Steel wire mesh fiber cloth reinforced pier column structure externally covered with concrete with ultra-high-performance

An ultra-high performance, steel mesh technology, applied in bridge reinforcement, building maintenance, bridge maintenance and other directions, to achieve the effect of convenient and fast construction, stable and obvious reinforcement effect, and less interference from environmental factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

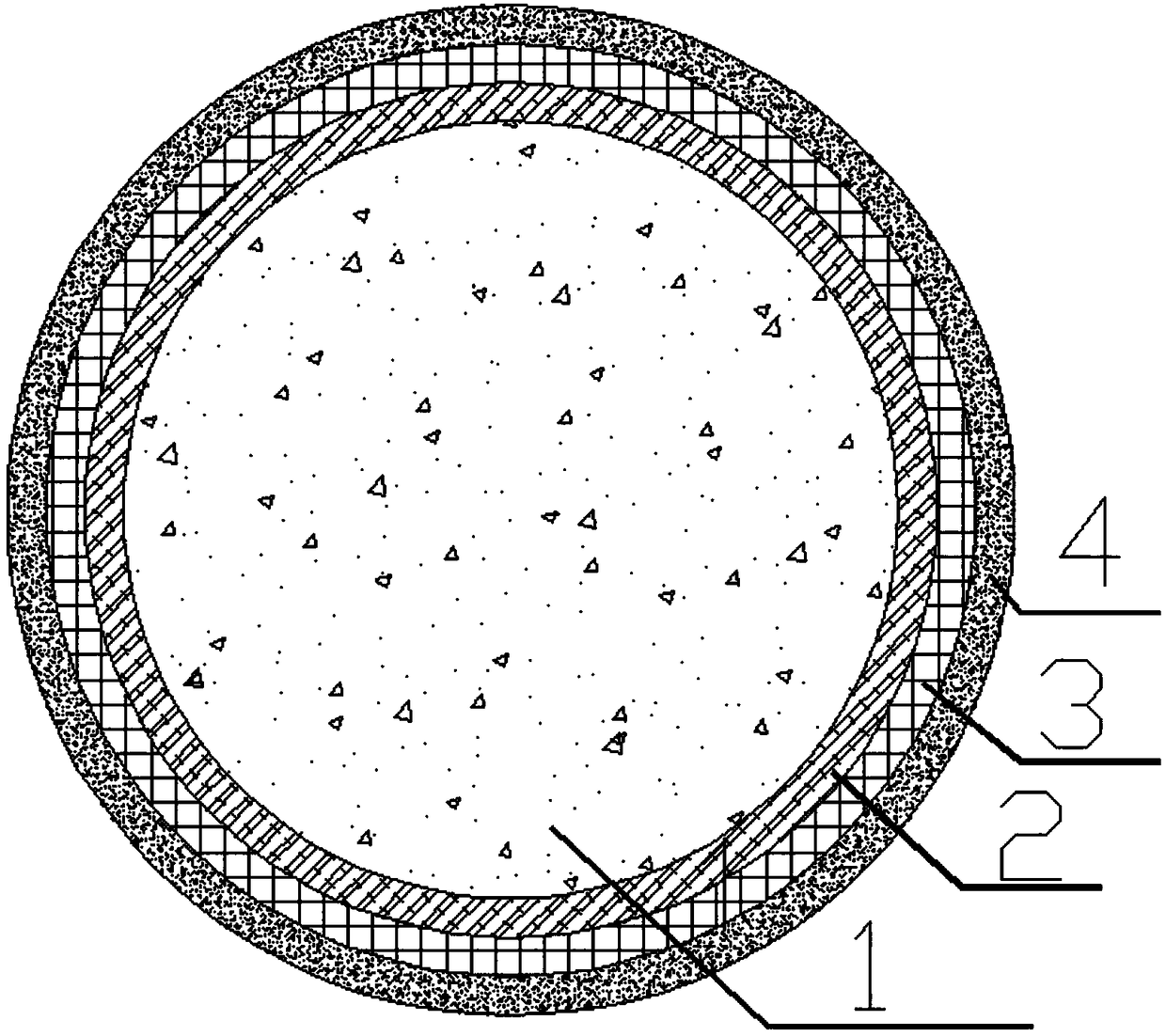

[0032] Example: such as figure 1 As shown, the steel mesh fiber cloth reinforced pier structure covered with ultra-high performance concrete in this embodiment includes a reinforced pier column body 1 and an FRP cloth 2 arranged on the outer surface of the above-mentioned reinforced pier column body 1 sequentially from the inside to the outside , steel wire mesh 3 and ultra-high performance concrete layer 4.

[0033] Compared with prior art, the beneficial effect of the present invention is:

[0034] 1) Using ultra-high performance concrete (UHPC), steel wire mesh and FRP cloth can reduce the cross-sectional size of the entire reinforced pier structure;

[0035] 2) UHPC has good construction performance and volume stability, and UHPC has a short curing time, which is convenient for rapid reinforcement and shortens the construction period;

[0036] 3) The mixed use of steel wire mesh and FRP improves the ductility of FRP, and finally makes the structure have obvious yield loa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com