Tunnel vault concrete void prevention forward jacking device

A concrete and vault technology, applied in tunnels, tunnel linings, shaft equipment, etc., can solve the problems of unfilled full linings and voids, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below by embodiment and in conjunction with accompanying drawing, the present invention will be further described:

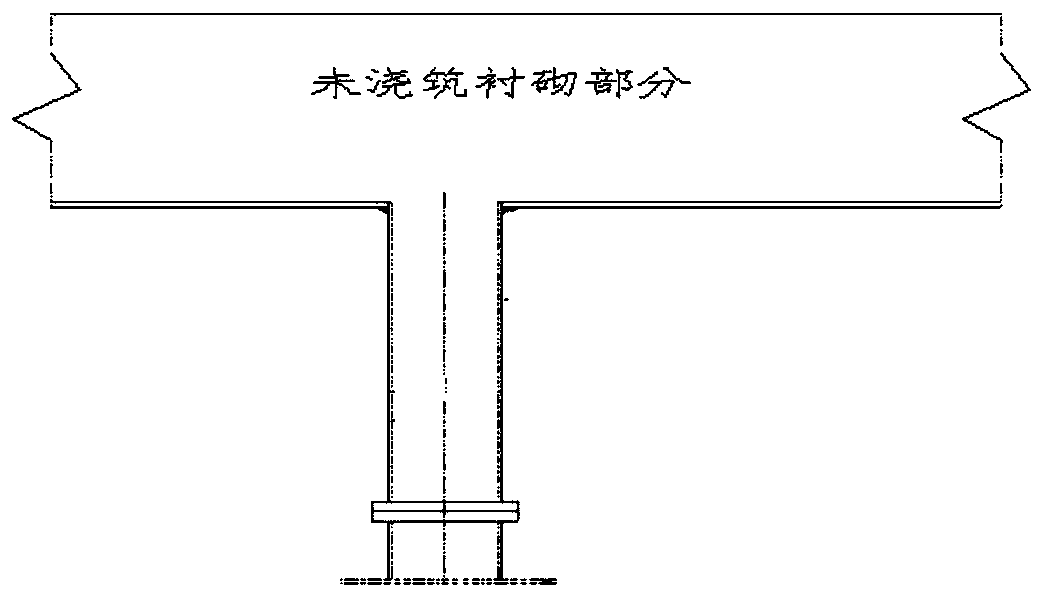

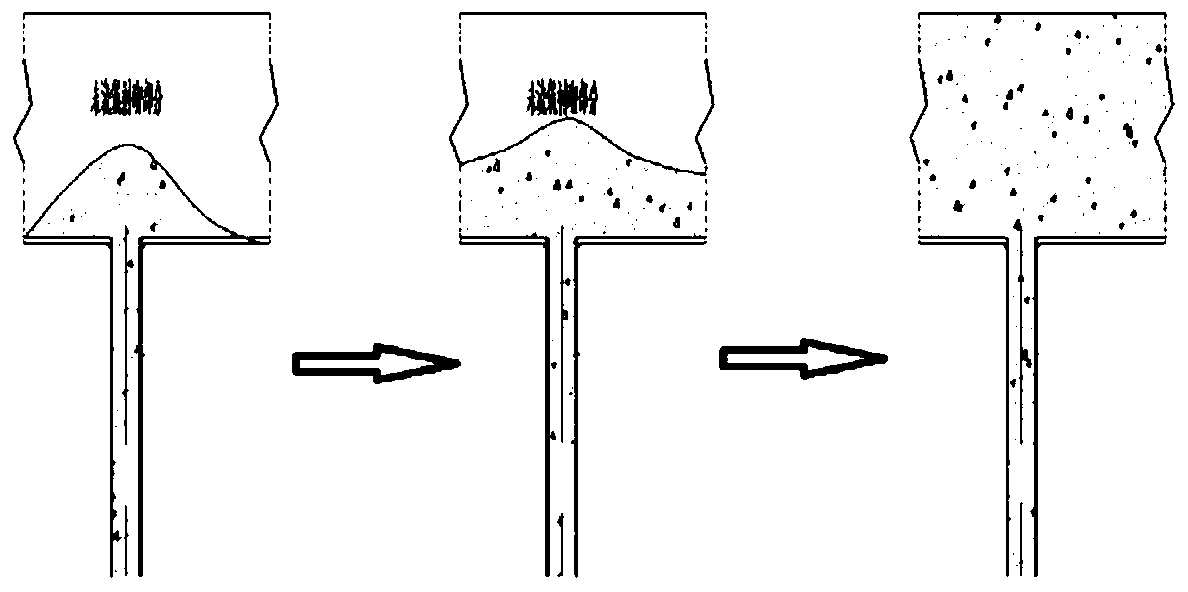

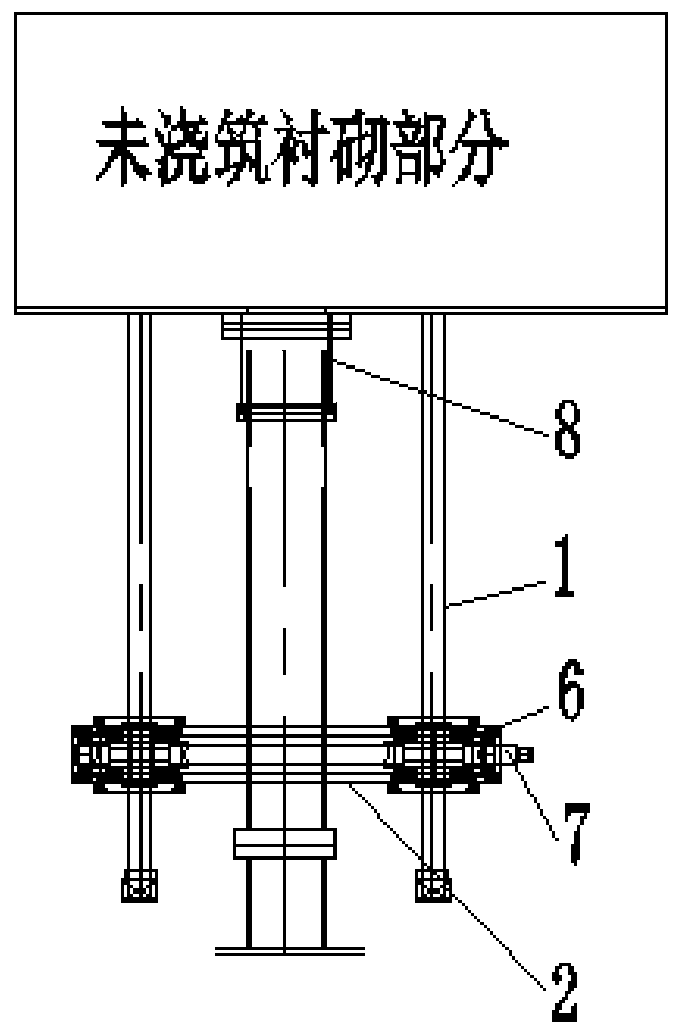

[0025] combine image 3 — Figure 5 As shown, a tunnel vault concrete anti-vacation forward punching device is mainly composed of a fixed vertical rod 1, a lifting seat 2, a closed gate valve 3 and a conduit 4. The conduit 4 is fixedly installed above the lifting seat 2, and is used for connecting the concrete delivery pump pipe. The closed gate valve 3 is installed on the upper end of the fixed vertical rod 1, and the opening and closing of the closed gate valve 3 is automatically controlled by a horizontal cylinder 5 or an electric push rod. The lifting seat 2 can move up and down under the drive of the power and the guidance of the fixed pole 1, thereby driving the conduit 4 to rise or fall through the gate hole of the closed gate valve 3. The driving power of lifting base 2 can be manually driven, can be pneumatic or electric mode. There are prefe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com