Preparation method of CuCrZr alloy material self-operated contact finger product

An alloy material, self-contained technology, used in electrical components, electrical switches, circuits, etc., can solve the problems of wasting copper, overheating conductive circuits, and insufficient contact pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

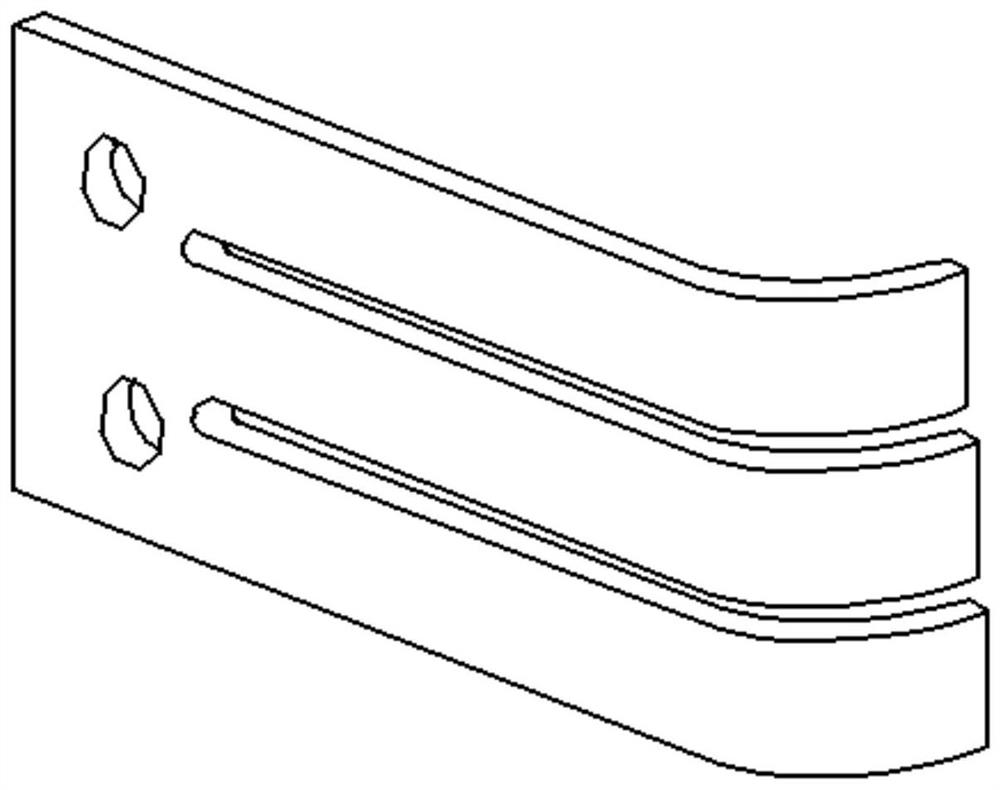

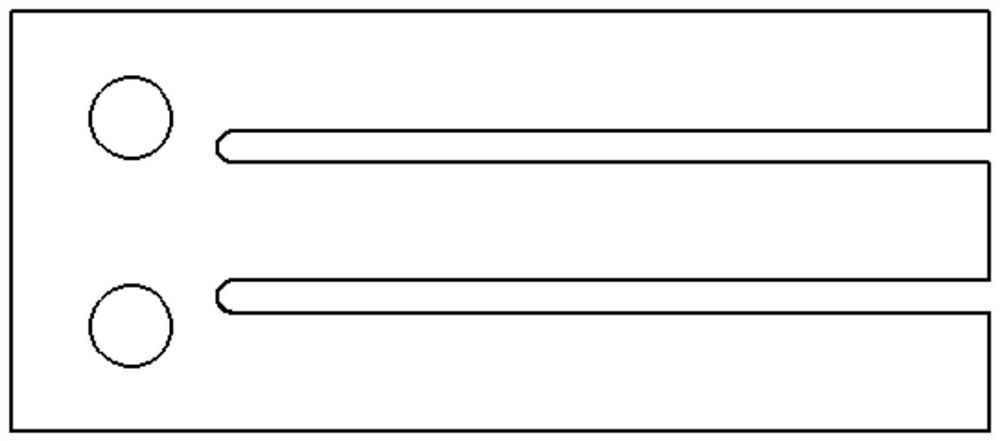

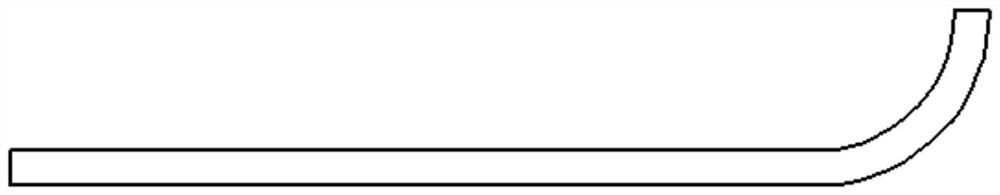

Image

Examples

Embodiment 1

[0040] Embodiment 1: A method for preparing a CuCrZr alloy material self-supporting contact finger product. The raw materials of the CuCrZr alloy material include chromium block, copper-zirconium 40 master alloy, rare earth and electrolytic copper plate. The preparation method includes the following steps:

[0041] S1: Ingredients

[0042] According to the weight percentage of 1.2% Cr, 0.15Zr, 0.05% La, and the balance is copper, take the above-mentioned raw material chromium block, copper-zirconium 40 master alloy, rare earth and electrolytic copper plate for use, and the raw material chromium block, copper-zirconium 40 master alloy, rare earth and electrolytic copper plate The total amount of unavoidable impurities contained in the copper plate is less than 0.30%;

[0043] S2: vacuum melting

[0044] Lay sheet-shaped electrolytic copper plates at the bottom of the vacuum intermediate frequency induction furnace, arrange strip-shaped electrolytic copper plates above the shee...

Embodiment 2

[0053] Embodiment 2: basically the same as Embodiment 1, the difference is:

[0054] S1: Ingredients

[0055] According to the weight percentage of 1.0% Cr, 0.1Zr, 0.05% La, and the balance is copper, take the above-mentioned raw material chromium block, copper-zirconium 40 master alloy, rare earth and electrolytic copper plate for use, and the raw material chromium block, copper-zirconium 40 master alloy, rare earth and electrolytic copper plate The total amount of unavoidable impurities contained in the copper plate is <0.30%.

Embodiment 3

[0056] Embodiment 3: basically the same as Embodiment 1, the difference is:

[0057] S1: Ingredients

[0058] According to the weight percentage of 0.8% Cr, 0.05Zr, 0.05% La, and the balance is copper, take the above-mentioned raw material chromium block, copper-zirconium 40 master alloy, rare earth and electrolytic copper plate for use, and the raw material chromium block, copper-zirconium 40 master alloy, rare earth and electrolytic The total amount of unavoidable impurities contained in the copper plate is <0.30%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com