Patents

Literature

39results about How to "Pour dense" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

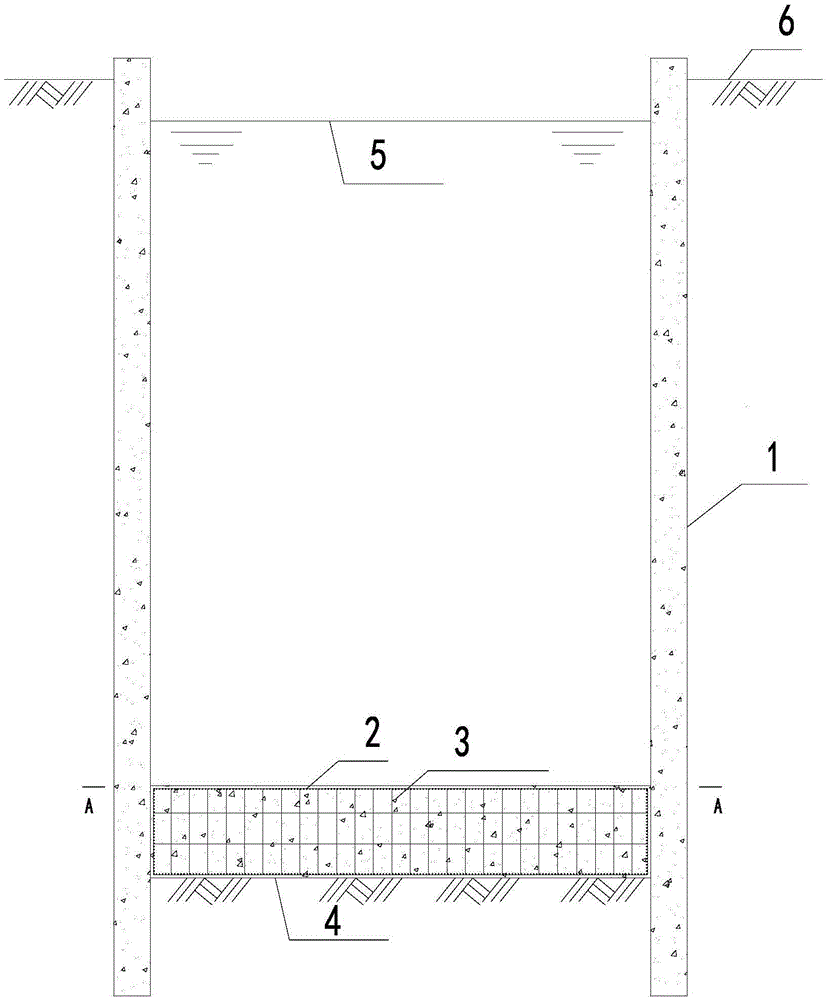

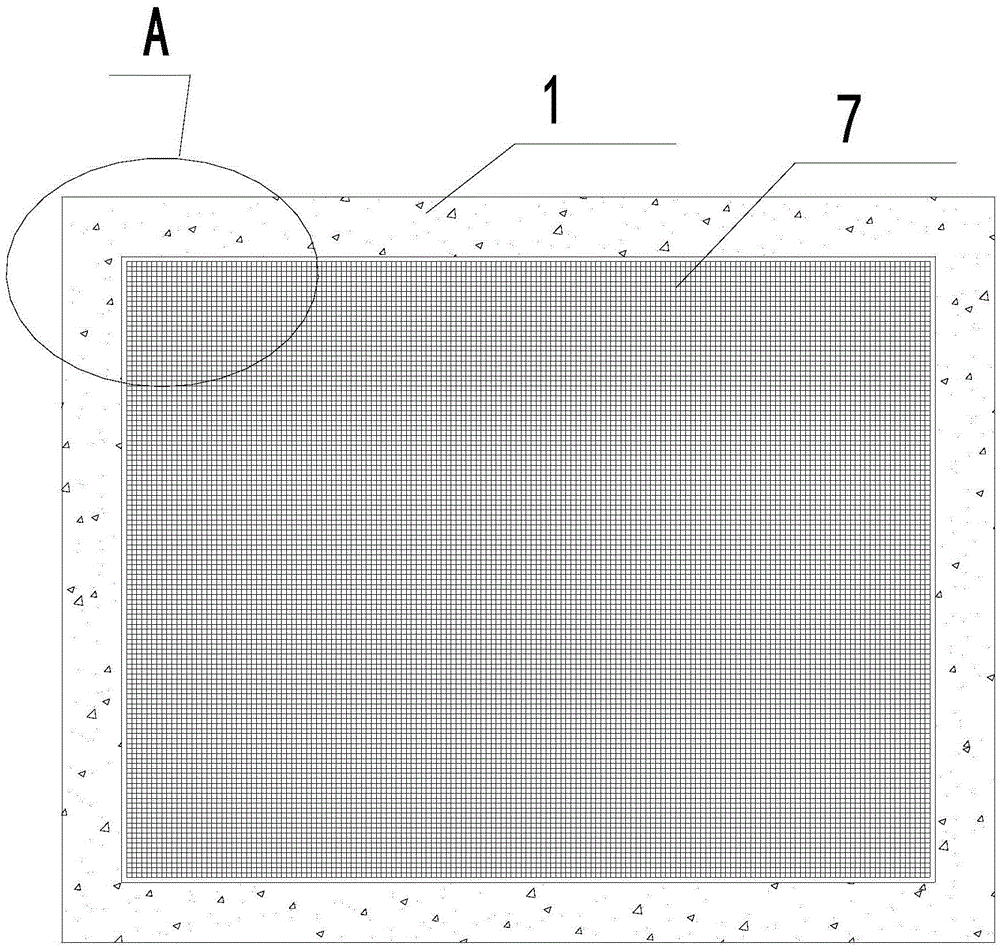

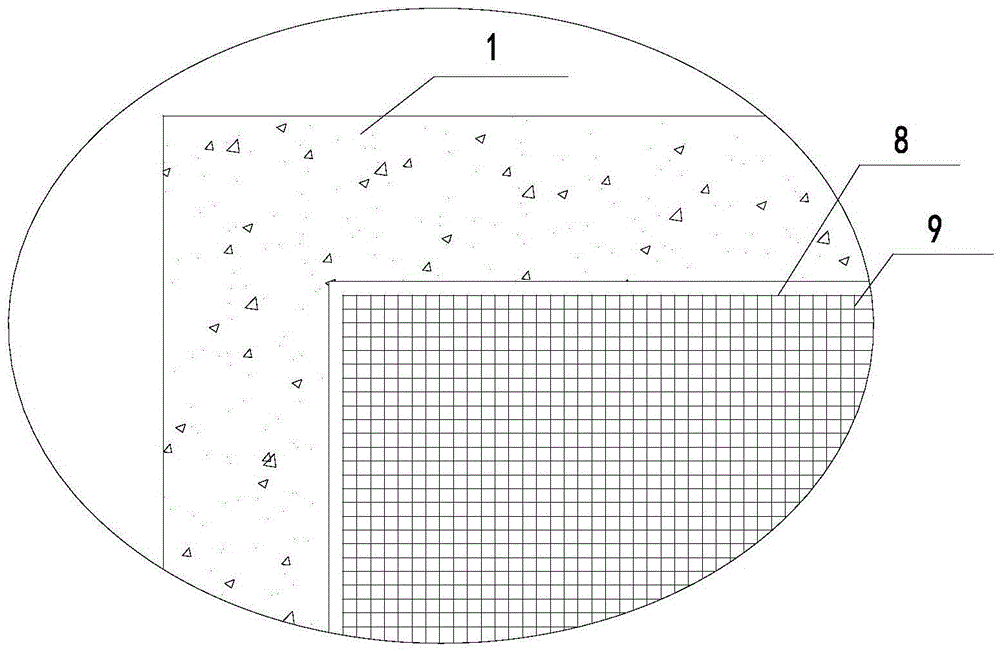

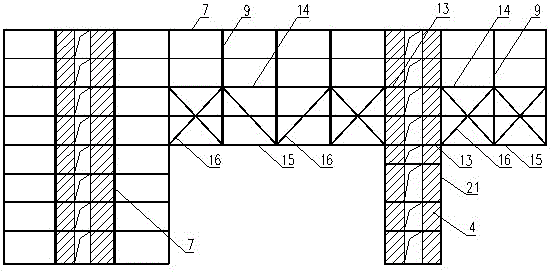

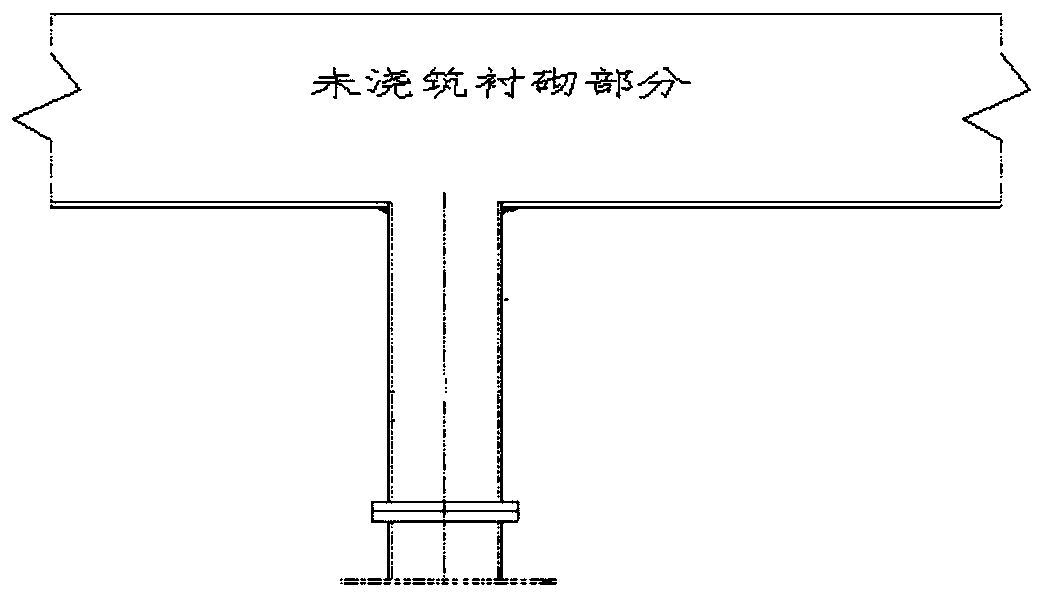

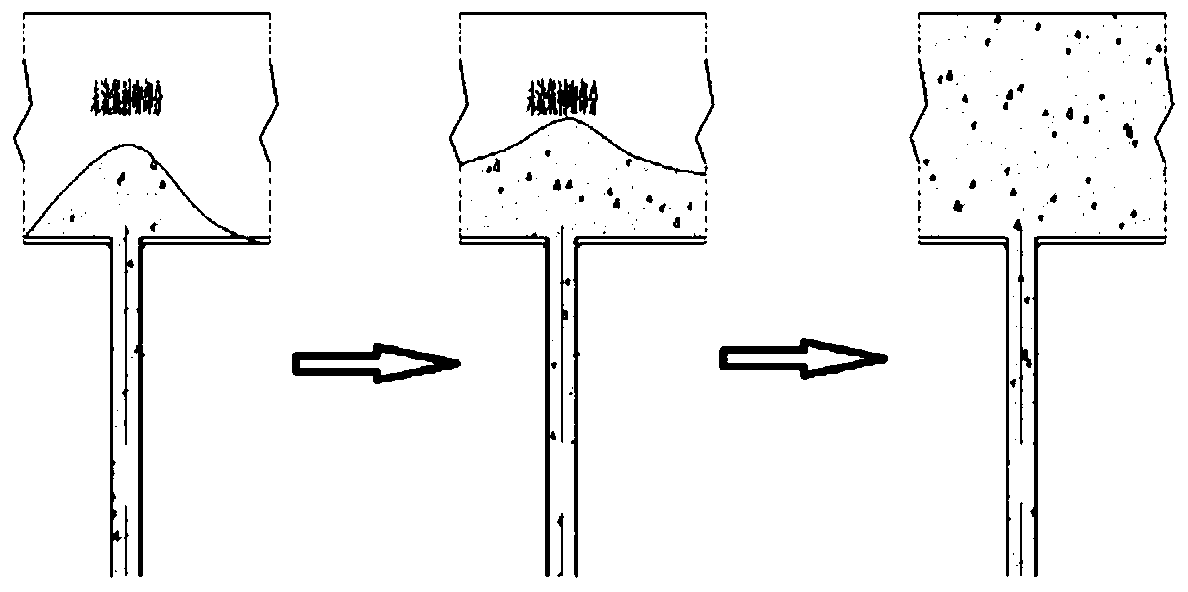

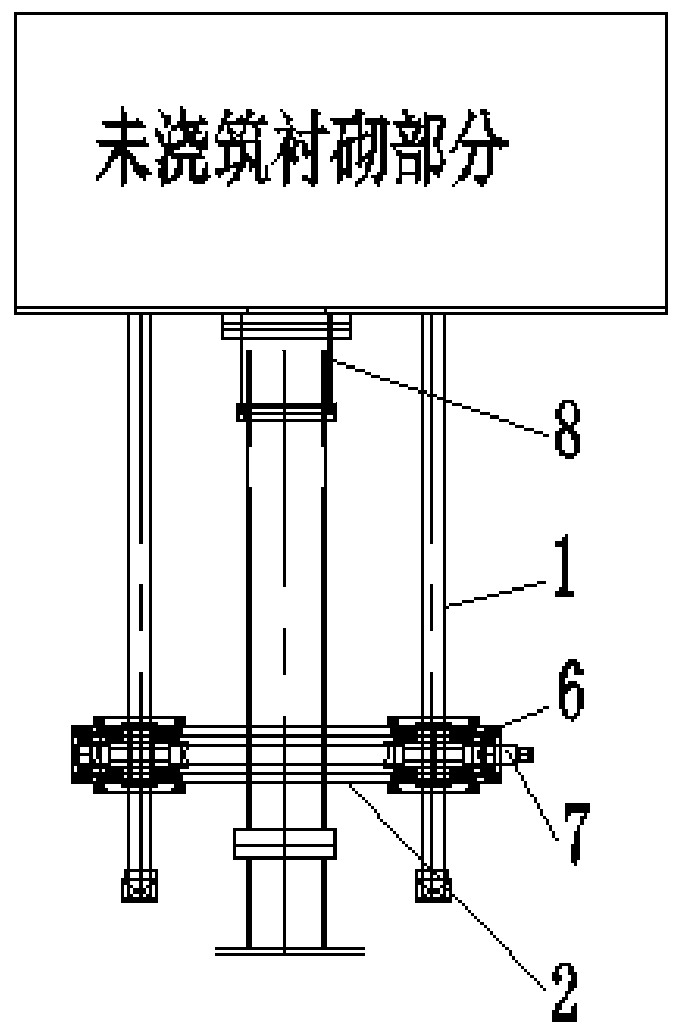

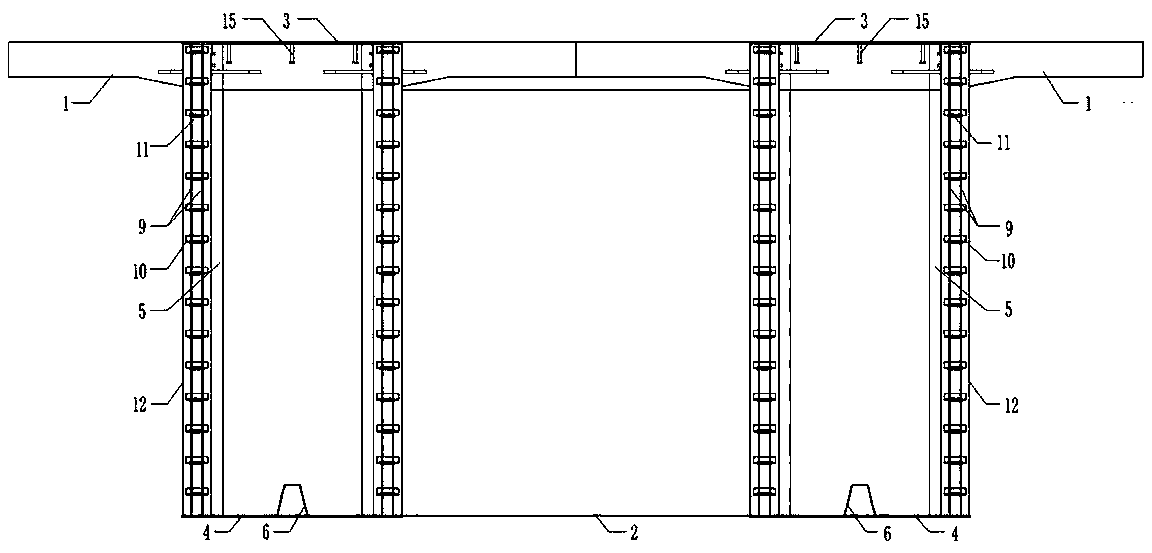

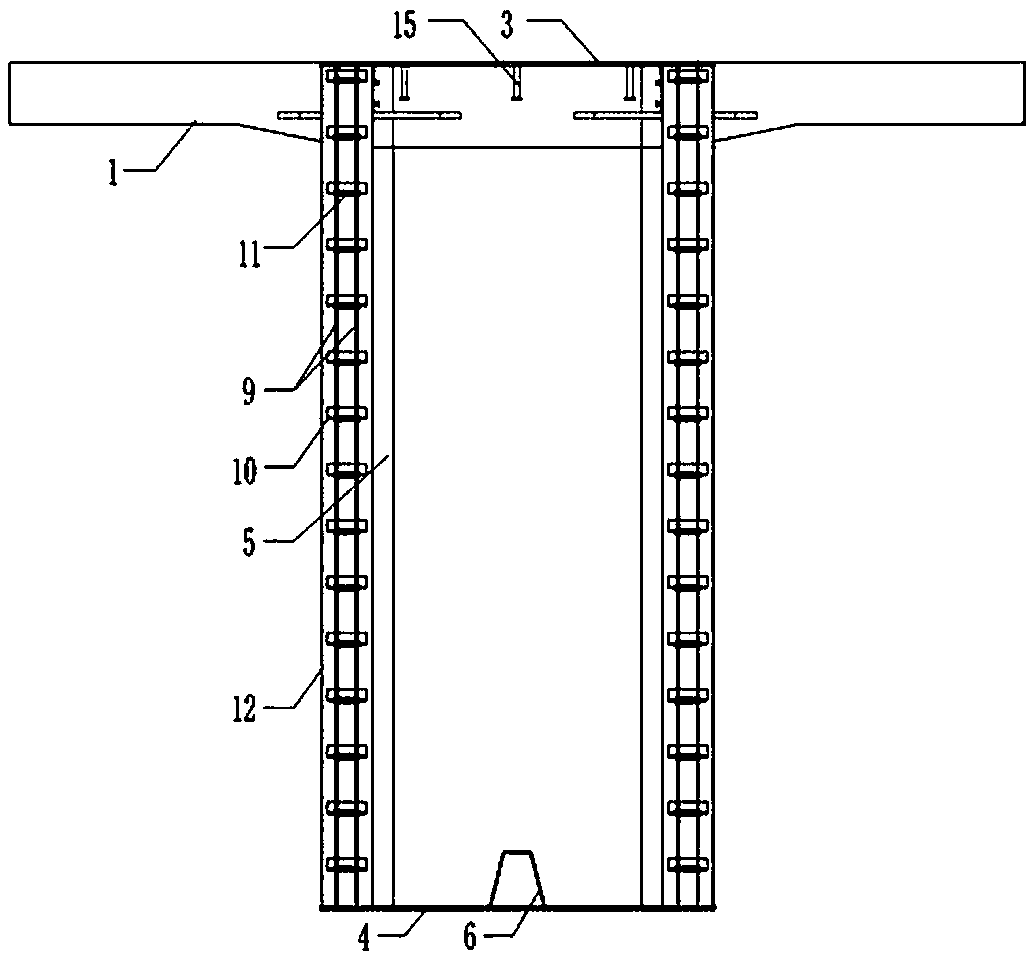

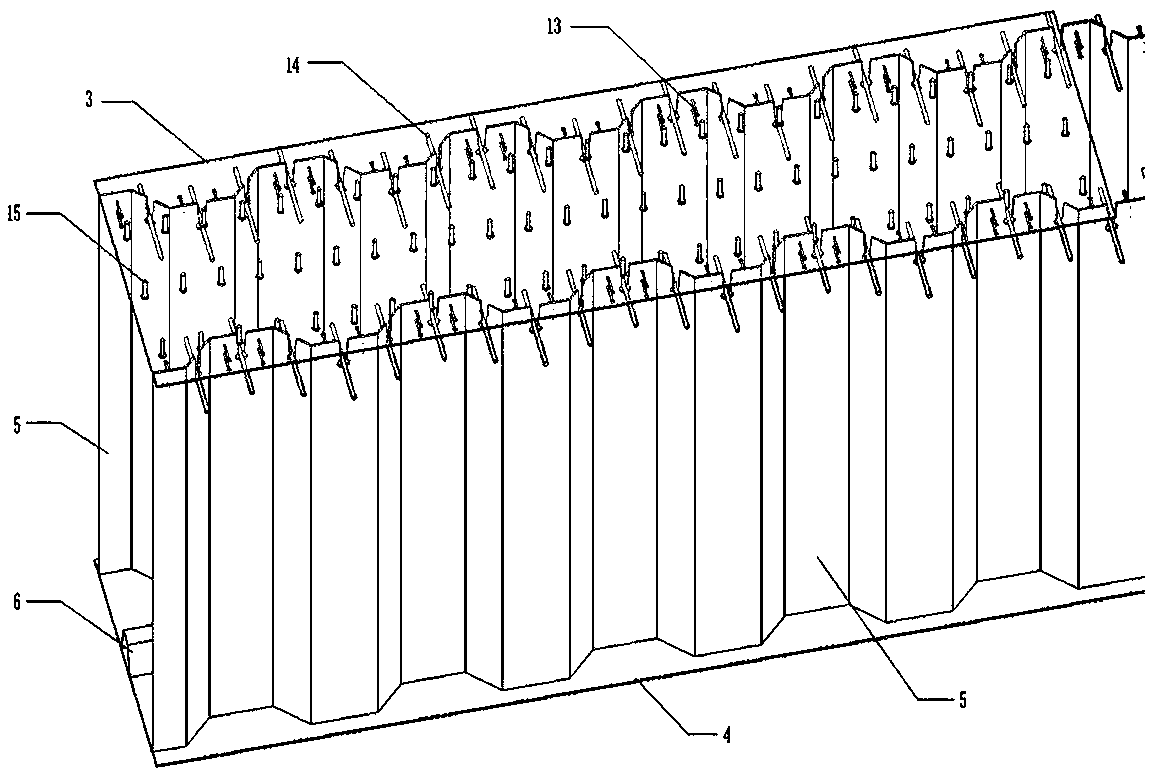

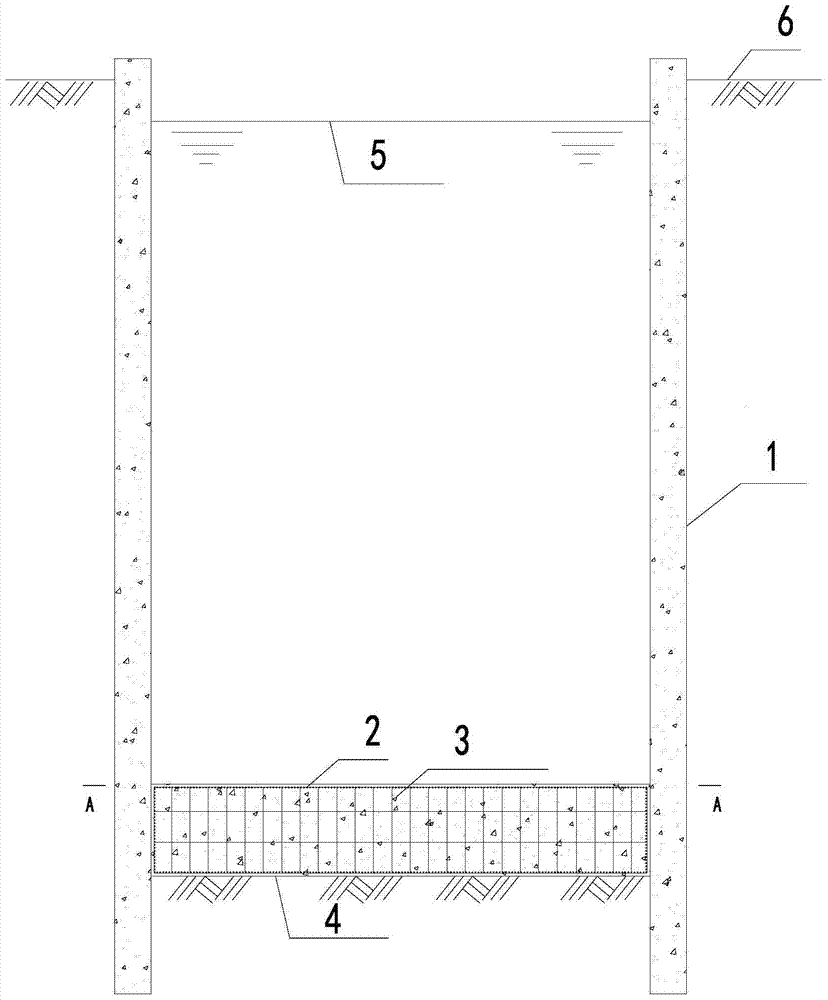

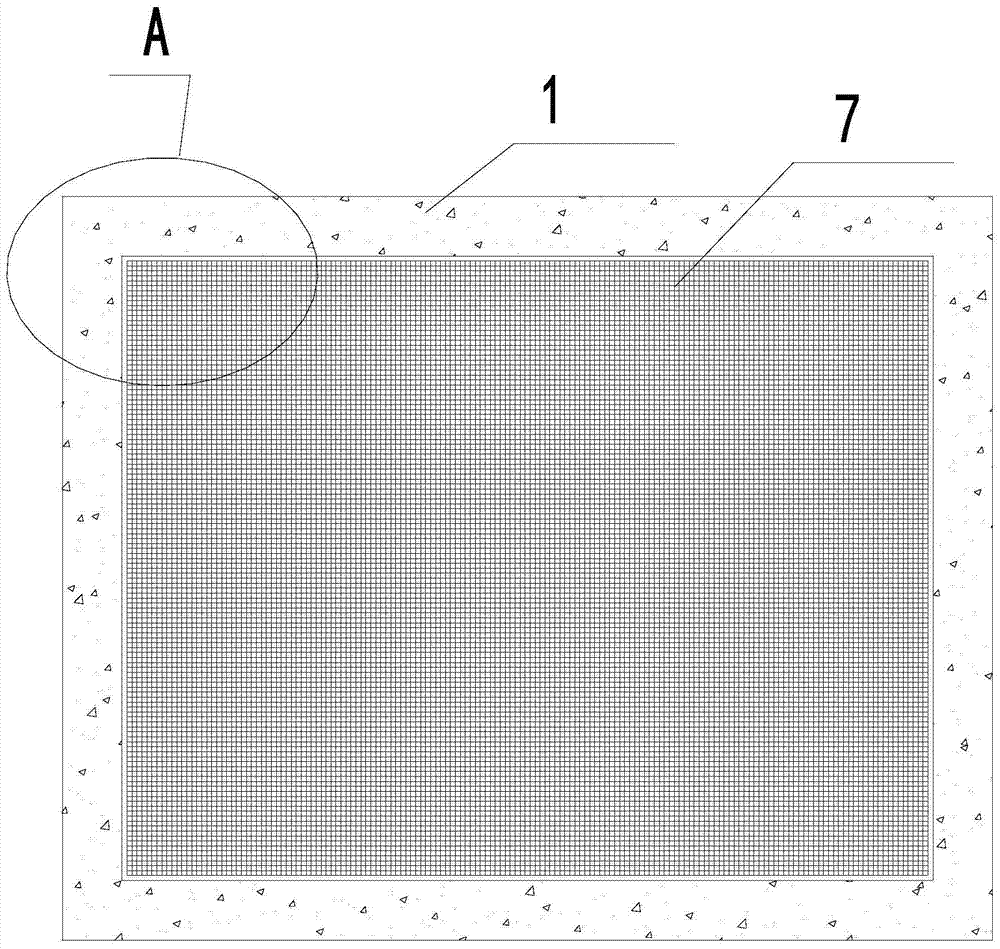

Underwater bottom sealing concrete construction method using steel truss for reinforcement

ActiveCN105544575AReduce distortionSmall areaFoundation engineeringCofferdamUltimate tensile strength

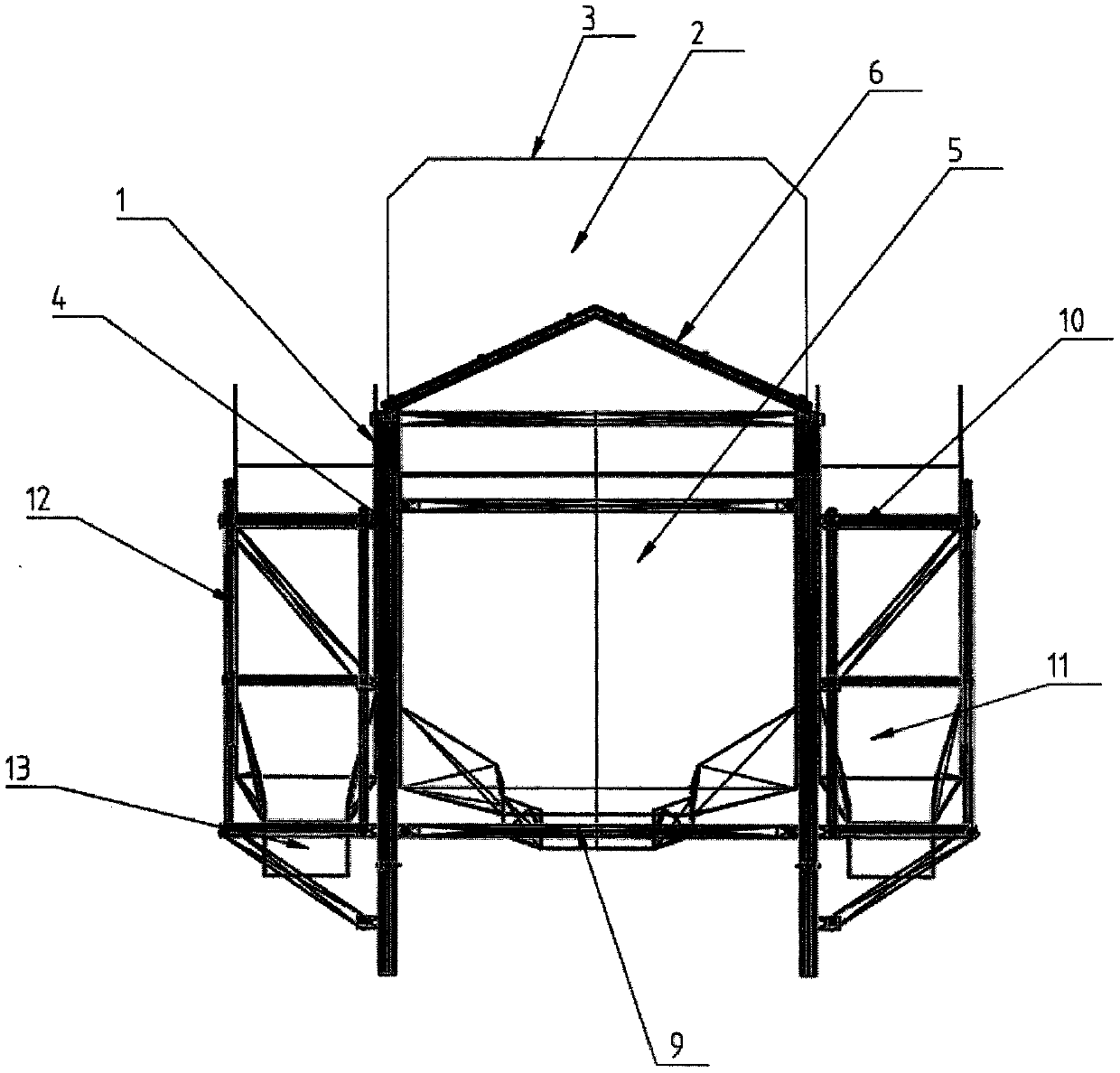

The invention discloses an underwater bottom sealing concrete construction method using a steel truss for reinforcement and belongs to the field of underwater bottom sealing for deep foundation pit construction. The underwater bottom sealing concrete construction method using the steel truss for reinforcement comprises the steps that after a cofferdam is installed or an underground diaphragm wall is constructed, underwater excavation is conducted in a foundation pit till the bottom elevation of bottom sealing concrete is reached; the steel truss is machined piece by piece or integrally on site on land; the steel truss is hoisted and lowered in place integrally or piece by piece; a bottom sealing platform is built, a central collection hopper and a chute are arranged, and a plurality of bottom sealing guide pipes are lowered; mixed concrete is conveyed to the site; tank opening is conducted step by step for head sealing construction, and then normal pouring is conducted; and the bottom sealing guide pipes, the central collection hopper, the chute and the bottom sealing platform are dismounted after bottom sealing is completed, and water pumping is conducted after the strength of the bottom sealing concrete reaches the design strength. By the adoption of the underwater bottom sealing concrete construction method using the steel truss for reinforcement, the reinforcement effect can be achieved, and the thickness of the bottom sealing concrete is reduced, so that the purpose of reducing the construction cost is achieved, the construction difficulty of the underwater bottom sealing concrete can be lowered, and the construction quality and construction safety of the bottom sealing concrete are guaranteed.

Owner:CCCC SHEC FOURTH ENG +1

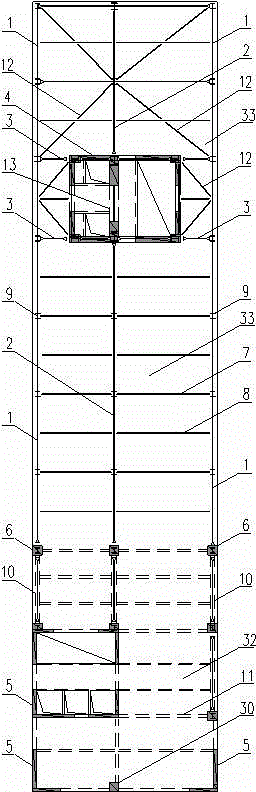

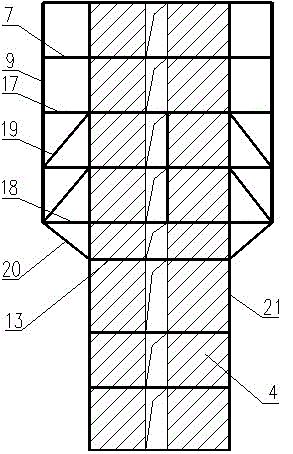

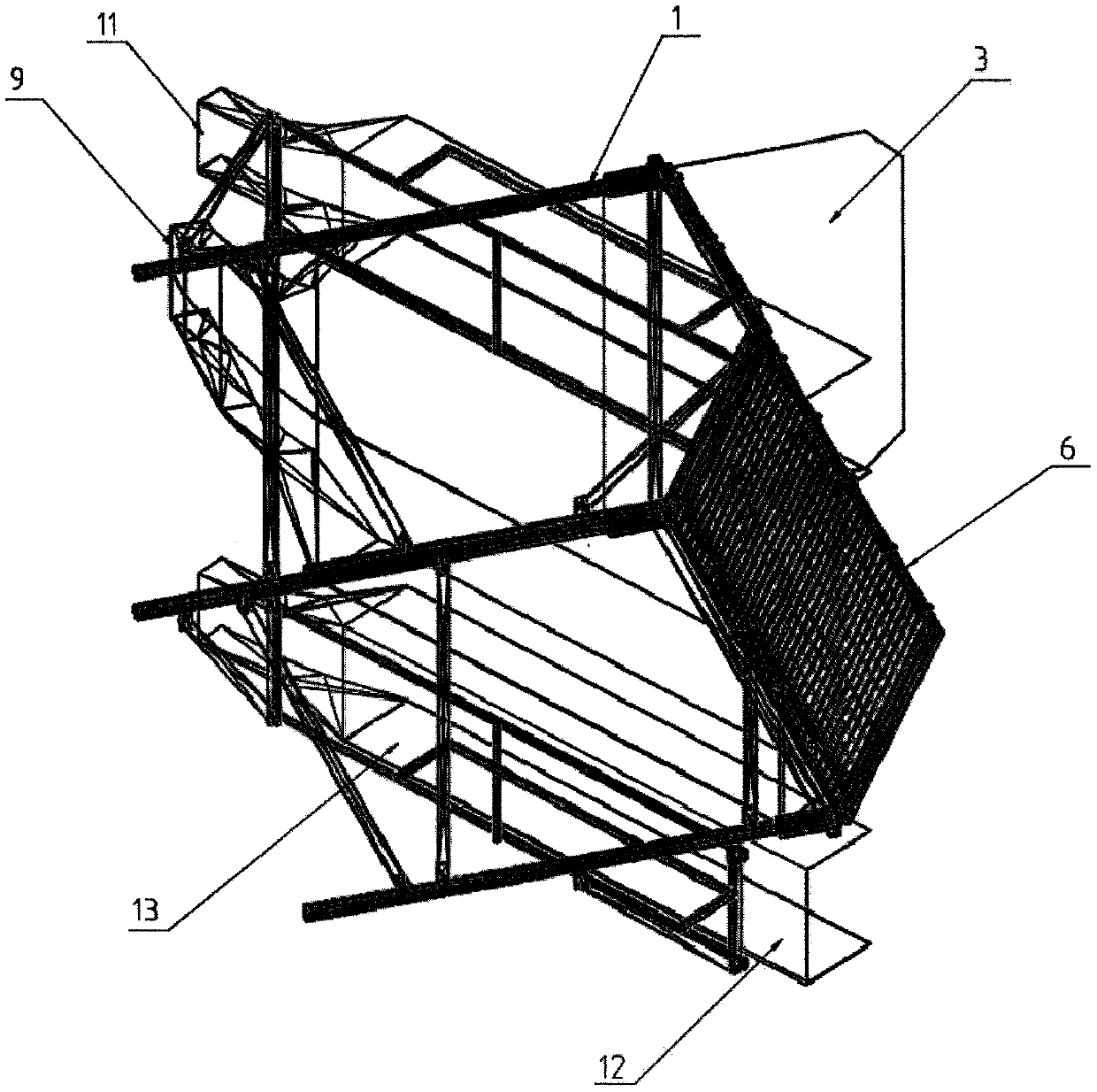

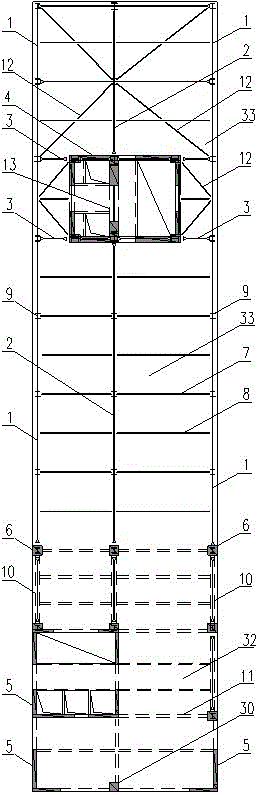

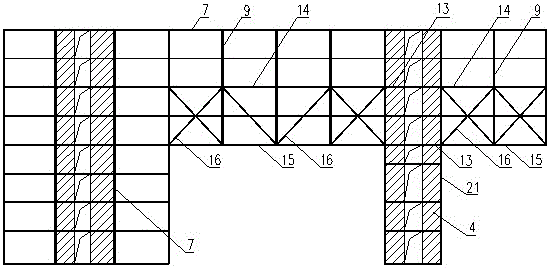

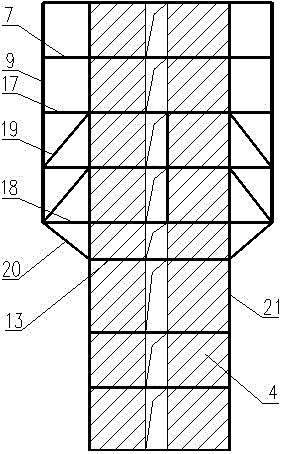

Large-span long-cantilever connection structure and construction technique

ActiveCN104818772AMeet the seismic performance requirementsThe structural system is safe and reliableBuilding material handlingSupporting systemTower

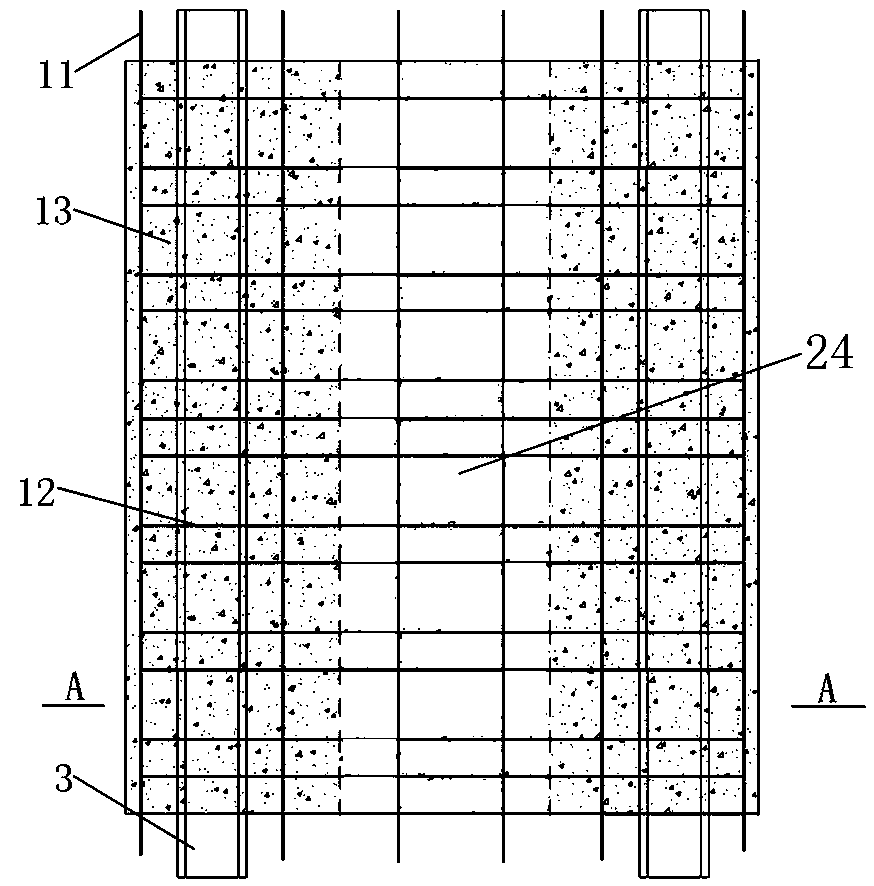

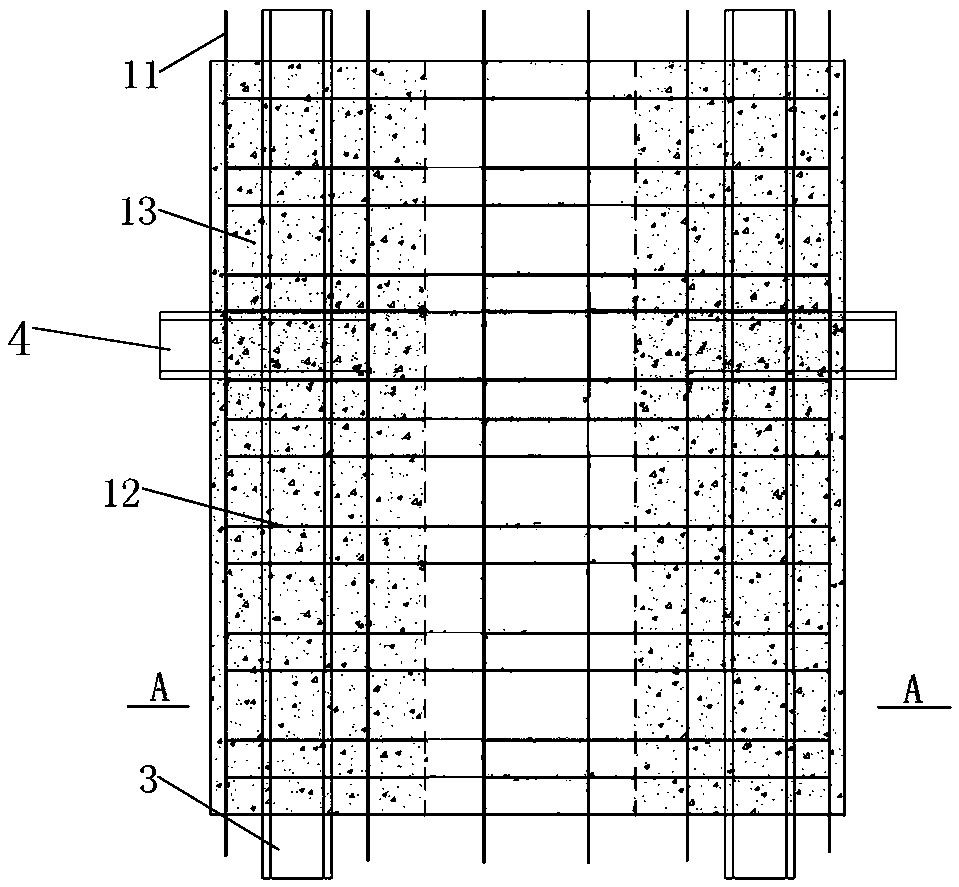

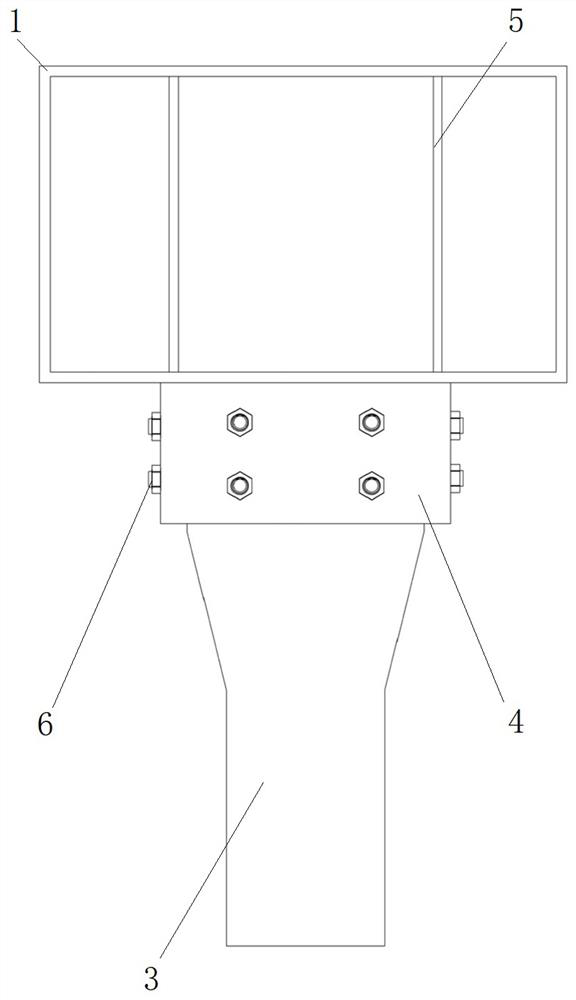

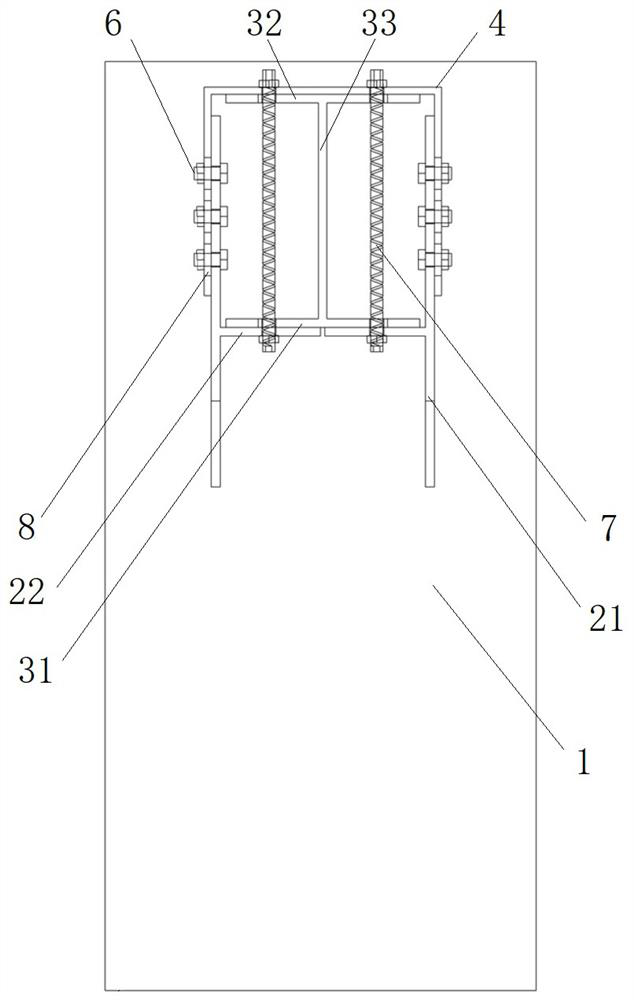

The invention discloses a large-span long-cantilever connection structure and a construction technique. The structure plane is arranged in the form of rectangle, two towers are arranged beneath the standard layer, wherein a tower is a cylinder body (4), the left and right sides of the tower respectively support a large-span and long-cantilever floor at the upper part, and the width of the cylinder body (4) is less than the width of the floor at the upper part, and the vertical face of the tower forms a model with a wide upper part and a narrow lower part; the other one tower is a framework shear wall structure. The large-span and long-cantilever is connected to the two towers through a side-span steel truss (1) and a middle-span steel truss (2) which are penetrated to each other. The side-span steel truss (1) is arranged within the scale of the cylinder (4), and supported on a supporting steel truss (3) extended from the cylinder (4) along the vertical direction. A steel framework beam (7) and a secondary steel beam (8) are equally arranged on the upper floor so as to form a floor cover supporting system. The floor cover adopts a steel bar truss floor support plate. The large-span long-cantilever connection structure solves the technical problem that the vertical face model is the connection structure with the wide upper part and the narrow lower part, and suitable for multi-layer and high rise buildings; moreover, the large-span long-cantilever connection structure has very strong universality and application scale.

Owner:香港华艺设计顾问(深圳)有限公司

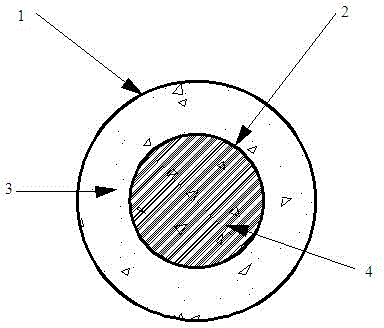

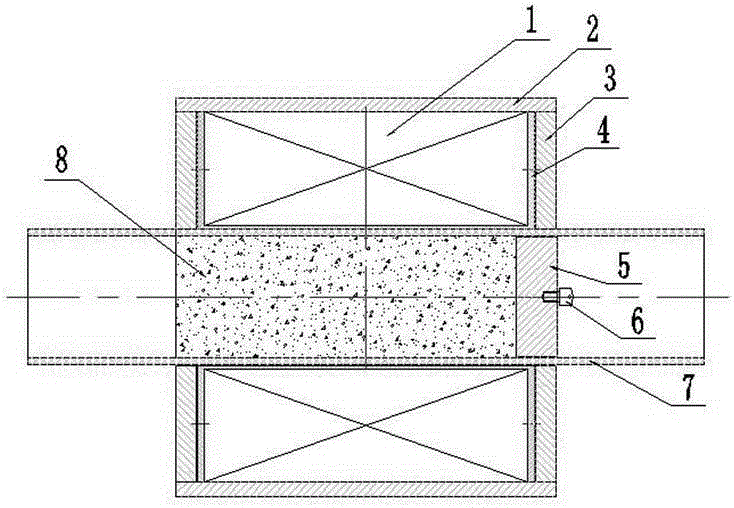

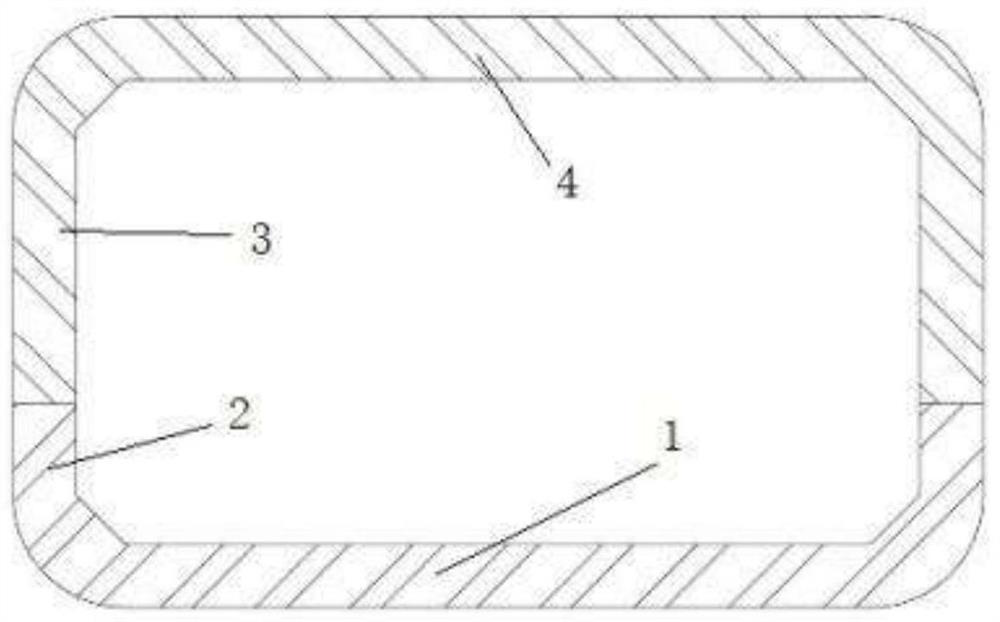

Dual steel pipe-encased concrete anti-seismic column with built-in rubber mixture and construction method

The invention discloses a dual steel pipe-encased concrete anti-seismic column with a built-in rubber mixture. The dual steel pipe-encased concrete anti-seismic column comprises round-in-round, square-in-square, round-in-square, square-in-round, rectangle-in-rectangle cross section forms, is composed of an outer steel pipe, an inner steel pipe, interlayer concrete and the rubber mixture; the inner and outer steel pipes are in fixed connection through welding or a bolt; and the interlayer concretely is disposed between the two steel pipes, the rubber mixture is packed in the inner steel pipe, and the interlayer concrete is self-compacting concrete. The rubber mixture is in the inner-layer steel pipe, has extremely good energy-consumption damping effect, is capable of effectively absorbing earthquake energy, and also is capable of effectively preventing fires. The dual steel pipe-encased concrete anti-seismic column with the built-in rubber mixture is relatively light in deadweight. The anti-seismic column is a main member of a framework structure of high-rise and wide-span buildings, and has the characteristics of high bearing capacity, light weight, good plasticity and toughness, good impact resistance and fatigue resistance, excellent earthquake-proof performance, good endurance and the like.

Owner:SHENYANG JIANZHU UNIVERSITY

End sealing method of tunnel dual-lining trolley air bag die containing built-in type water-stop belt

InactiveCN106150527AShorten the timeImprove ergonomicsUnderground chambersTunnel liningElectricityStandard interval

The invention provides an end sealing method of a tunnel dual-lining trolley air bag die containing a built-in type water-stop belt. The end sealing method is particularly suitable for projects of mountain tunnels, underground railroads, electric heating tunnels and other standard interval tunnels, the air bag die achieves effective fixation along the inner side and the outer side of the circular construction joint water-stop belt, installation and inflation are achieved joint by joint, close attachment is achieved between an air bag and a trolley formwork panel, between the air bag and the water-stop belt and between the air bag and a waterproof board, the size of the inflated air bag is controlled, and it is ensured that the built-in type water-stop belt is centered in the longitudinal and annular directions at a construction joint; after the air bag is installed, through long wooden boards are annularly and densely arrayed at one end of a trolley and fixed with wooden wedges. The method has the advantages of being convenient to operate, high in work efficiency, low in cost, little in pulp leakage and high in pressure bearing.

Owner:RANKEN RAILWAY CONSTR GROUP

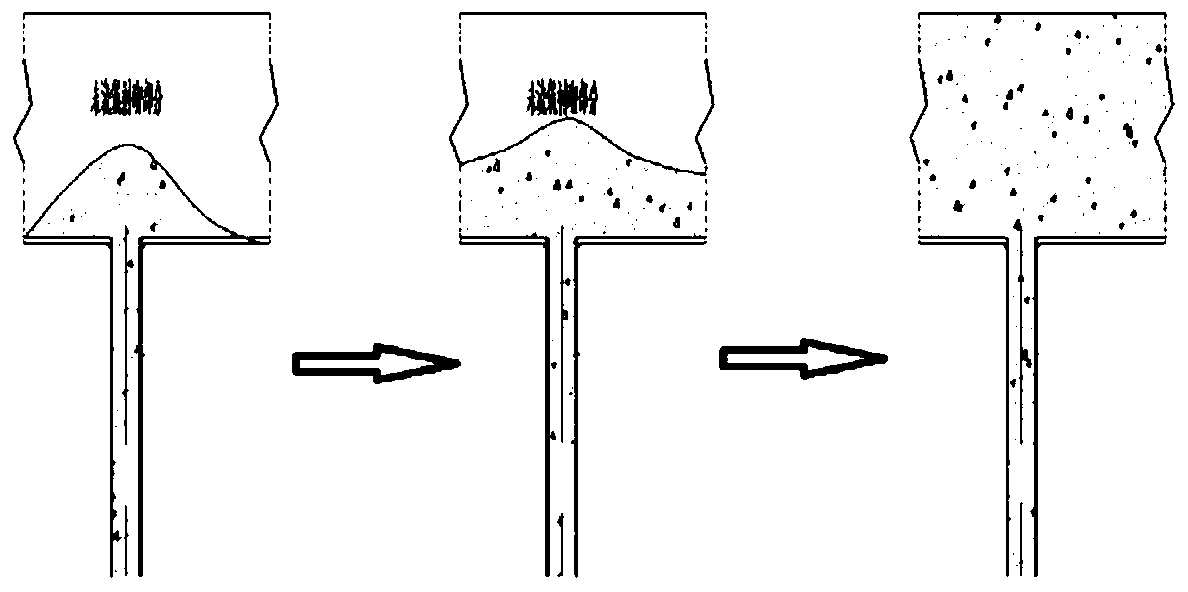

Method for pouring concrete based on magnetic drive

InactiveCN105587125ARealize the purpose of pouringSpeed up the flowSolid waste managementBuilding material handlingElectromagnetic shieldingElectromagnetic field

The invention provides a method for pouring concrete based on magnetic drive. The method is based on the principle that a magnetic substance is attracted by electromagnetic force at an electromagnetic field, concrete containing ferromagnetic aggregates is blended in a proper proportion, and the concrete is driven by a magnetic field erected outside to flow evenly in a member, so that dense pouring is achieved. By means of the pouring method, gravity constraint can be avoided, and omnibearing concrete pouring is achieved. The pouring quality is greatly improved, university is high, and the pouring method can be widely applied to various pouring construction schemes.

Owner:ZHEJIANG UNIV

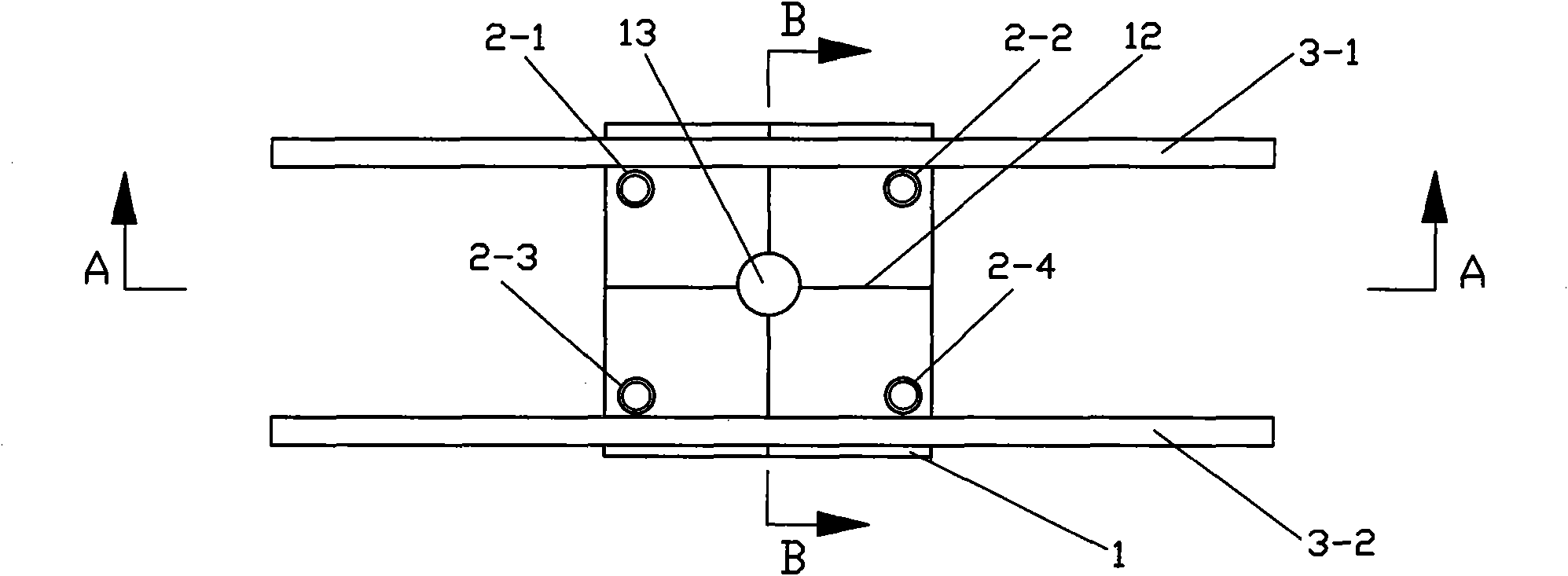

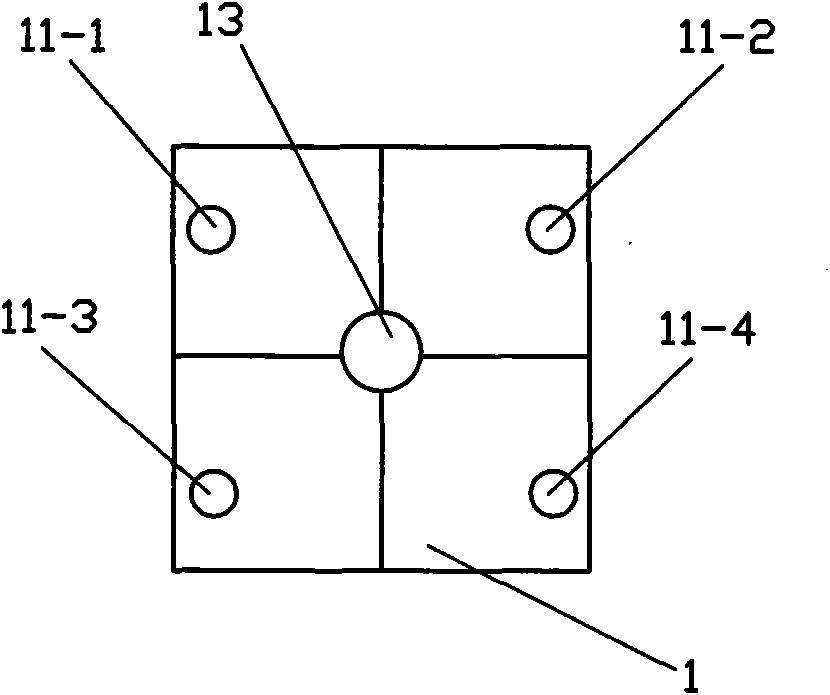

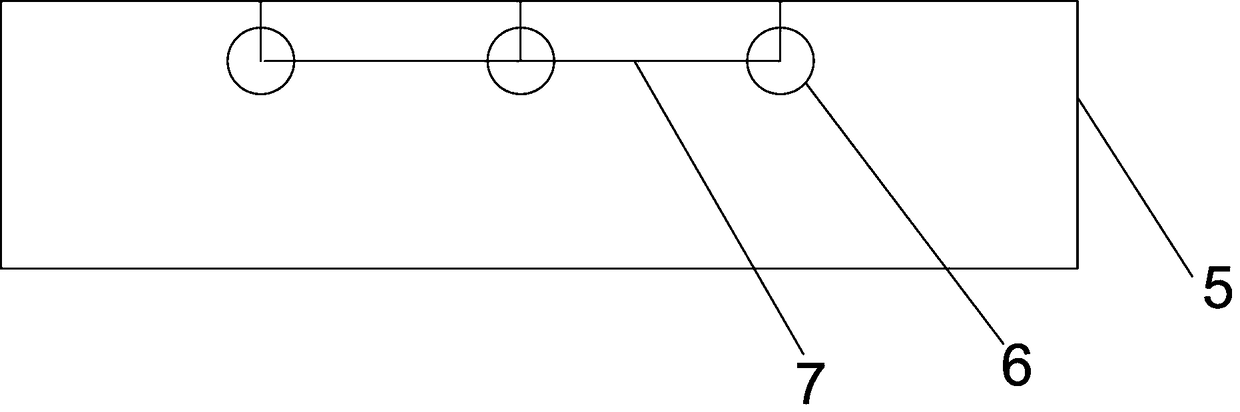

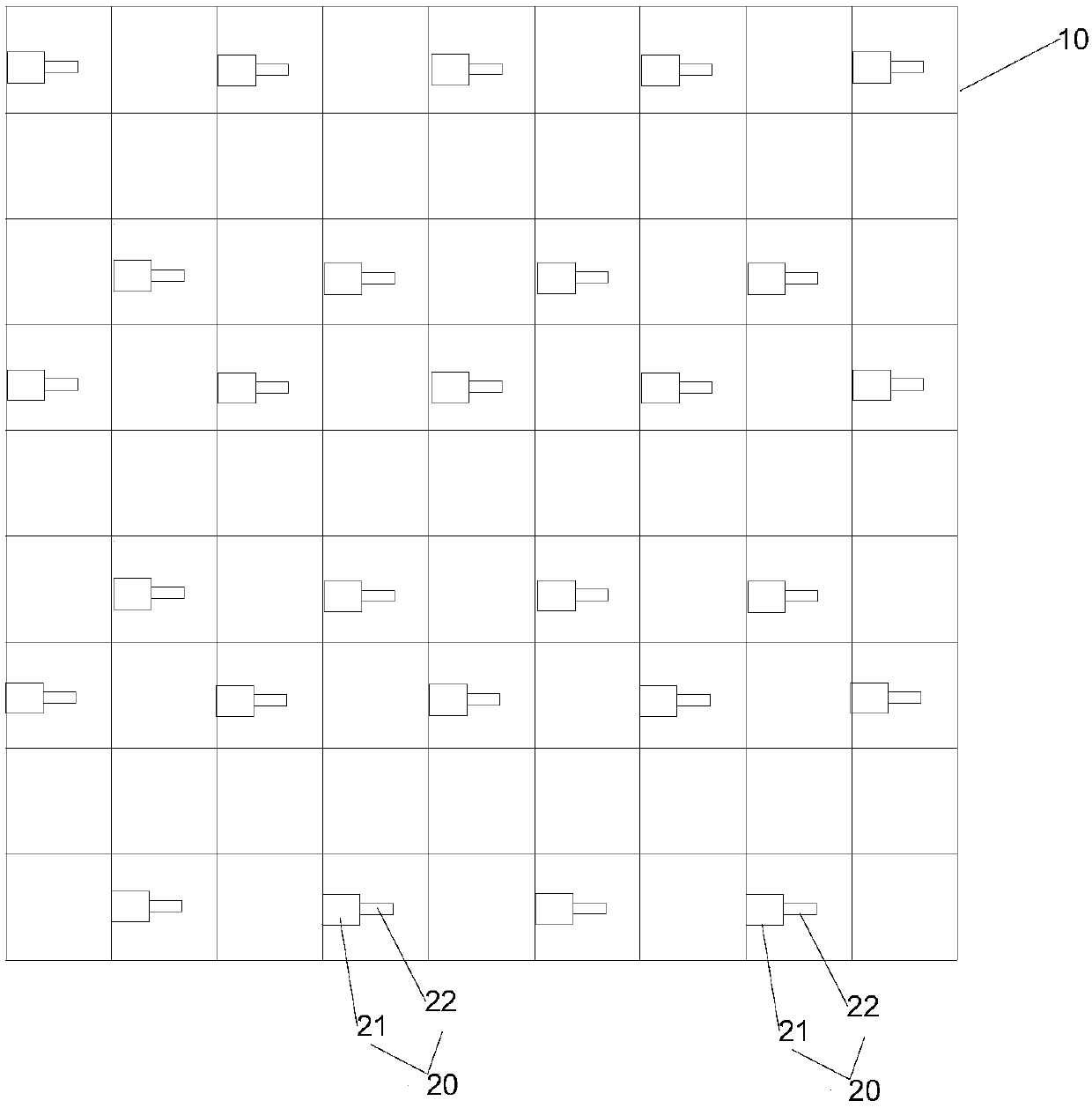

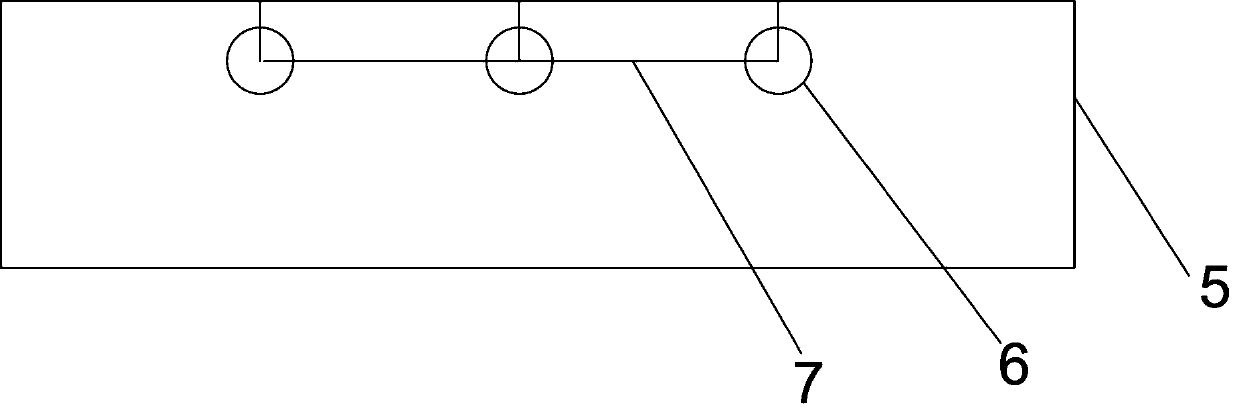

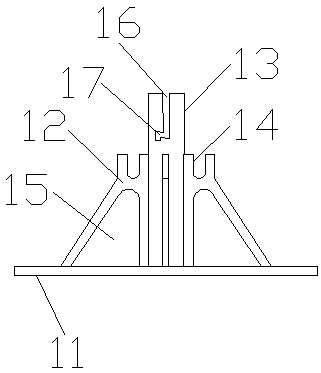

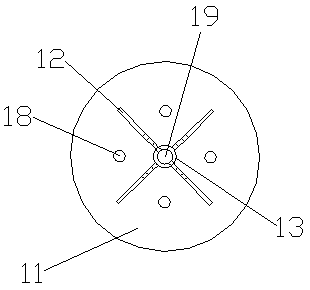

Embedded bolt cleading

The invention discloses an embedded bolt cleading which comprises a steel plate, galvanized pipes and two connecting steel pipes, wherein 2 to 10 positioning holes are drilled on the steel plate, a cross axis is carved on the steel plate, and the steel plate is also provided with a vibrating hole the center of which is positioned at the crossing point of the axis; the galvanized pipes are fixed on the upper end surface of the steel plate by welding, the axes of the galvanized pipes are vertical to the upper end face of the steel plate, each galvanized pipe is positioned at one positioning hole of the steel plate correspondingly, the inner diameter of the galvanized pipe is equal to the diameter of the positioning hole, and the axis of the galvanized pipe and the axis of the positioning hole are the same; and the two connecting steel pipes are respectively welded outside the galvanized pipes. The galvanized pipes are welded at the positioning holes, therefore, the embedded bolt cleading can well limit the position of a bolt. The connecting steel pipes enable the cleading to be convenient to install and dismantle.

Owner:顾晓刚

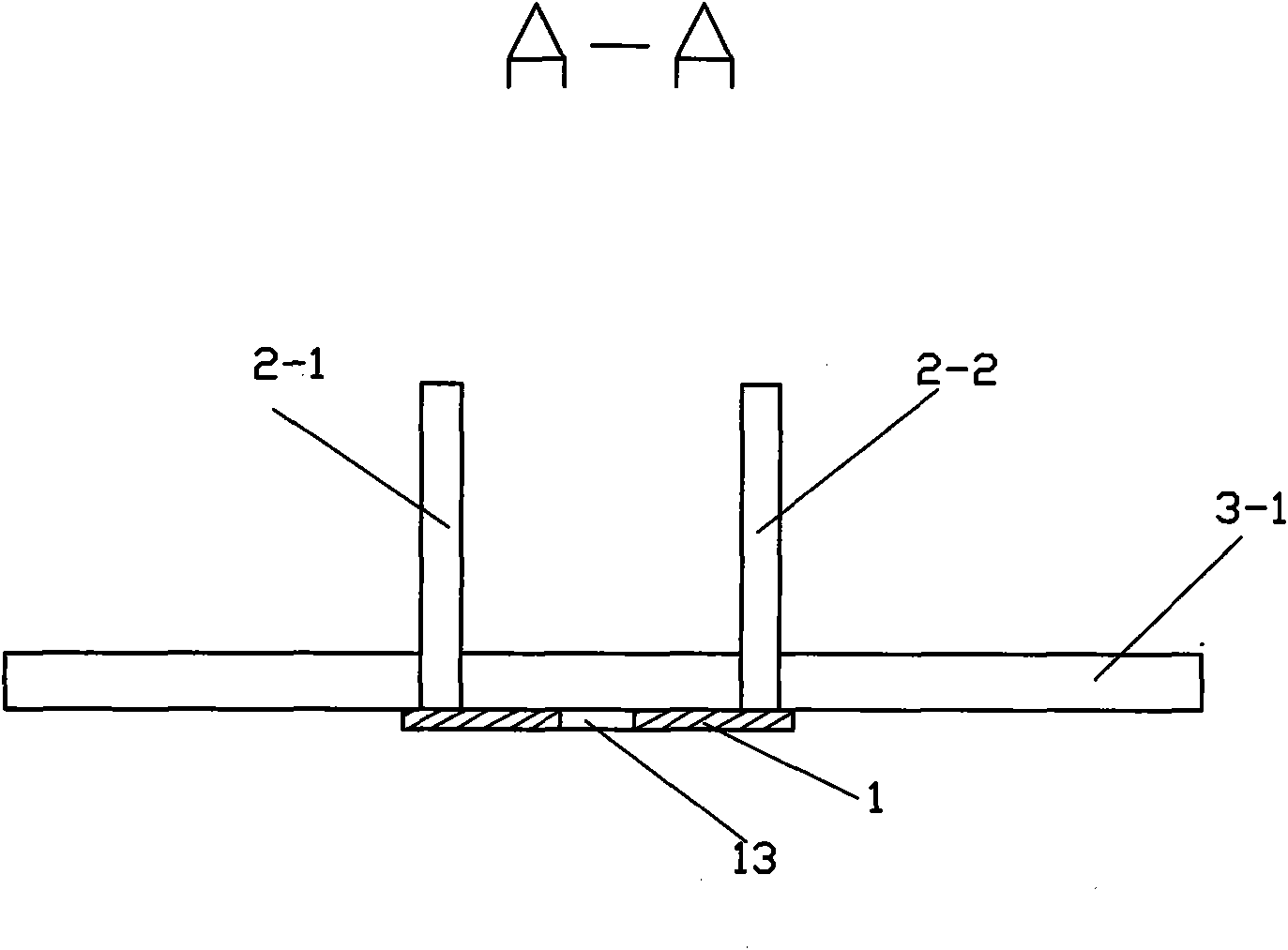

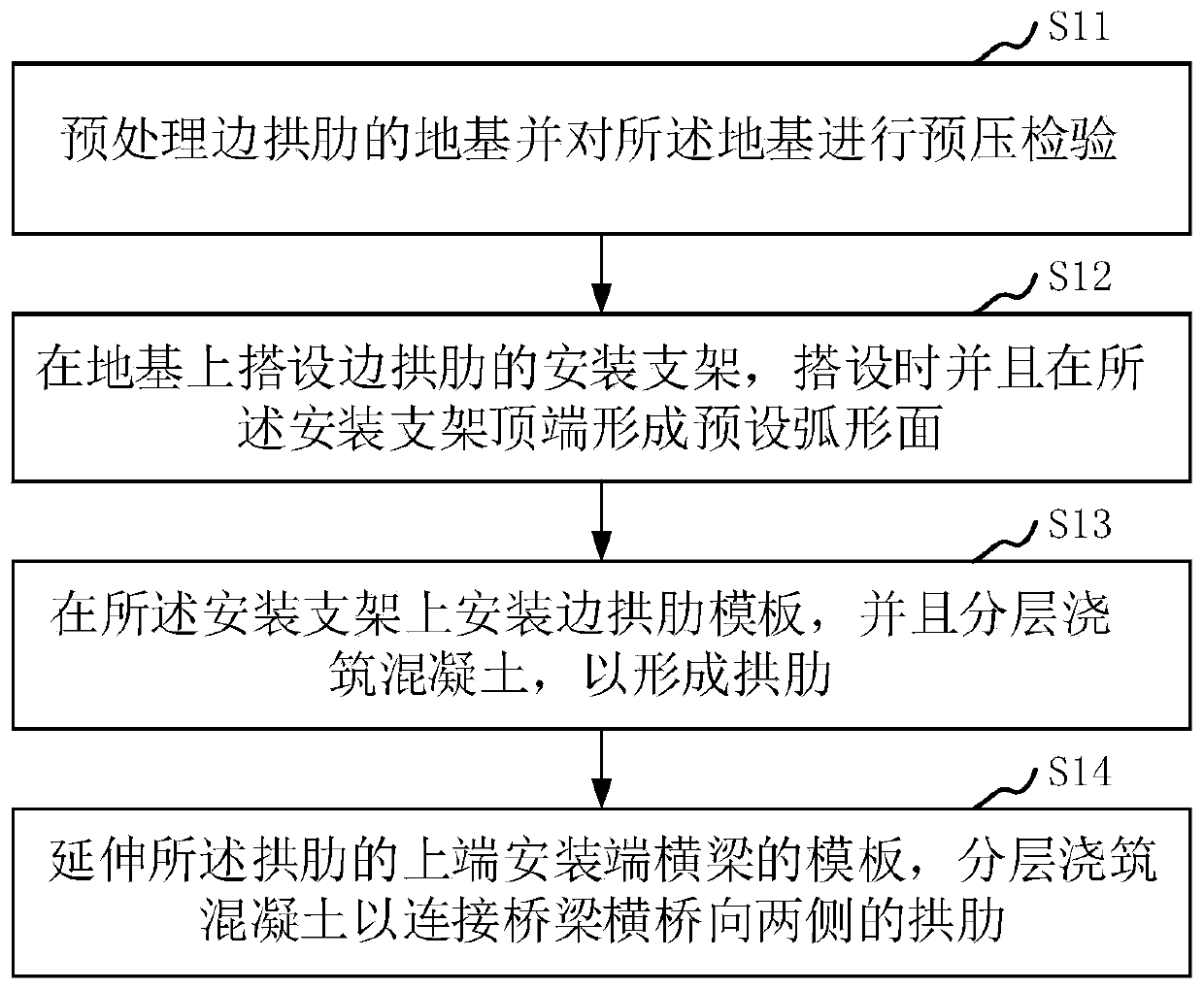

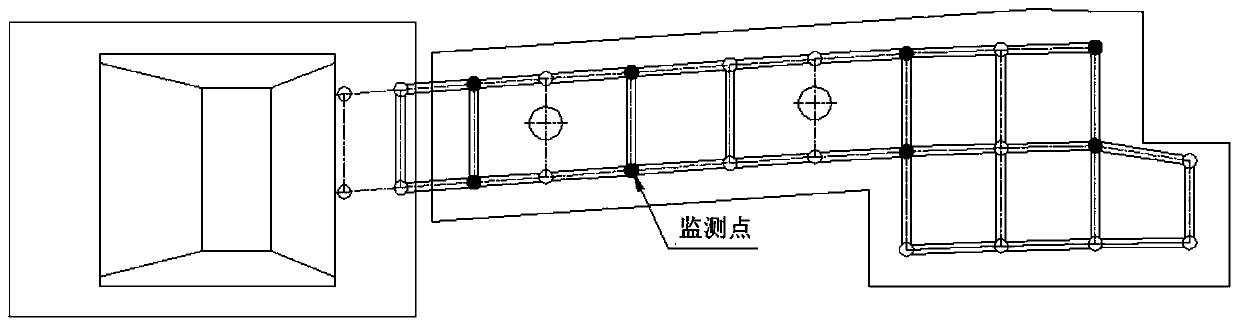

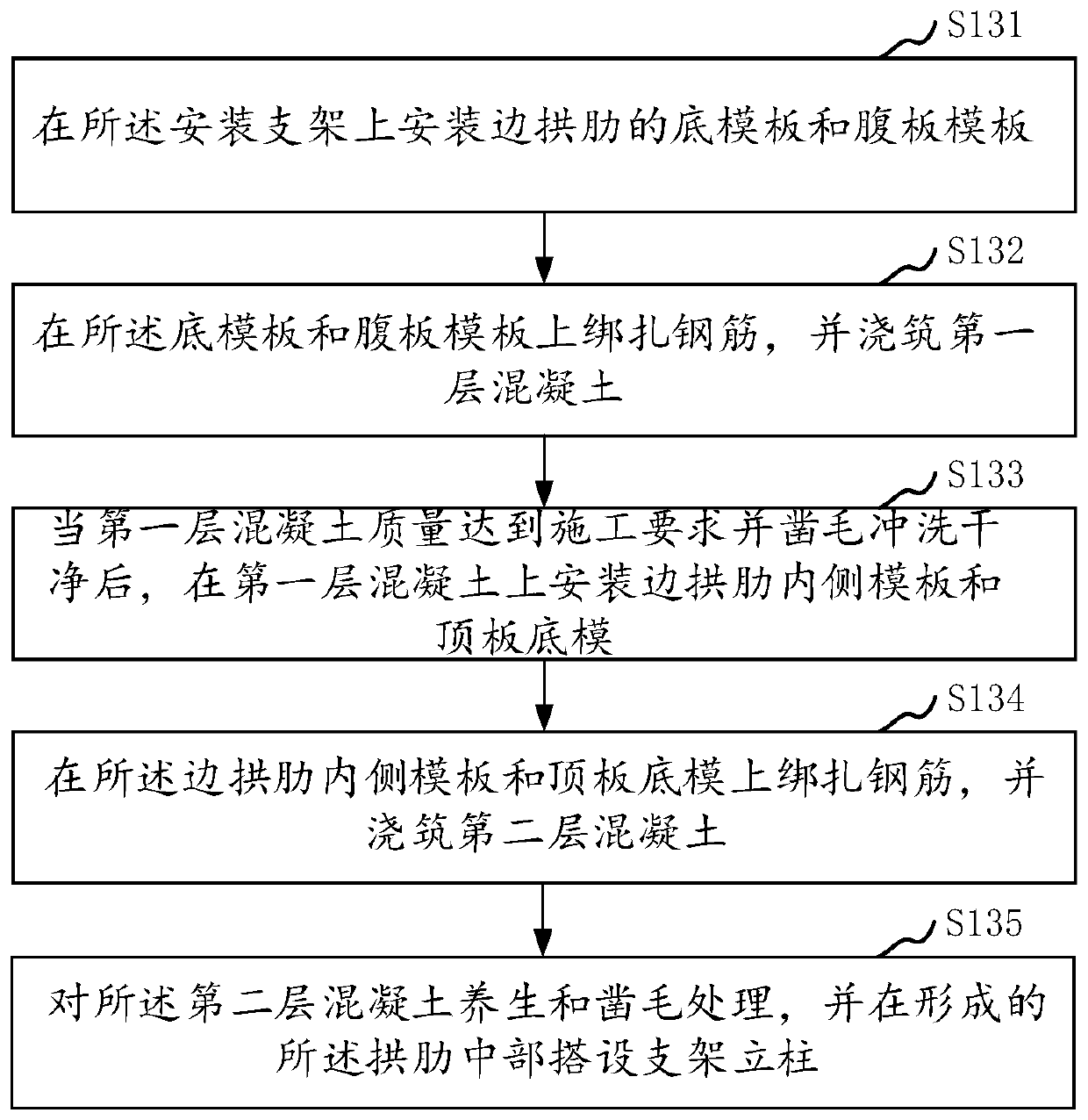

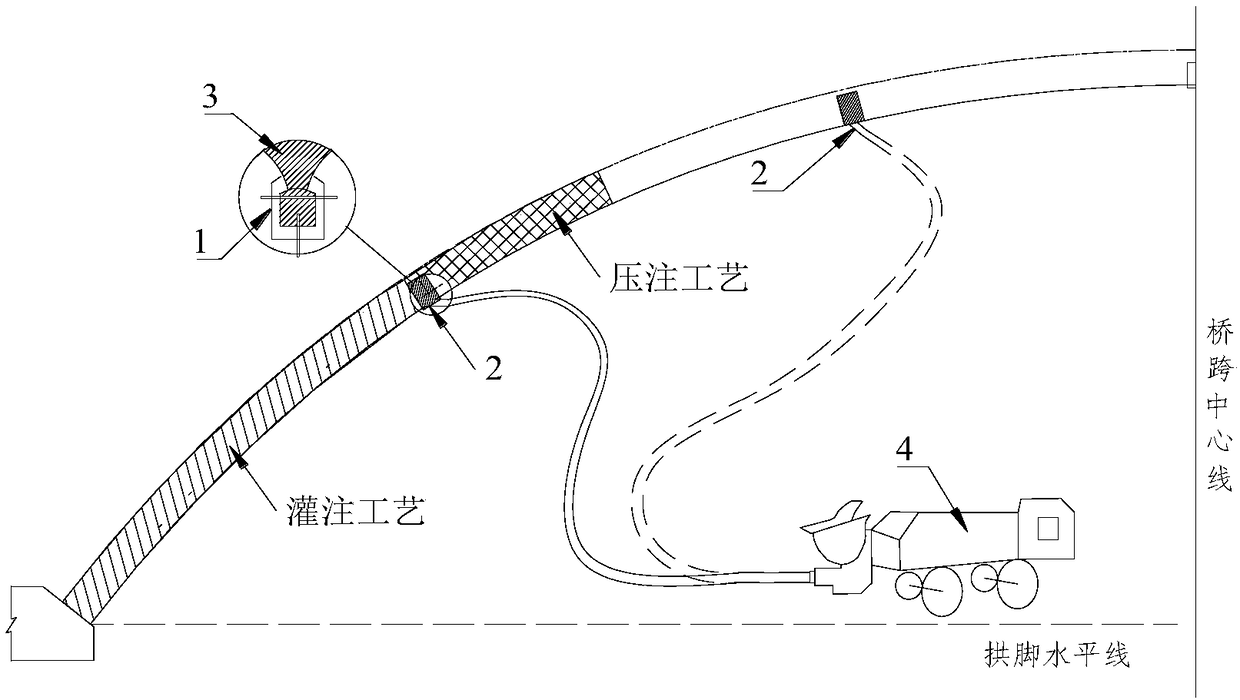

Side arch rib construction method and side arch rib

InactiveCN110777635AImprove stabilityImprove bearing capacityBridge erection/assemblyIn situ soil foundationArchitectural engineeringStructural engineering

Owner:ROAD & BRIDGE SOUTH CHINA EINGINEERING CO LTD +1

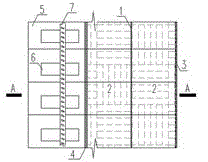

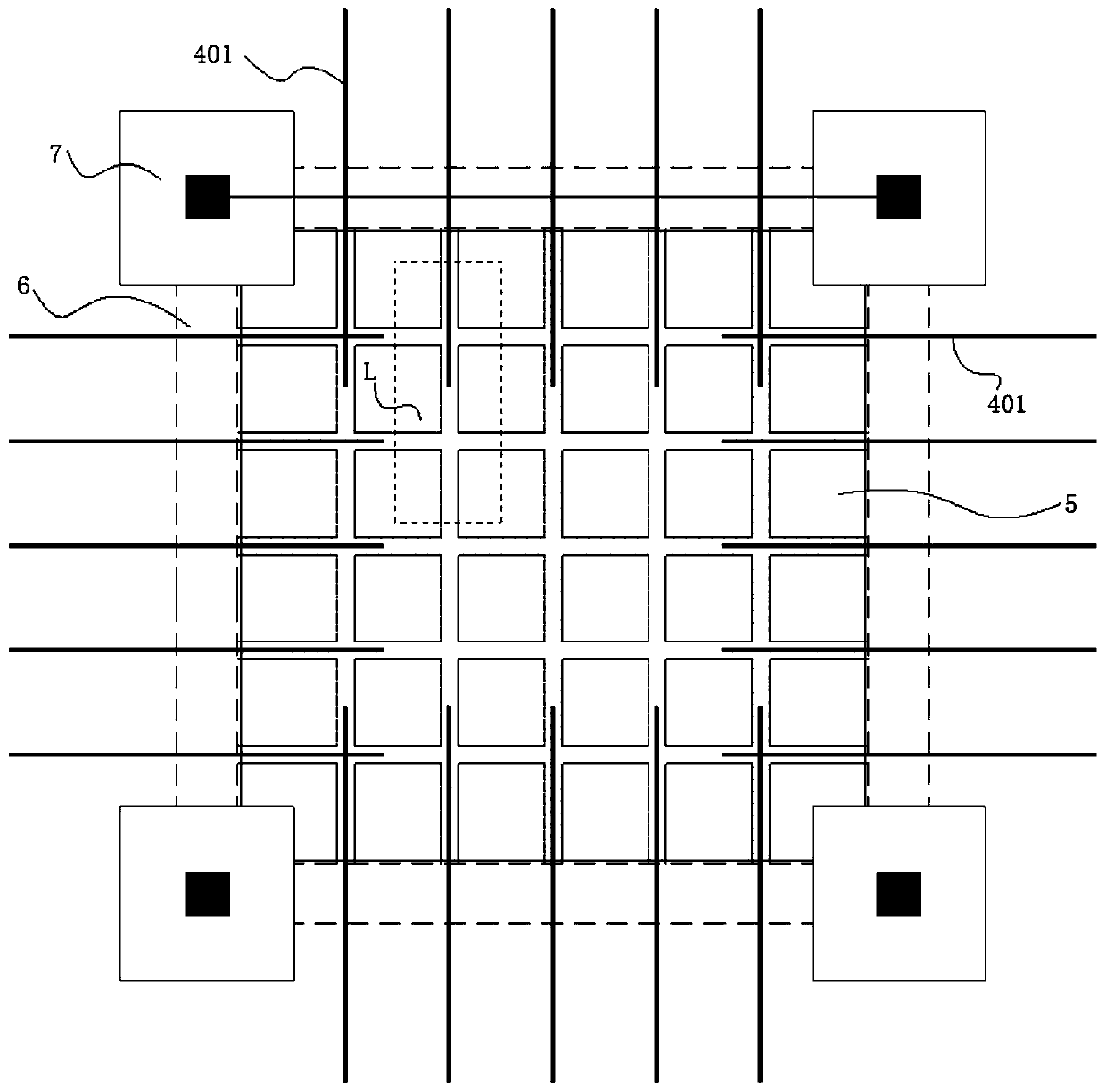

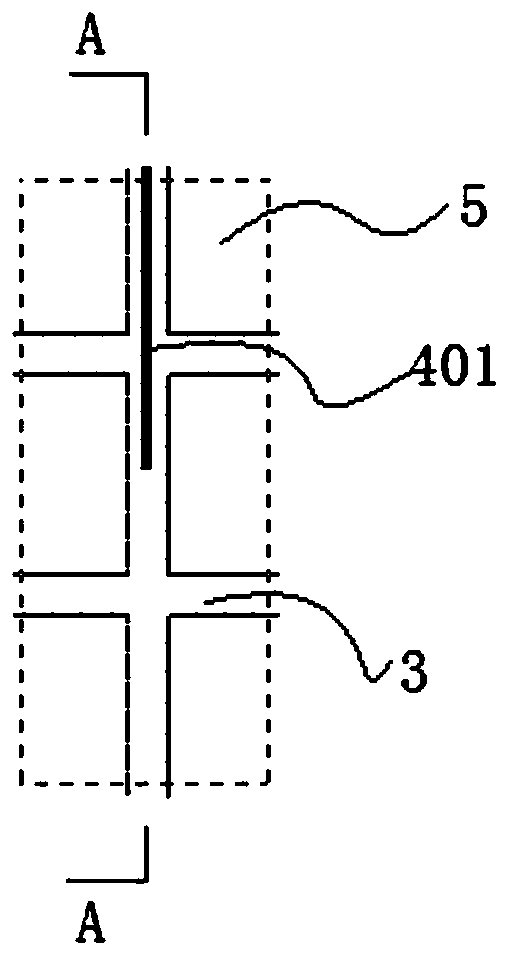

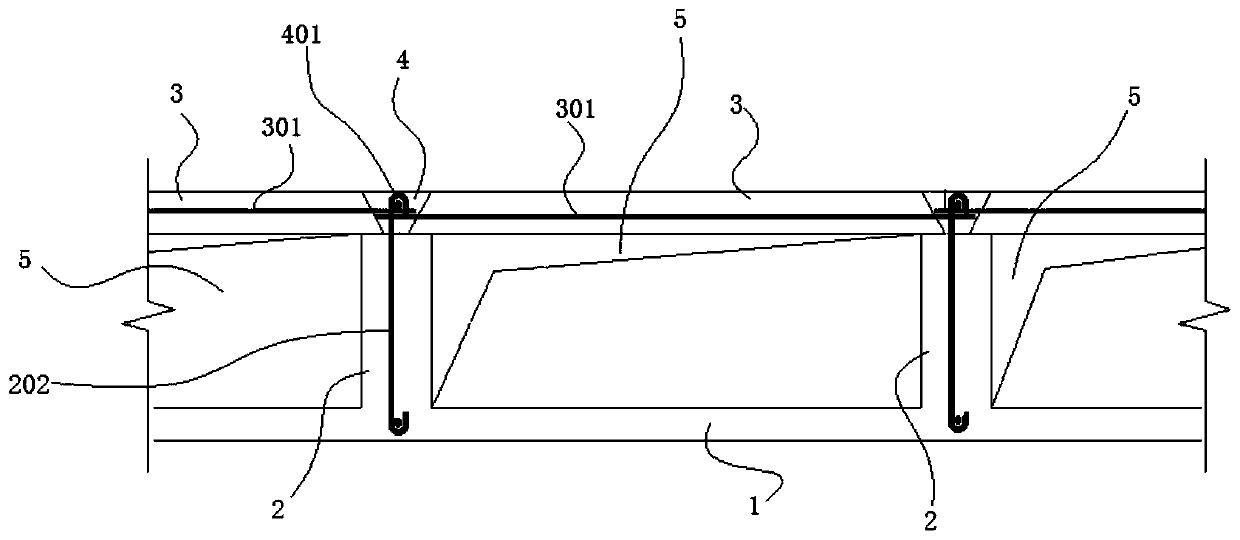

Partially-prefabricated assembled rear-stacking hollow floor

InactiveCN106836592ASolve all the aforementioned problemsReduce construction difficultyFloorsRebarHollow core

The invention discloses a partially-prefabricated assembled rear-stacking hollow floor, comprising cast-in-place floor bottom slabs, a cast-in-place rib beam slab grid and prefabricated flat slabs; a bottom formwork and beam rib side formworks are erected, and bottom slab and rib beam rebars are tied; the hollow floor bottom slabs and rib beam concrete are then cast, a construction joint is reserved at the bottom of the top slabs, the prefabricated flat plates corresponding to hollows in size are lifted to the tops of rib beams, stress-bearing vertical bars connected with hidden beams are arranged correspondingly at the rib beams, and secondary casting is performed at the rib beams between the flat slabs so as to finish maintenance. The inner formwork material in the hollow floor is omitted, and two novel hollow floor structures cast by means of secondary stacking are constructed. The partially-prefabricated assembled rear-stacking hollow floor with the structure allows all aforementioned problems present in traditional hollow floors can be solved, and construction difficulty is not reduced.

Owner:CHONGQING UNIV

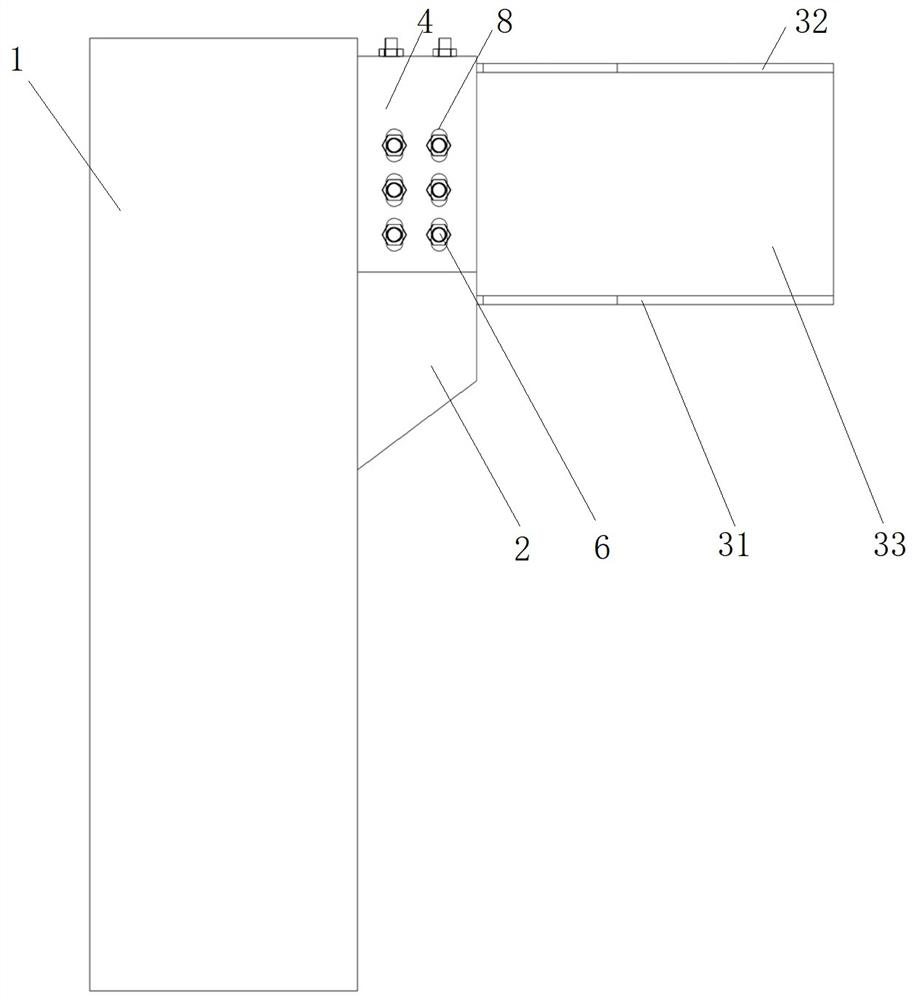

L shaped prefabricated beam column joint

InactiveCN111794377AEasy to weldFirmly connectedBuilding constructionsEarthquake resistanceArchitectural engineering

The invention belongs to the technical field of construction engineering and particularly relates to an L shaped prefabricated beam column joint which is mainly used for improving the anti-seismic property of a structure and comprises a prefabricated column and a prefabricated beam; the prefabricated column comprises a column body and a prefabricated column pouring connecting part; the prefabricated beam comprises a beam body and a prefabricated beam pouring connecting part; and the prefabricated column pouring connecting part and the prefabricated beam pouring connecting part are connected ina welding manner and are poured with concrete. Compared with the prior art, the L shaped prefabricated beam column joint is high in structural bearing capacity, large in rigidity and small in cross section, excellent in structural ductility and are more excellent in anti-seismic property. A combined structure is high in construction speed and short in construction period; before concrete pouring,profile steel forms a steel structure and has higher bearing capacity, so that a support does not need to be arranged, the construction speed is accelerated, and the construction period is shortened.

Owner:FUZHOU UNIV

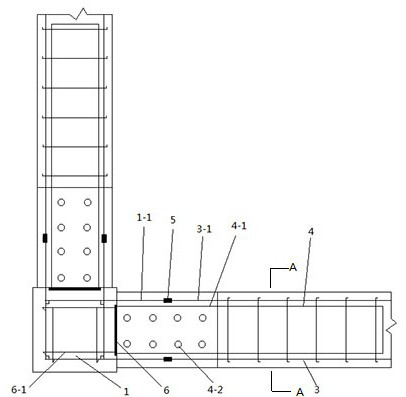

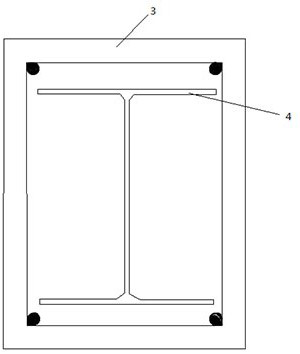

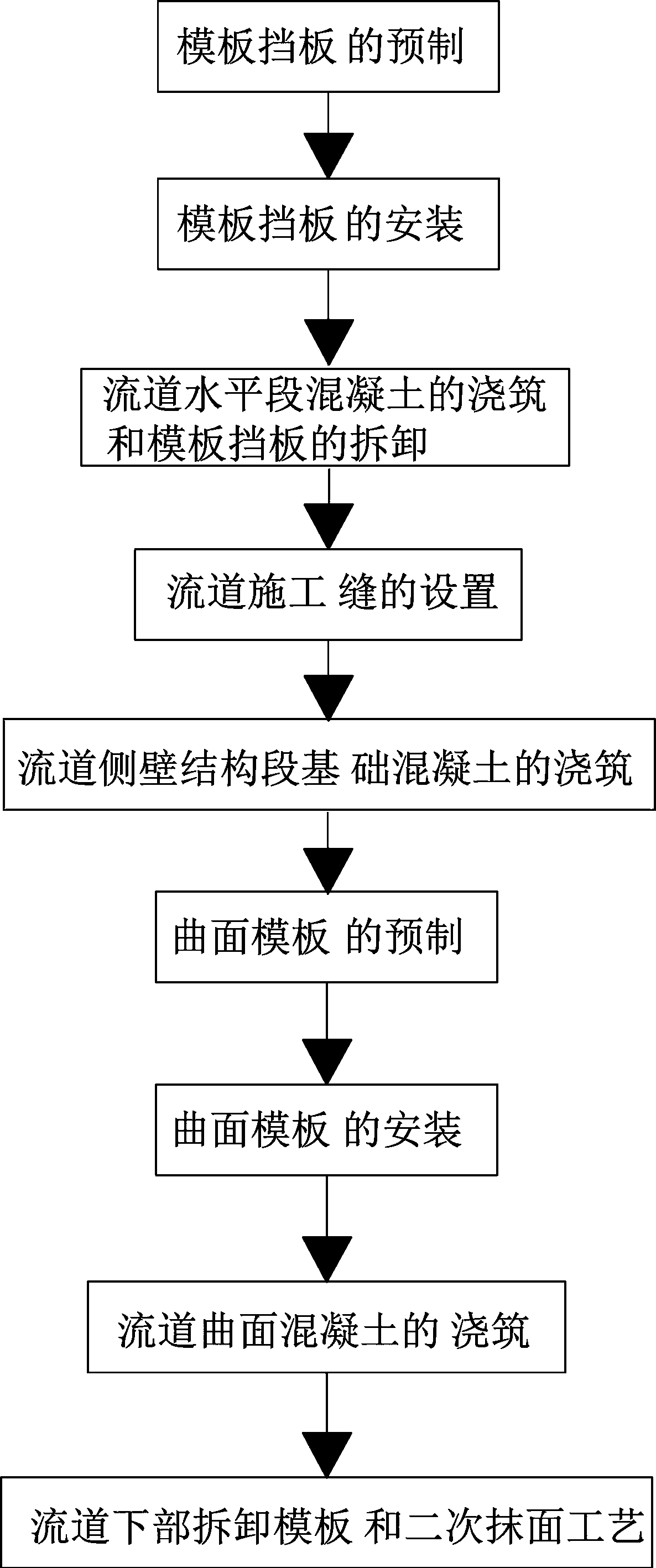

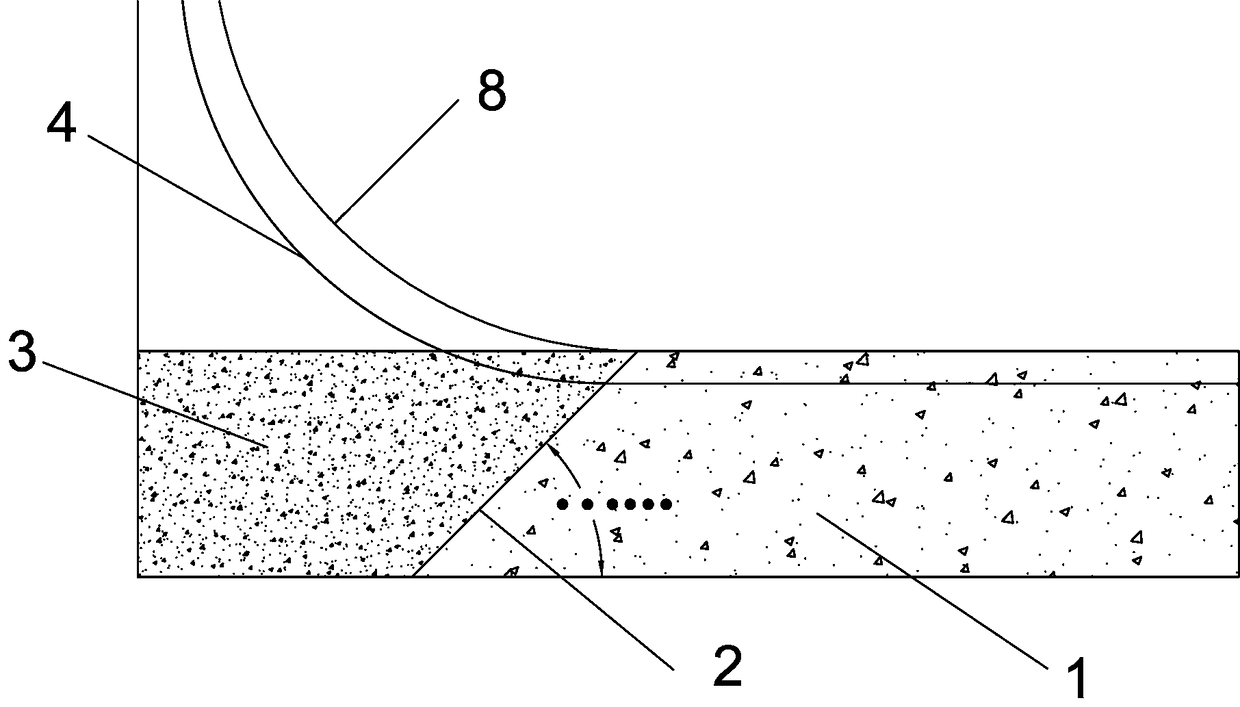

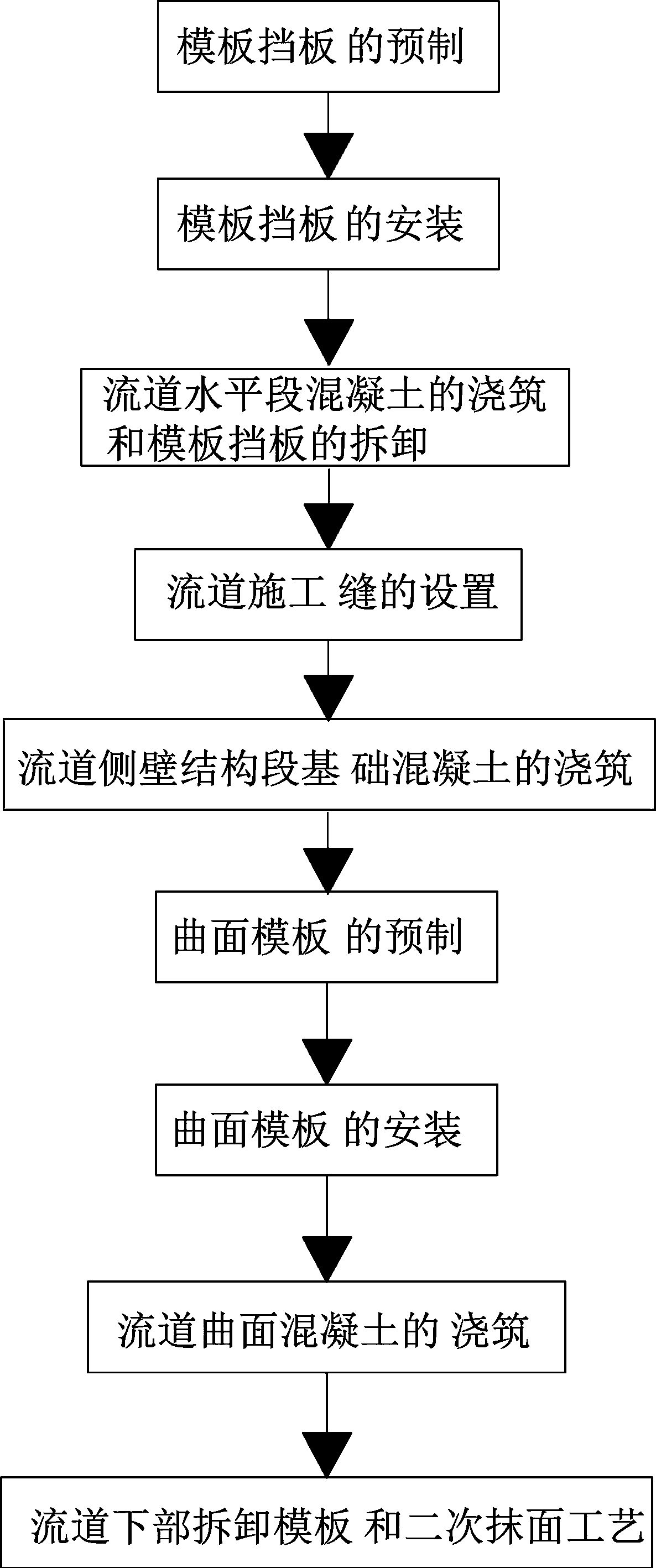

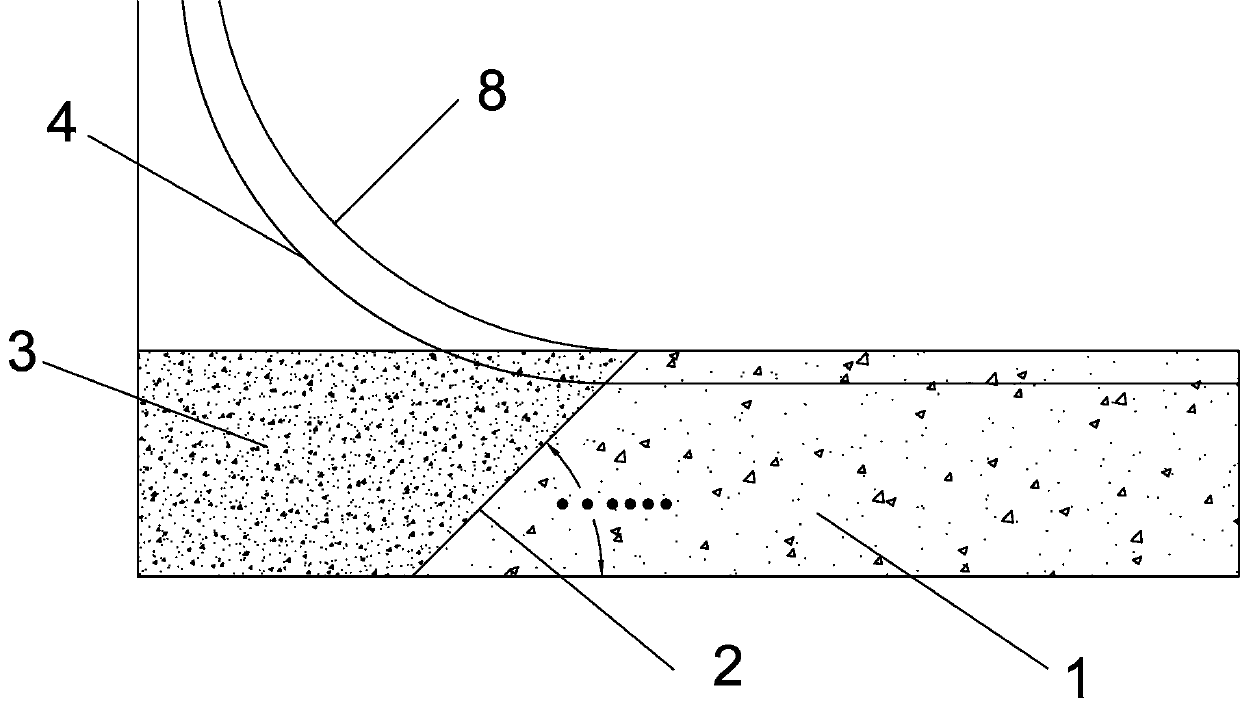

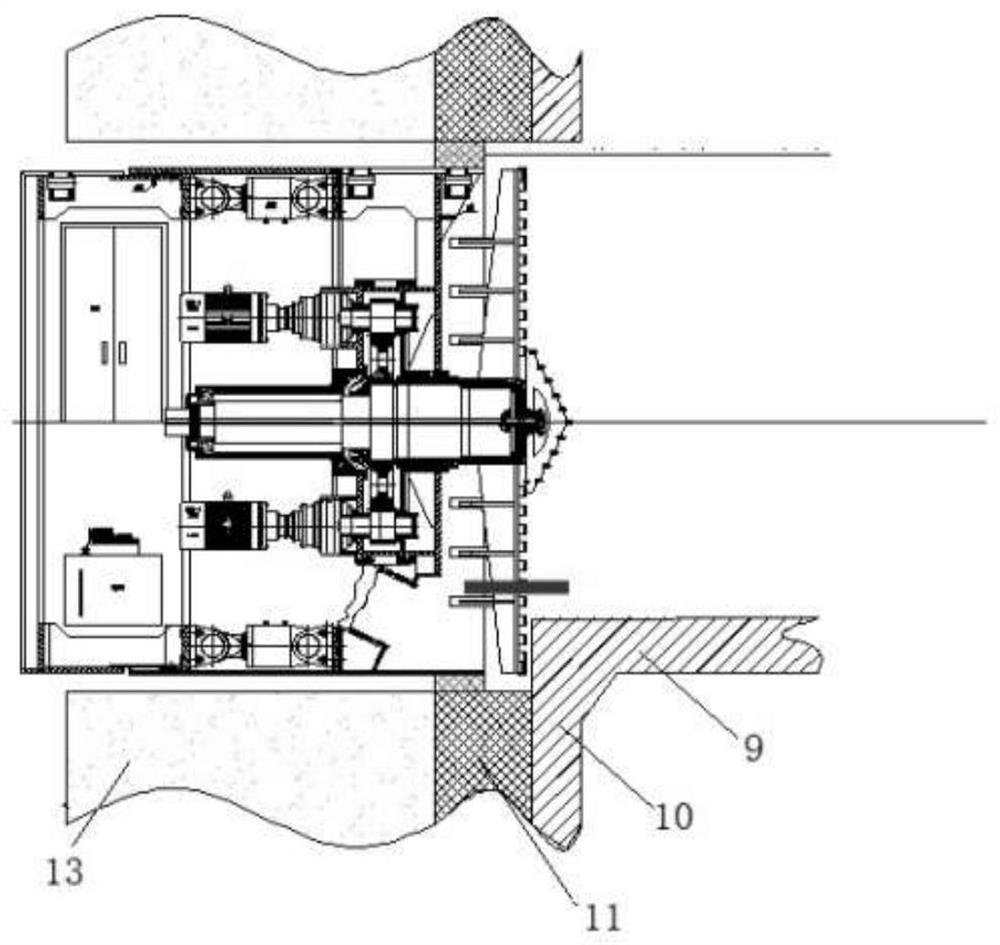

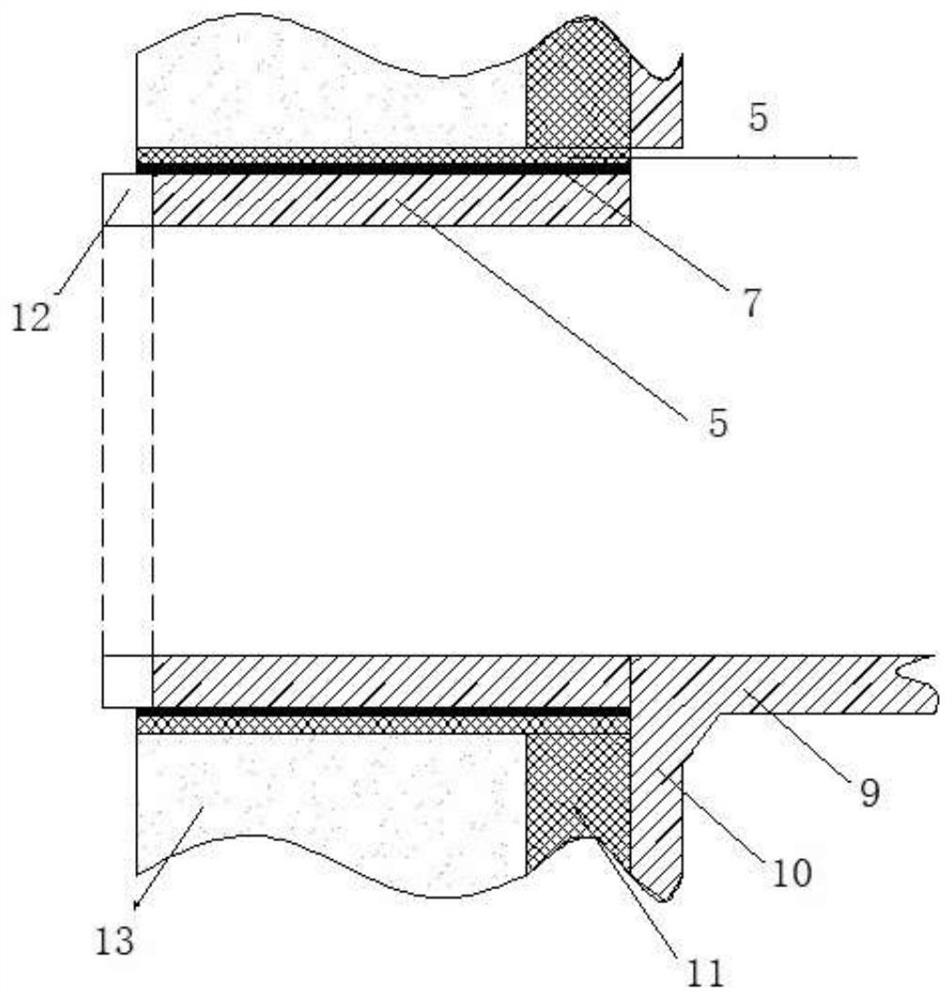

Concrete pouring method for tubular turbine unit runner of navigation-power junction engineering

The invention provides a concrete pouring method for a tubular turbine unit runner of navigation-power junction engineering. The method comprises steps as follows: prefabrication of form baffles; mounting of the form baffles; pouring of concrete at the horizontal section of the runner and dismounting of the form baffles; setting of construction joints of the runner; pouring of foundation concreteof side wall structure sections of the runner; prefabrication of curved forms; mounting of the curved forms; pouring of curved concrete of the runner; dismounting of forms at the lower part of the runner and a secondary plastering process. The contact area of two sections of concrete construction joints is increased through the construction joints formed by the form baffles, the problem that bottom concrete is difficult to pour compactly due to curved steel bars is solved, and concrete can be poured compactly; the problems that curved surfaces and horizontal planes cannot be contacted and vibrated uniformly through conventional pouring due to the fact that the included angle at the junction of the arc section and the horizontal section of the runner is smaller are solved through dismounting of forms at the lower part of the runner and the secondary plastering process, so that the surface flatness, plastering quality and linear control of the runner meet the design requirement.

Owner:CHINA GEZHOUBA (GRP) FIRST ENG CO LTD

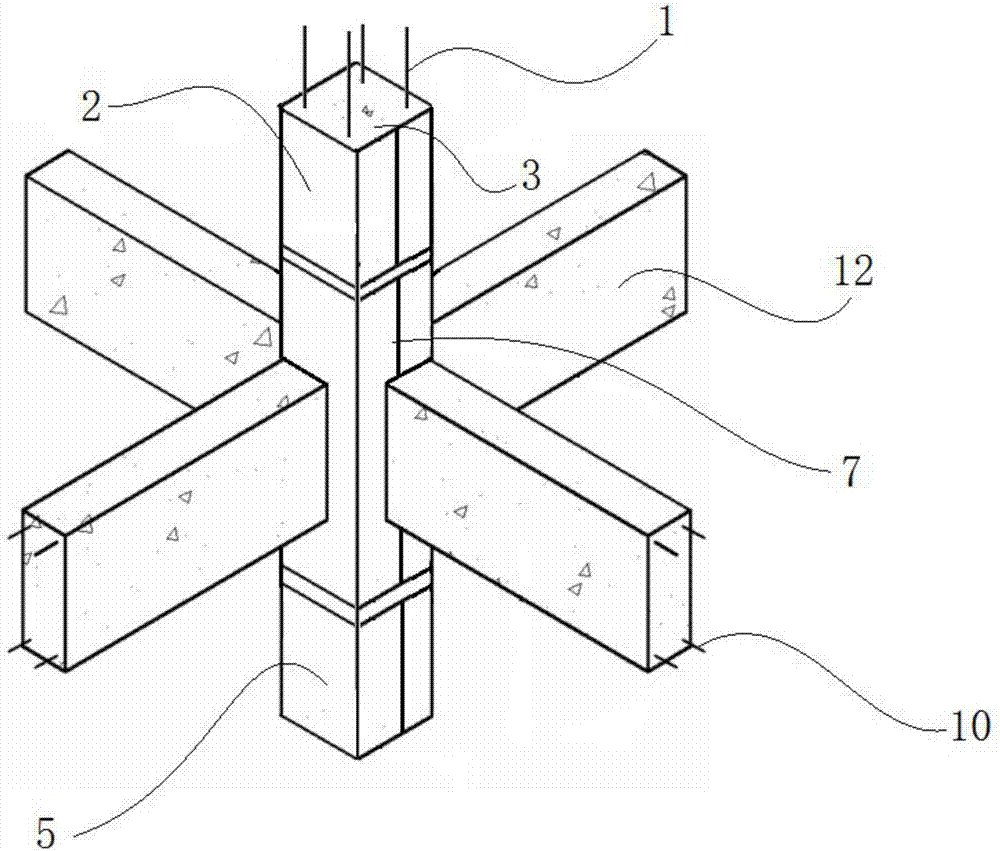

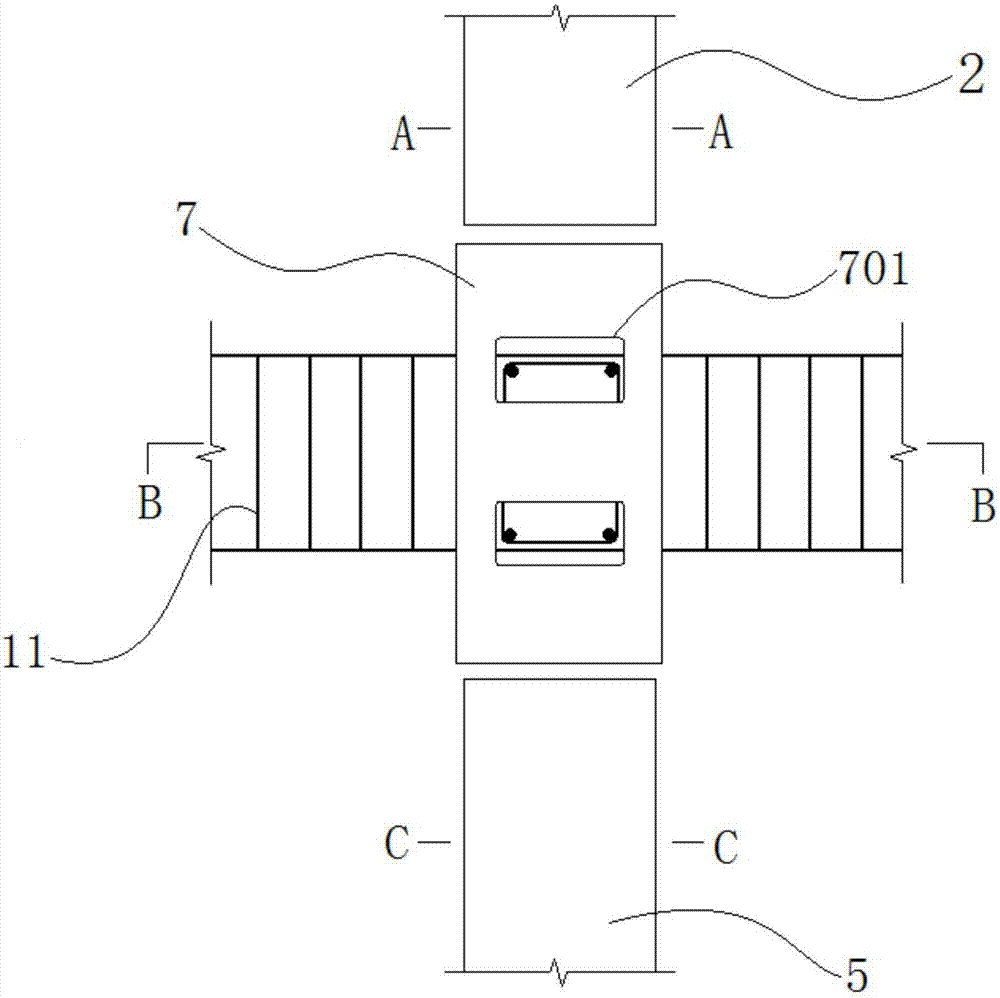

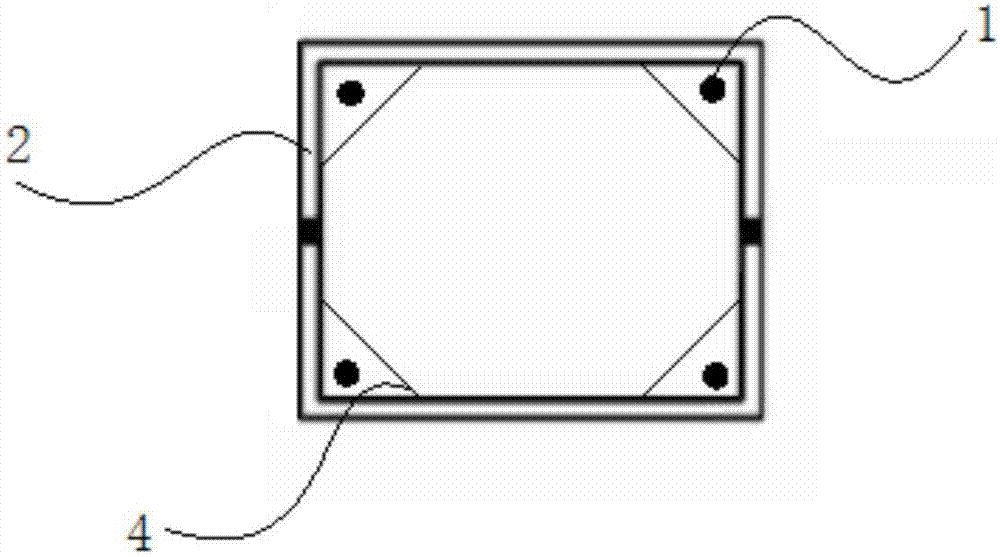

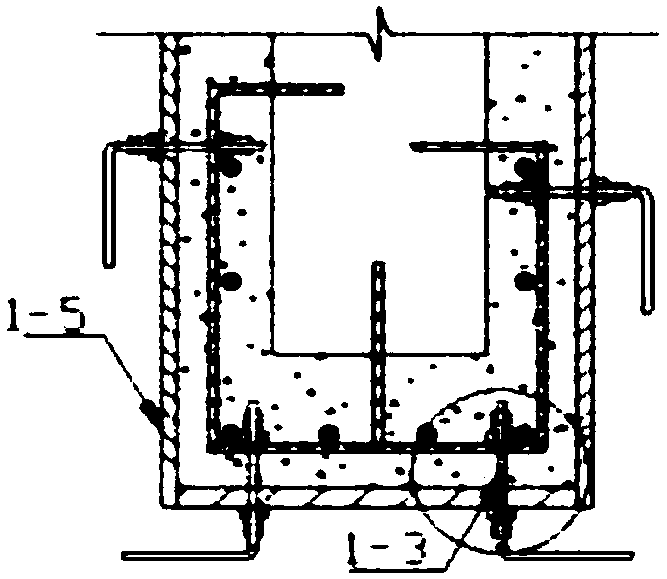

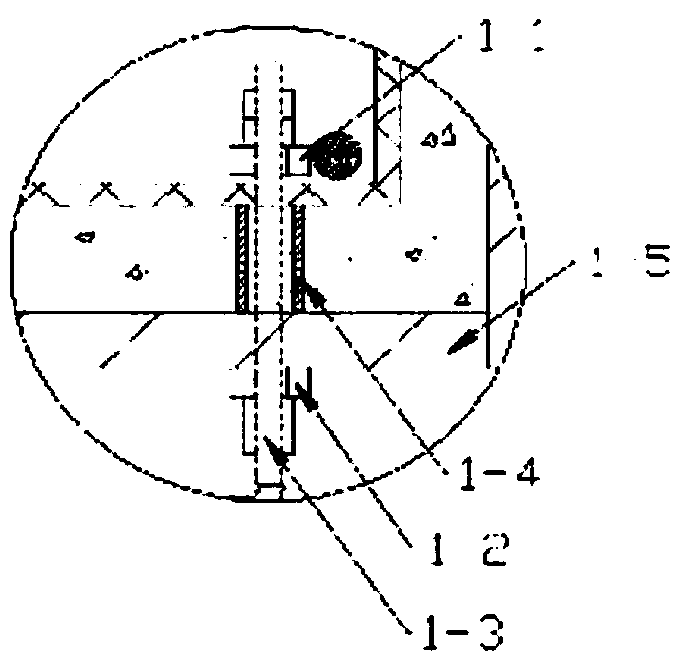

Rectangular steel pipe confined concrete column joint without stirrups and construction method thereof

InactiveCN107060076AImprove restraintImprove mechanical propertiesBuilding constructionsCold formedReinforced concrete

The invention provides a rectangular steel pipe confined concrete column joint without stirrups and a construction method thereof. The beam column joint comprises an upper column steel pipe, a lower column steel pipe, a joint steel pipe and reinforced concrete beams. The upper column steel pipe, the lower column steel pipe and the joint steel pipe are each composed of two pieces of cold-formed thin-walled groove-shaped steel which are buckled and welded together. The construction method of the structure comprises the steps of steel pipe machining, hoisting and welding, rib cage binding, concrete pouring and the like. Large diameter longitudinal ribs are restrained through stiffening ribs at the corners of the steel pipes, so that the column stirrups cannot be arranged while the number of the column longitudinal ribs is decreased, and construction is convenient and quick; partition plates with openings are adopted in the joint area, penetrating of the beam longitudinal ribs can be achieved, and column longitudinal rib positioning and concrete pouring are convenient; and meanwhile the inner partition plates can effectively strengthen a square steel pipe, joint force transmission is direct, performance is reliable, and convenience is provided for assembly type achieving.

Owner:CHONGQING UNIV

Whole-process visible anti-void forward top reaching construction method for tunnel vault concrete

ActiveCN110469346AAvoid voidsCause pouring is not fullUnderground chambersTunnel liningEngineeringStructural engineering

Owner:中铁十一局集团第五工程有限公司 +1

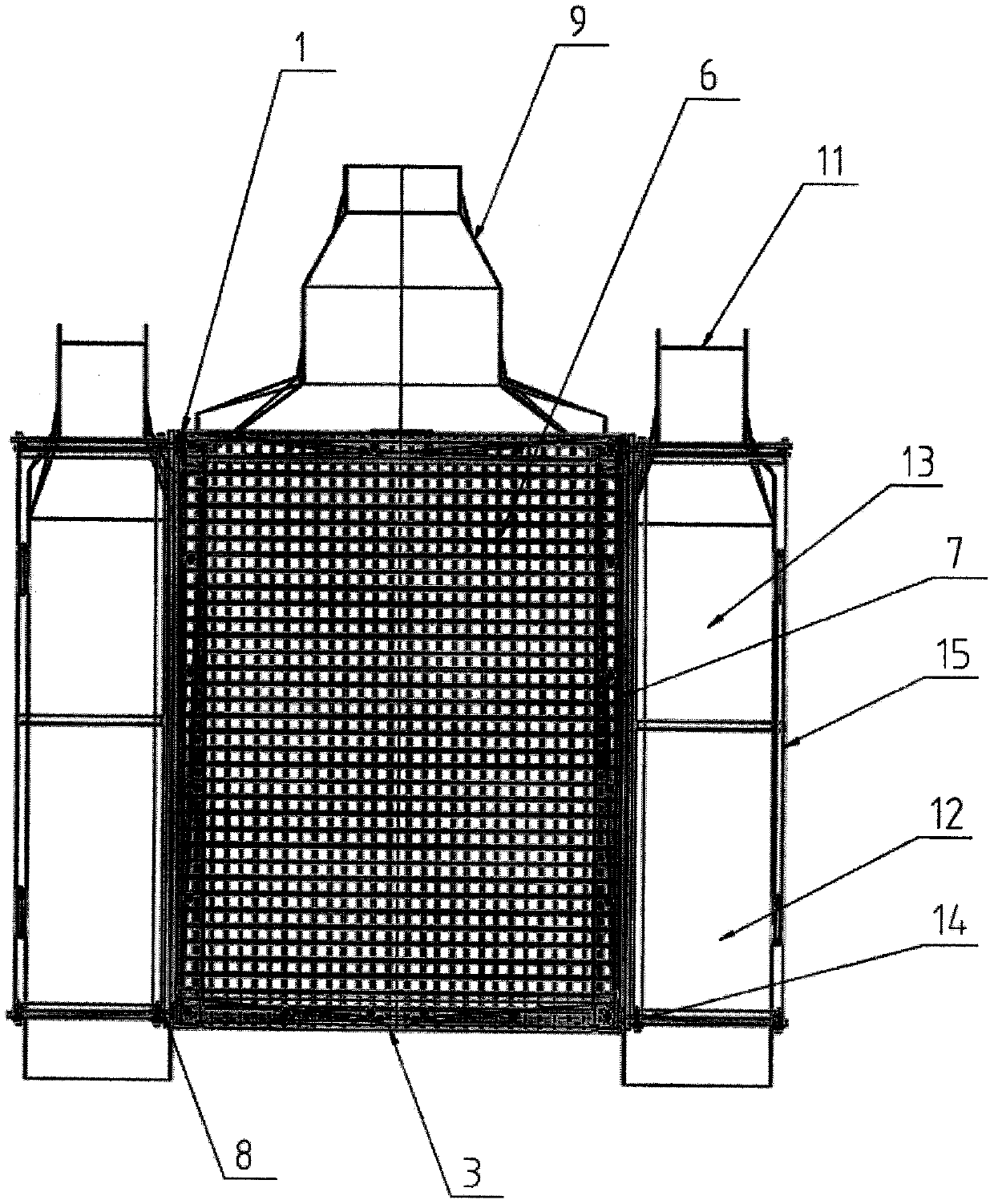

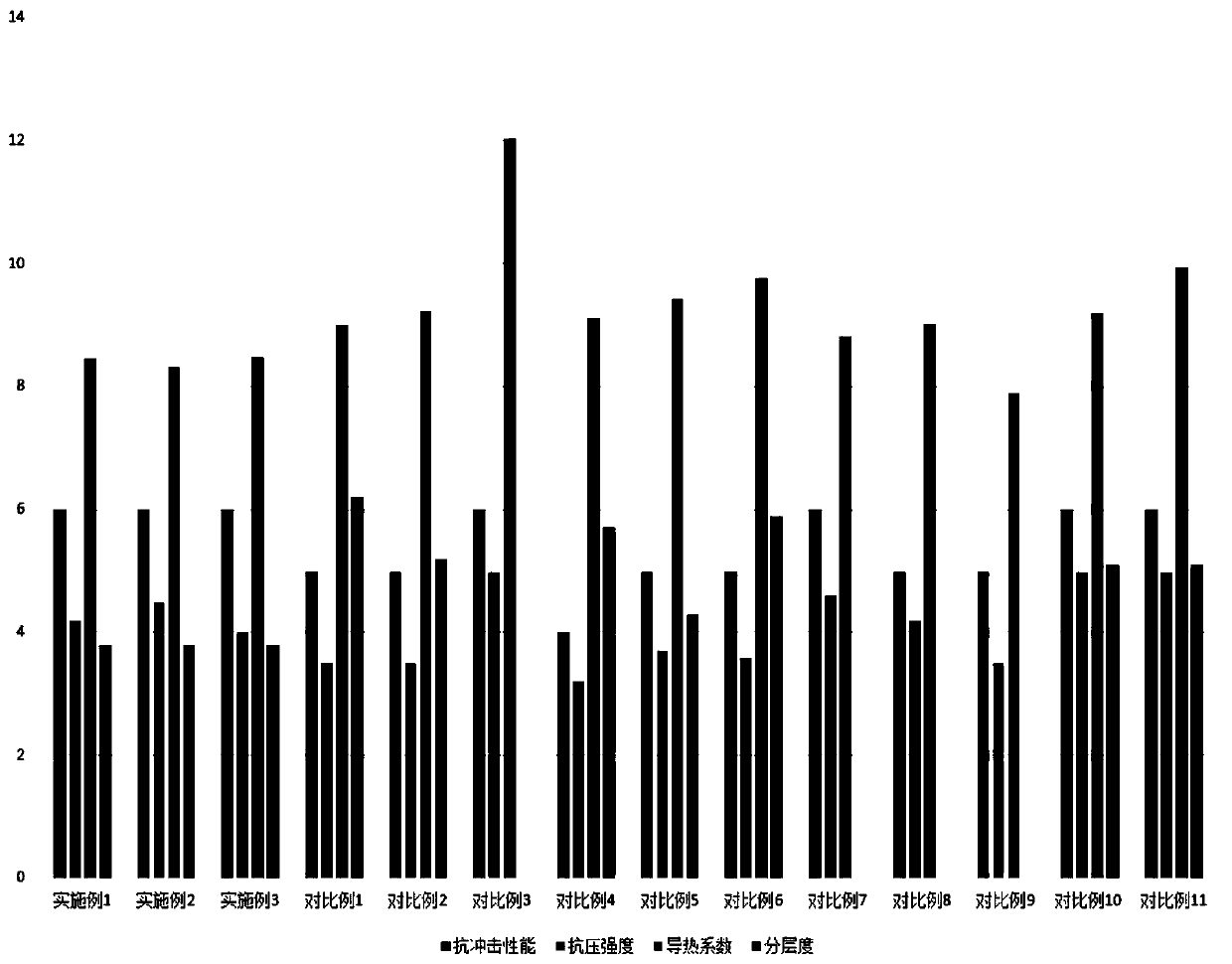

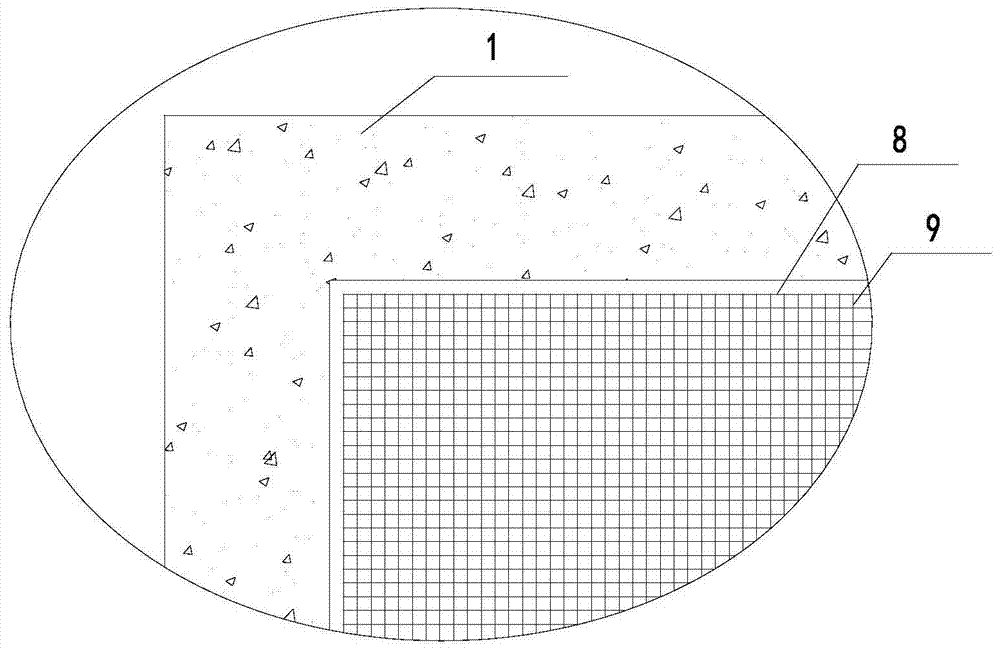

Cast-in-place concrete separator special for composite light-weight (CL)

PendingCN110067389AReduced coarse aggregate contentPour denseBuilding material handlingConstruction aggregateShear wall

The invention discloses a cast-in-place concrete separator special for composite light-weight (CL), and particularly relates to the field of building machinery. The cast-in-place concrete separator special for the CL comprises a separator bracket, a slip casting opening is formed in the top of the separator bracket, an overflowing-prevention baffle is arranged on the exterior of the slip casting opening, and a separating device is arranged at the bottom of the slip casting opening; the separating device comprises a separating cavity, a separating piece is arranged in the separating cavity, theseparating piece is made of steel wire meshes with different intervals, a shock pad is arranged on the separating piece, a blank pressing metal buckle is arranged on the shock pad, and the separatingpiece is arranged as a gable slope or arc structural mode; and a first slurry discharging groove is formed in the bottom of the separating cavity. According to the cast-in-place concrete separator special for the CL, the content of coarse aggregate in concrete after separation is reduced, vibration is suitable for being carried out on a concrete protection layer with the thickness of 50-60mm in the casting process, so that a concrete protection groove on the outer side of a CL shear wall is poured more densely, and the appearance is improved and the safety of building is improved.

Owner:河南西艾尔墙体科技有限公司

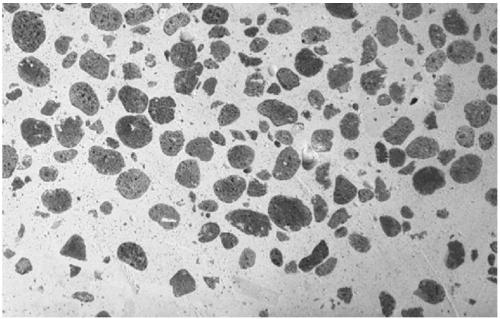

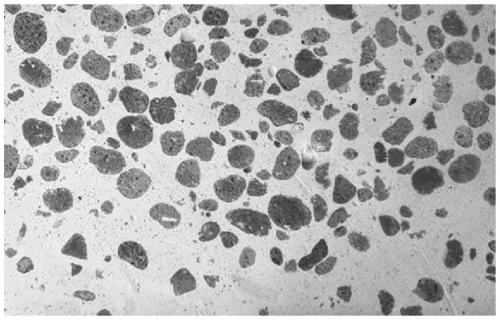

Thermal insulation ceramsite light wallboard

ActiveCN109555262AReduce intensityHigh strengthClimate change adaptationBuilding componentsSodium bicarbonateSurface layer

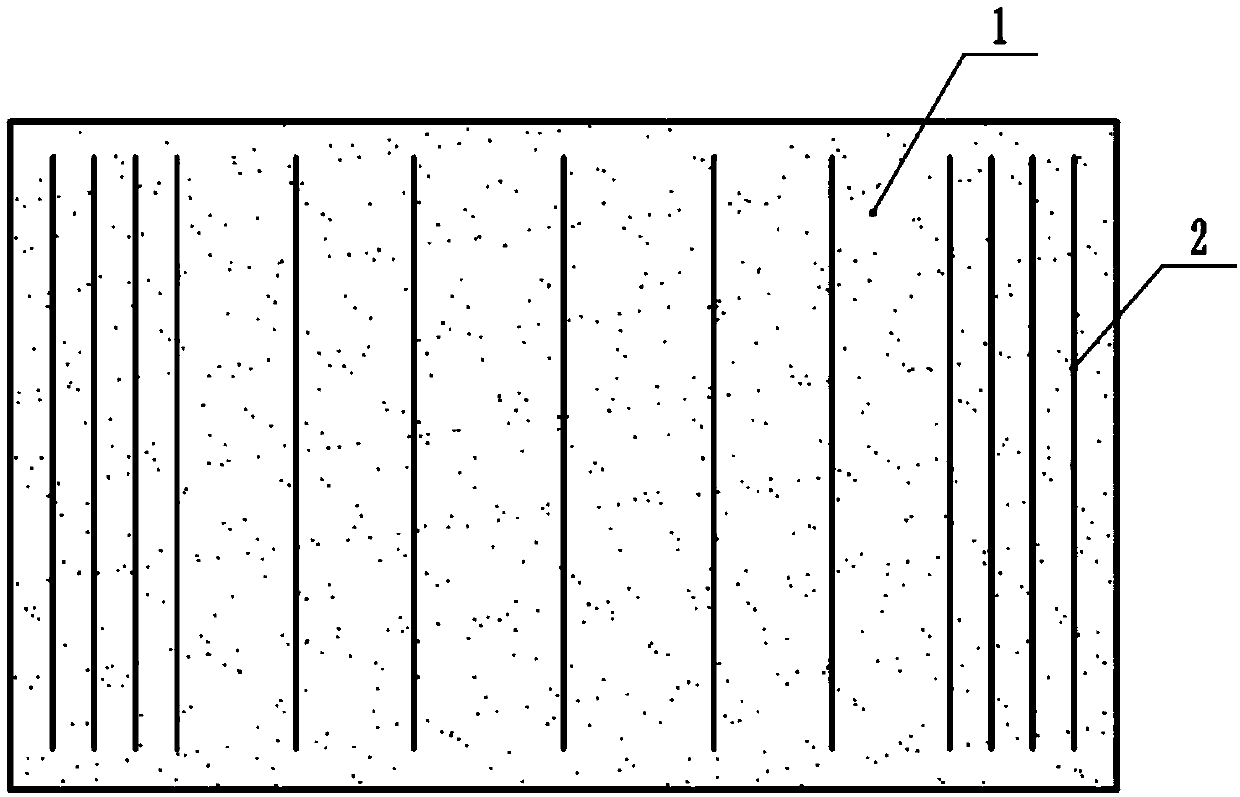

The invention relates to the technical field of wallboard production, in particular to a thermal insulation ceramsite light wallboard. The thermal insulation ceramsite light wallboard comprises a wallboard body, the wallboard body comprises wall surface layers on both sides, a thermal insulation wall core located between the wall surface layers on both sides and a net rack located in a wall surface. The wall surface layers are filled with concrete. The wall surface layers on both sides cover the thermal insulation wall core and the net rack. A plurality of through holes are formed in the thermal insulation wall core, the through holes are in the shape of a V, and the each through hole comprises two open ends and a connecting end. The two open ends are located on both sides of the thermal insulation wall core, the connecting end is located inside the thermal insulation wall core, and sodium bicarbonate is placed at the connecting end. A plurality of fine grooves are formed in the surface of the thermal insulation wall core. The net rack includes a plurality of vertical steel wires parallel to the wall surface layers. The filling components of the concrete of the wall surface layersinclude cement, mixing water, river sand, ceramsite, a water-reducing agent, fly ash, cellulose, a water-reducing agent and an early strength agent. According to the technical scheme of the thermal insulation ceramsite light wallboard, the wallboard is enabled to have high pressure resistance ability.

Owner:重庆成维轻质墙板有限公司

Pressure pouring combining concreting construction method used for structural cross section enlargement

InactiveCN108517788AImprove structural durabilityImprove pouring qualityBuilding repairsBridge erection/assemblySpatial structureConcrete pump

The invention discloses a pressure pouring combining concreting construction method used for a structural cross section enlargement. By installing a non-residual suspending template with a concrete valve on an old structure, a concrete pumping system is utilized to carry out segment dividing pouring construction on a cavity enclosed by the old structure and the suspending template structure. Self-leveling pouring is carried out by utilizing concrete self-weight on the portion below the concrete valve, and pressure pouring is carried out by utilizing the pressure of the concrete pumping systemon the portion above the concrete valve, thereby controlling the concrete pressure in the template within a reasonable range. A concrete pouring process combining the rotating screw suspending template and the pressure pouring is adopted to carry out the structural cross section enlargement, the construction is simple, the efficiency is high, and concrete quality and structure durability are improved; the method not only can be applied to concrete construction of small space structural cross section enlargement but also can be applied to other constructions of cross section enlargement of concrete structures which cannot be easily vibrated, and the application prospect is good.

Owner:CCCC ROAD & BRIDGE SPECIAL ENG

An assembled steel concrete composite beam and a forming method thereof

PendingCN109594461APour denseFirmly connectedBridge structural detailsBridge erection/assemblyBending momentSurface plate

The invention relates to an assembled steel concrete composite beam and a forming method thereof. The assembled steel concrete composite beam comprises a concrete panel and a support beam which are arranged along the vertical direction; the support beam is provided with an upper flange top plate; the concrete panel and the upper flange top plate are formed by casting; and the upper flange top plate is positioned at the upper part of the concrete panel. The casting position of the concrete panel is moved to the lower end of the upper flange top plate from the upper end of the upper flange top plate, so it is guaranteed that the upper flange top plate and the concrete panel are cast compactly and connected firmly, meanwhile, the upper flange top plate bears the stress of a hogging moment area, the material utilization rate is increased, and cost is saved.

Owner:ZHENGZHOU COMM PLANNING SURVEY & DESIGN INST +1

Diaphragm wall construction method

InactiveCN109972678AImprove liquidityEvenly distributedMechanical machines/dredgersBulkheads/pilesSlurry wallRebar

Owner:SHANGHAI YUANFANG GROUNDWORK ENG

A kind of preparation method of energy-saving ceramsite light-weight wallboard

ActiveCN109435011BReduce intensityHigh strengthSolid waste managementCeramic shaping apparatusSodium bicarbonateCellulose

The invention relates to the technical field of wallboard production, and particularly discloses a preparation method for an energy-saving ceramsite lightweight wallboard. The method comprises the following steps that S1, a rectangular heat preservation wall core is selected, a plurality of V-shaped through holes are formed in the heat preservation wall core, each through hole comprises two open ends and a connecting end, sodium bicarbonate is placed at the connecting ends, and a plurality of fine grooves are formed in the surface of the heat preservation wall core; S2, a mold is selected, theheat preservation wall core is vertically placed into the mold, one side edge of the heat preservation wall core is enabled to be in contact with the bottom of the mold; S3, net racks are placed on the two sides of the heat preservation wall core correspondingly; S4, a concrete filler with the filling components comprising cement, mixing water, river sand, ceramsite, a water reducer, fly ash, cellulose and an early strength agent is mixed and then is injected into the mold; S5, vibrating is performed on the concrete filler; and S6, demoulding is performed after the concrete filler is solidified and hardened, and the energy-saving ceramsite lightweight wallboard is prepared after demoulding. By adopting the technical scheme, the wallboard can have the relatively high compression resistance.

Owner:重庆成维轻质墙板有限公司

A kind of thermal insulation ceramsite lightweight wallboard

ActiveCN109555262BReduce intensityHigh strengthClimate change adaptationBuilding componentsSodium bicarbonateThermal insulation

The invention relates to the technical field of wallboard production, in particular to a thermal insulation ceramsite light wallboard. The thermal insulation ceramsite light wallboard comprises a wallboard body, the wallboard body comprises wall surface layers on both sides, a thermal insulation wall core located between the wall surface layers on both sides and a net rack located in a wall surface. The wall surface layers are filled with concrete. The wall surface layers on both sides cover the thermal insulation wall core and the net rack. A plurality of through holes are formed in the thermal insulation wall core, the through holes are in the shape of a V, and the each through hole comprises two open ends and a connecting end. The two open ends are located on both sides of the thermal insulation wall core, the connecting end is located inside the thermal insulation wall core, and sodium bicarbonate is placed at the connecting end. A plurality of fine grooves are formed in the surface of the thermal insulation wall core. The net rack includes a plurality of vertical steel wires parallel to the wall surface layers. The filling components of the concrete of the wall surface layersinclude cement, mixing water, river sand, ceramsite, a water-reducing agent, fly ash, cellulose, a water-reducing agent and an early strength agent. According to the technical scheme of the thermal insulation ceramsite light wallboard, the wallboard is enabled to have high pressure resistance ability.

Owner:重庆成维轻质墙板有限公司

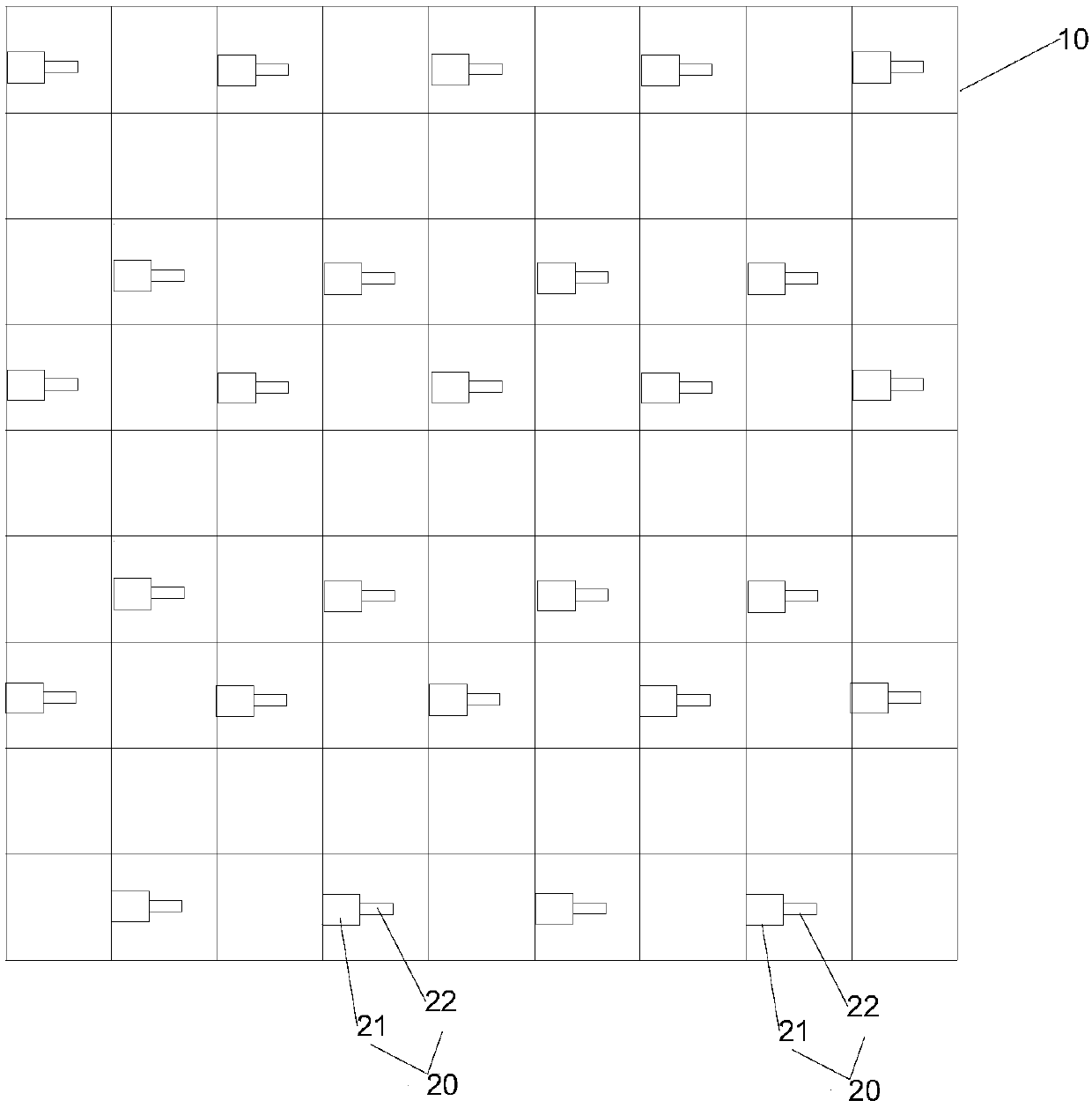

Inner-casting reinforced precast concrete wall panel, concrete wall, structure system and construction method

PendingCN110424566AIncreased horizontal shear resistanceReduce secondary pouringWallsCeramic shaping apparatusRebarWall plate

The invention relates to an inner-casting reinforced precast wall panel, a concrete wall, a structure system and a construction method. The wall panel comprises a precast part, wherein the precast part comprises precast part vertical reinforcing steel bars, precast part horizontal reinforcing steel bars and precast part concretes; vertical connecting pieces are arranged at the vertical connectingends of the precast part; vertical shear connectors are partially embedded into the precast part; at least one concrete inner-casting hole passage is arranged at the position, between the vertical connecting pieces, in the precast part; and the concrete inner-casting hole passages are continuously arranged along the vertical direction of the precast part. According to the inner-casting reinforcedprecast wall panel, the concrete wall, the structure system and the construction method provided by the invention, the concrete inner-casting hole passages are arranged, and at least one hole passageis located between the vertical shear connectors, so that the concretes between the vertical shear connectors are ensured to be poured densely, the concrete pouring quality between the vertical shearconnectors at a horizontal connecting area of the precast concrete wall panel is effectively improved, and the construction speed is fast.

Owner:姚攀峰

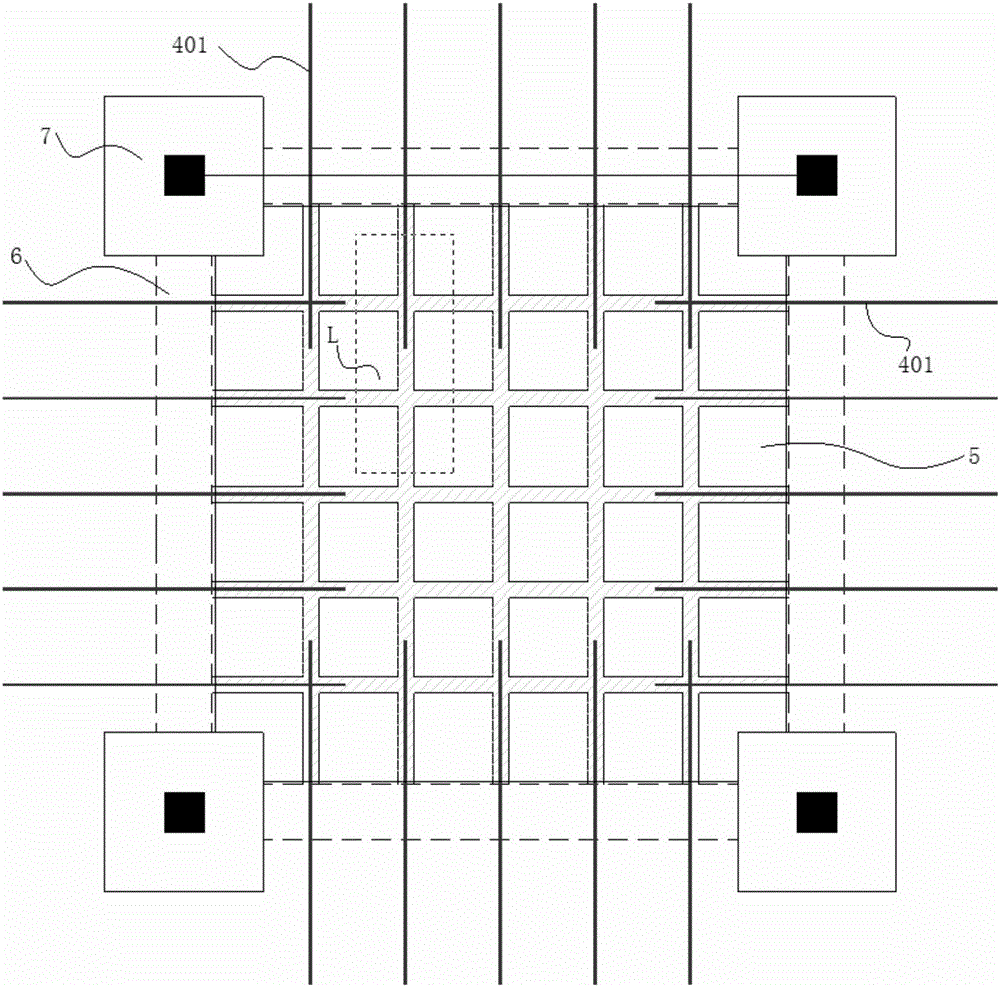

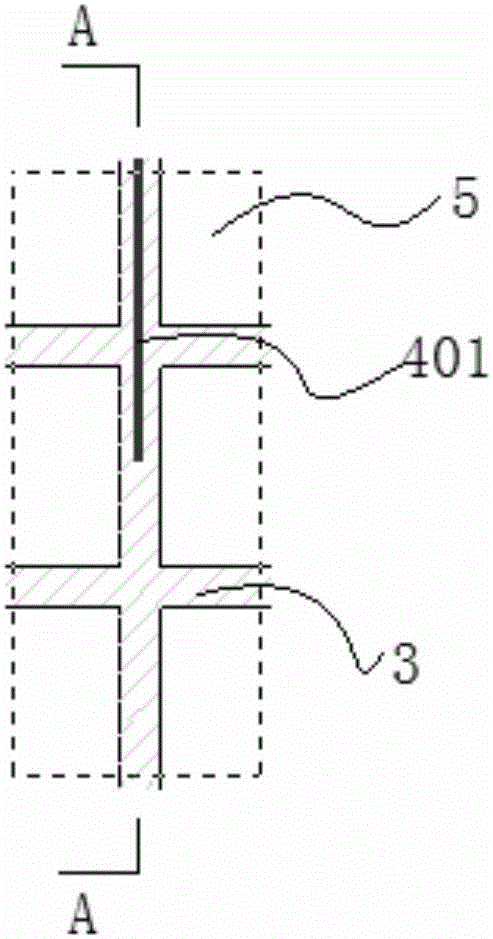

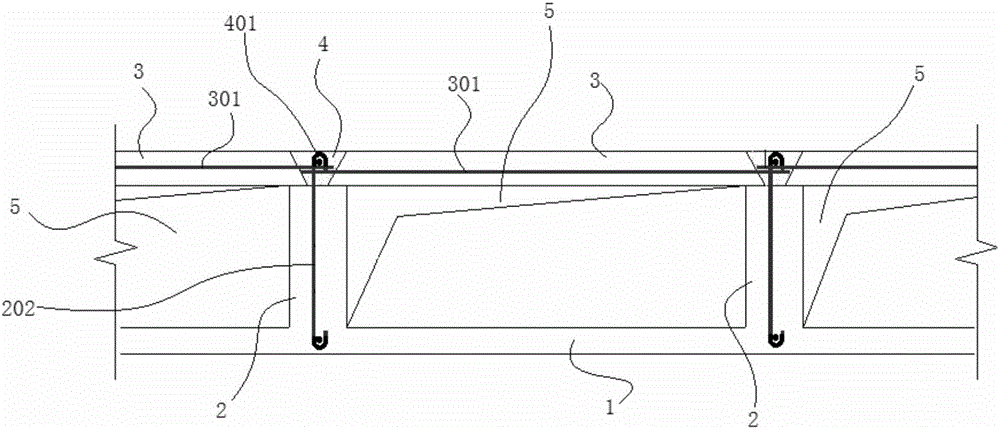

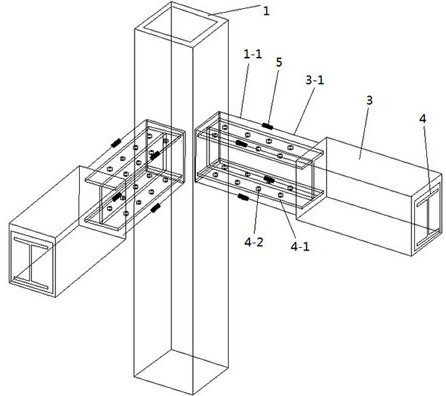

Repairable and easy-to-replace fabricated steel structure beam-column joint capable of realizing self-resetting

PendingCN113931308APour denseIntegrity guaranteedBuilding constructionsShaped beamShape-memory alloy

The invention provides a repairable and easy-to-replace fabricated steel structure beam-column joint capable of realizing self-resetting. The repairable and easy-to-replace fabricated steel structure beam-column joint comprises a rectangular tubular column, concrete, a supporting plate assembly, an I-shaped beam and an inverted U-shaped cover plate; the supporting plate assembly comprises a horizontal supporting plate and vertical side plates located on the two sides of the horizontal supporting plate; the end part of a lower wing plate of the I-shaped beam is placed on the horizontal supporting plate, the inverted U-shaped cover plate is buckled on the outer sides of the two vertical side plates and the end part of the upper wing plate of the I-shaped beam; a plurality of shape memory alloy vertical ribs are connected between the end part of the lower wing plate and the end part of an upper wing plate of the I-shaped beam, two ends of each shape memory alloy vertical rib are connected with the closed end of the inverted U-shaped cover plate and the horizontal supporting plate through bolt structures; and a plurality of vertical bolt long holes are formed in the vertical side plates and / or the side plates of the inverted-U-shaped cover plates, and the vertical side plates and the side plates of the inverted-U-shaped cover plates are connected through high-strength bolts arranged in the vertical bolt long holes in a penetrating mode.

Owner:ZHENGZHOU UNIV

Concrete pouring method for flow channel of tubular unit in aviation power project

The invention provides a concrete pouring method for a tubular turbine unit runner of navigation-power junction engineering. The method comprises steps as follows: prefabrication of form baffles; mounting of the form baffles; pouring of concrete at the horizontal section of the runner and dismounting of the form baffles; setting of construction joints of the runner; pouring of foundation concreteof side wall structure sections of the runner; prefabrication of curved forms; mounting of the curved forms; pouring of curved concrete of the runner; dismounting of forms at the lower part of the runner and a secondary plastering process. The contact area of two sections of concrete construction joints is increased through the construction joints formed by the form baffles, the problem that bottom concrete is difficult to pour compactly due to curved steel bars is solved, and concrete can be poured compactly; the problems that curved surfaces and horizontal planes cannot be contacted and vibrated uniformly through conventional pouring due to the fact that the included angle at the junction of the arc section and the horizontal section of the runner is smaller are solved through dismounting of forms at the lower part of the runner and the secondary plastering process, so that the surface flatness, plastering quality and linear control of the runner meet the design requirement.

Owner:CHINA GEZHOUBA (GRP) FIRST ENG CO LTD

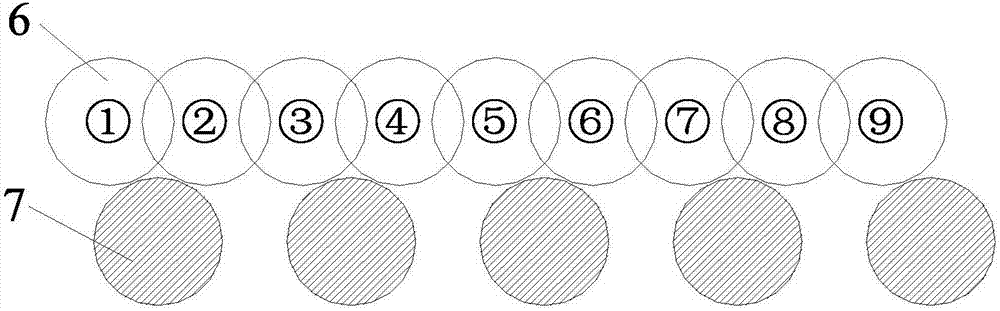

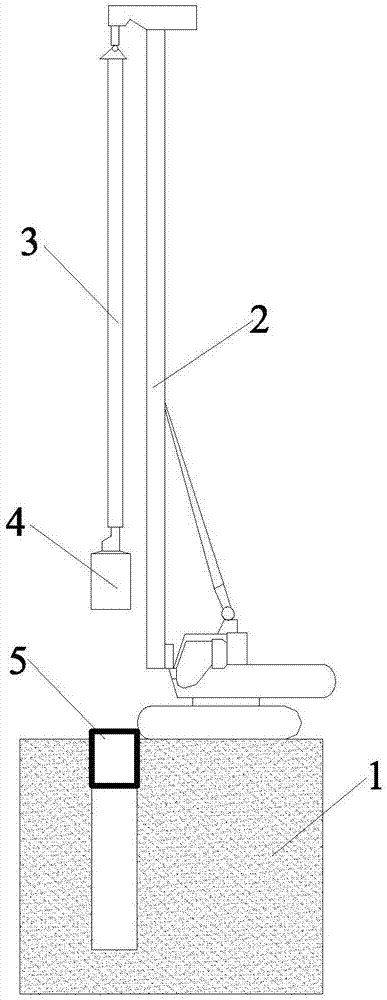

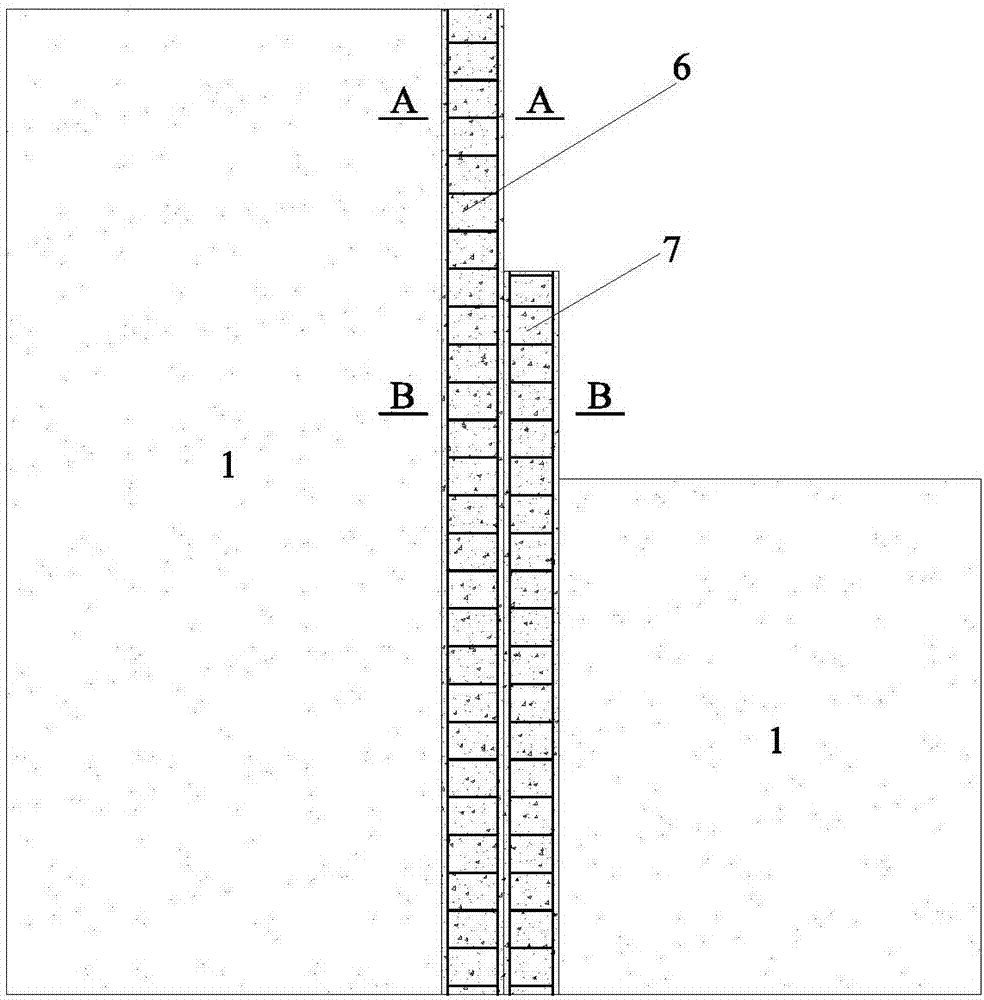

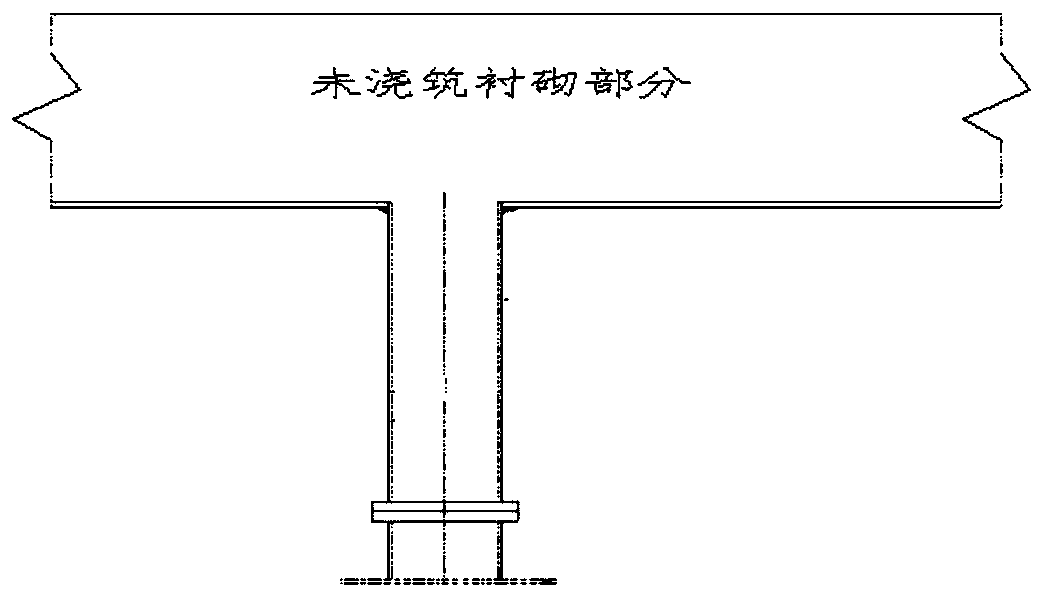

Densely arranged step-shaped revolving digging cast-in-place bored pile supporting and protecting system and construction method

The invention discloses a densely arranged step-shaped revolving digging cast-in-place bored pile supporting and protecting system. A continuous wall and reinforced piles are included; the continuouswall is installed in a hole groove broken through by a rotary drilling rig; the reinforced piles are arranged in hole grooves, on the front side of the continuous wall, broken through by the rotary drilling rig; and the plane where the reinforced piles arranged in parallel are located is parallel with the plane where the continuous wall is located. Due to the fact that different pile sections areadopted, the beneficial effects that concrete pouring is dense and connection seams are firm are achieved, the densely arranged step-shaped revolving digging cast-in-place bored pile supporting and protecting system is clear in construction step, ingenious in structural design and good in application prospect, the manufacturing cost of a revolving digging cast-in-place bored pile can also be reduced, safety of the supporting and protecting system is guaranteed, and the manufacturing cost is also saved.

Owner:GUANGZHOU FOURTH CONSTR

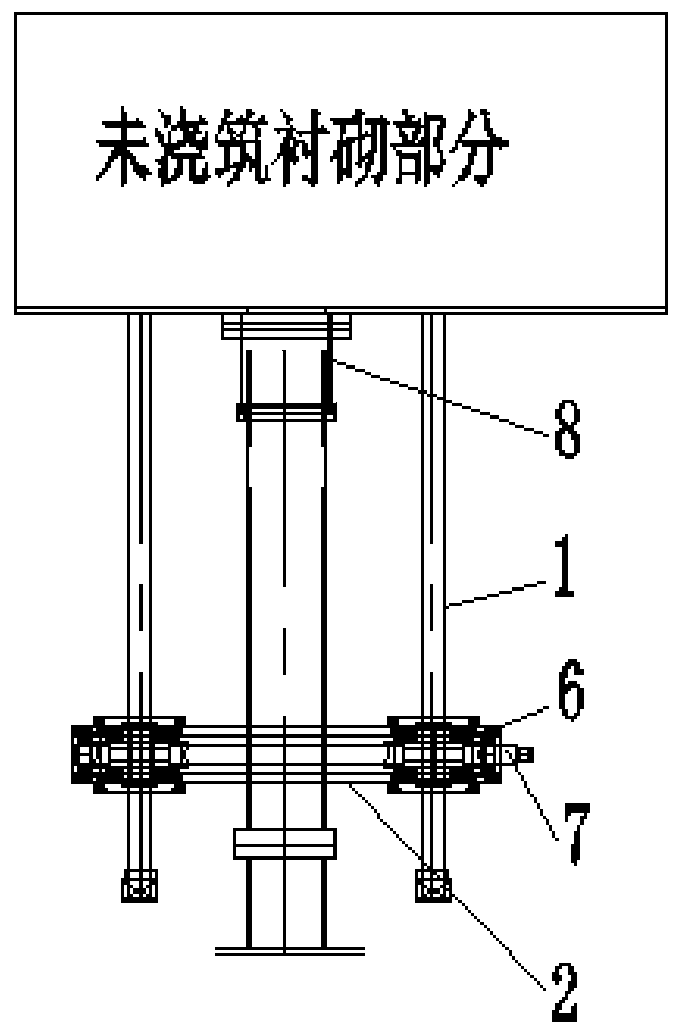

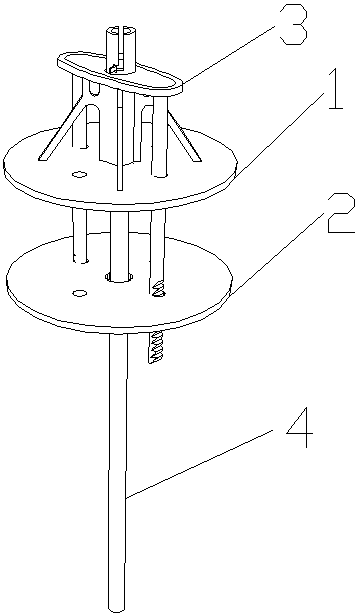

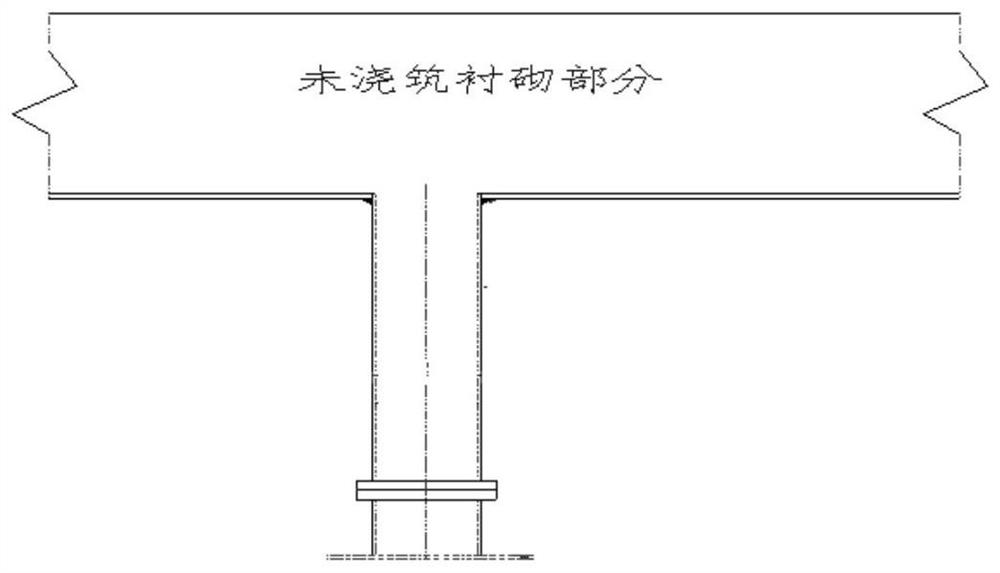

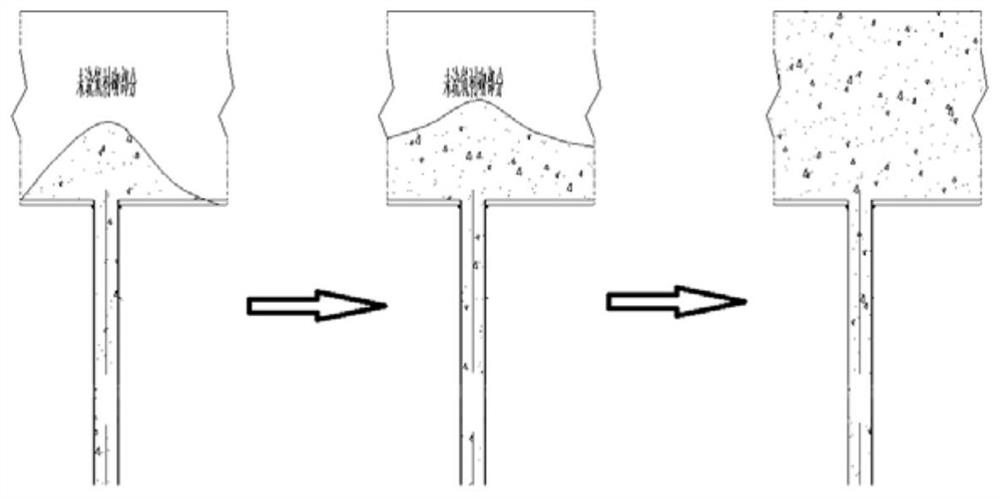

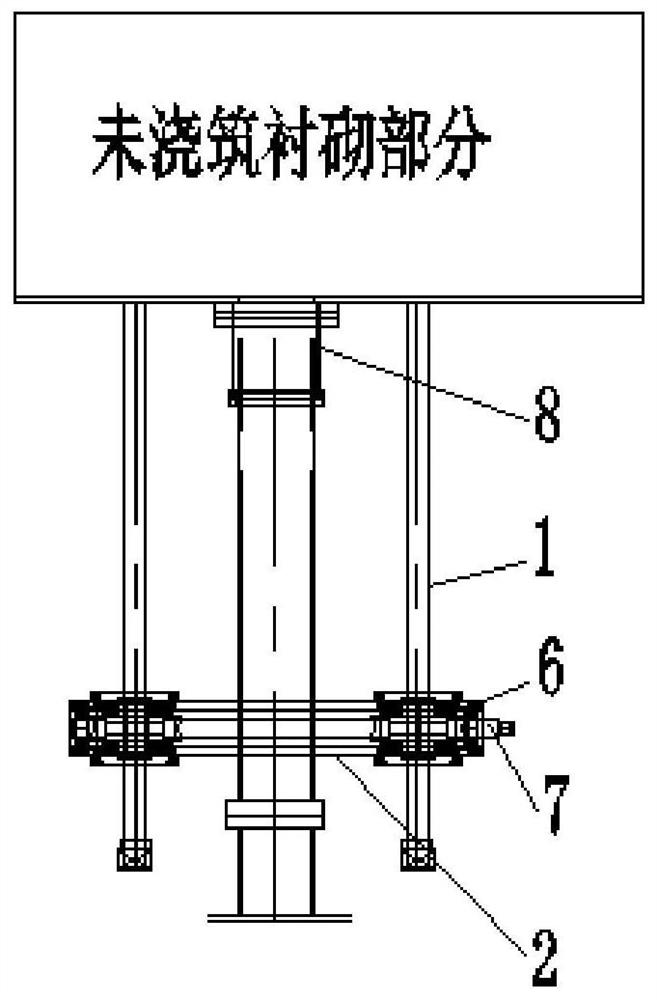

Tunnel vault concrete void prevention forward jacking device

The invention discloses a tunnel vault concrete void prevention forward jacking device. The tunnel vault concrete void prevention forward jacking device comprises fixed vertical rods, a lifting seat,sealed gate valves and a guide pipe, wherein the guide pipe is fixedly mounted at the upper part of the lifting seat; the sealed gate valves are mounted at the upper ends of the fixed vertical rods; the lifting seat is capable of moving up and down under driving of power and guidance of the fixed vertical rods so as to drive the guide pipe to rise or fall through gate holes of the gate valves. Thedevice is capable of carrying out forward layered pouring, layered jacking and perfusion jacking and ensuring that the vault concrete is poured densely and fully; and the problems of voids of tunnellinings are effectively solved.

Owner:中铁十一局集团第五工程有限公司 +2

Rectangular jacking pipe joint concrete pouring method utilizing bin dividing steel plates

ActiveCN112554909AImprove deformation resistanceReduce distortionUnderground chambersHydro energy generationArchitectural engineeringRebar

The invention discloses a rectangular jacking pipe joint concrete pouring method utilizing bin dividing steel plates. The rectangular jacking pipe joint concrete pouring method specifically comprisesthe steps that a cast-in-place section is divided into two parts for pouring, the first part is a bottom plate and a short flank wall, and the second part is a side wall and a top plate; in a jackingpipe steel shell, transverse upper bin dividing steel plates are welded with the shell, and longitudinal upper bin dividing steel plates are combined with assembled formworks to form independent pouring units; and vertical framework positioning ribs are welded on a casing, and double-layer reinforcing steel bars of the top plate and the framework positioning ribs are connected into a whole throughinsulating clamps and insulating binding wires, so that reinforcing steel bar corrosion caused by stray current after subway operation is prevented. The deformation of an abandoned shell section is reduced, and the concrete pouring quality of the cast-in-place section is guaranteed; and the concrete pouring difficulty is reduced, the concrete pouring efficiency is improved, and the durability ofa main body structure is improved.

Owner:CHINA RAILWAY 15TH CONSTR BUREAU GRP +1

A large-span long cantilever conjoined structure and its construction technology

ActiveCN104818772BMeet the seismic performance requirementsThe structural system is safe and reliableBuilding material handlingSupporting systemEngineering

The invention discloses a large-span long-cantilever connection structure and a construction technique. The structure plane is arranged in the form of rectangle, two towers are arranged beneath the standard layer, wherein a tower is a cylinder body (4), the left and right sides of the tower respectively support a large-span and long-cantilever floor at the upper part, and the width of the cylinder body (4) is less than the width of the floor at the upper part, and the vertical face of the tower forms a model with a wide upper part and a narrow lower part; the other one tower is a framework shear wall structure. The large-span and long-cantilever is connected to the two towers through a side-span steel truss (1) and a middle-span steel truss (2) which are penetrated to each other. The side-span steel truss (1) is arranged within the scale of the cylinder (4), and supported on a supporting steel truss (3) extended from the cylinder (4) along the vertical direction. A steel framework beam (7) and a secondary steel beam (8) are equally arranged on the upper floor so as to form a floor cover supporting system. The floor cover adopts a steel bar truss floor support plate. The large-span long-cantilever connection structure solves the technical problem that the vertical face model is the connection structure with the wide upper part and the narrow lower part, and suitable for multi-layer and high rise buildings; moreover, the large-span long-cantilever connection structure has very strong universality and application scale.

Owner:香港华艺设计顾问(深圳)有限公司

Partially prefabricated post-lamination hollow floor

The invention discloses a partially-prefabricated assembled rear-stacking hollow floor, comprising cast-in-place floor bottom slabs, a cast-in-place rib beam slab grid and prefabricated flat slabs; a bottom formwork and beam rib side formworks are erected, and bottom slab and rib beam rebars are tied; the hollow floor bottom slabs and rib beam concrete are then cast, a construction joint is reserved at the bottom of the top slabs, the prefabricated flat plates corresponding to hollows in size are lifted to the tops of rib beams, stress-bearing vertical bars connected with hidden beams are arranged correspondingly at the rib beams, and secondary casting is performed at the rib beams between the flat slabs so as to finish maintenance. The inner formwork material in the hollow floor is omitted, and two novel hollow floor structures cast by means of secondary stacking are constructed. The partially-prefabricated assembled rear-stacking hollow floor with the structure allows all aforementioned problems present in traditional hollow floors can be solved, and construction difficulty is not reduced.

Owner:CHONGQING UNIV

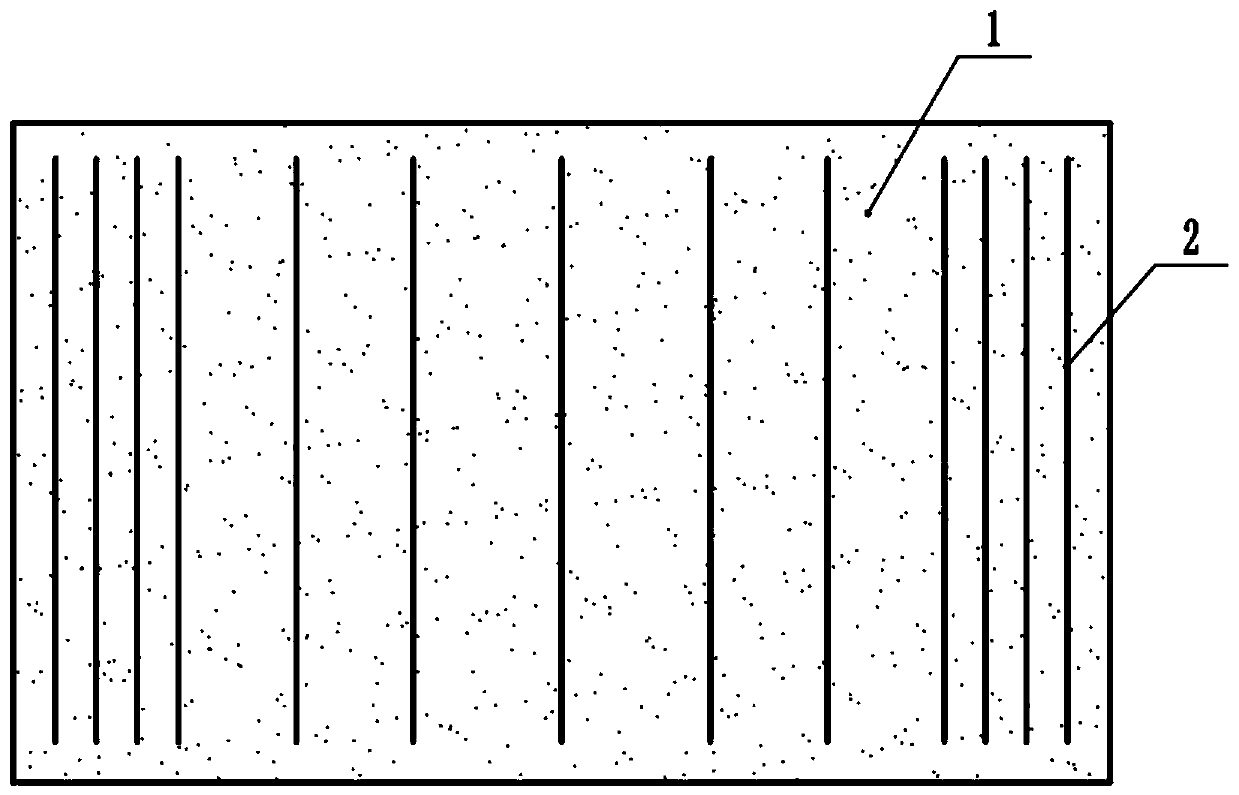

Combined sandwich type heat preservation layer structure

PendingCN109024940AWill not shiftEasy constructionWallsHeat proofingEngineeringMechanical engineering

The invention discloses a combined sandwich type heat preservation layer structure. The structure is characterized by comprising a heat preservation board, steel wire gauze and a combined sandwich piece; the combined sandwich piece comprises a pushing resistance sheet upper disc, a pushing resistance sheet lower disc, a double-rod penetrating nail and a connecting rod piece; through holes are formed in corresponding portions of the pushing resistance sheet upper disc and pushing resistance sheet lower disc respectively, gauze clamping grooves are formed in the pushing resistance sheet upper disc, and the pushing resistance sheet upper disc and the pushing resistance sheet lower disc are arranged on the front and back sides of a heat preservation plate; the steel wire gauze is arranged in the gauze clamping grooves, and the double-rod penetrating nail and the connecting rod piece penetrate through the heat preservation board from the through holes in the pushing resistance sheet upper disc and stretch out of the corresponding through holes in the pushing resistance sheet lower disc, wherein the double-rod penetrating nail and the connecting rod piece are casted in a wall body. According to the technical scheme, the problems are solved that in a sandwich combined process, a connection mode is not compact, the production efficiency is low, and the requirement for production conditions is high. The design is simple, no complicated structures are adopted, the production cost is reduced, and application and popularization of the sandwich combined process in a construction field are facilitated.

Owner:郑州乾顺建筑科技有限公司

A construction method of underwater bottom-sealing concrete using steel truss reinforcement

The invention discloses an underwater bottom sealing concrete construction method using a steel truss for reinforcement and belongs to the field of underwater bottom sealing for deep foundation pit construction. The underwater bottom sealing concrete construction method using the steel truss for reinforcement comprises the steps that after a cofferdam is installed or an underground diaphragm wall is constructed, underwater excavation is conducted in a foundation pit till the bottom elevation of bottom sealing concrete is reached; the steel truss is machined piece by piece or integrally on site on land; the steel truss is hoisted and lowered in place integrally or piece by piece; a bottom sealing platform is built, a central collection hopper and a chute are arranged, and a plurality of bottom sealing guide pipes are lowered; mixed concrete is conveyed to the site; tank opening is conducted step by step for head sealing construction, and then normal pouring is conducted; and the bottom sealing guide pipes, the central collection hopper, the chute and the bottom sealing platform are dismounted after bottom sealing is completed, and water pumping is conducted after the strength of the bottom sealing concrete reaches the design strength. By the adoption of the underwater bottom sealing concrete construction method using the steel truss for reinforcement, the reinforcement effect can be achieved, and the thickness of the bottom sealing concrete is reduced, so that the purpose of reducing the construction cost is achieved, the construction difficulty of the underwater bottom sealing concrete can be lowered, and the construction quality and construction safety of the bottom sealing concrete are guaranteed.

Owner:CCCC SHEC FOURTH ENG +1

The construction method of tunnel vault concrete anti-vacation full-process visualization forward punching

ActiveCN110469346BAvoid voidsCause pouring is not fullUnderground chambersTunnel liningArchitectural engineeringStructural engineering

Owner:中铁十一局集团第五工程有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com