Beam flange opening weakening type node for connecting steel beam and wide concrete filled steel tubular column

A technology of steel pipe concrete columns and steel beams, which is applied in the direction of construction and building construction, can solve the problems of complex flange cutting surface processing, out-of-plane instability, etc., achieve good rigidity and strength, improve stress state, and force transmission path clear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

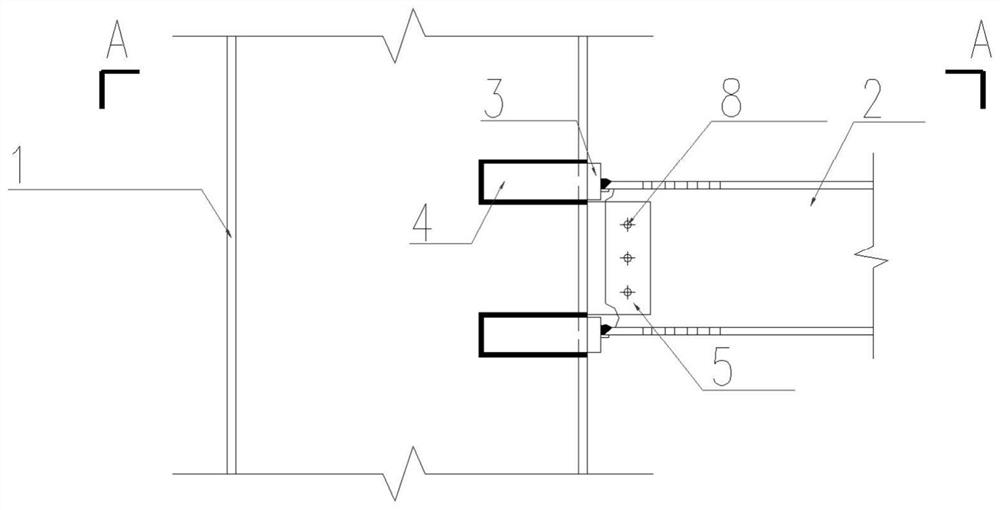

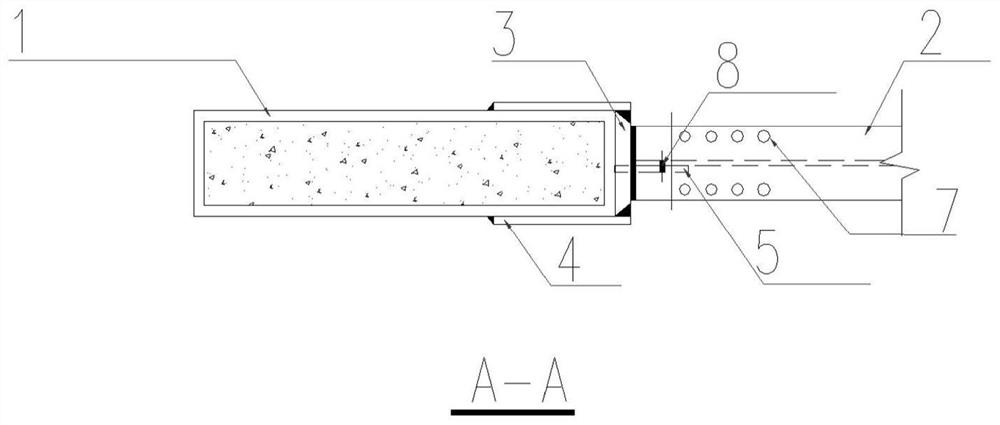

[0041] like figure 1 As shown, the present invention comprises a wide concrete-filled steel pipe column 1, a steel beam 2, a reinforcement plate 3, a pasting plate 4 and a connecting plate 5; The reinforcement plate 3 and the two pasting plates 4 are fixedly connected to the short side of the wide steel pipe concrete column 1, and the web plate of the steel beam 2 is fixedly connected to the short side of the wide steel pipe concrete column 1 through a connecting plate 5.

[0042] like figure 2As shown, the upper and lower flanges of the steel girder 2 are respectively welded to one end surface of a respective reinforcement plate 3 through a weld seam, and the other end surface of each reinforcement plate 3 is welded to the side where the short side of the wide steel pipe concrete column 1 is located through a weld seam. The upper and lower flanges of the steel beam 2 are provided with two stickers 4, and the two stickers 4 are respectively welded to the long side surfaces o...

Embodiment 2

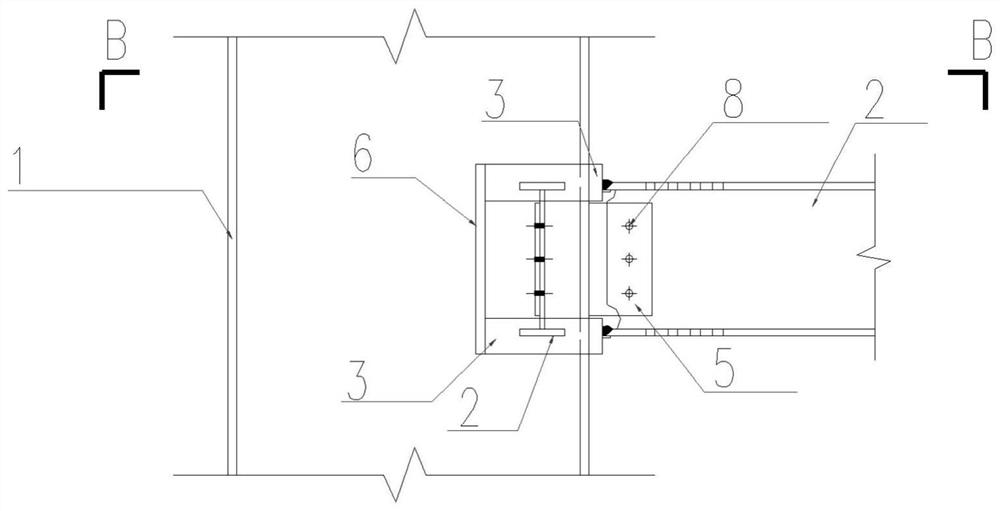

[0044] like image 3 As shown, it also includes inserting plate 6; the wide concrete-filled steel tube column 1 is located in the middle of the building plane, and the wide concrete-filled steel tube column 1 is respectively connected with three steel beams 2, and the three steel beams 2 are respectively connected to the wide concrete-filled steel tube column through the reinforcement plate 3 and the connecting plate 5 1 The three sides close to the short side are fixedly connected, the inserting plate 6 is vertically inserted into the wide steel pipe concrete column 1 along the direction parallel to the short side of the wide steel pipe concrete column 1, and the two ends of the inserting plate 6 are connected with the two reinforcing plates 3 Fixed connection.

[0045] like Figure 4 As shown, the wide concrete-filled steel tube column 1 is located in the middle of the building plane, and the wide concrete-filled steel tube column 1 is connected to three steel beams 2 respe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com