Production process of thin-wall boosting extruded tube and thin-wall boosting extruded tube

A production process and technology for extruding tubes, which are applied to the production process of thin-walled booster-extruded tubes and the field of thin-walled booster-extruded tubes, which can solve the problems of wall thickness, heavy weight, and production costs Advanced problems, to achieve the effect of improving production efficiency, high production cost, and long production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

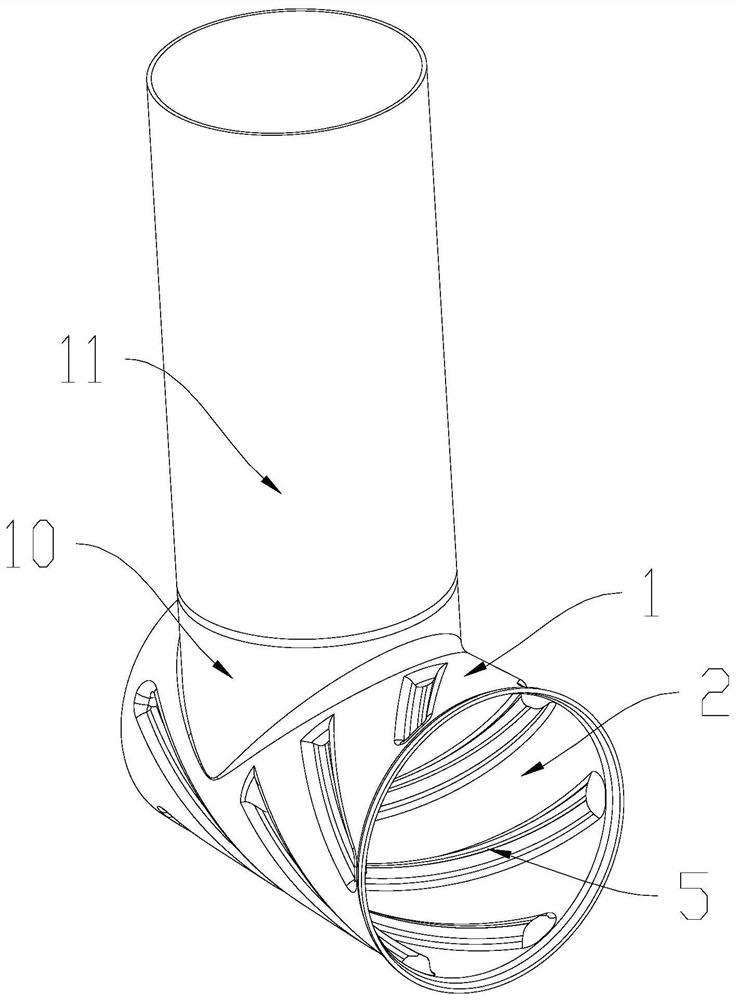

[0057] see Figure 2 to Figure 6 , a production process of a thin-walled booster extruded tube, comprising the following steps:

[0058] Step 1. Material selection: select high-quality pipes, and check and accept the quality of the pipes. Preferably, in the quality inspection of the pipes, according to the production process requirements of specific products, the material, roundness, diameter, and wall thickness of the pipes are selected. , straightness, and whether there are cracks, etc., to check and accept qualified pipes to ensure product quality. Among them, the material of the pipe blank is brass, copper or stainless steel, and the thickness of the pipe wall is 0.6mm-2.8mm. Brass, copper and stainless steel have good ductility, and after bulging, the metal properties of brass, copper and stainless steel, such as strength and toughness, can be greatly improved, and stainless steel is also resistant to oxidation and corrosion function; the pipe wall thickness of the pipe ...

Embodiment 2

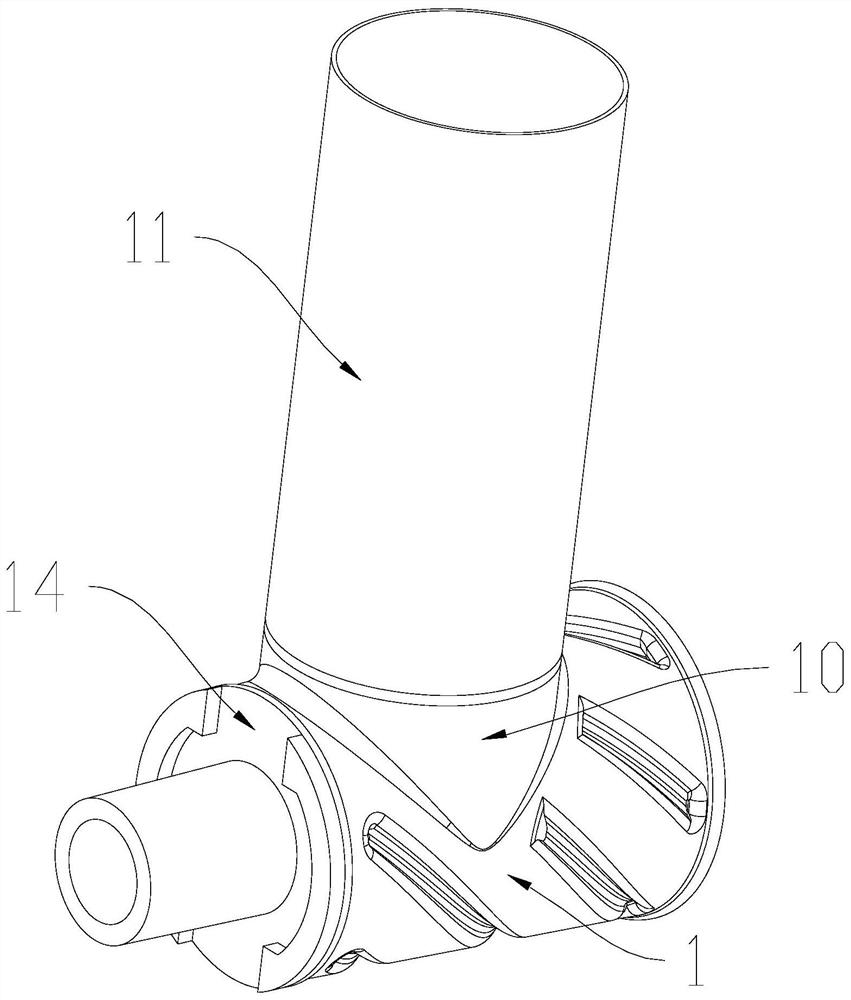

[0083] In addition, in order to achieve the purpose of designing the feeding tube as an eccentric structure (that is, the central axis of the feeding tube intersects with the central axis of the thin-walled booster extrusion tube), in addition to using the eccentricity of the mandrel and the drawing chamber in Example 1 In addition to the structural scheme, in this embodiment, the technical scheme of eccentric tube correction can also be adopted, specifically, see Figure 7 , the following steps are also included before machining after the annular tube is drawn from the tube blank:

[0084] Eccentric tube correction: use the correcting rod 15 matching the inner diameter of the annular tube 10, insert the correcting rod 15 into the annular tube 10, rotate the correcting rod 15 around the circumference of the tube blank, and the correcting rod 15 drives the circular tube The overall pipe wall of 10 deflects, so that the central axis of the annular pipe 10 intersects with the cen...

Embodiment 3

[0087] When applying the thin-walled push-and-extrude tube 1 to an actual product, for example, on a meat grinder, it is necessary to carry out a process between the thin-walled push-and-extrude tube 1 and other related parts in the actual product equipment. Cooperate with the design, take the meat grinder as an example in this embodiment, see Figure 8 and Figure 9 , when the thin-walled booster extruded tube 1 is installed on the meat grinder, the end of the minced meat outlet of the meat grinder is the end of the tube blank of the thin-walled boosted extruded tube 1 away from the annular tube 10, that is, the tube blank is far away from the annular tube 10. One end of the pipe 10 is the discharge end, and an extrusion discharge part is also installed on the discharge end to improve the efficiency of meat grinding. The extruded tube 1 is fixedly installed, and the end cover 16 is provided with a plurality of outlets for discharging materials. For the fixed installation of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com