Manufacturing method of laser additive for porous aluminum alloy

A technology of laser additive and manufacturing methods, which is applied in the direction of additive manufacturing, additive processing, and improvement of process efficiency. The effect of high metal performance and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

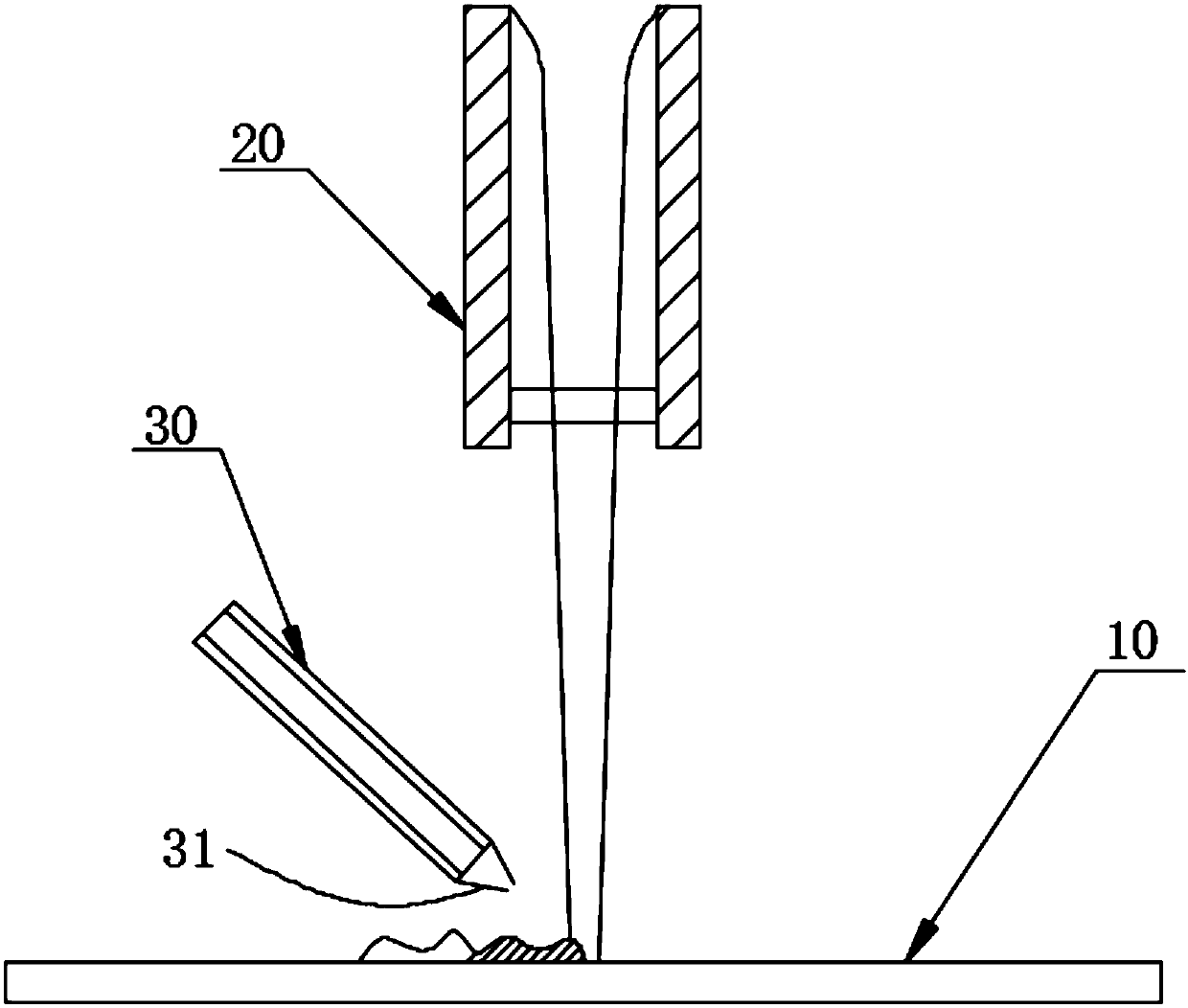

[0023] Now in conjunction with the accompanying drawings, the preferred embodiments of the present invention will be described in detail.

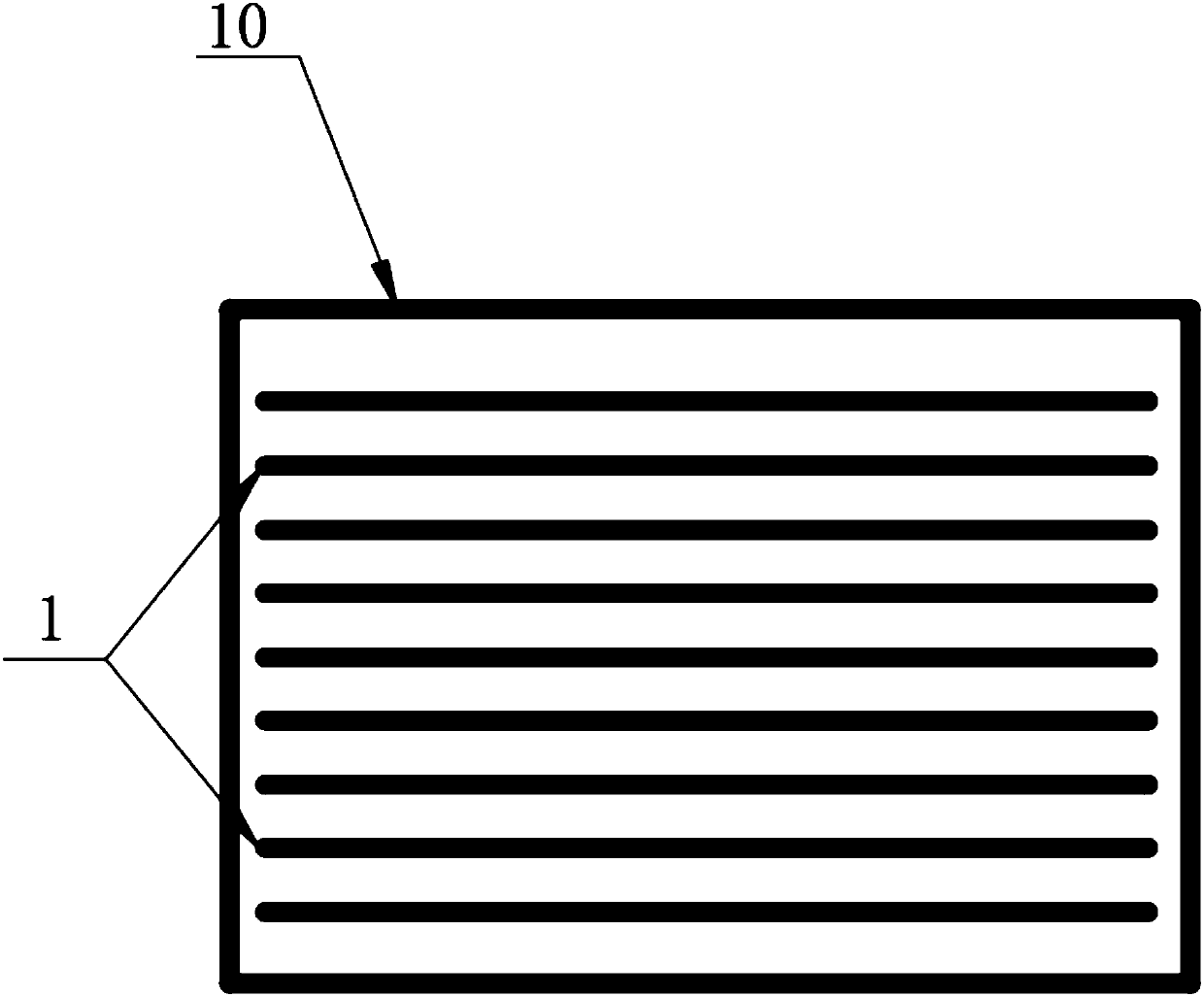

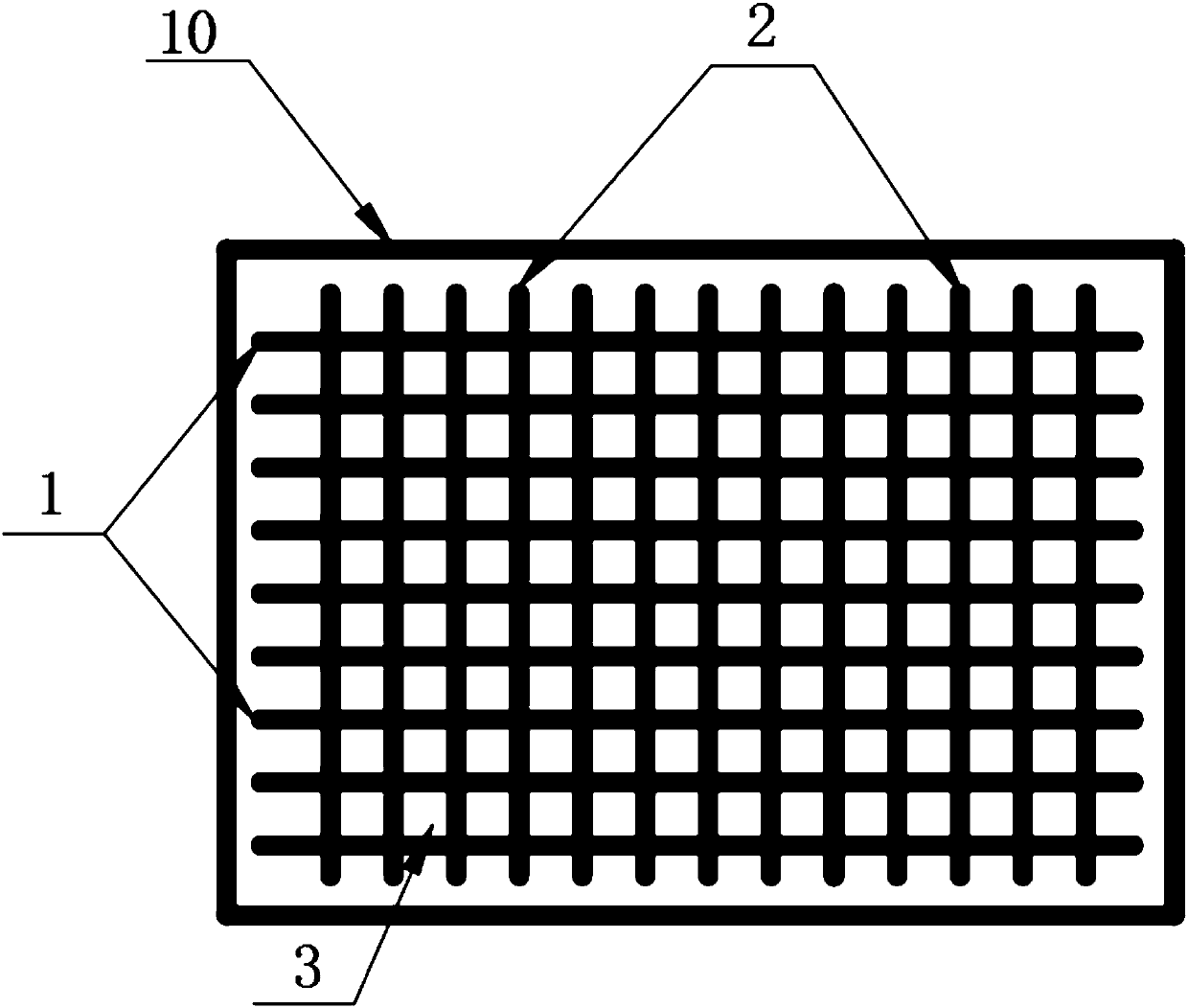

[0024] Such as figure 1 As shown, the present invention provides a method for laser additive manufacturing of porous aluminum alloys. The size of the formed pores is controlled by precisely controlling the interval of the linear trajectory, and then the porosity of the aluminum alloy is controlled. In this way, a dense structure and high hardness can be obtained. , Aluminum alloy with high metal performance.

[0025] The method includes the following steps:

[0026] S1: uniformly paving the first layer of alloy powder on the substrate 10;

[0027] S2: The laser 20 focuses on the first layer of alloy powder for scanning to form a number of first linear trajectories 1, while scanning, the gas blowing device 30 blows protective gas to the melting place of the alloy powder; wherein, several first linear trajectories 1 are parallel Interval ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com