Fixed device for curb side ditch formworks in tunnel

A fixing device and technology in the tunnel, applied in the direction of tunnels, tunnel linings, mining devices, etc., can solve the problems such as the inability to achieve the purpose of pouring the curb ditch and pavement, hidden quality problems, and small thickness of the curb gutter.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

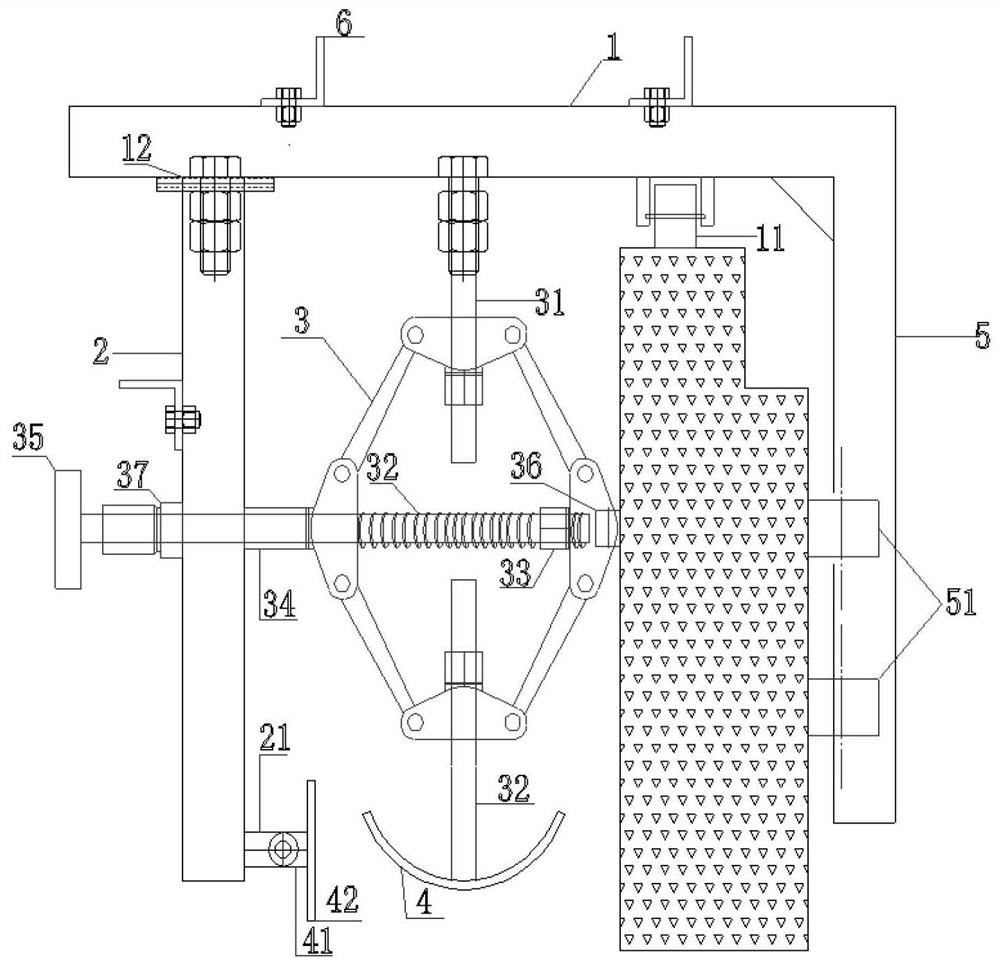

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0022] In order to solve the problem of integral pouring of the curb ditch and the tunnel pavement slab in the tunnel, the present invention can provide a formwork setting method during the construction process to ensure that the curb gutter formwork and the pavement slab formwork do not interfere with each other, thereby realizing the integrated The purpose of pouring, on the other hand, the positioning and removal of the formwork can be quickly realized through the power provided by the mechanical jack, and the repositioning and reconstruction can be quickly carried out through the walking system.

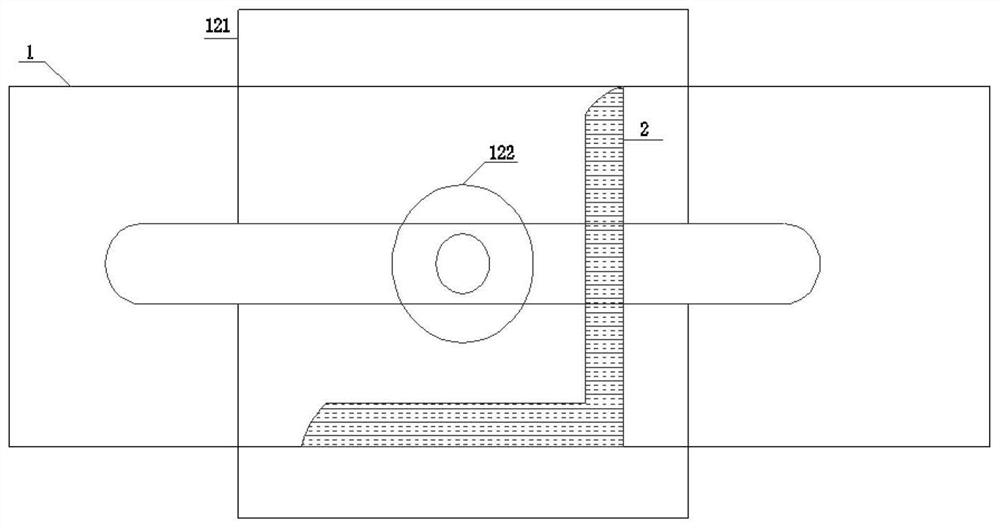

[0023] Such as figure 1 , figure 2 As shown, the present invention provides a fixing device for a curb gutter formwork in a tunnel, which includes two fixing device bodies, and the two fixing device bodies are respectively placed at both ends o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com