Partially prefabricated post-lamination hollow floor

A prefabricated, hollow floor technology, applied in the direction of floor slabs, buildings, building components, etc., to achieve the effect of reducing engineering costs, high hollow ratio, and increasing construction difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the examples, but it should not be understood that the scope of the subject of the present invention is limited to the following examples. Without departing from the above-mentioned technical ideas of the present invention, various replacements and changes made according to common technical knowledge and conventional means in this field shall be included in the protection scope of the present invention.

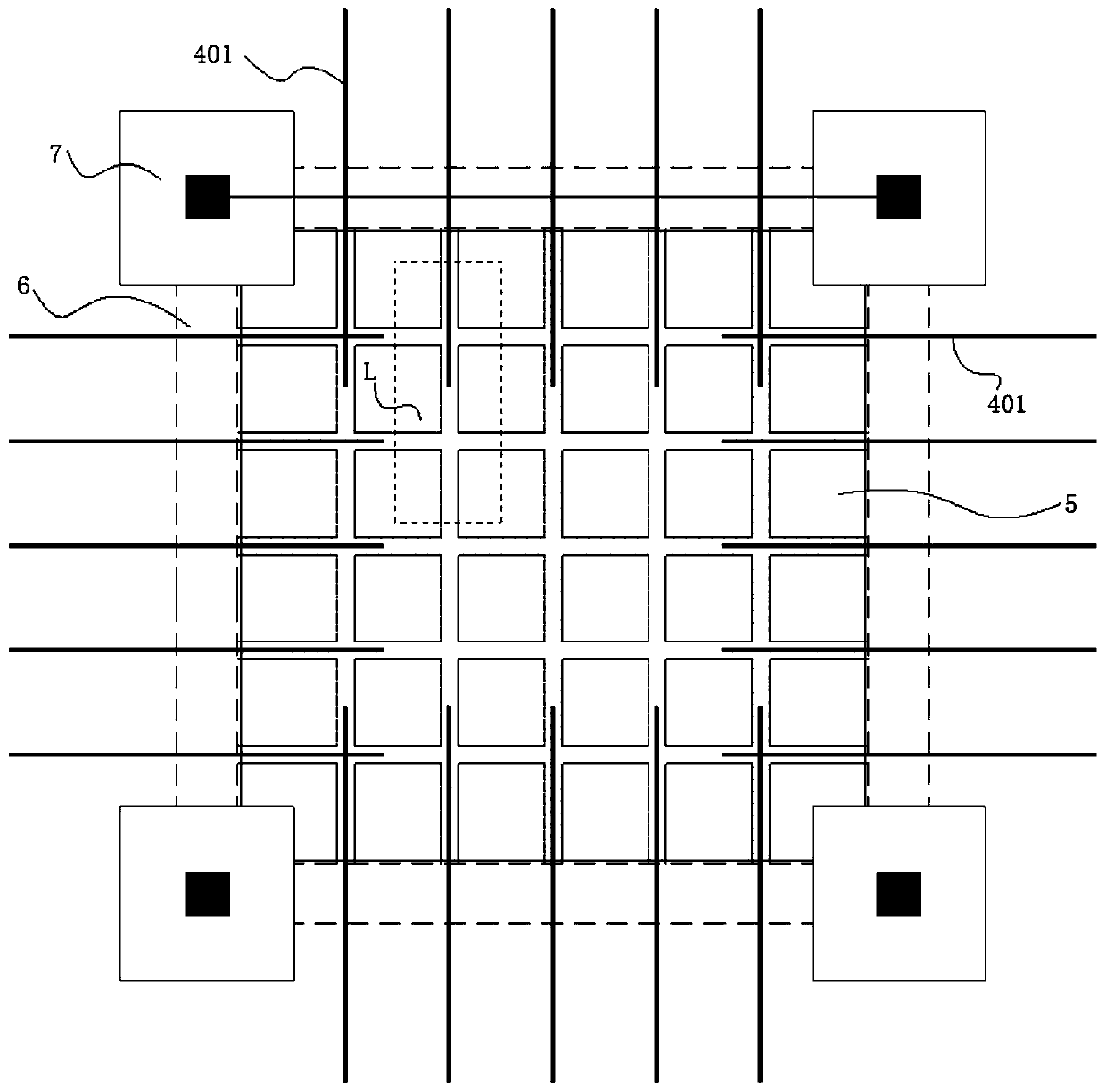

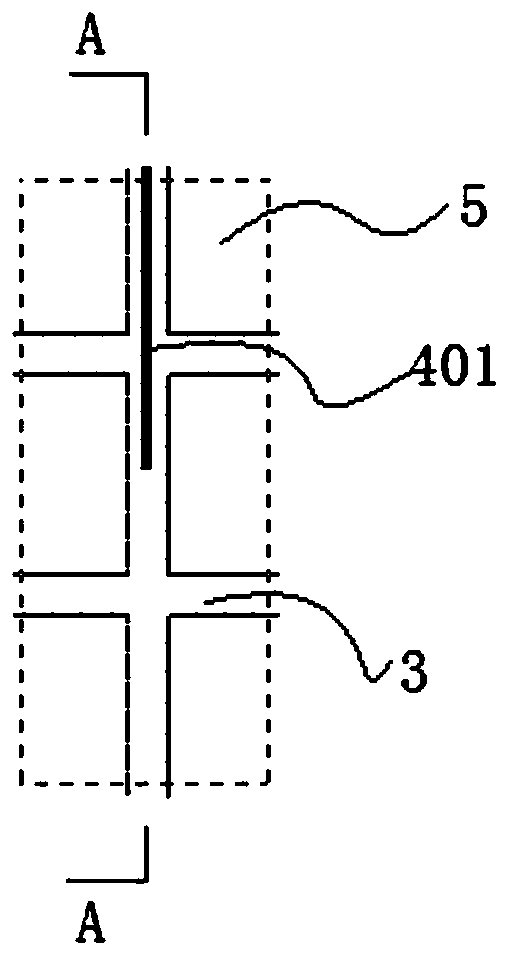

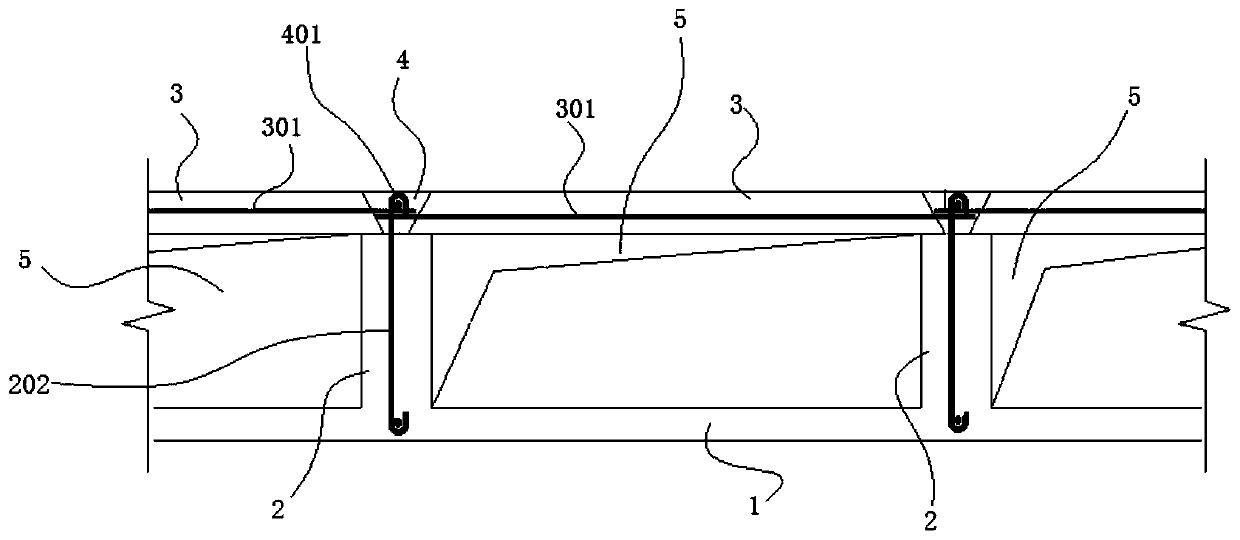

[0030] A partially prefabricated assembled post-lamination hollow floor, characterized in that it includes a cast-in-place floor floor 1, a cast-in-place rib beam slab grid 2 and a prefabricated flat plate 3. The cast-in-place floor slab 1 and the cast-in-place rib beam slab grid 2 are formed by one-time casting. The construction process is as follows: first support the bottom formwork and beam rib side formwork, tie the bottom plate and rib beam reinforcement, and then pour the bottom plate 1 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com