Dual steel pipe-encased concrete anti-seismic column with built-in rubber mixture and construction method

A technology of rubber mixture and steel tube concrete, which is applied in the direction of columns, pier columns, pillars, etc., can solve problems such as brittle failure, and achieve the effects of reducing rubber consumption, good energy consumption, and beautiful development and saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

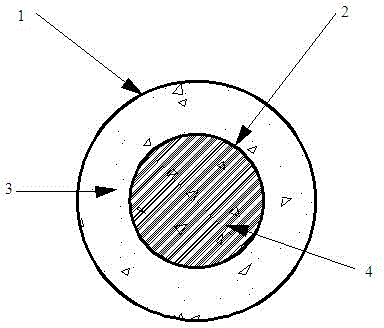

[0018] The present invention includes circle-covered circle, square-covered square, square-covered circle, round-covered square, and rectangular-covered rectangular section forms, and is characterized in that it consists of an outer steel pipe 1, an inner steel pipe 2, interlayer concrete 3 and a rubber mixture 4, with two inner and outer layers The steel pipes are fixed by welding or bolting, wherein the interlayer concrete 3 is located in the middle of the double steel pipes, the rubber compound 4 is filled in the inner steel pipes, and the interlayer concrete 3 is self-compacting concrete.

[0019] The specific process is as follows:

[0020] 1. Select inner and outer steel pipes and interlayer concrete according to the bearing capacity check;

[0021] 2. Pour 40~50mm cement mortar at the bottom of the inner steel pipe, and fix the inner and outer two layers of steel pipes by welding or bolting, keeping them vertical or at a certain angle;

[0022] 3. Pouring self-compacti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com