Whole-span prefabricated H-steel-concrete composite beam bridge and construction method

A prefabricated installation, H-beam technology, used in the erection/assembly of bridges, bridges, bridge parts, etc., can solve the problems of increasing dead load, difficult quality control, hidden safety hazards, etc., to reduce the processing workload, save materials and Process, the effect of enhancing the durability of the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

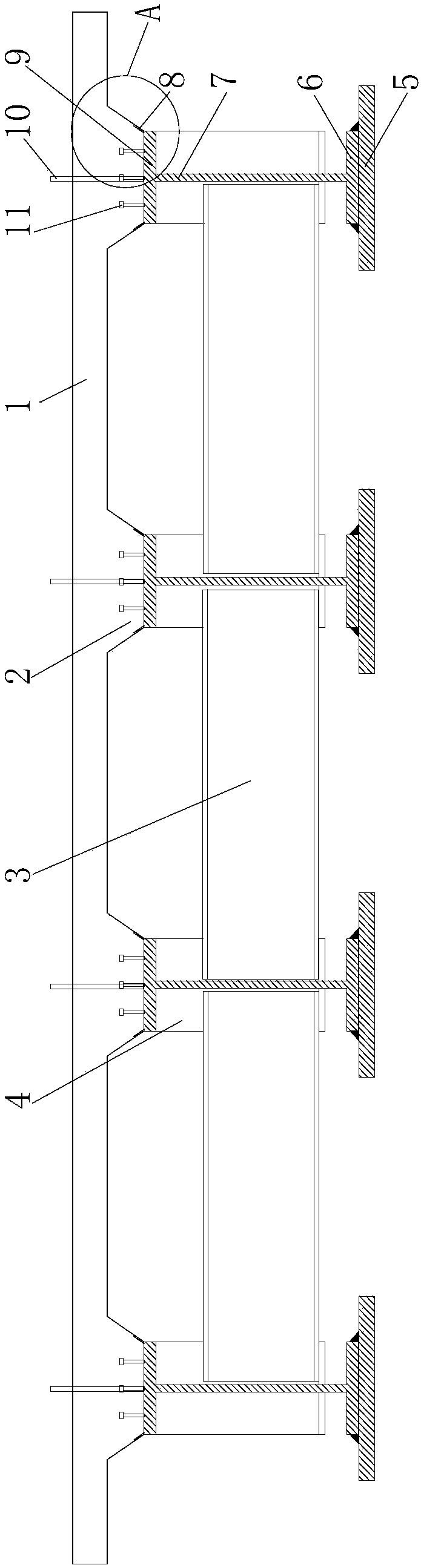

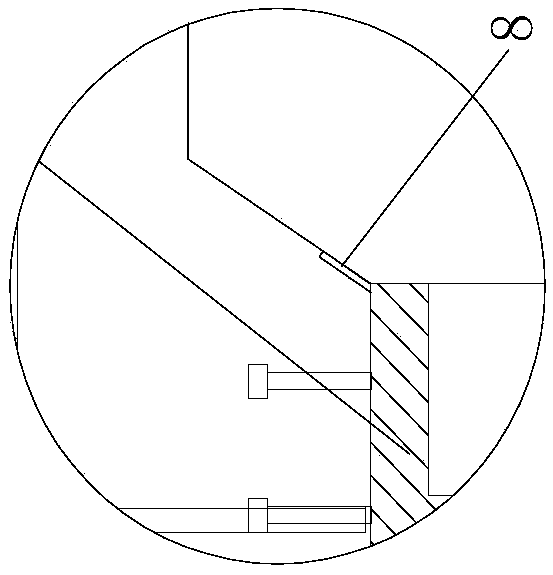

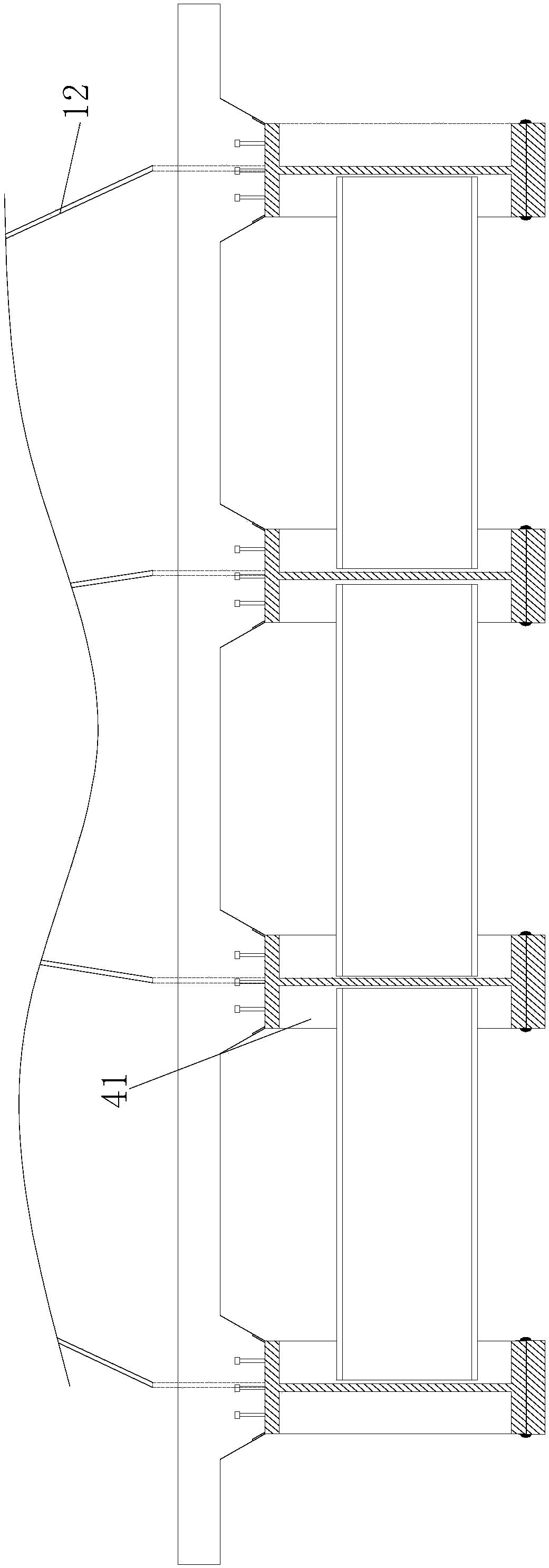

[0027] figure 1 It is a schematic diagram of the cross-sectional structure of the mid-span section of the present invention, figure 2 for figure 1 Enlarged view at A, image 3 It is a schematic diagram of the cross-sectional structure of the pier top support section of the present invention, Figure 4 for figure 1 The schematic diagram of the longitudinal structure, as shown in the figure: the whole-span prefabricated H-shaped steel-concrete composite girder bridge of the present embodiment includes an H-shaped steel combination and a concrete bridge slab 1 poured on the H-shaped steel combination, and the H-shaped steel combination It includes H-shaped steels arranged side by side along the bridge width direction, and the H-shaped steels are the entire span length along the length direction. The steel girder adopts H-shaped steel, which is the whole length of the H-shaped steel beam when it leaves the factory, without welding, which can significantly reduce the cost of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com