Construction method for coordinated settlement of ring beam, structural column and rammed earth wall

A construction method and technology for rammed earth walls, which are applied to building structures, walls, building components, etc., can solve problems such as cracking, weakening of overall performance, and inability to settle freely, so as to improve overall performance, improve earthquake resistance, and improve horizontal resistance. The effect of shear performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

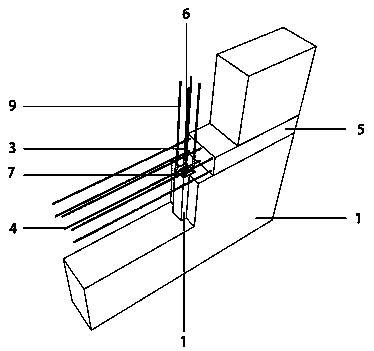

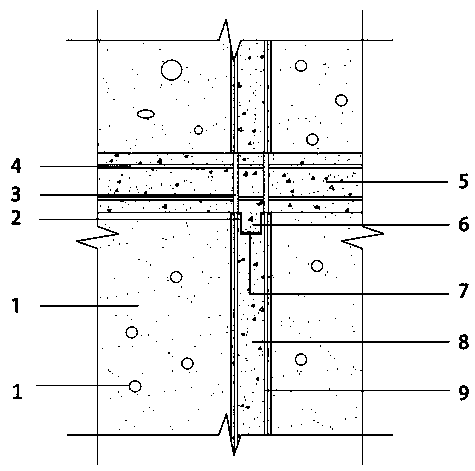

[0024] Embodiment 1: as Figure 1-3 As shown: the present invention adopts the addition of a specially designed reinforced concrete ring beam 5 and reinforced concrete structural column 8 in the original rammed earth wall 1 to realize the coordinated settlement of the three to avoid cracking of the rammed earth wall and improve its seismic performance. The specific construction Proceed as follows:

[0025] Step1 In the raw material of the rammed earth wall 1, according to 5%~30% of the volume ratio of the rammed earth wall 1, add the volume compressible resilient aggregate 10, and carry out the tamping of the lower rammed earth wall 1;

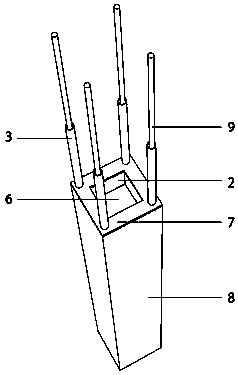

[0026] Step2 Reinforced concrete structural columns 8 are set in the rammed earth wall 1 of the lower floor and extend to the upper rammed earth wall 1. The vertical steel bars 9 of the reinforced concrete structural columns 8 are sleeved with sleeves 3, and the two ends of the sleeves 3 are respectively connected with the steel bars. The upp...

Embodiment 2

[0034] Embodiment 2: In this embodiment, the inner diameter of the casing 3 is 10-20 mm larger than the outer diameter of the vertical steel bar 9 of the reinforced concrete construction column 8 . The casing 3 can be made of PVC, metal, raw bamboo or other suitable materials. The thickness of foam cushion layer 7 is 10-20mm.

[0035] Such as Figure 4 As shown, it is a scene diagram of the application of the present invention in the main construction project of "Yunnan Rural Revitalization Research and Development Center", in which the casing 3 is the PVC pipe used. Cracking at the junction of structural columns.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com