A kind of preparation method of energy-saving ceramsite light-weight wallboard

A light-weight wallboard and ceramsite technology, which is applied in the field of wallboard production, can solve problems such as general thermal insulation performance of light-weight thermal insulation interior wallboards, heat generation of cement, and poor compression resistance of wallboards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

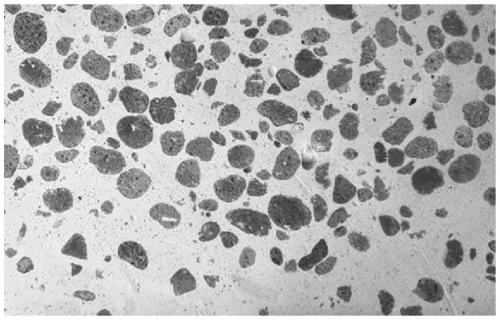

Image

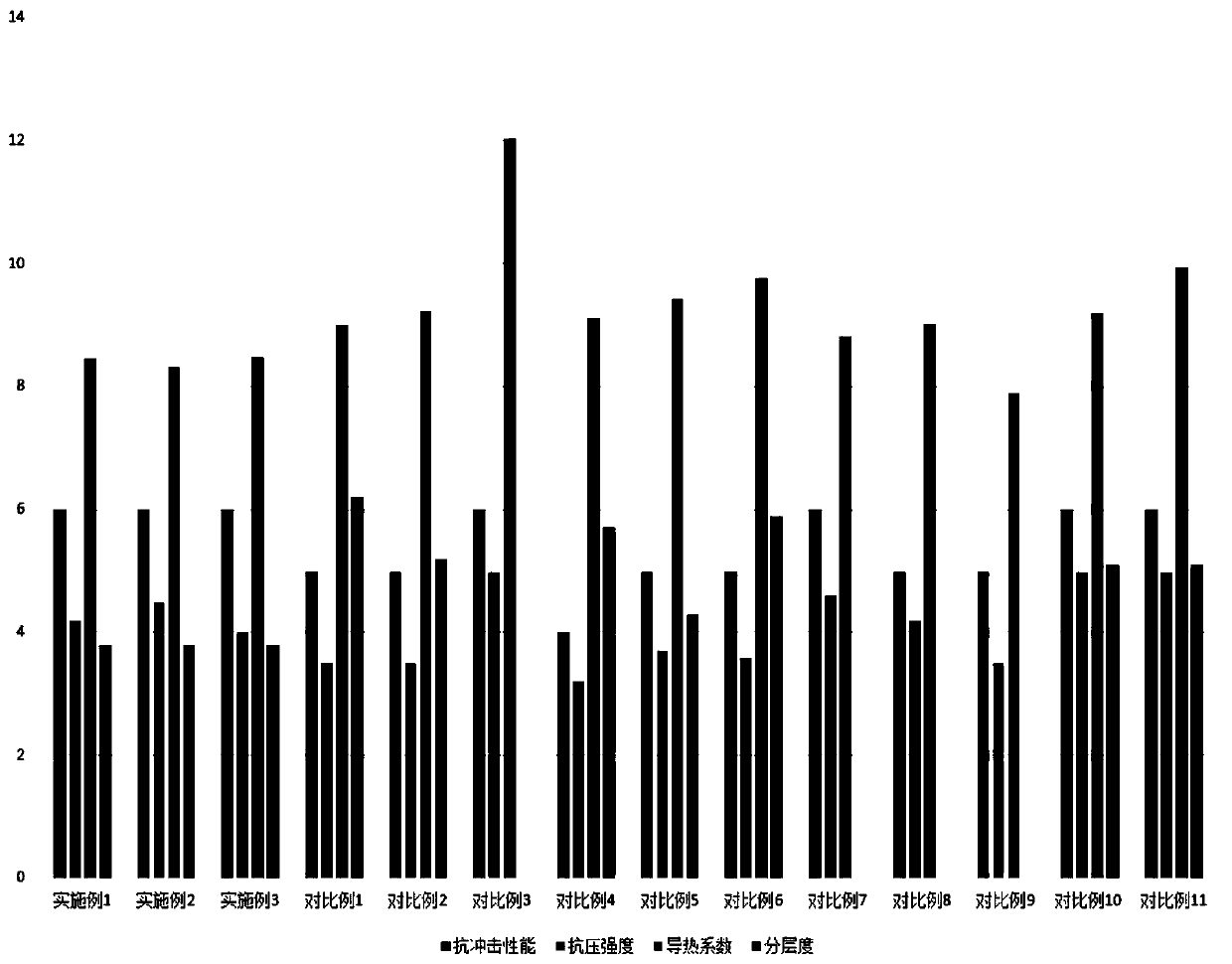

Examples

Embodiment 1

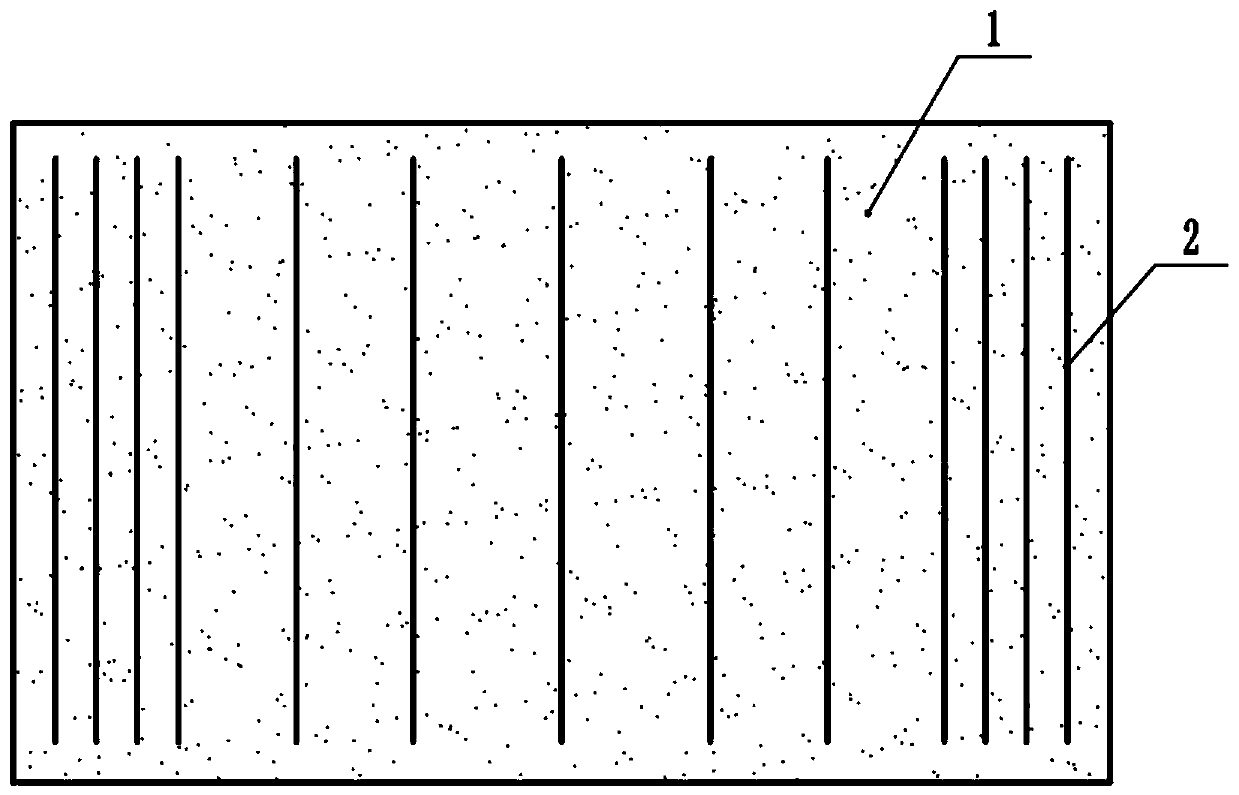

[0040] A preparation method of energy-saving ceramsite lightweight wallboard includes the following steps:

[0041] S1. Select a rectangular thermal insulation wall core including short sides and long sides. In this embodiment, an extruded board with a thickness of 30mm is selected as the thermal insulation wall core; a number of V-shaped through holes are opened on the thermal insulation wall core. The hole includes two open ends and a connecting end; the two open ends are respectively located on both sides of the thermal insulation wall core, and the connecting ends are located inside the thermal insulation wall core; the open end faces upward, and the connection end is located below the open end; at the connection end Place sodium bicarbonate; open several small grooves on the surface of the insulation wall core

[0042] S2. Select a rectangular mold including short sides and long sides, so that the left long side and the upper short side are recessed inward to form a rectangula...

Embodiment 2

[0055] Compared with Embodiment 1, the difference is that the included angle in step S1 is 22°.

Embodiment 3

[0057] Compared with Embodiment 1, the difference is that the included angle in step S1 is 30°.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com