End sealing method of tunnel dual-lining trolley air bag die containing built-in type water-stop belt

A waterstop and airbag technology, which is applied to the field of airbag mold end capping of the tunnel secondary lining trolley, can solve the problems of long consumption time, reduced concrete strength, expansion of the waterstop or leakage of slurry, etc., and saves a lot of time and work efficiency. High, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

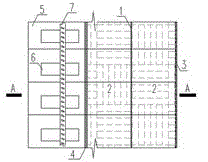

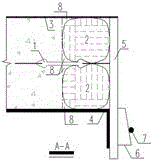

[0021] The air bag mold sealing method of the second lining trolley of the tunnel including the buried waterstop 1, including:

[0022] Step 1. Positioning of the trolley: including checking the elevation of the trolley and the size of the center line. When the trolley is moving, observe whether the end of the trolley moves to the edge of the water stop 1;

[0023] Step 2: Inflate the airbags 2: Before installation, inflate all the airbags 2, and check whether there is any air leakage in the airbag body or valve;

[0024] Step 3, Airbag mold installation: The airbag mold is effectively fixed along the inner and outer sides of the construction joint waterstop 1 along the ring, installed and inflated section by section, so that the airbag 2 and the trolley formwork panel 4, the airbag 2 and the waterstop 1, and the airbag 2 is closely attached to the waterproof board 3, and the size of the inflated airbag 2 is controlled to ensure that the buried waterstop 1 is centered in the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com