhenium, manganese, silicon, magnesium, and titanium into the melting furnace in sequence. The specific operation steps: first add nickel, copper, iron, and chromium to melt, and then Add rhenium, manganese, silicon, stir with electromagnetic, finally add titanium, magnesium, sample and cast;

[0021] (3) Annealing: steel ingot annealing temperature 1150°C--110...

Embodiment 2

[0026] A manufacturing process of nickel-copper alloy, which mainly includes the following components, expressed in weight percentage: 50% copper, 8% iron, 10% chromium, 0.5% rhenium, 2% manganese, and 0.15% silicon , magnesium is 0.05%, titanium is 0.1%, nickel is 29%, and the rest is other components.

[0027] The manufacturing process steps include the following operations in sequence:

[0028] (1) Retrieving materials: select nickel, copper, iron, chromium, rhenium, manganese, silicon, magnesium and titanium as raw materials to prepare alloy materials according to the stated ratio;

[0029] (2) Smelting: Put nickel, copper, iron, chromium, rhenium, manganese, silicon, magnesium, and titanium into the melting furnace in sequence. The specific operation steps: first add nickel, copper, iron, and chromium to melt, and then Add rhenium, manganese, silicon, stir with electromagnetic, finally add titanium, magnesium, sample and cast;

[0030] (3) Annealing: steel ingot anneali...

Embodiment 3

[0035] A manufacturing process of nickel-copper alloy, which mainly includes the following components, expressed in weight percentage: 40% copper, 10% iron, 12% chromium, 1.5% rhenium, 2% manganese, and 0.17% silicon , magnesium is 0.06%, titanium is 0.12%, nickel is 34%, and the rest is other components.

[0036] The manufacturing process steps include the following operations in sequence:

[0037] (1) Retrieving materials: select nickel, copper, iron, chromium, rhenium, manganese, silicon, magnesium and titanium as raw materials to prepare alloy materials according to the stated ratio;

[0038] (2) Smelting: Put nickel, copper, iron, chromium, rhenium, manganese, silicon, magnesium, and titanium into the melting furnace in sequence. The specific operation steps: first add nickel, copper, iron, and chromium to melt, and then Add rhenium, manganese, silicon, stir with electromagnetic, finally add titanium, magnesium, sample and cast;

[0039] (3) Annealing: steel ingot annea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com