A kind of thermal insulation ceramsite lightweight wallboard

A lightweight wallboard and thermal insulation wall technology, applied in building components, construction, climate change adaptation, etc., can solve problems such as application limitations of composite wallboards, falling off of concrete surfaces, and easy cracks in walls, achieving enhanced strength, Improve the ability to withstand pressure, the effect of tight bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

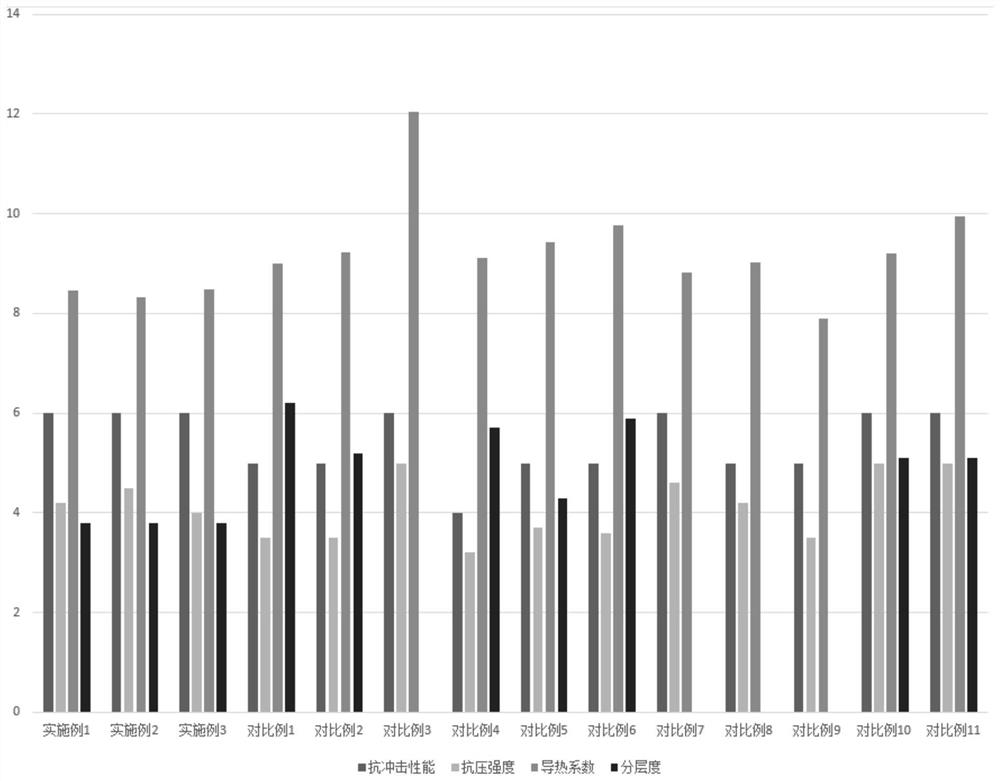

Embodiment 1

[0037] A heat-insulating ceramsite lightweight wallboard,

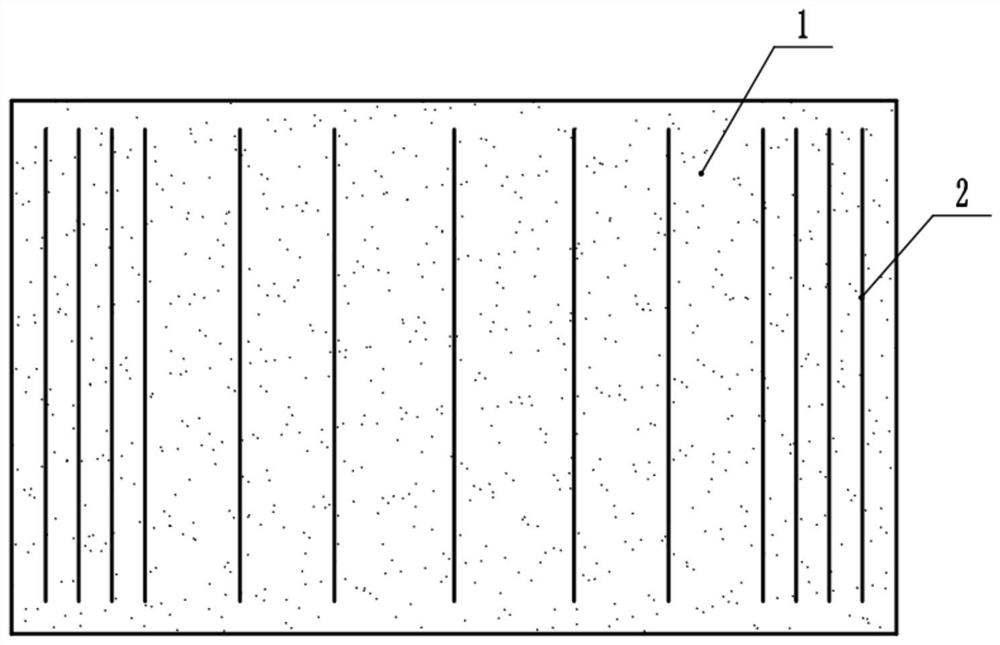

[0038] Including the wallboard body, the wallboard body includes the wall surface layer 1 on both sides, the insulation wall core between the wall surface layers 1 on both sides, and the grid frame located in the wall surface; the wall surface layer 1 is filled with concrete ;

[0039] The wall surface layer 1 on both sides covers the insulation wall core and the grid frame; there are several through holes on the insulation wall core; the through holes are V-shaped, including two open ends and a connecting end; On both sides of the core, the connecting end is located inside the insulation wall core, and sodium bicarbonate is placed at the connecting end; an included angle is provided at the connecting end of the V-shaped through hole, and the included angle is 15°-30°. 15°.

[0040] There are several fine grooves on the surface of the thermal insulation wall core; the grid frame includes several vertical steel wires...

Embodiment 2

[0045] Compared with Embodiment 1, the difference lies in that the included angle is 22°.

Embodiment 3

[0047] Compared with Embodiment 1, the difference lies in that the included angle is 30°.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com