Pressure pouring combining concreting construction method used for structural cross section enlargement

A technology for pouring concrete and increasing cross-section, applied in construction, building maintenance, building construction, etc., can solve problems affecting construction quality, slurry leakage, etc., and achieve high construction efficiency, good application prospects, and high efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with specific drawings and examples, so as to facilitate a clear understanding of the present invention, but they do not limit the present invention.

[0031] In order to make the content of the present invention easier to understand, the present invention will be described in further detail below according to specific embodiments:

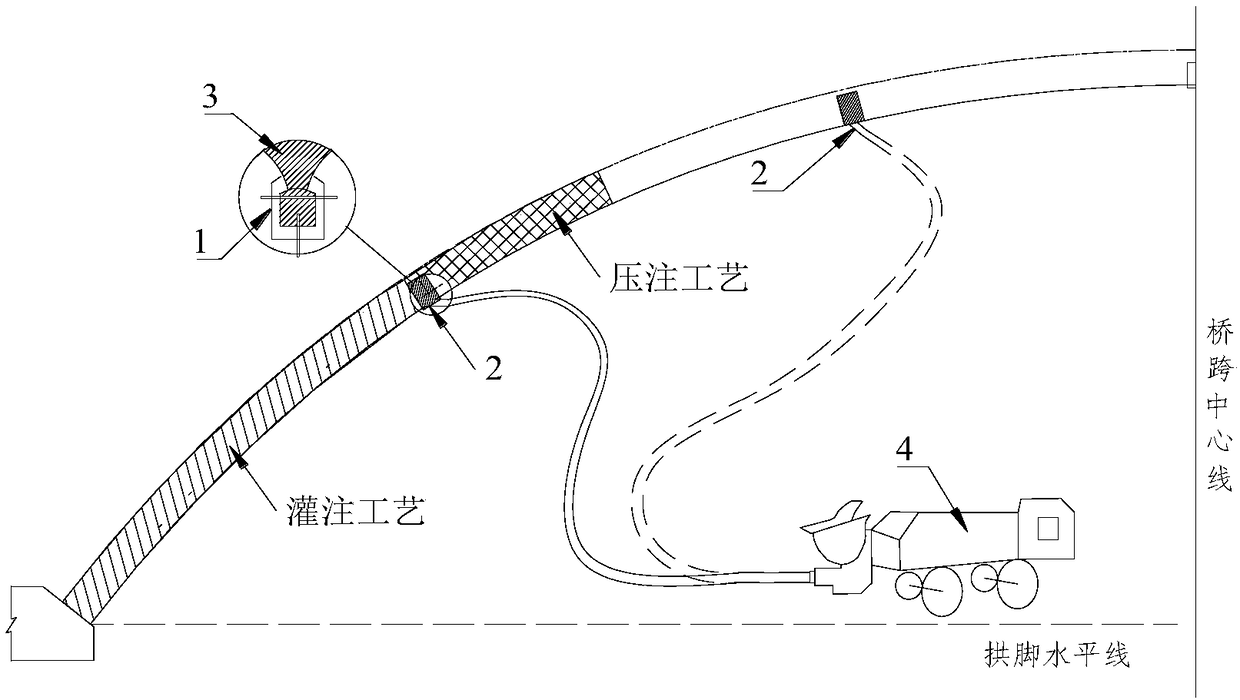

[0032] Such as figure 1 As shown, the specific implementation includes the following steps: installing no residue hanging formwork 1 on the old structure 3 → installing a concrete valve 2 → arranging a concrete pumping system 4 → pouring concrete in stages.

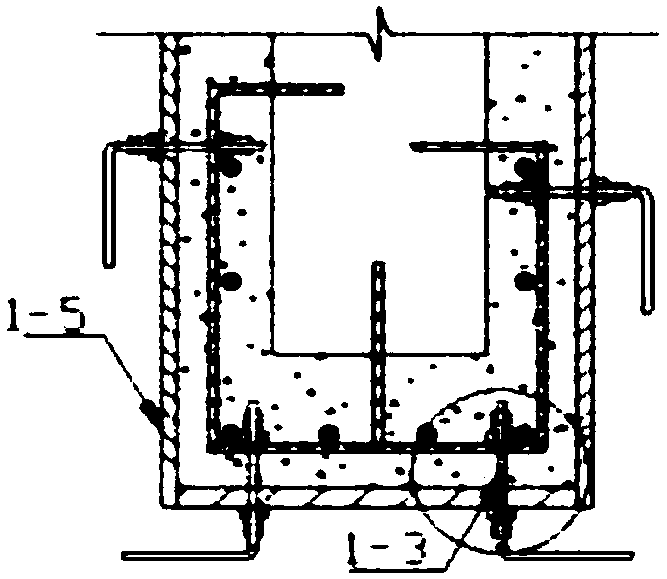

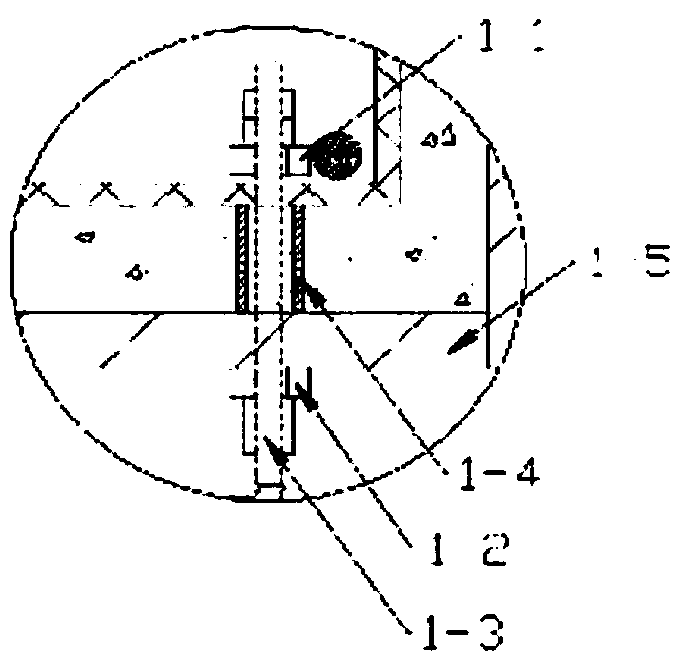

[0033] Such as figure 2 As shown, the no-residue hanging form 1 proposed by the present invention is composed of an inner bolt group 1-1, an outer bolt group 1-2, a screw rod 1-3, a sleeve 1-4 and a template 1-5. The inner bolt group 1-1 is embedded inside the concrete to be poured, the outer bolt group 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com