Method for pouring concrete based on magnetic drive

A technology of pouring concrete and magnetic drive, which is applied in the processing of building materials, construction, building structure, etc., can solve the problems of inability to pour compactly, uneven distribution of concrete, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

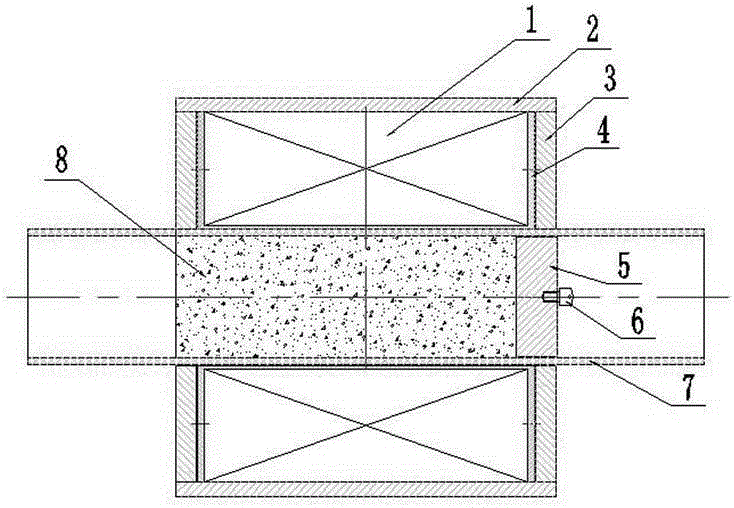

[0028] Embodiments of the present invention are simulation experiments for practical engineering applications, and the specific experimental devices are as figure 1 As shown, among them: No. 1 represents the coil, No. 2 represents the coil steel pipe shell, No. 3 represents the steel end plate, No. 4 represents the coil skeleton (non-metallic), No. 5 represents the steel mandrel, No. 6 represents the copper bolt, and No. 7 represents Plexiglass tube (placed horizontally), serial number 8 represents ferromagnetic aggregate concrete.

[0029] For the above components, No. 7 simulates the component to be poured; No. 1 to 4 simulates the magnetic field erected on the outer periphery of the component, and the coil 1 is wound on the bobbin 4, and the bobbin 4 is wrapped in the shell 2, and the shell 2 is fixed by the steel end plate 3 On the periphery of the component 7 to be poured; serial numbers 5-6 simulate a magnetic induction device, the steel mandrel 5 is installed on one end...

PUM

| Property | Measurement | Unit |

|---|---|---|

| slump | aaaaa | aaaaa |

| slump | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com