Preparation method of protection and repair system for surface of concrete base

A concrete base layer and system technology, applied in the field of preparation of protection and repair systems, can solve the problems of hollowing of the protective layer, failure of protection, single thin coating, etc., and achieve the goal of improving adhesion, improving integrity, and being easy to use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

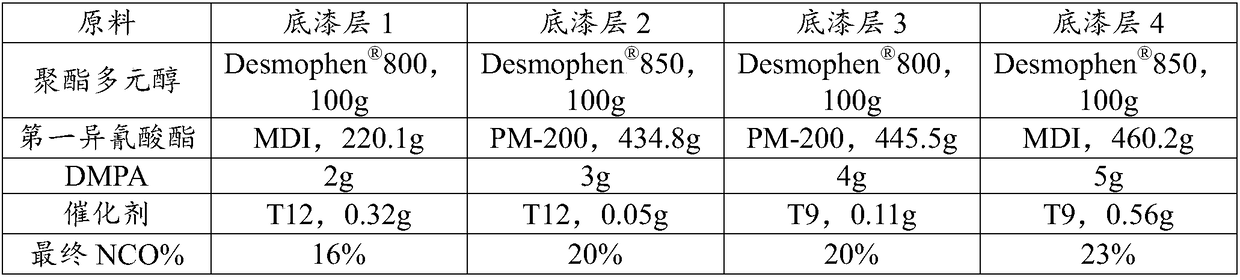

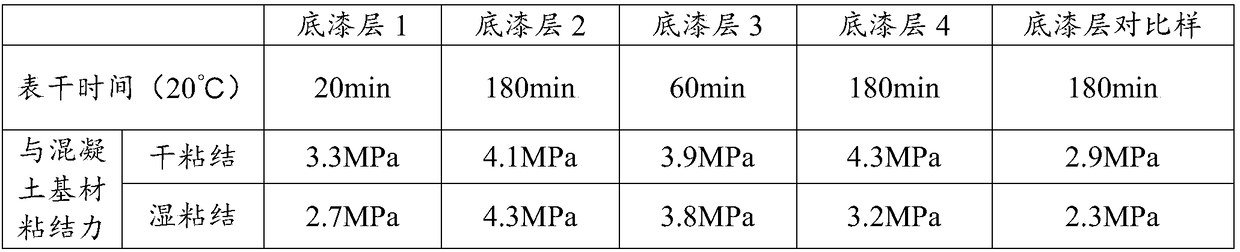

Embodiment Construction

[0047] The raw materials and reagents in the present invention are all industrial grade and commercially available; the present invention is not limited by the content of the following examples.

[0048] Manufacturers and models of some raw materials in the embodiments are as follows:

[0049] 1. Isocyanate

[0050] (1) Diphenylmethane diisocyanate (hereinafter referred to as MDI): produced by Yantai Wanhua, model MDI-50, NCO%=33.5%;

[0051] (2) Polyphenyl polymethylene polyisocyanate (hereinafter referred to as PAPI): produced by Yantai Wanhua, model PM-200, NCO%=30.0%;

[0052] (3) Toluene diisocyanate (hereinafter referred to as TDI): produced by Yantai Wanhua, model TDI-80, NCO%=48.2%;

[0054] Bayer Polymers AG's 800 (hydroxyl content 8.6%), 850 (hydroxyl content 8.5%);

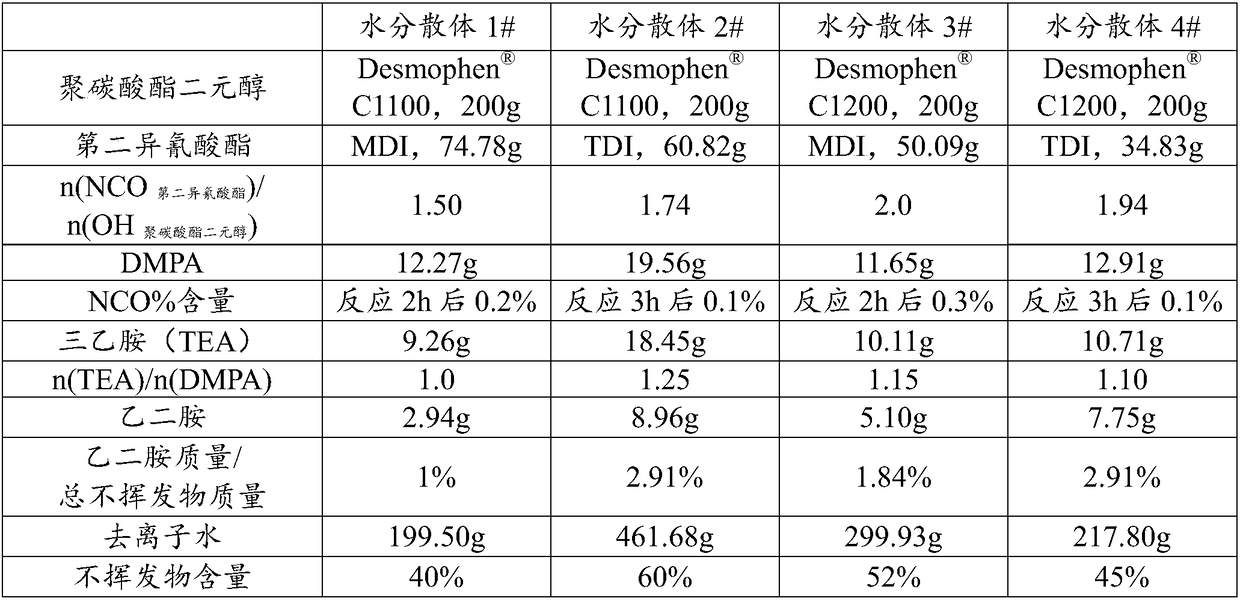

[0055] 3. Polycarbonate diol:

[0056] Bayer Polymers AG's C1100 (hydroxyl content 3.4%), C1200 (hydroxyl content 1.7%);

[0057] 4. Water-dispersed polyisocy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com