Splicing variable-diameter rigid pile casing compaction pile and construction method thereof

A technology of compacted piles and casings, which is applied in the field of geotechnical engineering, can solve problems such as insufficient bearing capacity of pile bodies, necking or collapse of compacted piles, threats to people's lives and property safety, etc., to improve the level of shear resistance, The effect of improving the bearing capacity of the foundation and improving the integrity of the pile body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

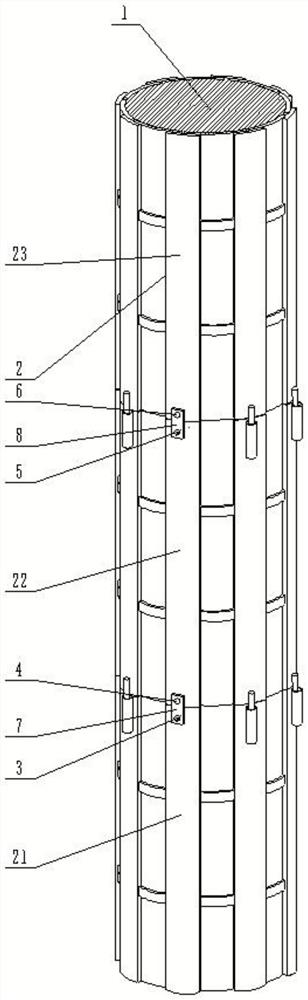

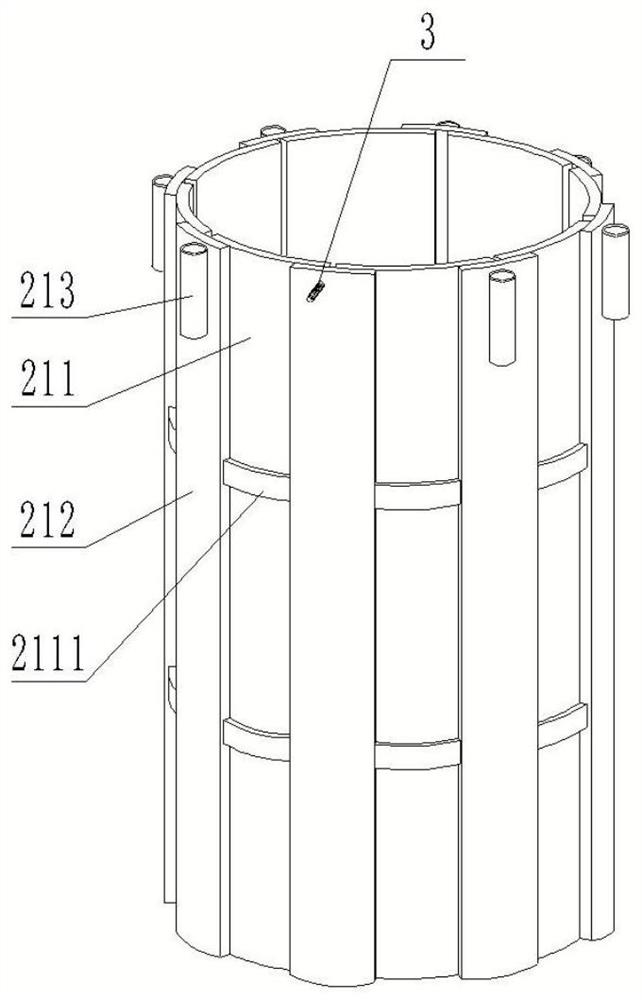

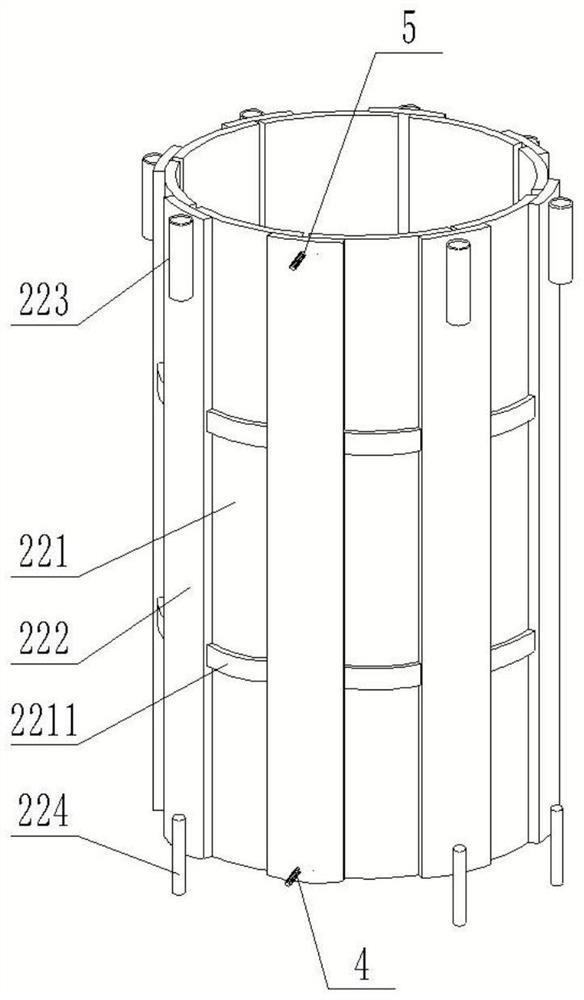

[0033] like Figure 1-Figure 7 As shown in the figure, a splicable variable-diameter rigid casing compaction pile includes a pile body 1 and a casing 2 sleeved outside the pile body 1. The casing 2 includes a bottom cylinder 21, a middle cylinder 22 and a The top cylinder 23, the outer wall of the bottom cylinder 21 in the axial direction close to the middle cylinder 22 is uniformly distributed with the bottom cylinder fixing bolts 3 in the annular direction, and the outer wall of the middle cylinder 22 in the axial direction close to the bottom cylinder 21. The first fixing bolt 4 of the cylinder, the outer wall of one end of the middle cylinder 22 which is close to the top cylinder 23 in the axial direction, and the second fixing bolts 5 of the middle cylinder corresponding to the fixing bolts of the bottom cylinder 3 are evenly distributed in the annular direction, and the outer wall of one end of the top cylinder 23 is close to the axial direction of the middle cylinder 22 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com