Rectangular steel pipe confined concrete column joint without stirrups and construction method thereof

A technology for constraining concrete and rectangular steel pipes, which is applied to buildings and building structures, etc., can solve problems such as failure to meet the seismic design requirements of strong joints and weak members, and joint weakening, and achieve reliable joint performance, prevent instability, and simplify the construction process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

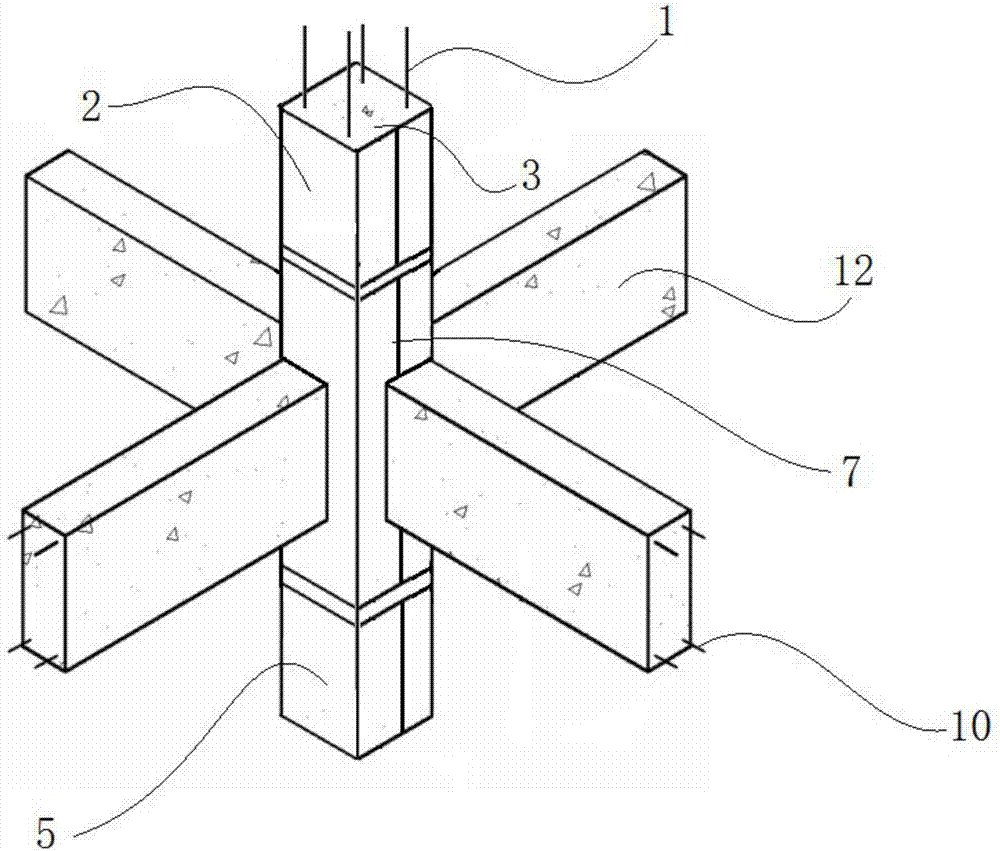

[0056] This embodiment discloses a rectangular steel pipe bound concrete column-reinforced concrete beam partly through joint without stirrups, including an upper column steel pipe 2, a lower column steel pipe 5, a node steel pipe 7, and a reinforced concrete beam.

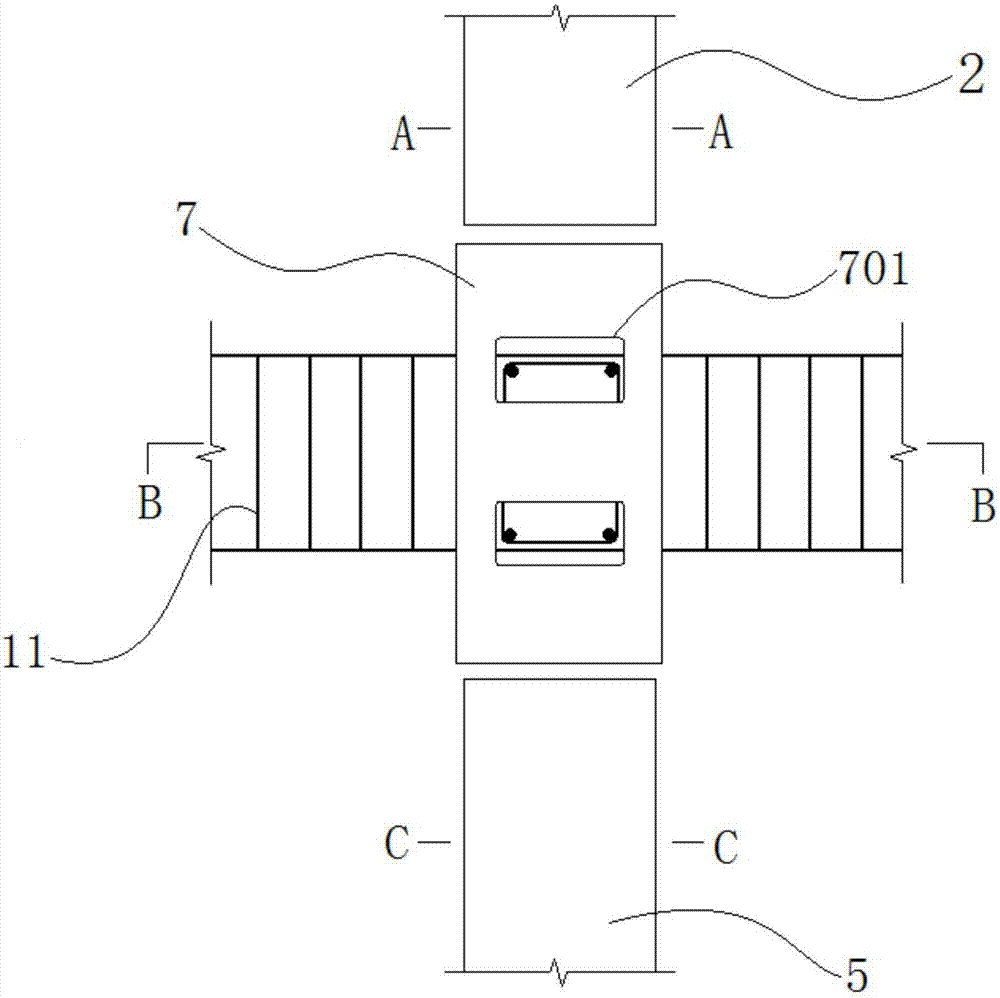

[0057] see figure 1 , image 3 and Figure 5 , the upper column steel pipe 2, the lower column steel pipe 5 and the node steel pipe 7 are all composed of two cold-formed thin-walled channel steels buckled and welded together.

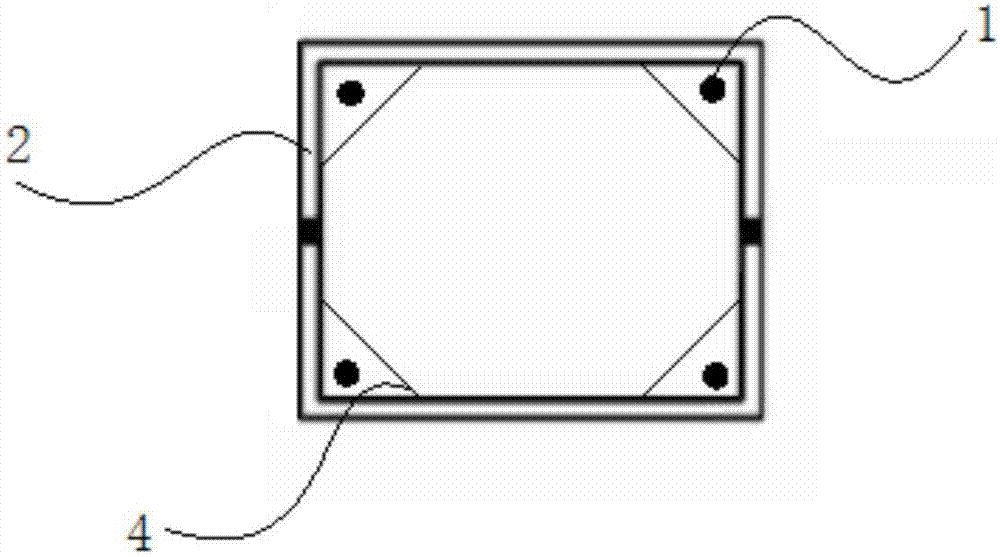

[0058] see image 3 , the four inner corners of the upper column steel pipe 2 are welded with oblique-stayed stiffeners I4. The cable-stayed stiffener I4 vertically penetrates into the steel pipe 2 of the upper column. Each cable-stayed stiffener I4 is connected between two adjacent sides of the upper column steel pipe 2 through a fillet weld.

[0059] see figure 2 and Figure 4 , multiple groups of holes 701 are evenly opened on the node steel pipe 7 for the reinforced concrete bea...

Embodiment 2

[0066] This embodiment discloses a rectangular steel tube-constrained concrete column node without stirrups, including an upper column steel tube 2, a lower column steel tube 5, a node steel tube 7, and a reinforced concrete beam.

[0067] The upper column steel pipe 2, the lower column steel pipe 5 and the node steel pipe 7 are all composed of two cold-formed thin-walled channel steels buckled and welded together.

[0068] see Figure 6 and Figure 7 , the four inner corners of the upper column steel pipe 2 are welded with oblique-stayed stiffeners I4. The cable-stayed stiffener I4 vertically penetrates into the steel pipe 2 of the upper column. Each cable-stayed stiffener I4 is provided with five exhaust holes I401. Each cable-stayed stiffener I4 is connected between two adjacent sides of the upper column steel pipe 2 through a fillet weld. The cable-stayed stiffener I4 and the inner corner of the upper column steel pipe 2 form a hollow triangular prism A with both upper...

Embodiment 3

[0076] This embodiment discloses a construction method for a rectangular steel pipe-confined concrete column without stirrups described in Embodiment 1, which includes the following steps:

[0077] 1) Process the upper column steel pipe 2, the node steel pipe 7 and the lower column steel pipe 5 according to the design requirements:

[0078] Two pieces of cold-formed channel steel are selected, and four obliquely-stayed stiffeners I4 are respectively welded to each inner corner of the cold-formed channel steel through fillet welds. The two pieces of cold-formed channel steel are buckled and welded together with a penetration weld to form the upper column steel pipe 2 . Among them, the upper column steel pipe 2 and the cable-stayed stiffener I4 together constitute the upper column steel pipe complex.

[0079] Two pieces of cold-formed channel steel are selected, and four oblique-stayed stiffeners III6 are respectively welded to the inner corners of the two pieces of cold-formed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com