Inner-casting reinforced precast concrete wall panel, concrete wall, structure system and construction method

A technology of prefabricated wall panels and concrete walls, applied in the direction of manufacturing tools, walls, building components, etc., can solve the problems of difficult construction quality control, long construction period, low tensile strength, etc., to improve the level of shear resistance, reduce Shrinkage and creep, reducing the effect of secondary pouring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

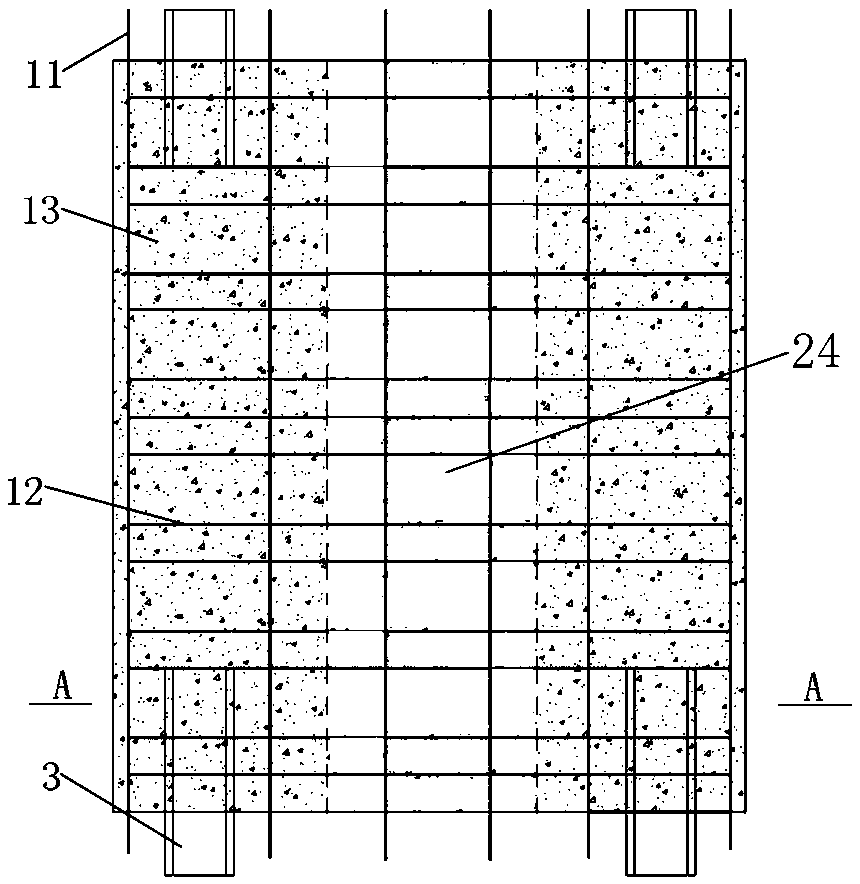

[0081] Embodiment one sees figure 1 with Figure 4 As shown, a self-supporting prefabricated concrete wall panel includes a panel body 10, and the shape of the panel body can be I-shaped, L-shaped or T-shaped. In this embodiment, it is a font.

[0082] The slab body includes a prefabricated part 1, the prefabricated part includes a prefabricated vertical reinforcement 11, a prefabricated horizontal reinforcement 12 and a prefabricated concrete 13, the vertical connection end of the prefabricated part has a vertical connector, the vertical The vertical connectors include the vertical steel bars 11 of the prefabricated part protruding from the edge face of the prefabricated part and more than two vertical shear connectors 3 . In this embodiment, four vertical shear connectors are arranged symmetrically on the left and right, and symmetrically on the top and bottom.

[0083] The vertical steel bars 11 of the prefabricated part protrude from one side of the edge end face of the...

Embodiment 2

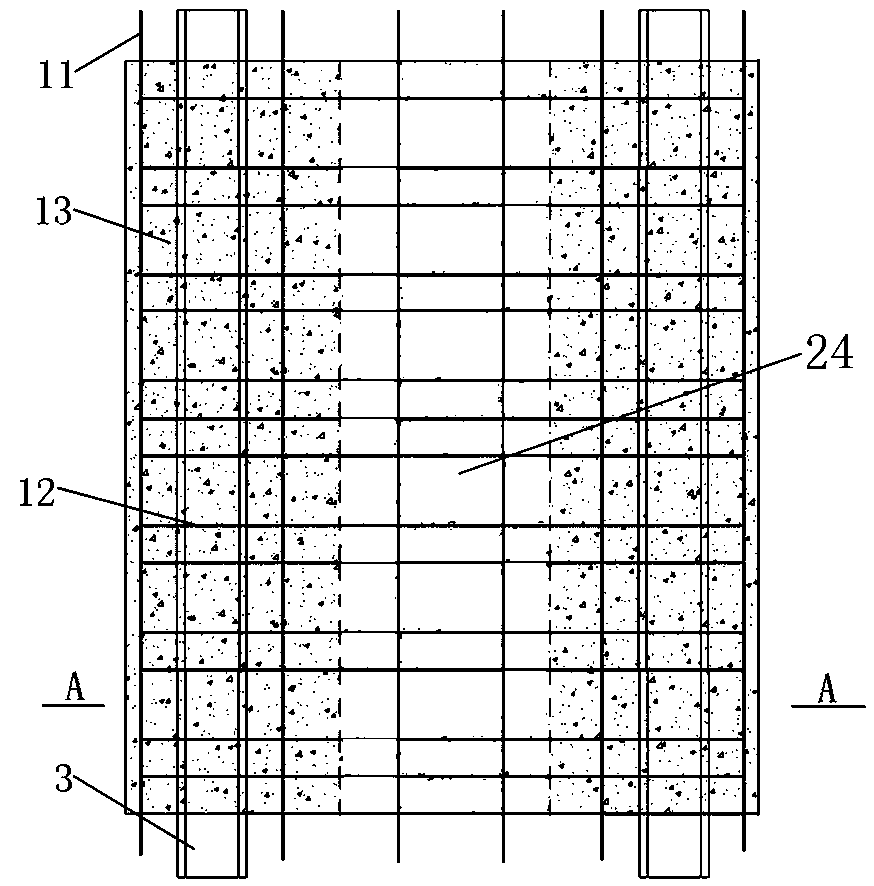

[0090] Embodiment two see figure 2 with Figure 4 As shown, the difference from the first embodiment is that the vertical shear connector 3 is a steel piece arranged along the vertical length of the prefabricated part 1 .

Embodiment 3

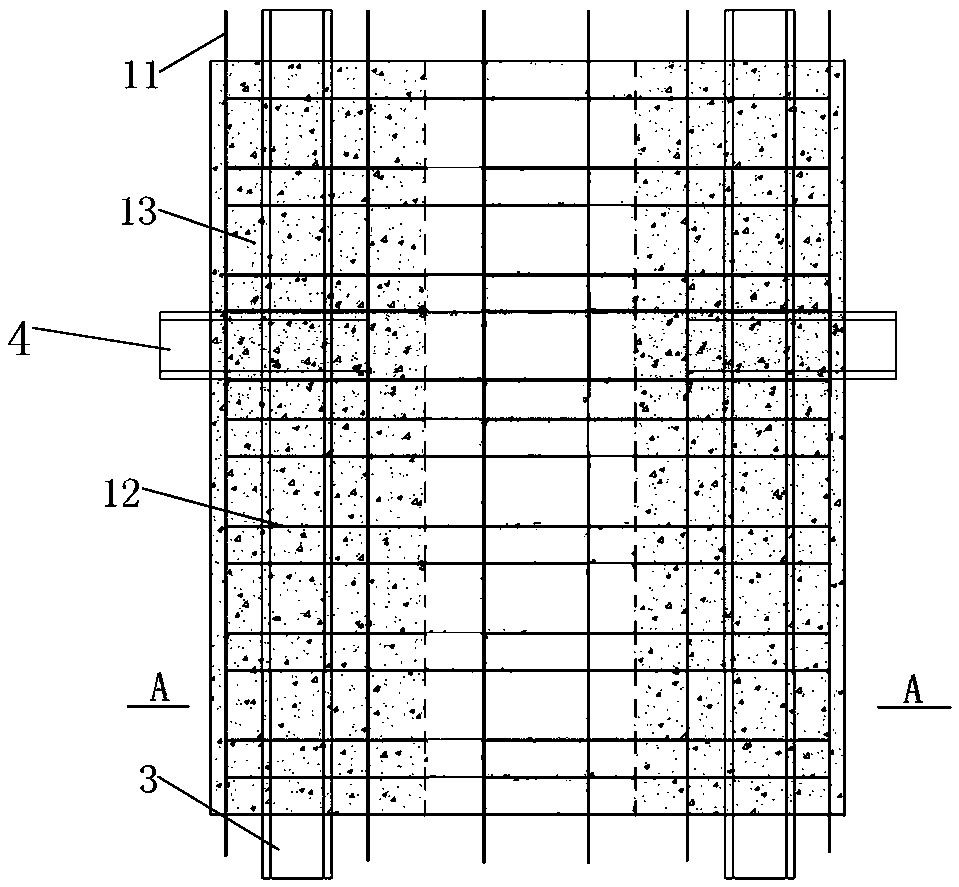

[0091] Embodiment three see image 3 with Figure 4 As shown, the difference from the second embodiment is that the horizontal sides of the prefabricated part 1 have horizontal connectors, and the horizontal connectors include two symmetrical horizontal shear connectors 4 protruding from the edge end faces of the prefabricated part. The horizontal shear connector 4 is partially pre-buried in the prefabricated part, and the pre-embedded part is wrapped by the vertical reinforcement 11 of the prefabricated part and the horizontal reinforcement 12 of the prefabricated part. The horizontal shear connector 4 is an additional horizontal steel bar, steel plate, section steel or welded steel member.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com