Rectangular jacking pipe joint concrete pouring method utilizing bin dividing steel plates

A rectangular pipe jacking and concrete technology, which is used in earth-moving drilling, wellbore lining, tunnel lining, etc., can solve the problems of incompact concrete, increase the difficulty of construction, and narrow working space, so as to improve construction efficiency and quality, and reduce costs. The effect of secondary operation strength and improvement of anti-deformation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific implementation methods.

[0037] A method for concrete pouring of rectangular pipe jacking joints utilizing sub-silo steel plates of the present invention comprises the following steps:

[0038] Step 1: Preparation before concrete pouring:

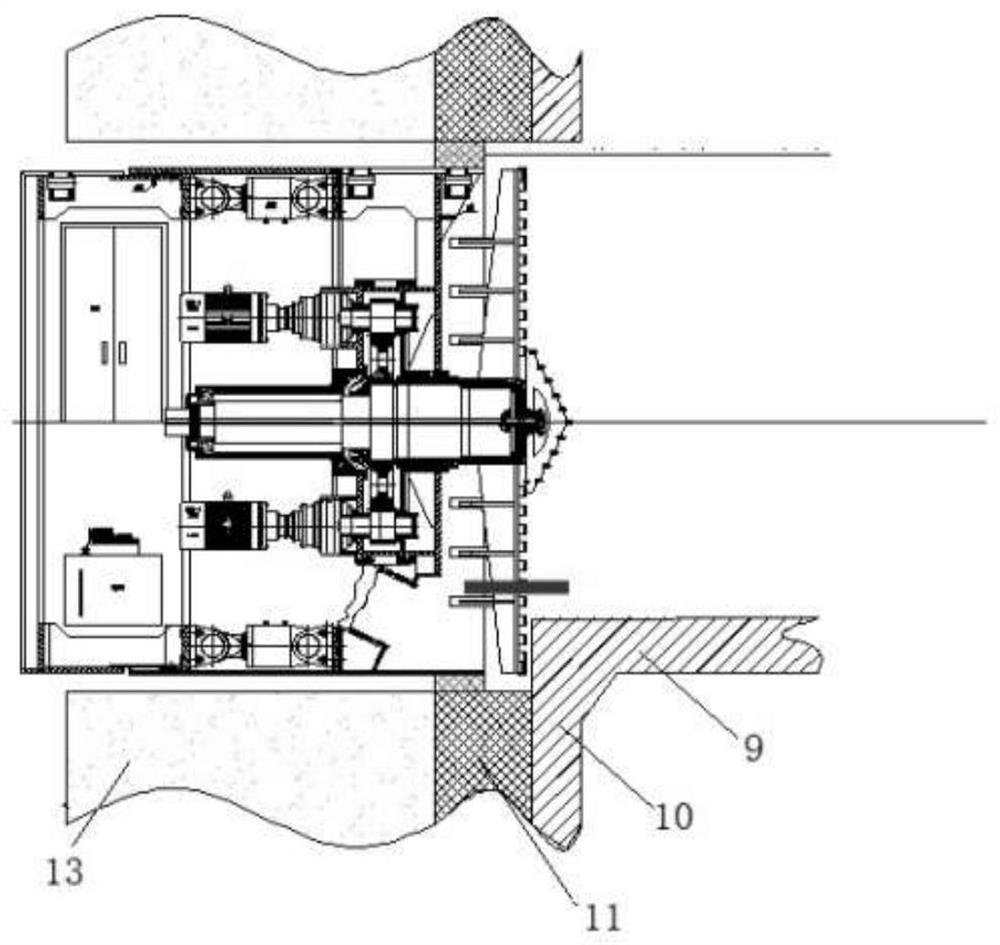

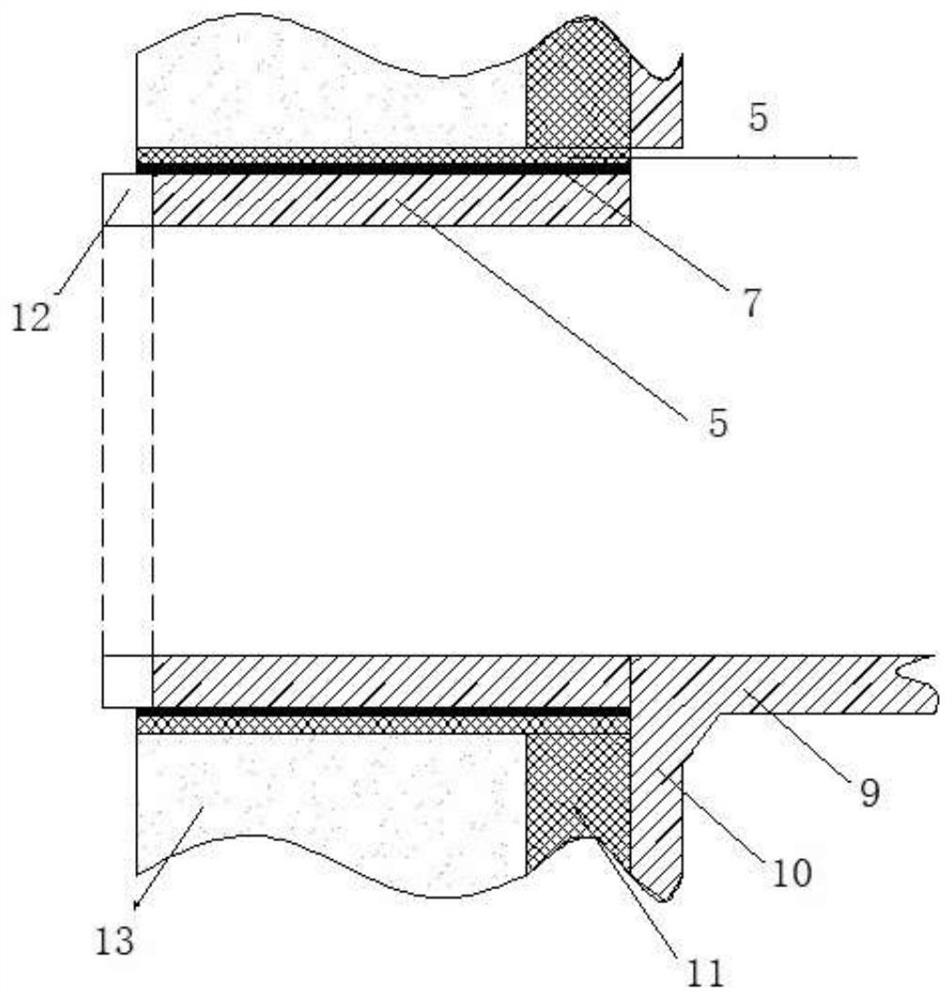

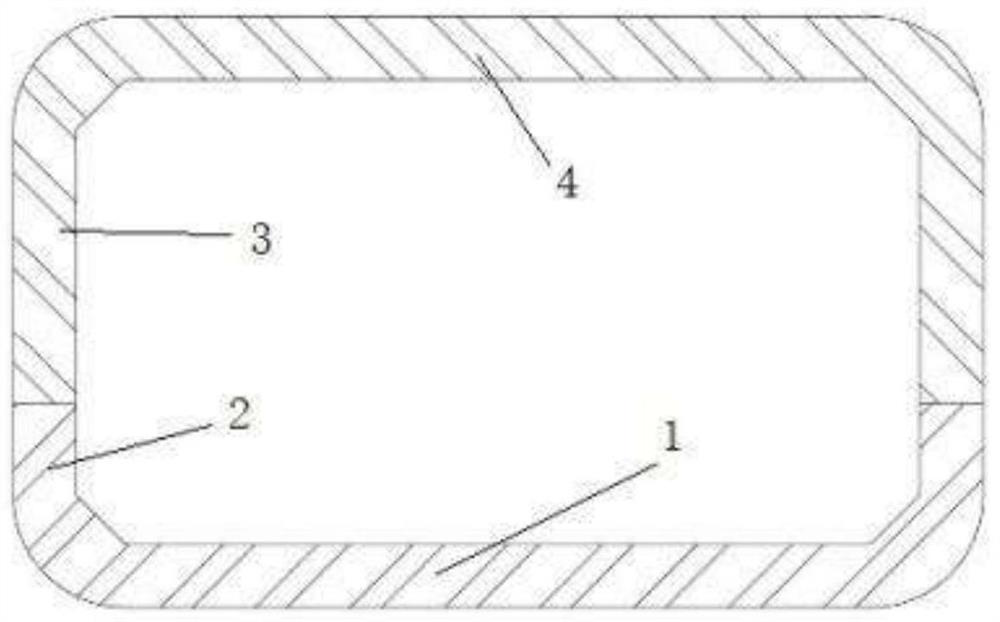

[0039] After all the equipment in the pipe jacking shell 7 has been dismantled and hoisted, hoist the steel formwork to the bottom of the receiving shaft, and then transfer it manually to the cast-in-place section, such as figure 1 , figure 2 shown. The cast-in-place section is divided into two parts for pouring, the first part is the base plate 1 and the low side wall 2, the second part is the side wall 3 and the roof 4, see details image 3 .

[0040] Step 2: Formwork erection of base plate 1 and low side wall 2 and concrete pouring:

[0041] Bind the steel bars at the bottom plate 1 and the low side wal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com