Large-span long-cantilever connection structure and construction technique

A technology of conjoined structure and long cantilever, applied in building construction, construction, building material processing and other directions, can solve the problem of inconvenient direct application of large-span and long cantilever solutions, achieve a broad scope of application and development space, and meet earthquake resistance. Performance requirements, simple and reliable connections

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

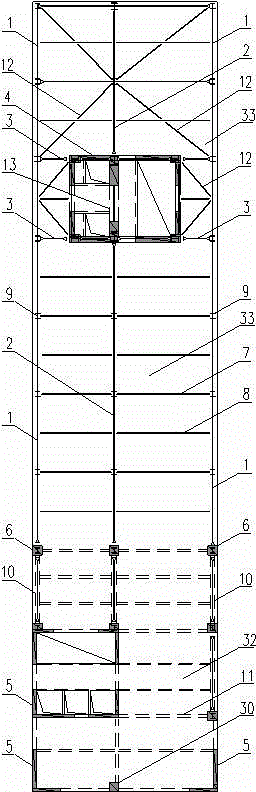

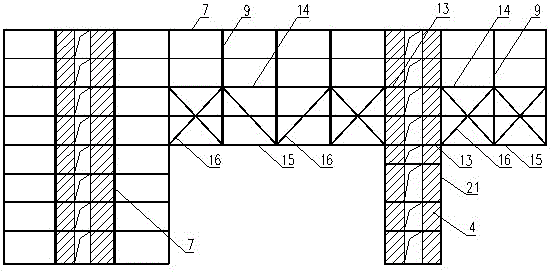

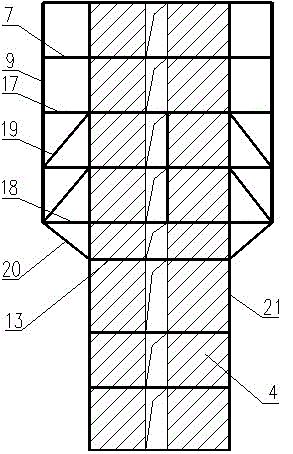

[0034] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0035] A kind of large-span long cantilever hybrid structure of the present invention, such as figure 1shown. Its structural plane is rectangular on the standard floor, and below the standard floor it is divided into two towers, one of which is a cylinder 4, which supports the upper long-span floor area and the long-cantilever floor area on its left and right sides respectively. Among them, the long-span floor area is composed of side-span steel truss 1, middle-span steel truss 2, steel frame beam 7, steel secondary beam 8, steel column 9 and steel truss floor deck 33; the long-cantilever floor area is composed of side-span steel truss 1. The middle span steel truss 2, the steel frame beam 7, the steel secondary beam 8, the steel column 9, the floor brace 12 and the steel truss floor deck 33.

[0036] The above-mention...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com