Surface pre-coating method for crack self-repairing of cement-based material

A cement-based material and self-repairing technology, applied in the field of interdisciplinary science, can solve problems such as steel bar damage, shorten the service life of concrete structures, economic losses and hidden safety hazards, and achieve the goal of improving structural durability, saving crack detection and manpower repair costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

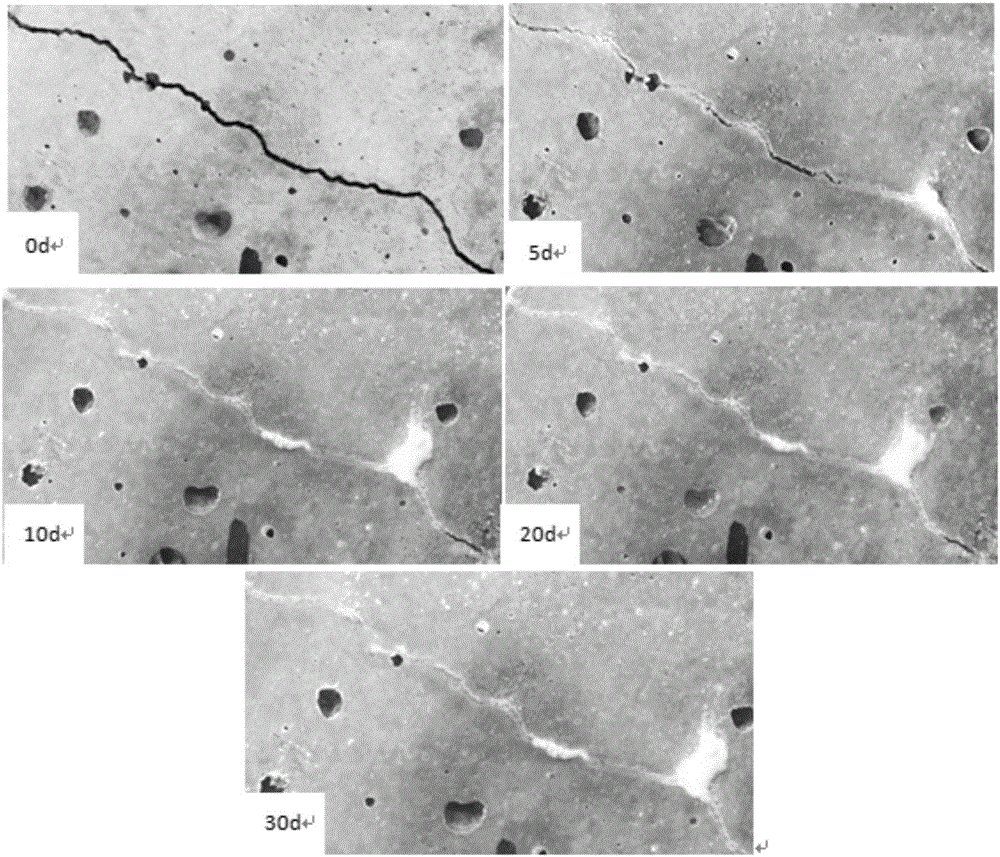

Embodiment 1

[0035] (1) Weigh 10g of sucrose, Na 2 HPO 4 12H 2 O 2g, MgSO 4 0.5g, CaCO 3 1.0g, KCl0.2g, (NH 4 ) 2 SO 4 Dissolve 0.5g and 0.3g of yeast extract in deionized water, prepare the required medium solution, adjust the pH to 7, and sterilize at 125°C for 25 minutes, inoculate Bacillus colioids into the cooled medium solution, Shake culture at 35°C for 12h, the shaking frequency is 170r / min, and the culture time is 24h;

[0036] (2) Centrifuge the cultured bacteria solution at high speed for 10 minutes, the speed of the centrifuge is 8000rpm, and the temperature is controlled at 4°C. After removing the upper layer of medium, add deionized water, and then place it in a freeze dryer at -10°C to dry into bacteria. powder spare;

[0037] (3) Prepare Bacillus colioids powder into 0.5g / mL bacterial liquid, add hydrophilic thickener sodium alginate to the bacterial liquid, and the concentration of the hydrophilic thickener in the bacterial liquid is 0.3g / mL ; At this time, the st...

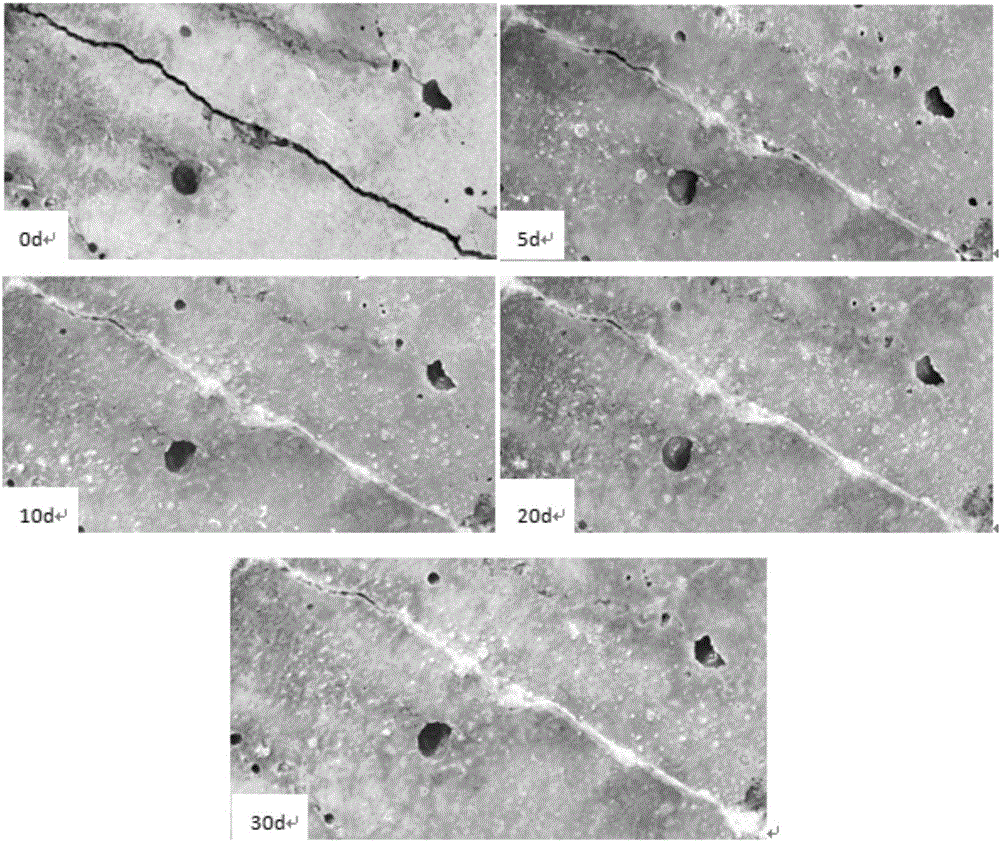

Embodiment 2

[0042] (1) Weigh 12g of sucrose, Na 2 HPO 4 12H 2 O 3g, MgSO 4 0.6g, CaCO 3 0.8g, KCl 0.3g, (NH 4 ) 2 SO 4 Dissolve 0.3g and 0.2g of yeast extract in deionized water, configure the required medium solution, and adjust the pH to 8, sterilize at 125°C for 25min, inoculate Bacillus colioids into the cooled medium solution, Shake culture at 35°C for 12h, the shaking frequency is 170r / min, and the culture time is 24h;

[0043] (2) Centrifuge the cultured bacteria solution at high speed for 10 minutes, the speed of the centrifuge is 8000rpm, and the temperature is controlled at 4°C. After removing the upper layer of medium, add deionized water, and then place it in a freeze dryer at -10°C to dry into bacteria powder spare;

[0044] (3) Prepare Bacillus colioids powder as 1.0g / mL bacterial liquid, add hydrophilic thickener sodium alginate to the bacterial liquid, and the concentration of the hydrophilic thickener in the bacterial liquid is 0.5g / mL , the strain concentration...

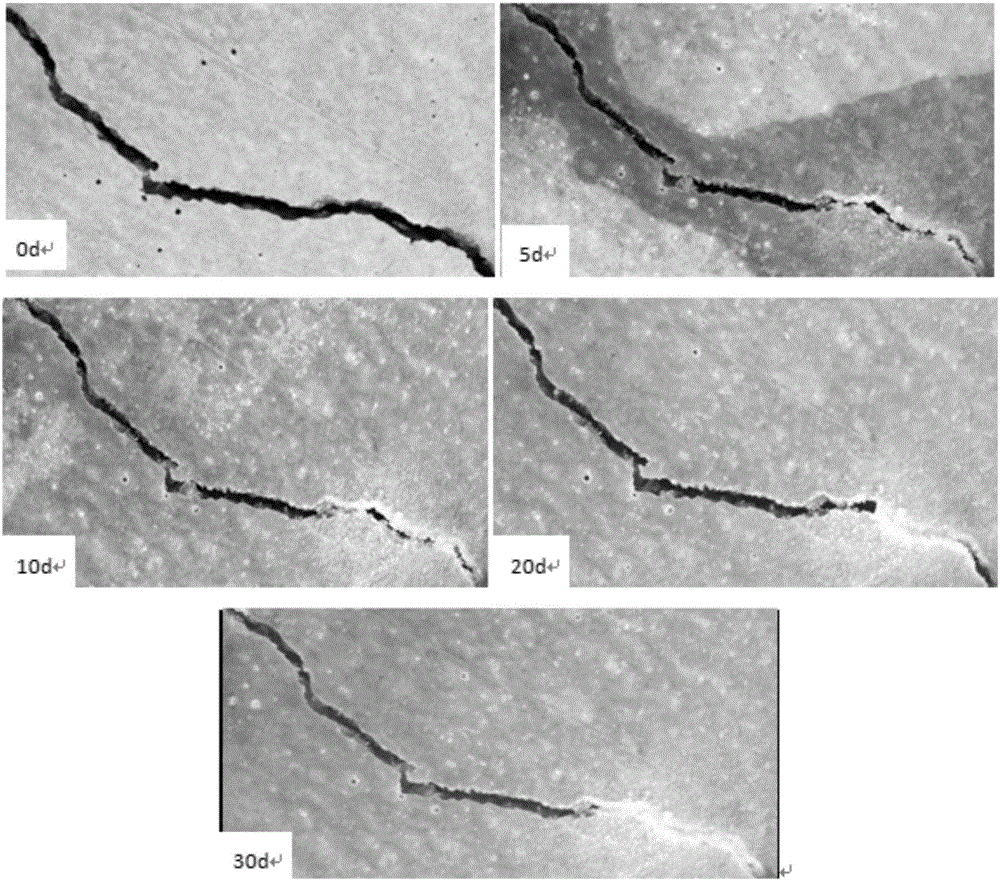

Embodiment 3

[0049] (1) Weigh 11g of sucrose, Na 2 HPO 4 12H 2 O 2g, MgSO 4 0.6g, CaCO 3 1.5g, KCl 0.3g, (NH 4 ) 2 SO 4 Dissolve 0.6g and 0.4g of yeast extract in deionized water, configure the required medium solution, adjust the pH to 7, and sterilize at 125°C for 25 minutes, inoculate Bacillus colloidus into the cooled medium solution, Shake culture at 35°C for 12h, the shaking frequency is 170r / min, and the culture time is 24h;

[0050] (2) Centrifuge the cultured bacteria solution at high speed for 10 minutes, the speed of the centrifuge is 8000rpm, and the temperature is controlled at 4°C. After removing the upper layer of medium, add deionized water, and then place it in a freeze dryer at -10°C to dry into bacteria. powder spare;

[0051] (3) Prepare Bacillus colioids powder into 0.8g / mL bacterial liquid, add hydrophilic thickener sodium alginate to the bacterial liquid, and the concentration of the hydrophilic thickener in the bacterial liquid is 0.8g / mL , the strain co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com