Concrete self-insulation mould-locking block

A self-insulation and concrete technology, applied in building materials and other directions, can solve the problems of water leakage of blocks, pollute the environment, occupy arable land, etc., and achieve the effect of less energy consumption, obvious effect, and conducive to crack resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

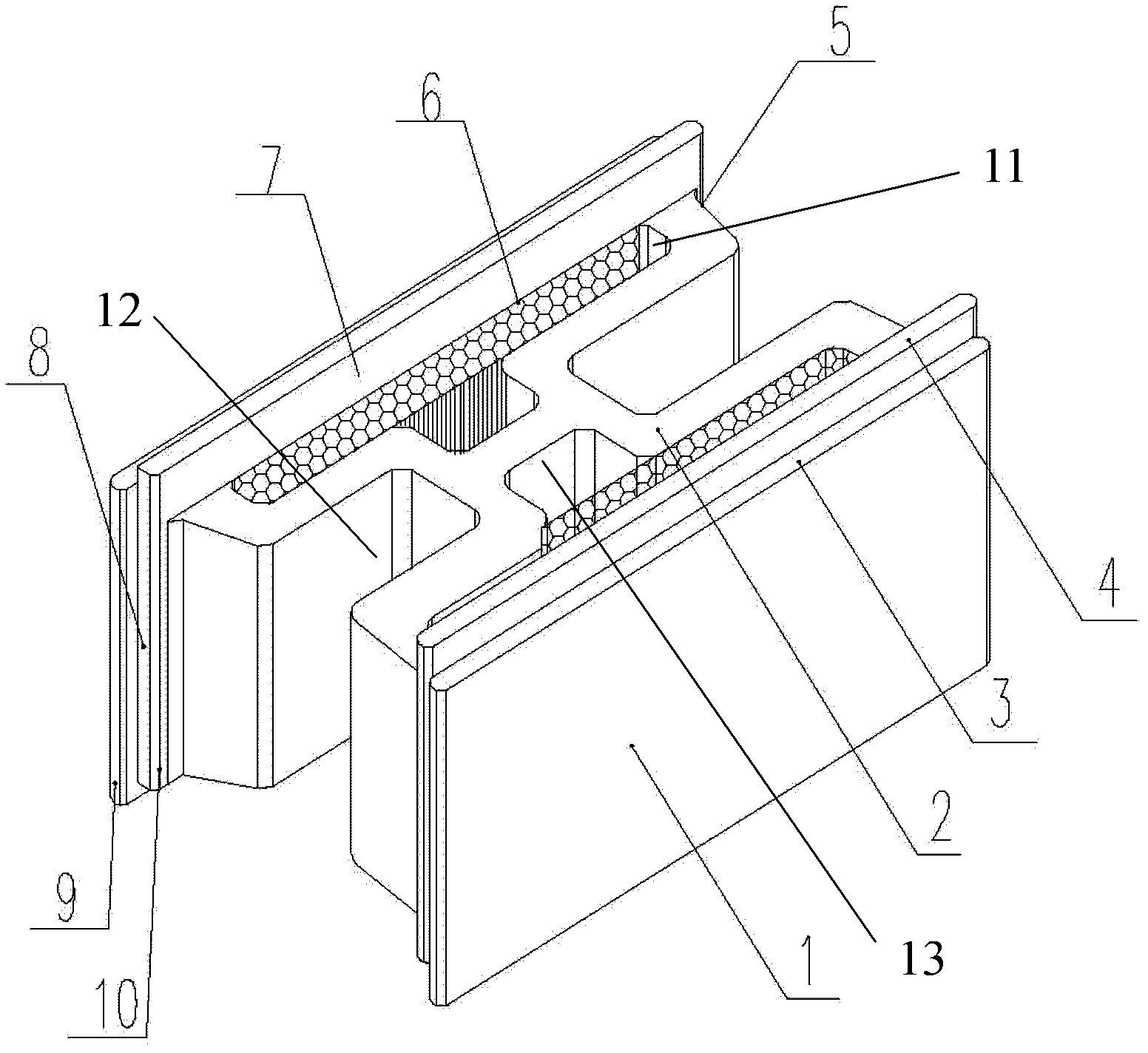

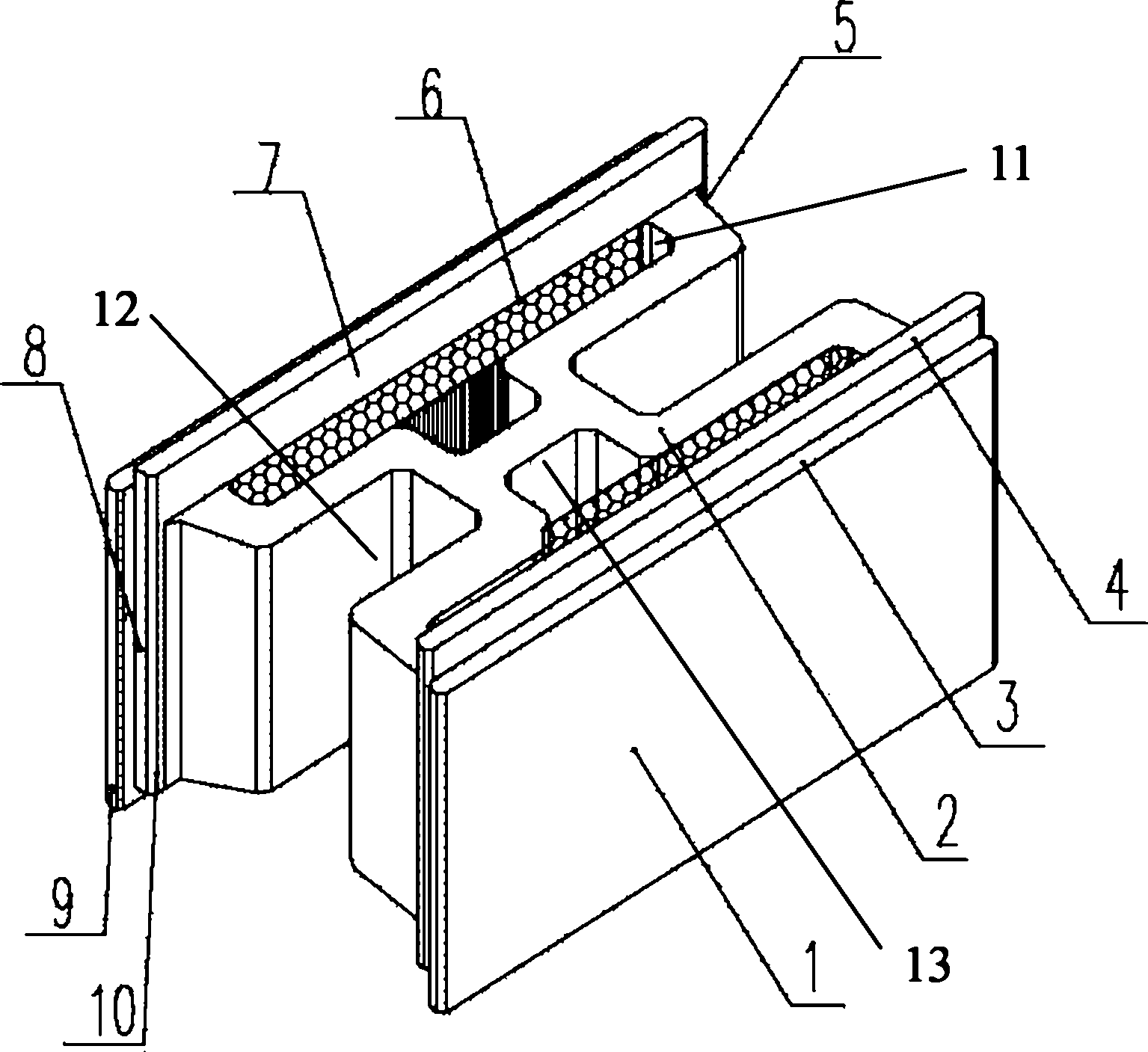

[0022] Such as figure 1 As shown, the concrete self-insulating formwork block of the present invention includes a solid component 1, and the solid component 7 includes a top surface, a bottom surface, two end surfaces and two parallel outer planes 1, wherein the The solid member 7 is provided with two first heat insulation grooves 11 in parallel, the first heat insulation groove 11 vertically runs through the solid member 7, and the first heat insulation groove 11 is parallel to the two sides of the solid member 7. The middle part of the two end faces of the parallel outer plane 1 and the solid member 7 is respectively provided with a second heat insulation groove 12, and the second heat insulation groove 12 is located between the two first heat insulation grooves 11 Between and parallel with the first thermal insulation groove 11, one side of the second thermal insulation groove 12 is opened in the end face of solid member 7, and the two end faces of solid member 7 are sunken...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com