Concrete pouring method for flow channel of tubular unit in aviation power project

A concrete and through-flow technology, which is applied in the direction of infrastructure engineering, construction, etc., can solve the problem of difficult quality control of the curved surface of the flow channel, so as to achieve the satisfaction of plastering surface quality and linear control, increase the contact area, and ensure flatness and quality effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

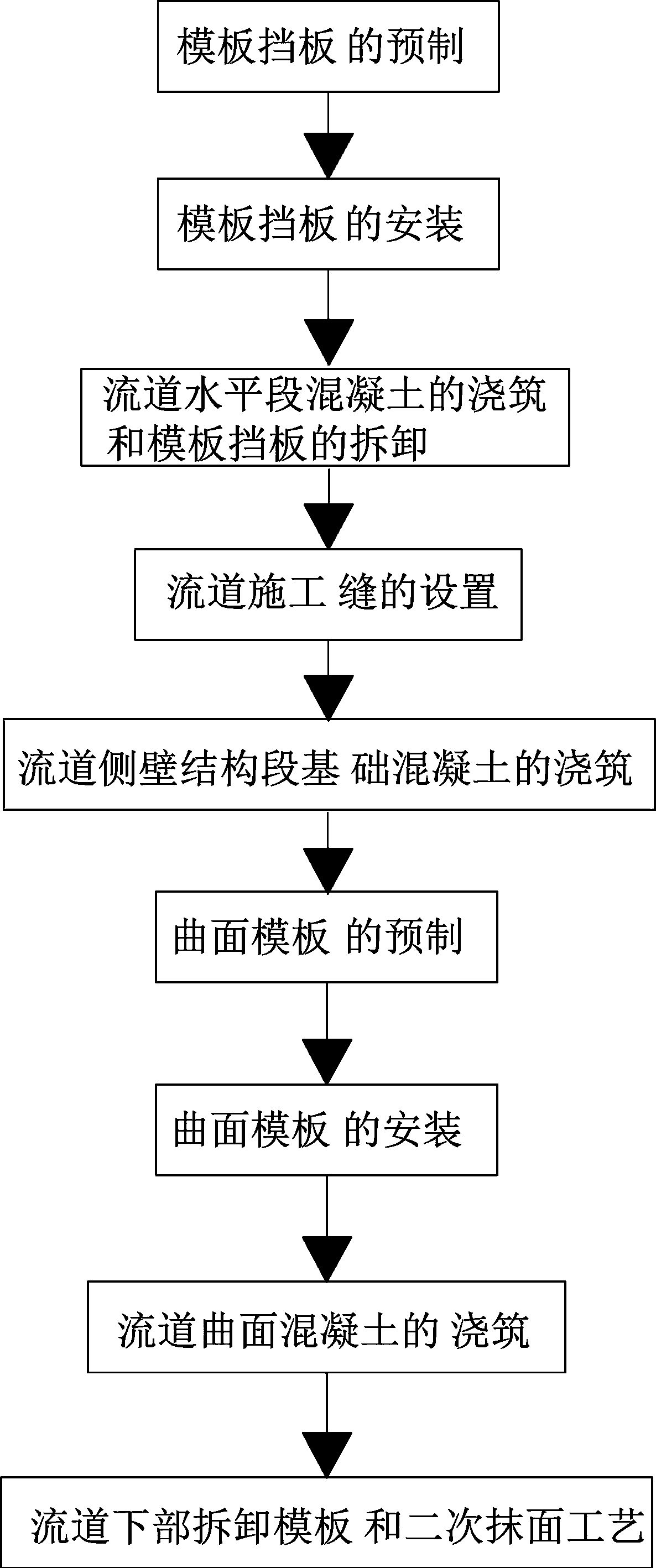

[0034] see Figure 1~6 Among them, a concrete pouring method for the flow channel of the tubular unit of the navigation and power hub project, including the following steps:

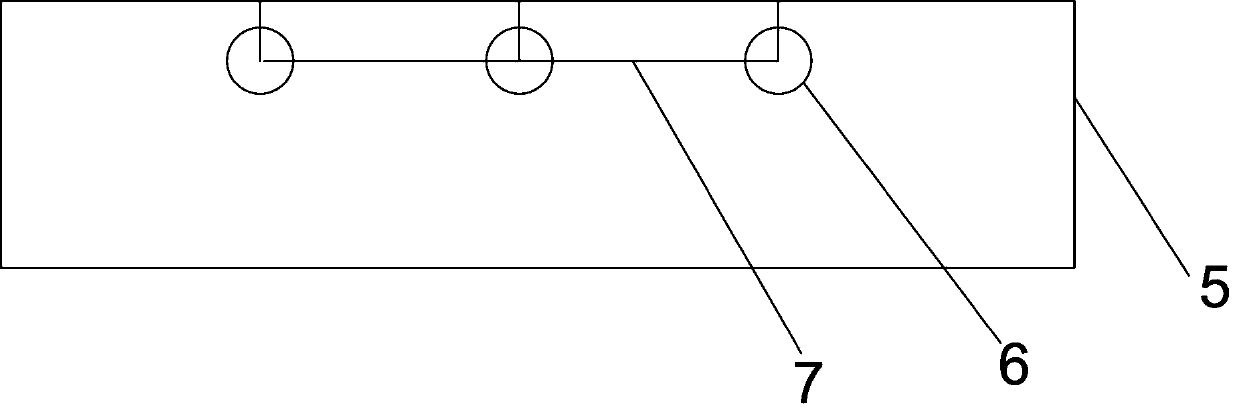

[0035] 1) Prefabrication of the formwork baffle 5: one side of the formwork baffle 5 is provided with a reserved hole 6 for the circular steel bar on the side wall of the flow channel, and the formwork baffle 5 is connected to the annular steel bar 4 on the side wall of the flow channel through the mold back corrugated locking buckle 7;

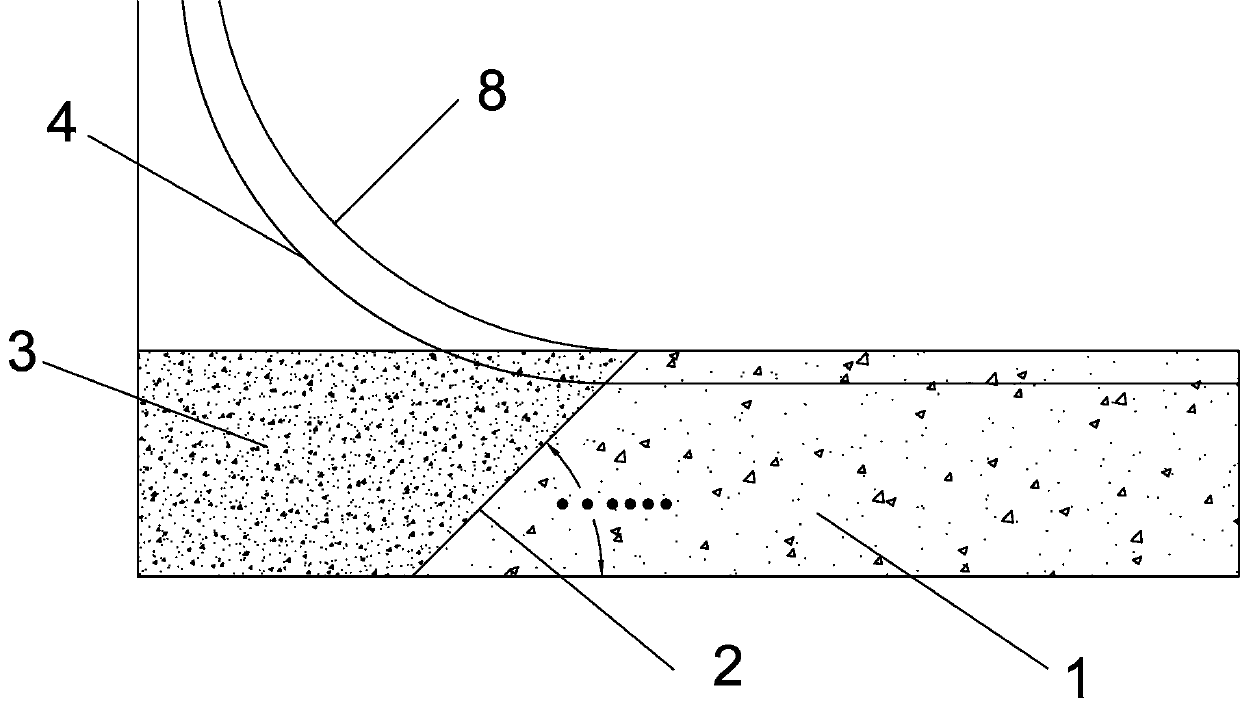

[0036] 2) Installation of template baffle plate 5: the flow channel is divided into a horizontal section 1 of the flow channel and a curved surface structure section 8 of the side wall of the flow channel. The annular steel bar 4 of the side wall of the flow channel is arranged in the flow channel, and the bottom of the curved surface structure section 8 of the side wall of the flow channel The foundation 3 of the structure section of the side wall of the flow channel i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com