Repairable and easy-to-replace fabricated steel structure beam-column joint capable of realizing self-resetting

A beam-column joint and self-resetting technology, which is applied in building construction and construction, can solve problems such as difficult to control the quality of welds, low level of joint assembly, and easy damage or destruction of welds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solutions of the present invention will be described in further detail below through specific implementation methods.

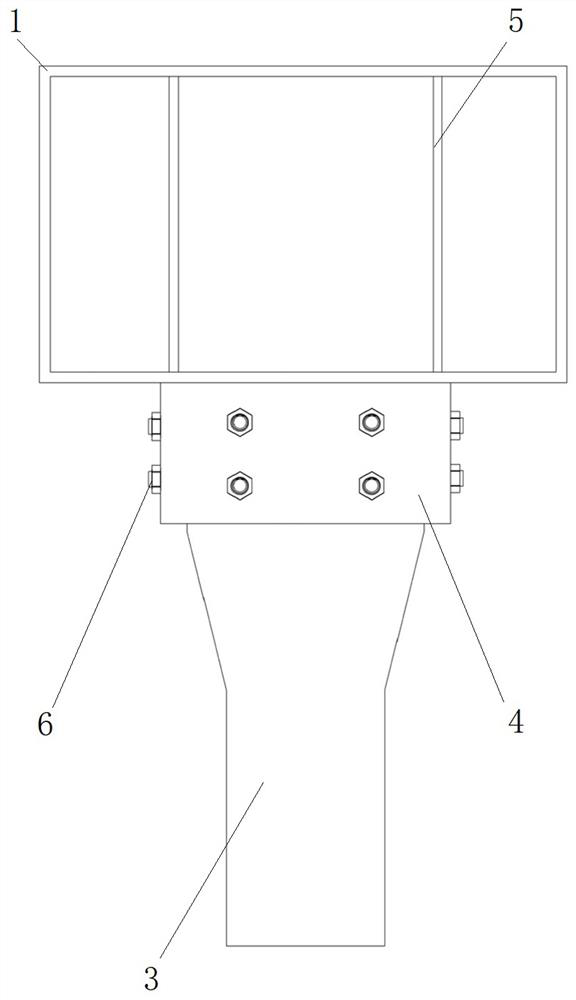

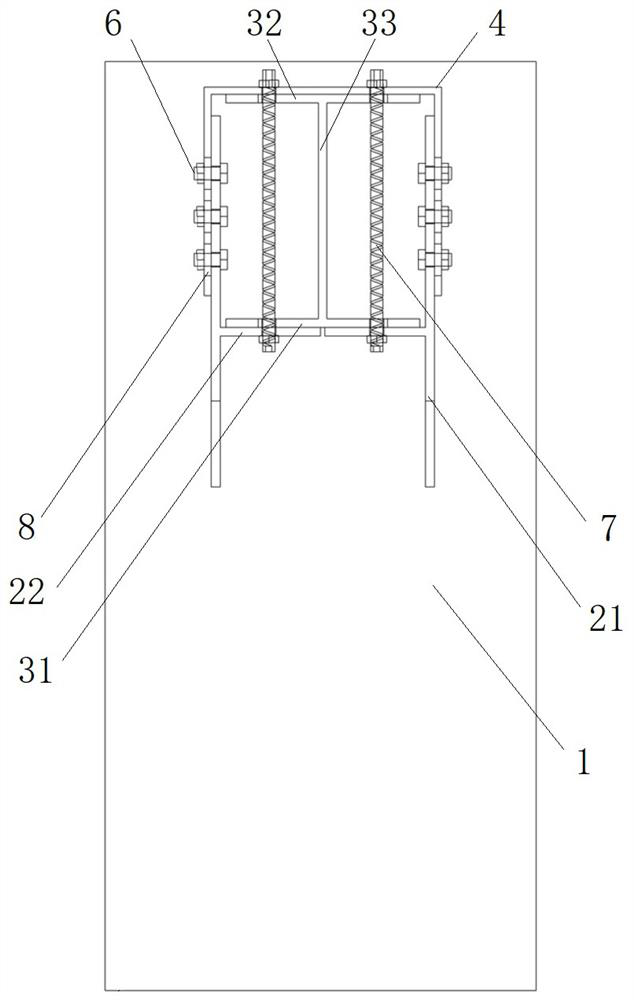

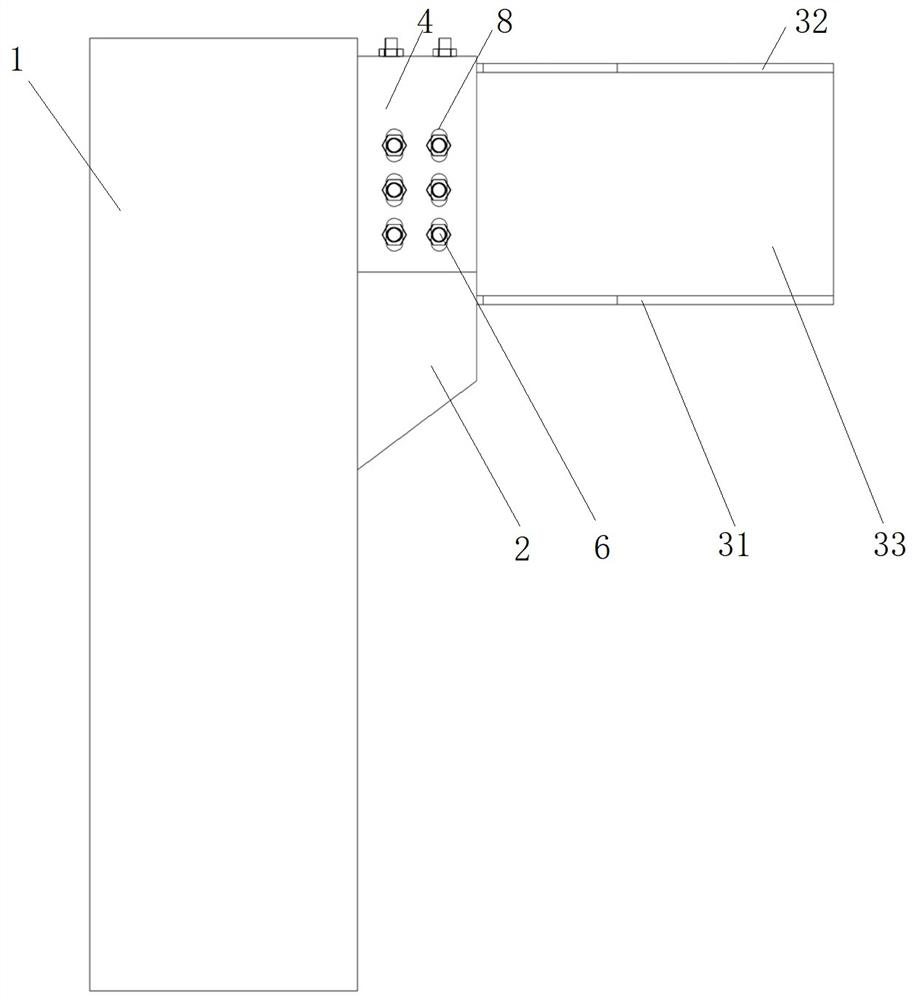

[0020] like Figure 1-3 As shown, a repairable, easily replaceable and self-resetting assembled steel structure beam-column node includes a vertically arranged rectangular pipe column 1, concrete filled in the rectangular pipe column 1, two T-shaped Plate 2, I-shaped beam 3 and inverted U-shaped cover plate 4; the T-shaped plate 2 specifically includes a broken head plate 22 and a vertical side plate 21 connected to the outer end of the broken head plate 22, and the bottom end of the vertical side plate 21 extends The decapitation plate 22 is arranged, and the decapitation plates 22 of the two T-shaped plates 2 are arranged oppositely and are on the same horizontal plane, so that the two decapitation plates 22 form a horizontal supporting plate, and the two T-shaped plates 2 are welded on a rectangular The predetermined position on the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com